PARAMETER

Parameters and functions

%param = expression, "description", rid, quantity

Parameter definition

Description

The purpose of this command is to define parameters, that can be used inside expressions anywhere in the command file. Brackets are used to mark the beginning and end of an expression. Parameters should always be preceeded by the prefix %.

The range ID (rid) refers to either one of the commands PARAMETER_RANGE_CONTINUOUS, PARAMETER_RANGE_DISCRETE or PARAMETER_RANGE_BOOL.

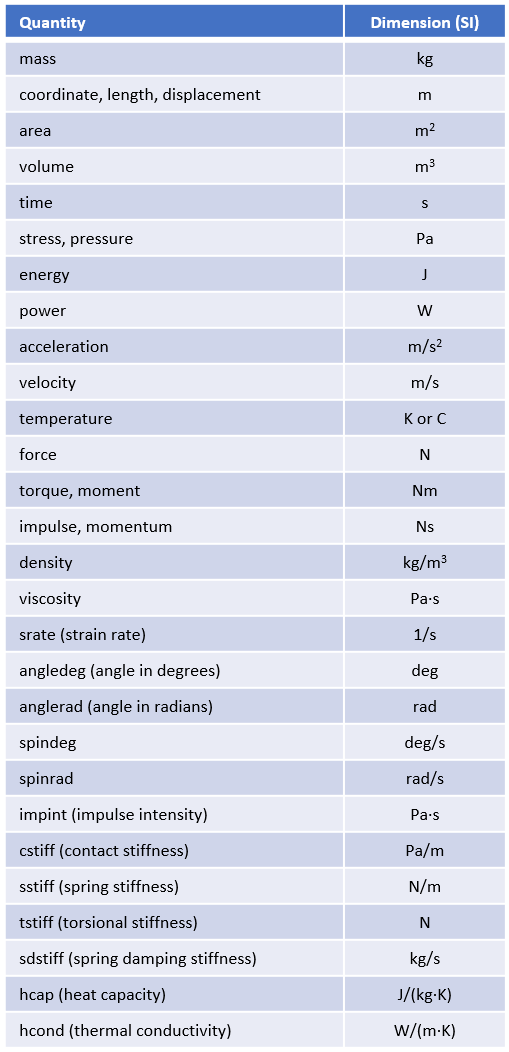

Defining a physical quantity (quantity) is optional. It helps IMPETUS Solver determine how to convert parameters between different unit systems.

Example

Density

Definition of density parameters.

Conversion between unit systems

A material command defined in SI-units is included in a model file working in MM/TON/S. The flow stress parameter $A=760 \mathrm{MPa}$ (defined in main.k) will replace the default value $A=640 \mathrm{MPa}$ (defined in material.k).

The resulting flow stress function in the material command is going to be:

$\displaystyle{\sigma_y = 760 + 450 \cdot \left( \varepsilon_{eff}^p \right)^n \; [MPa]}$

main.k:

material.k: