Verification - Input Commands

Introduction

This document presents verification tests for the input commands available in the software.

Tests are continuously added to a database which currently contains over 400 tests. The tests consist of small models, often based on a single element or component, and are designed to test a specific feature of the input command under consideration.

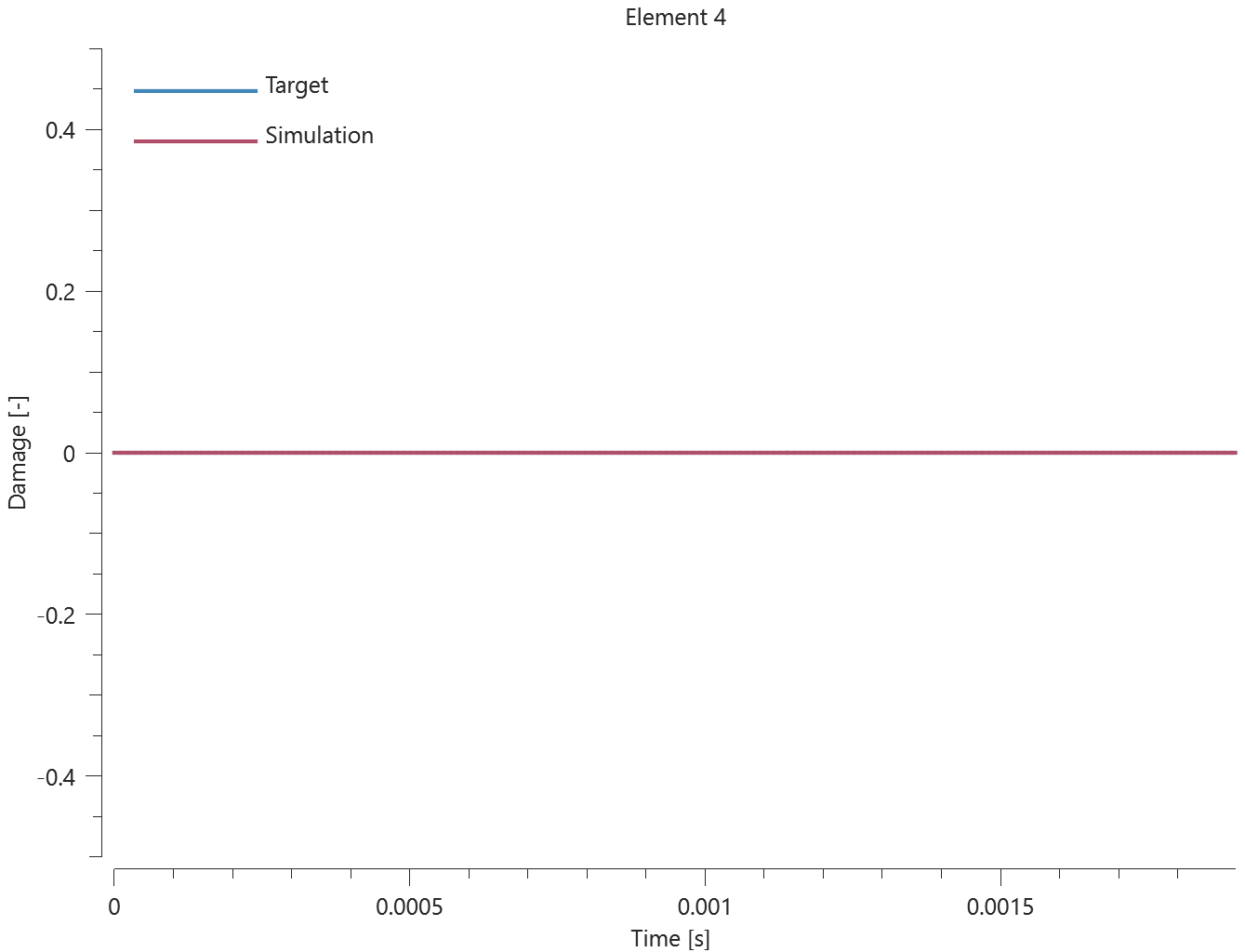

Each test is associated with at least one target which is defined based on analytical solutions, results from other numerical methods or in a few cases, results at implementation to ensure consistency in results for new solvers. The targets are automatically checked after running the tests in the database with a new solver.

Version control

The tests presented in this document are subjected to version control, meaning that the tests are run and evaluated prior to release of a new solver. This document is updated in conjunction with official releases of the software.

*ACTIVATE_ELEMENTS

Activation and deactivation of elements

"Optional title"

$coid$, $entype$, $enid$, $t_{birth}$, $t_{death}$, $\xi$

Activation and deactivation of elements in *ACTIVATE_ELEMENTS are verified in this test.

Tested parameters:  and

and  .

.

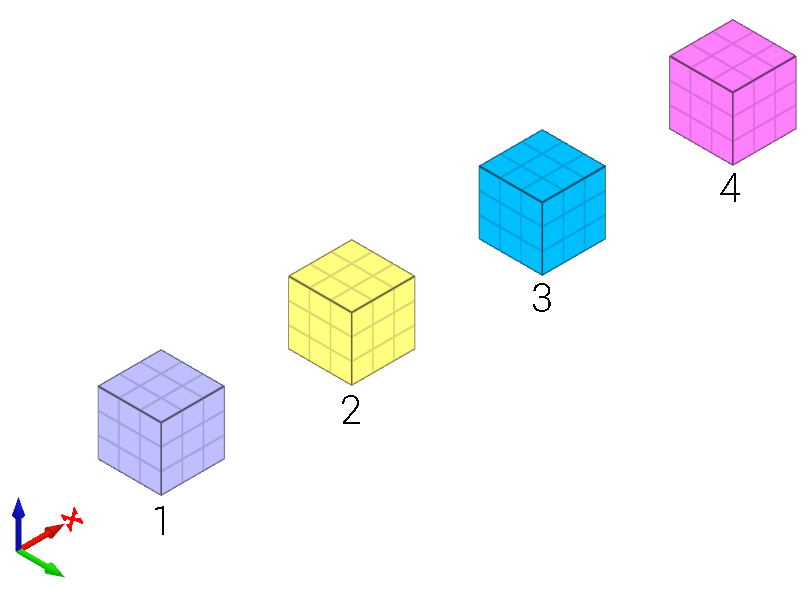

Four CHEX elements are positioned along the X-axis as displayed in Figure 1. The activation and deactivation of each element is presented in Table 1.

An initial velocity in the X-direction is imposed on element 1. Once element 1 has passed the position of element 2, element 2 and 4 are activated and element 3 deactivated. Element 1 continues to translate along the X-axis and then collides with element 4, bounces back, and eventually collides with element 2.

The positions of the elements at initiation and termination are checked.

Tests

This benchmark is associated with 1 tests.

Strength of elements prior to activation

"Optional title"

$coid$, $entype$, $enid$, $t_{birth}$, $t_{death}$, $\xi$

Strength prior to element activation in *ACTIVATE_ELEMENTS is verified in this test.

Tested parameters:  .

.

Four CHEX elements are positioned as displayed in Figure 1.

Element 1 and 3 are merged to element 2 and 4 respectively.

Element 2 and 4 are given an initial velocity in the X-direction and element 1 and 3 are not activated until half the simulation time has passed.

Before activation, element 1 has full strength while element 3 has no strength. Once the elements are activated, there should be no gap between element 1 and 2.

The positions of the elements at initiation and termination are checked.

Tests

This benchmark is associated with 1 tests.

*ADD_MASS

Rotating discs

"Optional title"

$coid$, $entype$, $enid$, $m$, $distribution$

The different mass distribution options available in *ADD_MASS are verified in this test.

Tested parameters:  and

and  .

.

