CHANGE_P-ORDER

Nodes and connectivity

*CHANGE_P-ORDER

"Optional title"

entype, enid, order, gid

"Optional title"

entype, enid, order, gid

Parameter definition

Variable

Description

entype

Entity type

enid

Entity identification number

order

New element polynomial order

gid

ID of a GEOMETRY that defines a sub-space for change of polynomial order

Description

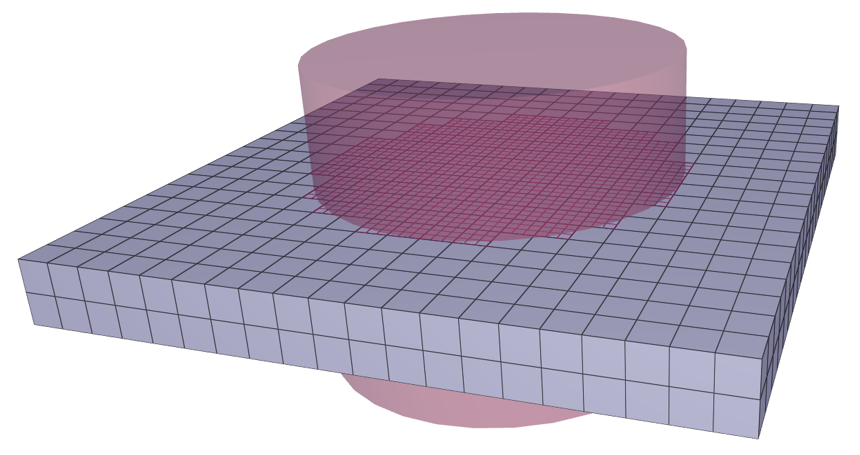

Change element polynomial order in a selected region of a part or part set.

Example

Change of polynomial order

The following command defines a region in space where linear elements are converted to cubic.

*COMPONENT_BOX

1, 1, 20, 20, 2

0, 0, 0.45, 1, 1, 0.55

*PART

1, 1

*MAT_RIGID

1, 7800

*CHANGE_P-ORDER

P, 1, 3, 123

*GEOMETRY_PIPE

123

0.5, 0.5, 0.25, 0.5, 0.5, 0.75, 0.3

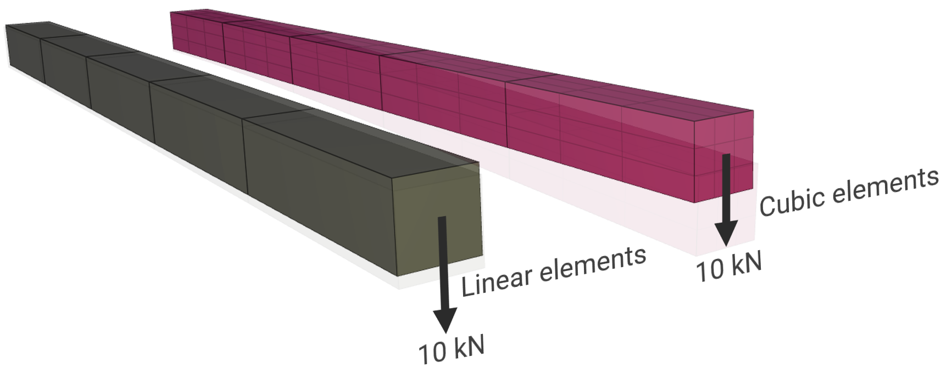

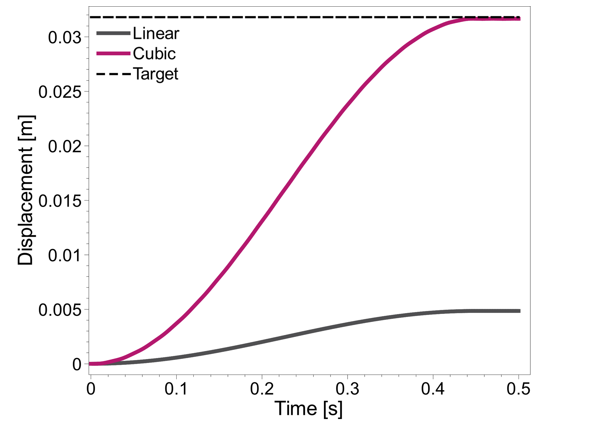

Linear vs. cubic elements

Two cantilever beams are subjected to a transverse point load at the unconstrained end. One of the beams is modeled with five LHEX (Linear hexagonal) elements and the other with five CHEX (Cubic hexagonal) elements. From Euler-Bernoulli beam theory, the maximum deflection, $\mathbf\delta_{max}$ is:

$\mathbf\delta_{max} = \displaystyle{ \frac{PL^3}{3EI} } = \displaystyle{ \frac{1.0e4 \cdot 1.0^3}{3 \cdot 200e9 \cdot \frac{0.05 \cdot 0.05^3}{12}} = 32 mm}$

where, $P$ is the applied load, $L$ is the length of the beam, $E$ is the elastic modulus and $I$ is the moment of inertia. The higher order elements are superior to the linear elements for this model setup.

*PARAMETER

%tend = 0.5, "Termination time"

%l = 1.0, "Length of the beam"

%t = 0.05, "Thickness of the beam"

%d = 0.1, "Distance value"

%F_max = 1e4, "Load applied"

*TIME

[%tend]

*OUTPUT

[%tend/5]

*UNIT_SYSTEM

SI

*COMPONENT_BOX

"Linear elements"

1, 1, 5, 1, 1

0, 0, [-%d], [%l], [%t], [%t - %d]

*COMPONENT_BOX

"Cubic elements"

2, 2, 5, 1, 1

0, 0, [%d], [%l], [%t], [%t + %d]

*MAT_ELASTIC

1, 7800, 200e9, 0.3

*CHANGE_P-ORDER

P, 2, 3

*PART

1, 1

2, 1

#Fixed ends

*BC_MOTION

1

G, 1, XYZ

*GEOMETRY_SEED_COORDINATE

1

0, [%t/2], [%t/2 - %d]

*BC_MOTION

2

G, 2, XYZ

*GEOMETRY_SEED_COORDINATE

2

0, [%t/2], [%t/2 + %d]

# Prescribed force

*LOAD_FORCE

11

G, 11, Y, 10

*GEOMETRY_SEED_COORDINATE

11

[%l], [%t/2], [%t/2 - %d]

*LOAD_FORCE

12

G, 12, Y, 10

*GEOMETRY_SEED_COORDINATE

12

[%l], [%t/2], [%t/2 + %d]

*FUNCTION

10

smooth_d(%F_max, 0, 0.9*%tend)

*OUTPUT_SENSOR

"Linear"

1, 1, [%l], [%t/2], [%t/2 - %d]

*OUTPUT_SENSOR

"Cubic"

2, 2, [%l], [%t/2], [%t/2 + %d]

*CURVE

"Target"

10000

[0.0*%tend], 0.032

[1.0*%tend], 0.032

*END