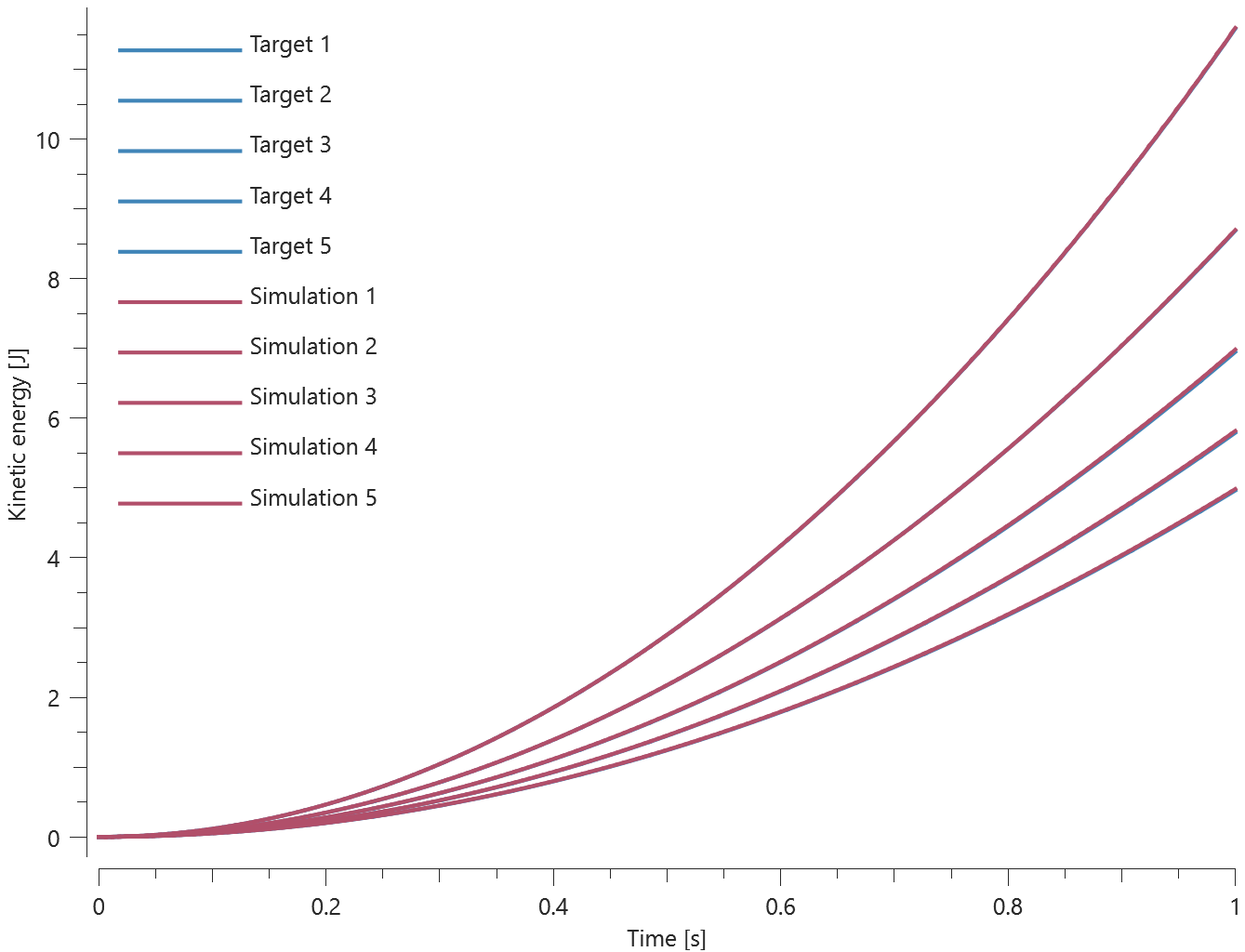

Three discs are spinning around their central axes. In the first disc, the added mass is distributed over the nodes (option 0).

In the second and third disc, the added mass is distributed over the area (option 1 and 2).

An added mass equal to the actual mass of the disc is used.

The kinetic energy due to the added mass for each disc is calculated as:

is the angular velocity and

is the angular velocity and  is the moment of inertia, defined as:

is the moment of inertia, defined as:

is the mass and

is the mass and  is the radius of the disc.

is the radius of the disc.

The kinetic energy of each disc at termination is checked.

Tests

This benchmark is associated with 1 tests.

*BC_MOTION

Activation and deactivation

"Optional title"

$ coid $

$entype$, $enid$, $bc_{tr}$, $bc_{rot}$, $csysid_{tr}$, $csysid_{rot}$, $t_{beg}$, $t_{end}$

$pmeth_1$, $direc_1$, $cid_1$, $sf_1$, $fid_1$

.

$pmeth_n$, $direc_n$, $cid_n$, $sf_n$, $fid_n$

Activation and deactivation of *BC_MOTION are verified in this test.

Tested parameters:  and

and  .

.

Two CHEX elements are subjected to a constant force. The first element is fixed in XYZ at initiation and released after half the termination time. The second element is free at initiation and fixed in XYZ after half the termination time. The displacement at termination,  , should therefore be the same in both elements:

, should therefore be the same in both elements:

The displacements of the elements are checked at termination.

Tests

This benchmark is associated with 1 tests.

Prescribed rotational motions

"Optional title"

$ coid $

$entype$, $enid$, $bc_{tr}$, $bc_{rot}$, $csysid_{tr}$, $csysid_{rot}$, $t_{beg}$, $t_{end}$

$pmeth_1$, $direc_1$, $cid_1$, $sf_1$, $fid_1$

.

$pmeth_n$, $direc_n$, $cid_n$, $sf_n$, $fid_n$

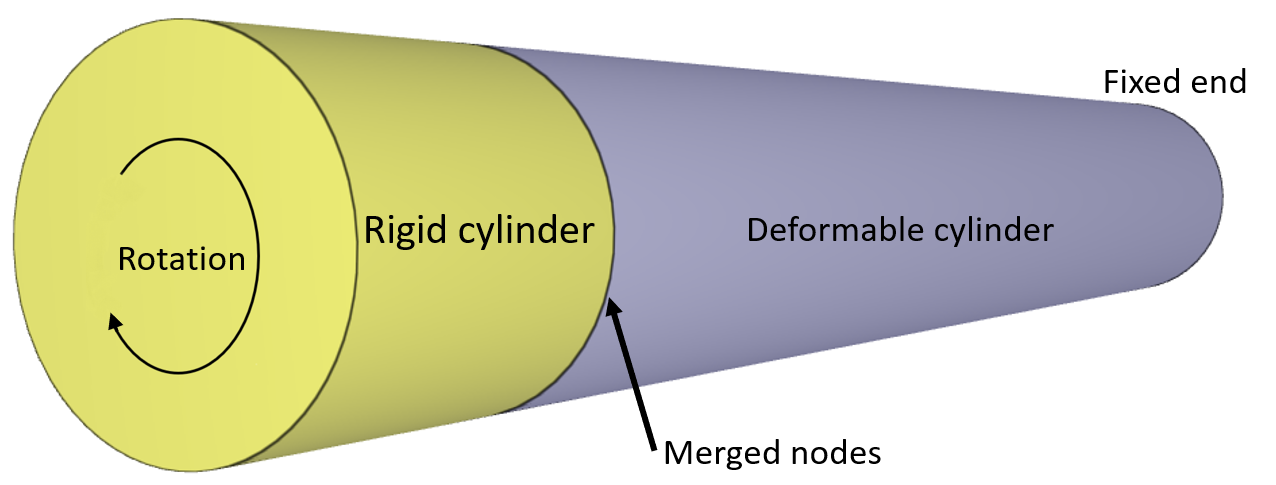

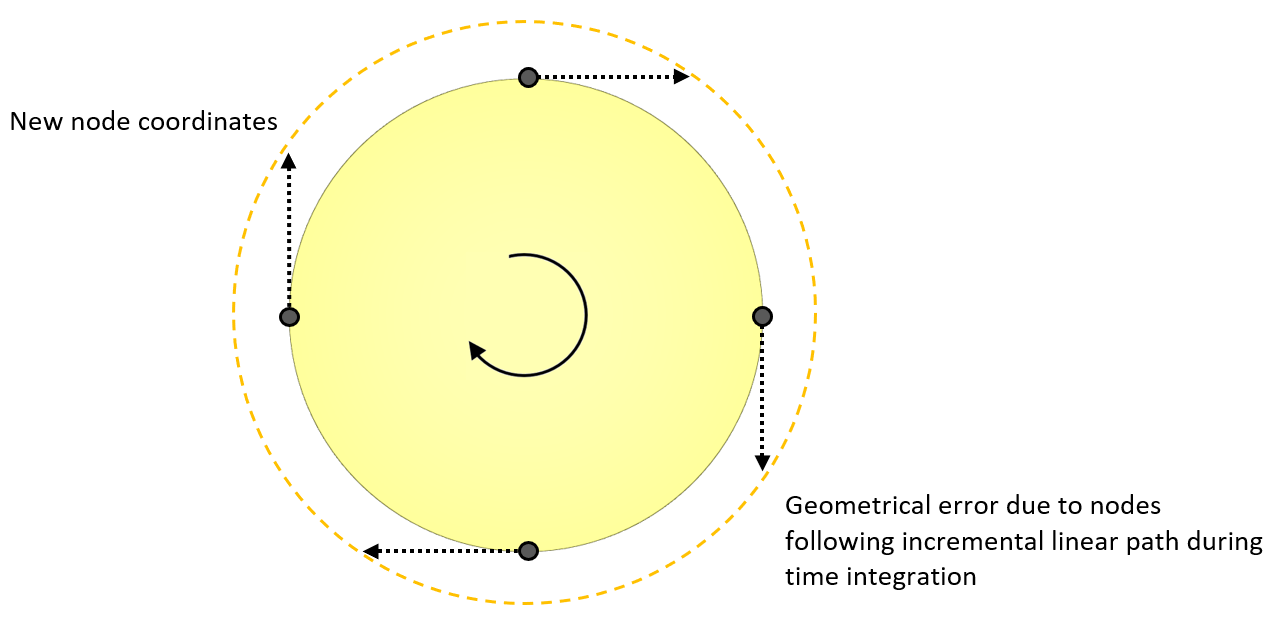

The options for prescribed rotational motions in *BC_MOTION are verified in this test.

Tested parameter:  .

.

A rotational motion is imposed on three CHEX elements. In the first element, the rotation is defined as:

is the current time in the simulation and

is the current time in the simulation and  is the termination time.

is the termination time.

In the second element, the angular velocity is defined as:

In the third element, the angular acceleration is defined as:

The rotation of the elements at termination should therefore be  /4 rad.

/4 rad.

The rotations of the elements are checked at termination.

Tests

This benchmark is associated with 1 tests.

Prescribed translational motions

"Optional title"

$ coid $

$entype$, $enid$, $bc_{tr}$, $bc_{rot}$, $csysid_{tr}$, $csysid_{rot}$, $t_{beg}$, $t_{end}$

$pmeth_1$, $direc_1$, $cid_1$, $sf_1$, $fid_1$

.

$pmeth_n$, $direc_n$, $cid_n$, $sf_n$, $fid_n$

The options for prescribed translational motions in *BC_MOTION are verified in this test.

Tested parameters:  ,

,  ,

,  and

and  .

.

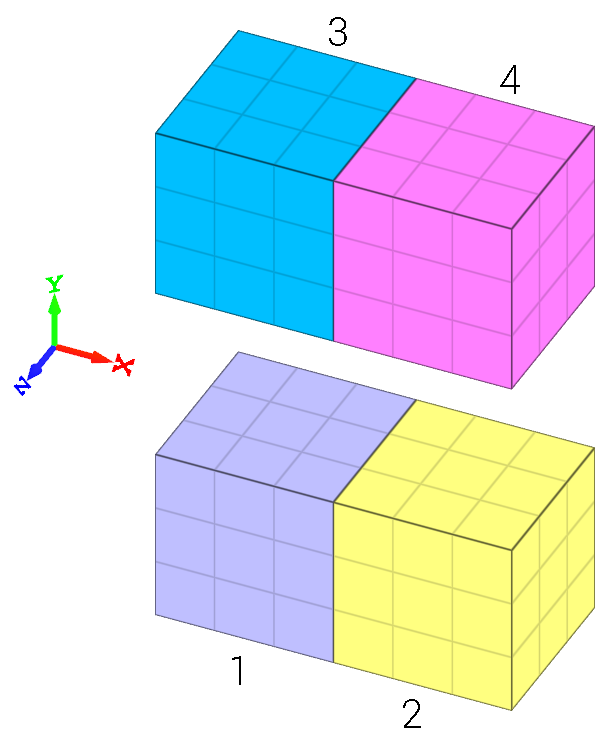

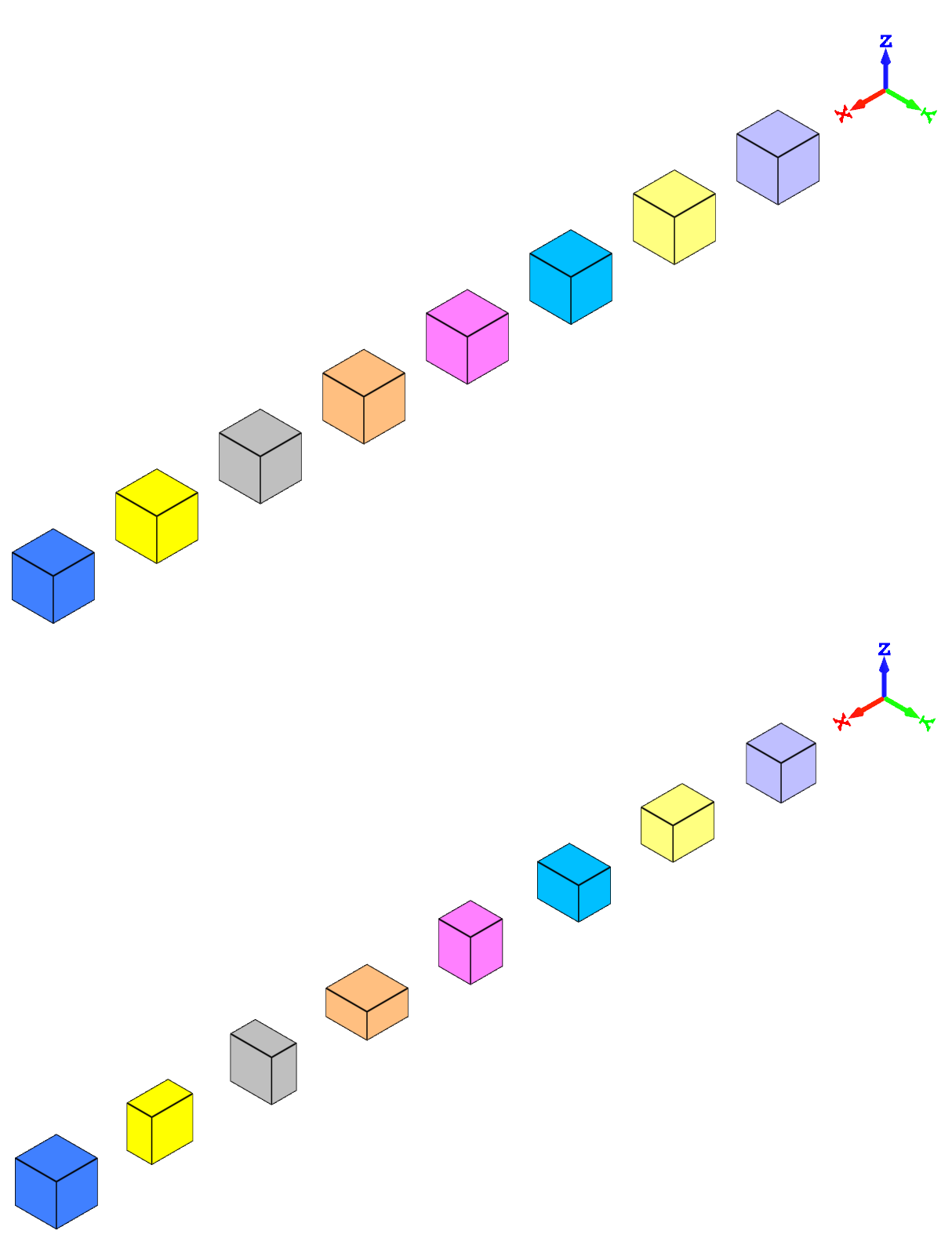

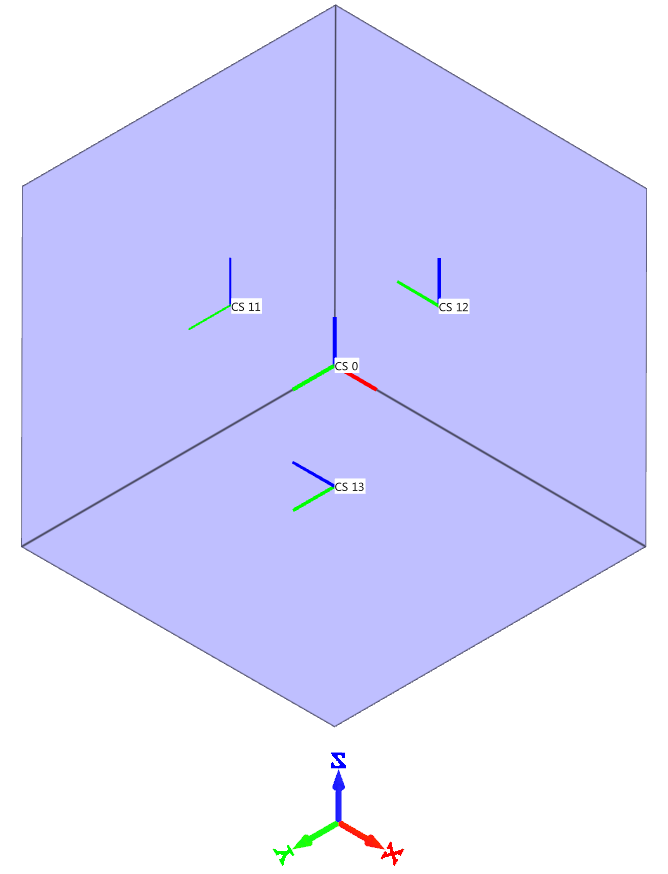

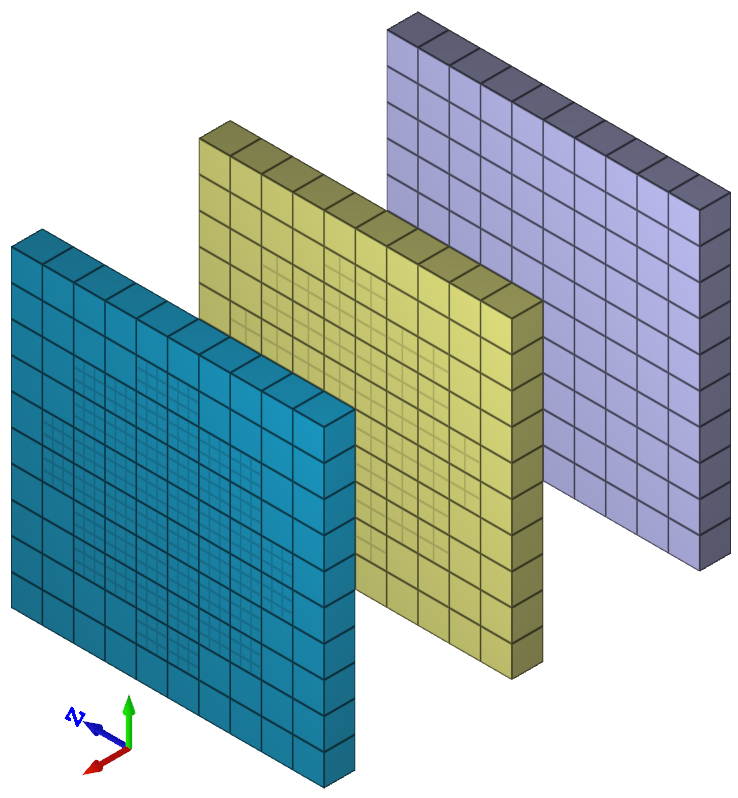

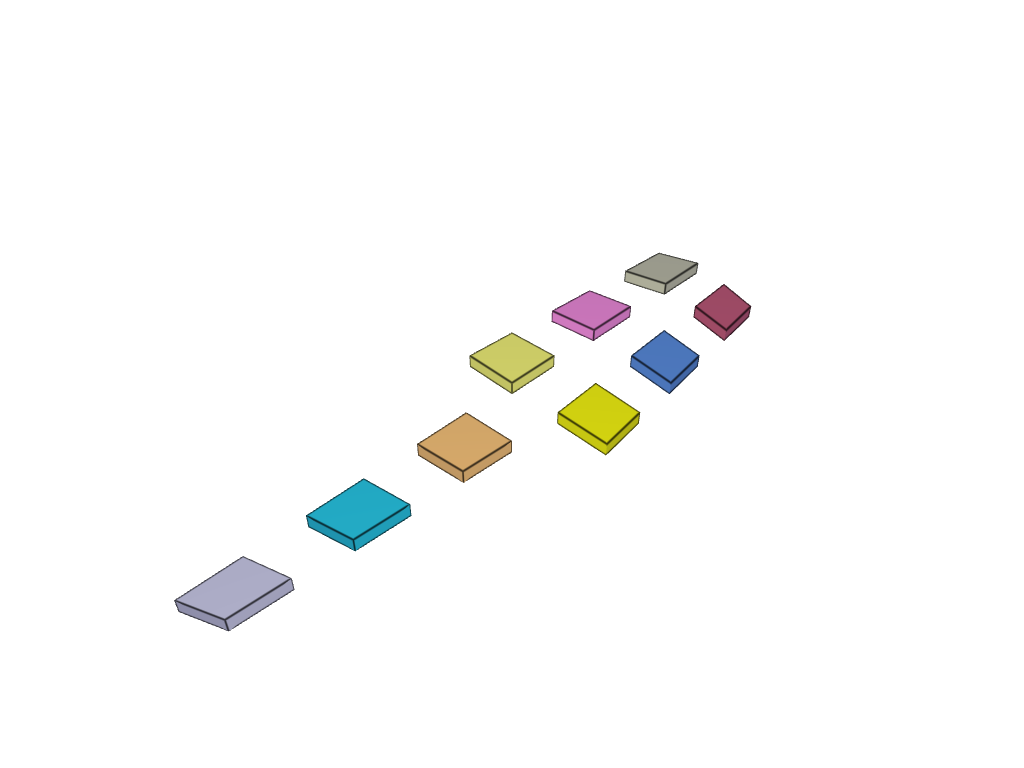

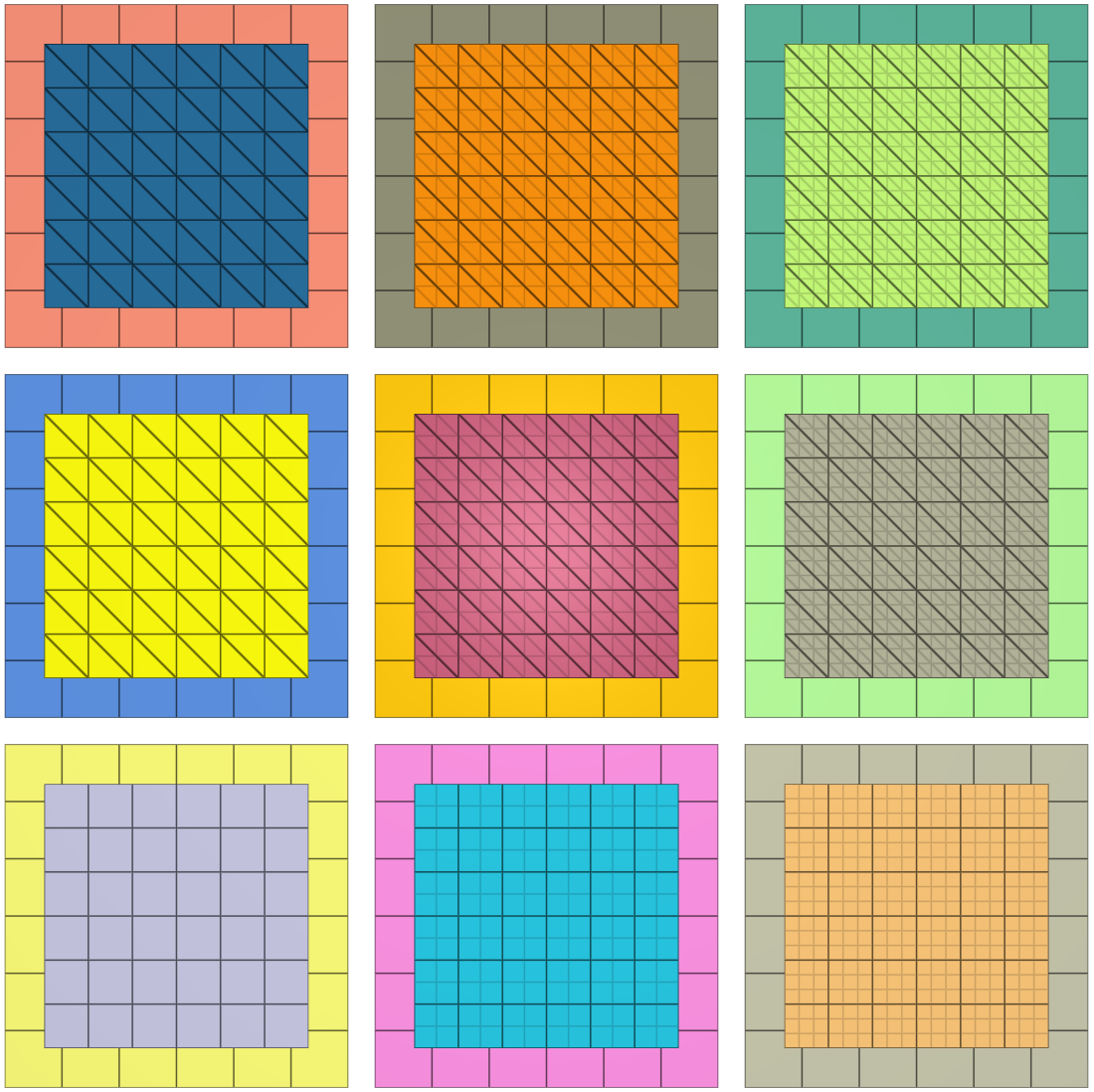

The test consists of 27 CHEX elements in a grid of 3 x 3 x 3, as displayed in Figure 1.

Each element in the grid has unique settings in *BC_MOTION:

1, 1:3, 1:3 - prescribed motions in the X-direction

2, 1:3, 1:3 - prescribed motions in the Y-direction

3, 1:3, 1:3 - prescribed motions in the Z-direction

1:3, 1, 1:3 - prescribed accelerations

1:3, 2, 1:3 - prescribed velocities

1:3, 3, 1:3 - prescribed displacements

1:3, 1:3, 1 - motions defined using a curve

1:3, 1:3, 2 - motions defined using a function

1:3, 1:3, 3 - motions defined using either a curve or a function, with a scale factor defined

For example, the element in position 2, 2, 2 has a prescribed velocity in the Y-direction defined by a function.

The displacement,  , velocity,

, velocity,  , and acceleration,

, and acceleration,  , are defined so that the displacements of the elements are the same at termination:

, are defined so that the displacements of the elements are the same at termination:

The displacements of the elements are checked at termination.

Tests

This benchmark is associated with 1 tests.

Rotational constraints in local coordinate systems

"Optional title"

$ coid $

$entype$, $enid$, $bc_{tr}$, $bc_{rot}$, $csysid_{tr}$, $csysid_{rot}$, $t_{beg}$, $t_{end}$

$pmeth_1$, $direc_1$, $cid_1$, $sf_1$, $fid_1$

.

$pmeth_n$, $direc_n$, $cid_n$, $sf_n$, $fid_n$

This test is similair to the test "*BC_MOTION - Rotational constraints in the global coordinate system". In the current test, the rotational constraints are defined in local coordinate systems instead.

Tests

This benchmark is associated with 1 tests.

Rotational constraints in the global coordinate system

"Optional title"

$ coid $

$entype$, $enid$, $bc_{tr}$, $bc_{rot}$, $csysid_{tr}$, $csysid_{rot}$, $t_{beg}$, $t_{end}$

$pmeth_1$, $direc_1$, $cid_1$, $sf_1$, $fid_1$

.

$pmeth_n$, $direc_n$, $cid_n$, $sf_n$, $fid_n$

Rotational constraints defined in the global coordinate system are verifed in this test.

Tested parameters:  and

and  .

.

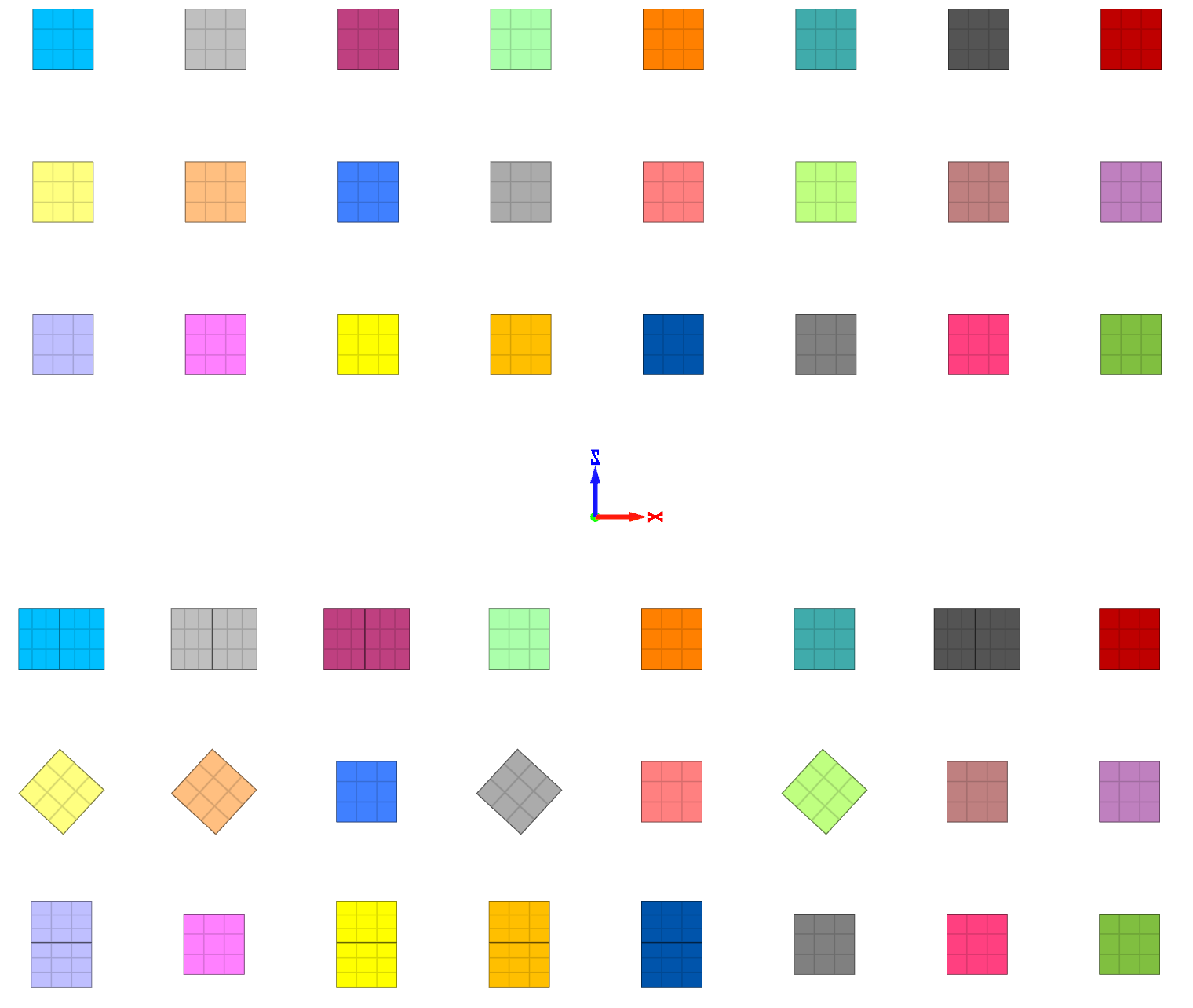

The test consists of 24 CHEX elements positioned as displayed in Figure 1. The three elements in each column has the same rotational constraint. From left to right: 0, X, Y, Z, YZ, ZX, XY, XYZ.

A spin is applied to all elements. The eight elements in each row spin around the same axis but each about its own center of gravity. The rotation point is set in the center of gravity by setting  = 0.

= 0.

The top row rotates around the Z-axis, the middle row around the Y-axis and the bottom row around the X-axis. At termination the elements that are free to rotate should have rotated  /4 rad.

/4 rad.

The rotations of the elements are checked at termination.

Tests

This benchmark is associated with 1 tests.

Translational constraints in a local coordinate systems

"Optional title"

$ coid $

$entype$, $enid$, $bc_{tr}$, $bc_{rot}$, $csysid_{tr}$, $csysid_{rot}$, $t_{beg}$, $t_{end}$

$pmeth_1$, $direc_1$, $cid_1$, $sf_1$, $fid_1$

.

$pmeth_n$, $direc_n$, $cid_n$, $sf_n$, $fid_n$

This test is similair to the test "*BC_MOTION - Translational constraints in the global coordinate system". In the current test, the translational constraints are defined in local coordinate systems instead.

Tests

This benchmark is associated with 1 tests.

Translational constraints in the global coordinate system

"Optional title"

$ coid $

$entype$, $enid$, $bc_{tr}$, $bc_{rot}$, $csysid_{tr}$, $csysid_{rot}$, $t_{beg}$, $t_{end}$

$pmeth_1$, $direc_1$, $cid_1$, $sf_1$, $fid_1$

.

$pmeth_n$, $direc_n$, $cid_n$, $sf_n$, $fid_n$

Translational constraints defined in the global coordinate system are verified in this test.

Tested parameter:  .

.

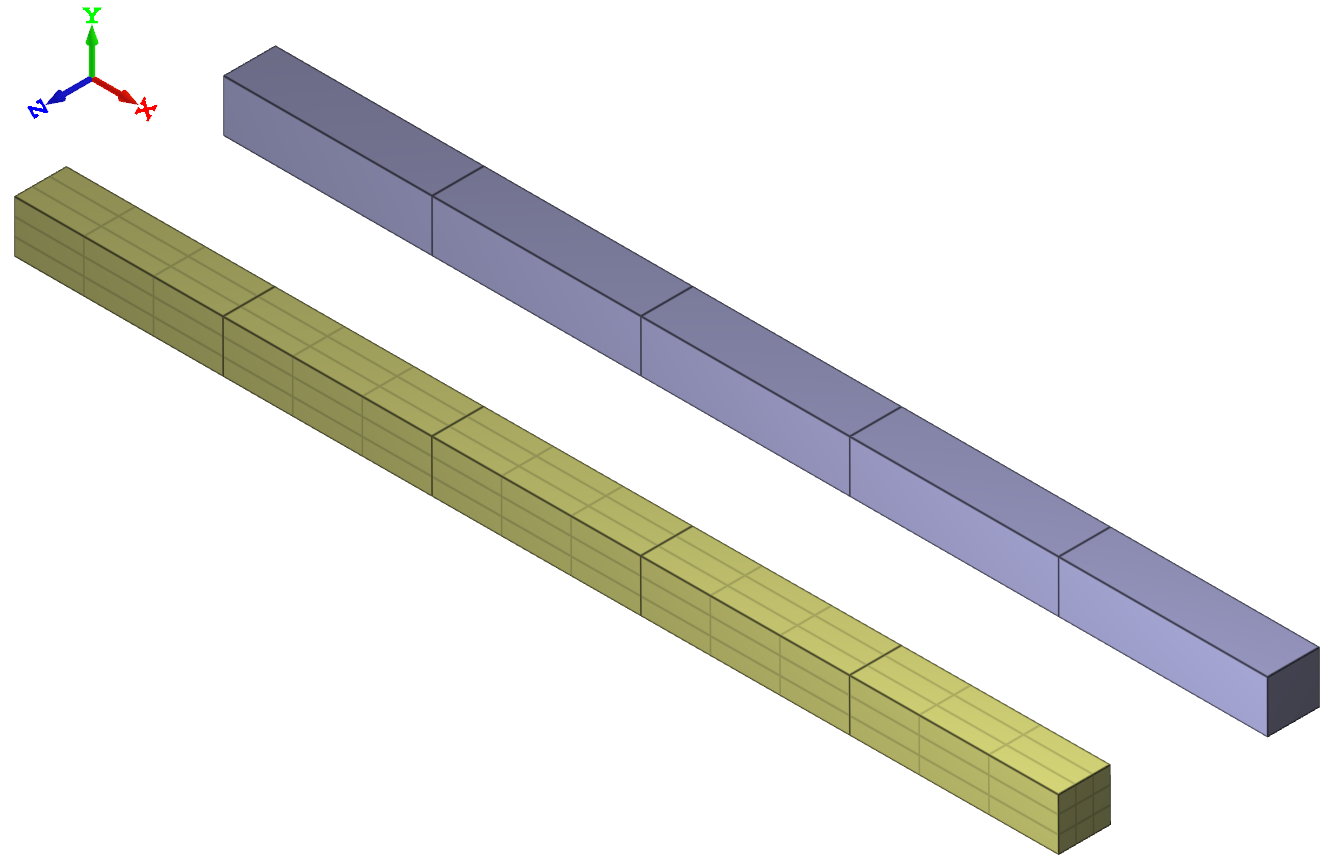

Eight CHEX elements are aligned along the global X-axis as displayed in Figure 1.

A unique translational constraints are imposed on each element. From left to right: 0, X, Y, Z, XY, YZ, ZX, XYZ. A pressure is applied, causing deformation of all elements except the one fixed in XYZ.

At termination, the displacement should be zero in the constrained directions. Displacements in the free directions are calculated based on the applied pressure and bulk modulus of the material.

The displacements of the elements are checked at termination.

Tests

This benchmark is associated with 1 tests.

*BC_PERIODIC

Cyclic symmetry

"Optional title"

coid

entype$_{1}$, enid$_{1}$, entype$_{2}$, enid$_{2}$

Tested parameters: coid, entype , enid

, enid , entype

, entype , enid

, enid .

.

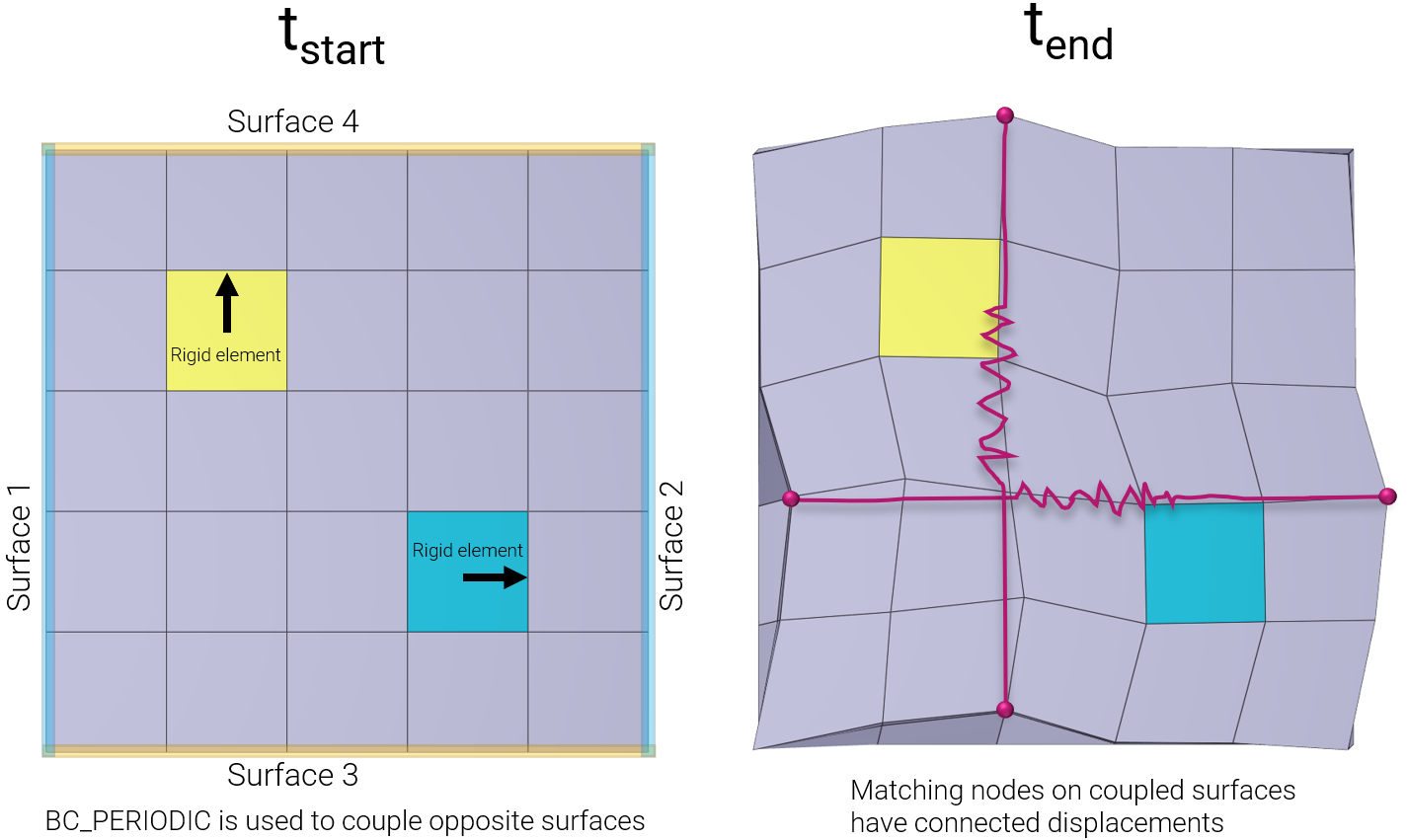

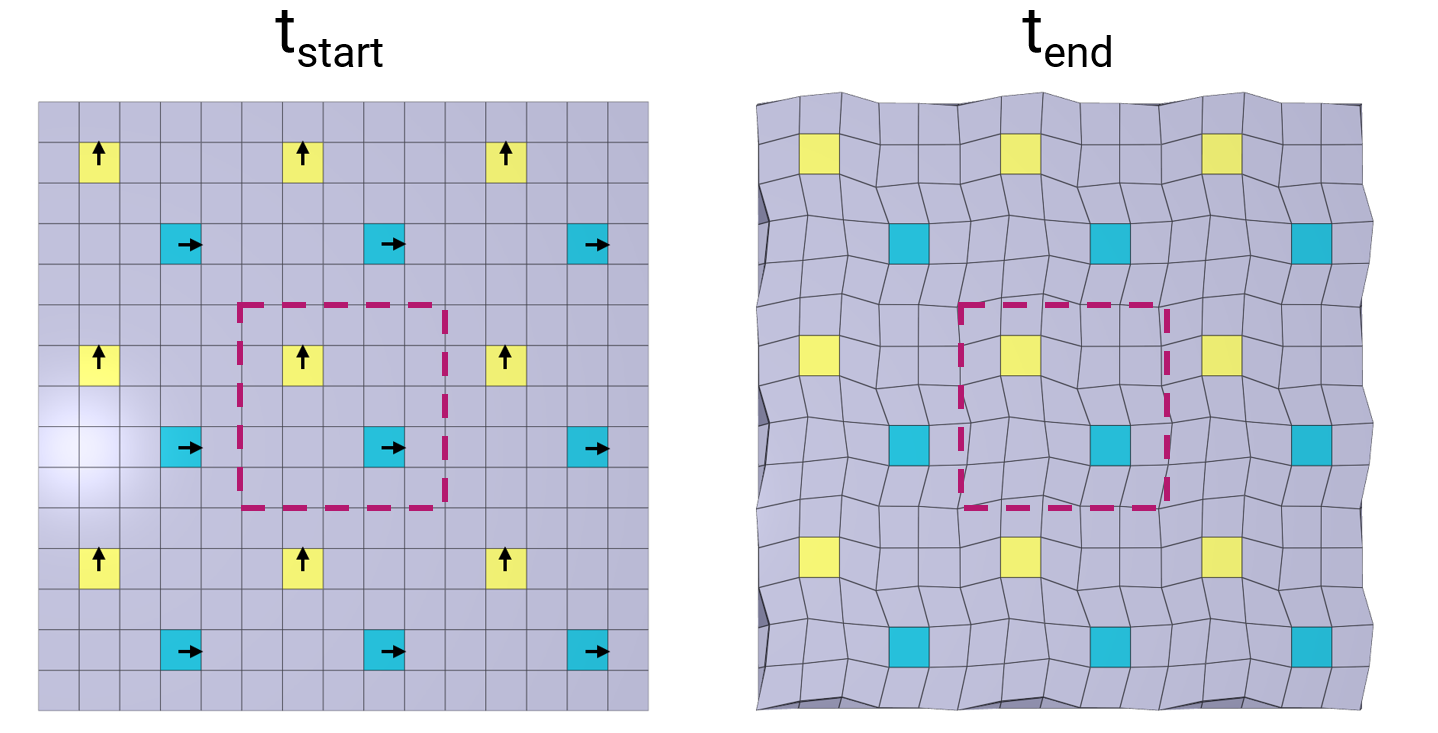

This model tests the command *BC_PERIODIC.

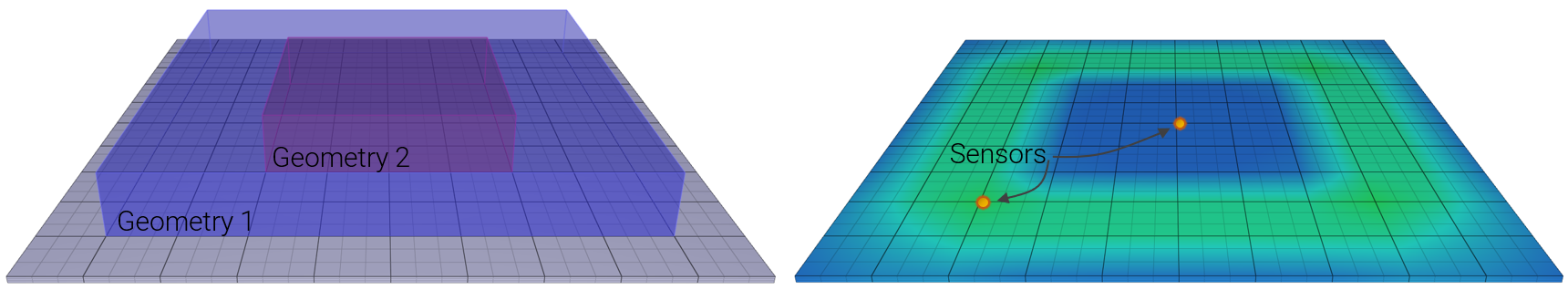

Two rigid elements inside a box component is given a prescribed motion in X & Y-direction. The box component consists of a mesh of 5x5x2 elements.

Motion in Z-direction is restricted for the entire model. The bottom surface is completely fixed.

To apply cyclic symmetry to the model, periodic boundary conditions are used to couple surface 1 & 2, and surface 3 & 4.

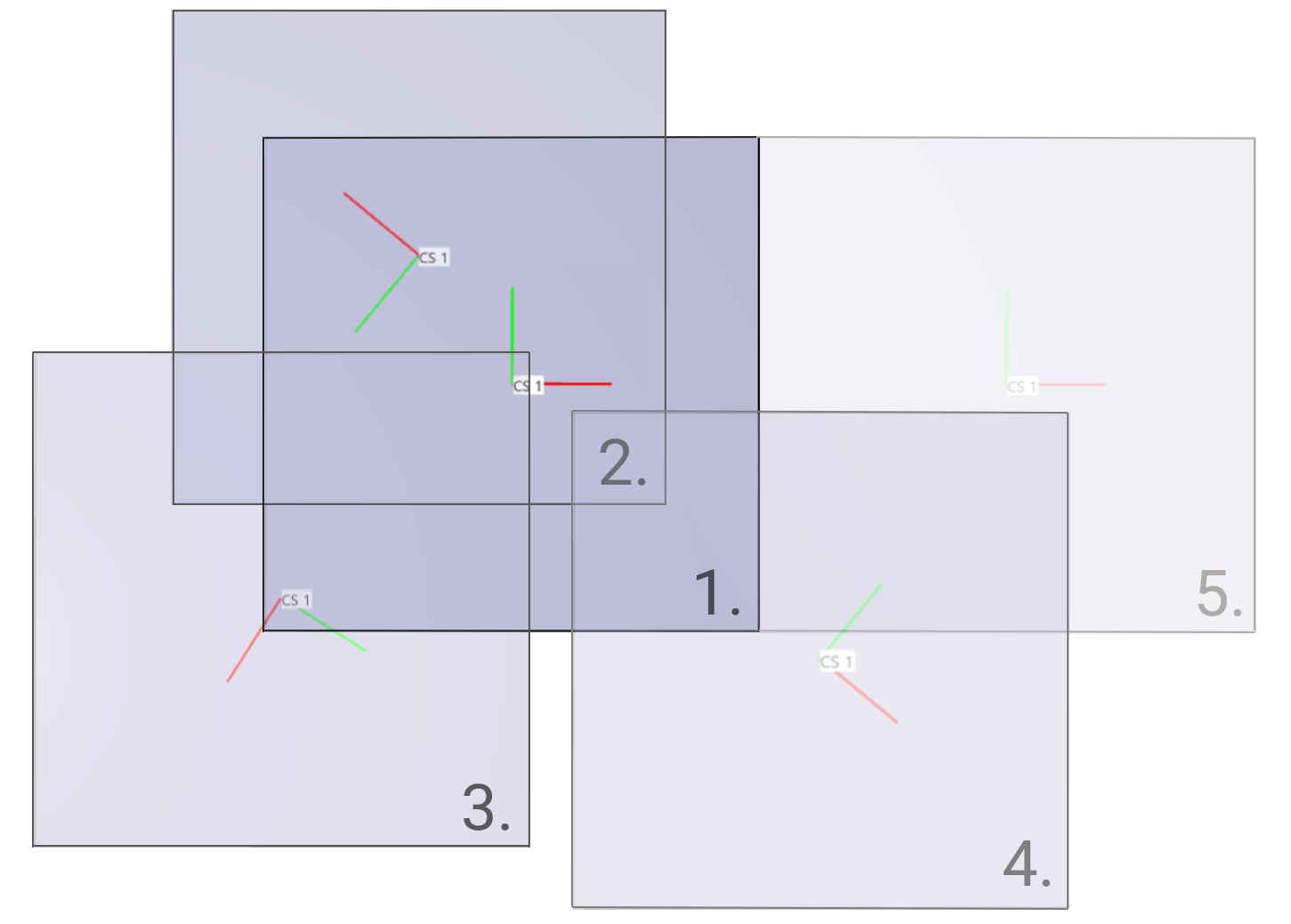

The corresponding nodes for the coupled surfaces experience equivalent displacements. See Figure 1.

A larger model displaying the repetitive pattern is illustrated in Figure 2.

Node displacements are checked for version control.

Tests

This benchmark is associated with 1 tests.

*BC_SYMMETRY

Rigid wall

$plane$, $csysid_1$, $csysid_2$, $csysid_3$, $tol$

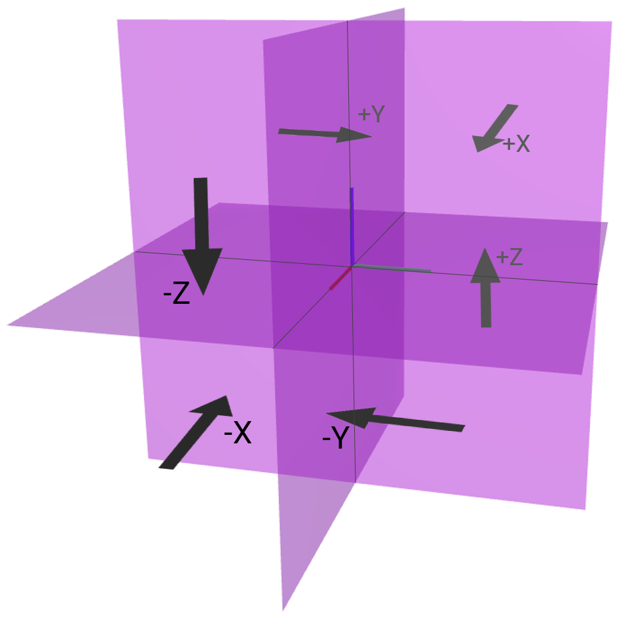

This model tests the command *BC_SYMMETRY. The test consists of six CHEX elements, all located at a distance from the symmetry planes defined in the global coordinate system.

The elements are given a prescribed velocity in the -Z, +Z, -Y, +Y, -X, +X directions.

None of the elements should pass through any of the axes of the symmetry planes.

See Figure 1.

X, Y and Z coordinates of the elements are checked for version control.

Tests

This benchmark is associated with 1 tests.

Symmetry in local coordinate systems

$plane$, $csysid_1$, $csysid_2$, $csysid_3$, $tol$

Symmetry and tolerance defined in local coordinate systems are verified in this test.

Tested parameters:  ,

,  ,

,  and

and  .

.

An element is defined by the coordinates ( ,

,  ,

,  ) and (

) and ( ,

,  ,

,  ), where

), where  is the element side length and

is the element side length and  is an offset distance. Three local coordinate systems are defined as displayed in Figure 1 and described in Table 1. Symmetry conditions are defined in these local coordinate systems.

is an offset distance. Three local coordinate systems are defined as displayed in Figure 1 and described in Table 1. Symmetry conditions are defined in these local coordinate systems.

Prescribed motions are imposed on the three surfaces opposite the surfaces affected by the symmetry.

Two tests are done. In the first test, the tolerance is greater than  , meaning that symmetry will be active, and the element expands because of the prescribed motions.

In the second test, the tolerace is smallar than

, meaning that symmetry will be active, and the element expands because of the prescribed motions.

In the second test, the tolerace is smallar than  , meaning that symmetry conditions are not active, and the cube will translate instead of expanding.

, meaning that symmetry conditions are not active, and the cube will translate instead of expanding.

The displacements of the nodes initially located at ( ,

,  ,

,  ) and (

) and ( ,

,  ,

,  ) are checked at termination.

) are checked at termination.

Tests

This benchmark is associated with 2 tests.

Symmetry in the global coordinate system

$plane$, $csysid_1$, $csysid_2$, $csysid_3$, $tol$

Symmetry options and tolerance defined in the global coordinate system are verified in this test.

Tested parameters:  and

and  .

.

The test consists of a CHEX element defined by the coordinates ( ,

,  ,

,  ) and (

) and ( ,

,  ,

,  ), where

), where  is the element side length and

is the element side length and  is an offset distance. Prescribed displacements are imposed on the surfaces opposite the symmetry surfaces. The displacements are in the normal directions of the surfaces.

is an offset distance. Prescribed displacements are imposed on the surfaces opposite the symmetry surfaces. The displacements are in the normal directions of the surfaces.

A total of 16 configurations of the model are run and these can be divided into two sets. All symmetry options (0, X, Y, Z, XY, YZ, ZX, XYZ) are tested for both sets. In one of the sets, the tolerance is greater than the offset distance and in the other set it is not, meaning that the symmetry is not activated.

At termination, the displacement of the surfaces affected by the symmetry should be equal to zero. The displacement of free surfaces should be equal to the prescribed displacement.

The displacements of the nodes initially located at ( ,

,  ,

,  ) and (

) and ( ,

,  ,

,  ) are checked at termination.

) are checked at termination.

Tests

This benchmark is associated with 16 tests.

*BC_TELEPORT

Displacements and velocities in the global coordinate system

"Optional title"

$ coid $

$entype$, $enid$, $csysid$, $trig$, $multiple$, $velocity$

$\Delta_x$, $\Delta_y$, $\Delta_z$, $\theta_x$, $\theta_y$, $\theta_z$, $\Delta v_x$, $\Delta v_y$, $\Delta v_z$

Teleportation displacements and velocities in the global coordinate system are verfied in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  .

.

A CHEX element is given the initial velocity  ,

,  and

and  .

.

Teleportation displacements are defined in the global coordinate system as:

,

,  ,

,

Parameter  is set to half the termination time.

is set to half the termination time.

Teleportation velocities are defined as:

,

,  and

and  .

.

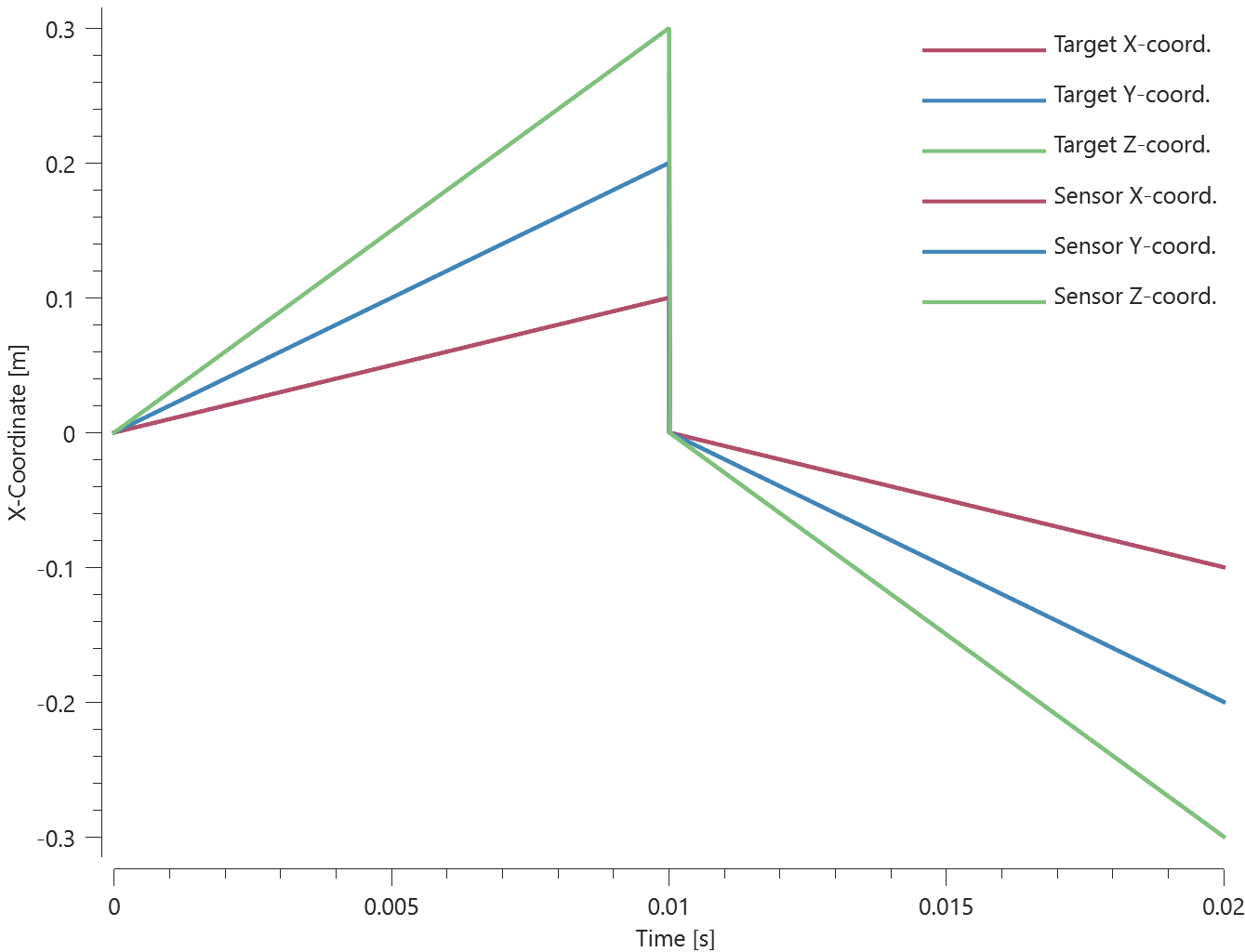

A sensor is located in the center of the element, which coincides with the origin of the global coordinate system at initiation.

Coordinates of the sensor at teleportation should be:

,

,  and

and  in the X-, Y- and Z-direction.

in the X-, Y- and Z-direction.

Coordinates of the sensor at termination should be:

,

,  and

and  in X-, Y- and Z-direction.

in X-, Y- and Z-direction.

Parameter  is the termination time.

is the termination time.

Sensor coordinates vs. time is presented in Figure 1 together with target curves.

Max, min and average values of sensor coordinates are checked.

Tests

This benchmark is associated with 1 tests.

Multiple teleportations using trigger function

"Optional title"

$ coid $

$entype$, $enid$, $csysid$, $trig$, $multiple$, $velocity$

$\Delta_x$, $\Delta_y$, $\Delta_z$, $\theta_x$, $\theta_y$, $\theta_z$, $\Delta v_x$, $\Delta v_y$, $\Delta v_z$

Multiple teleportations using a trigger function is verfied in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  and

and  .

.

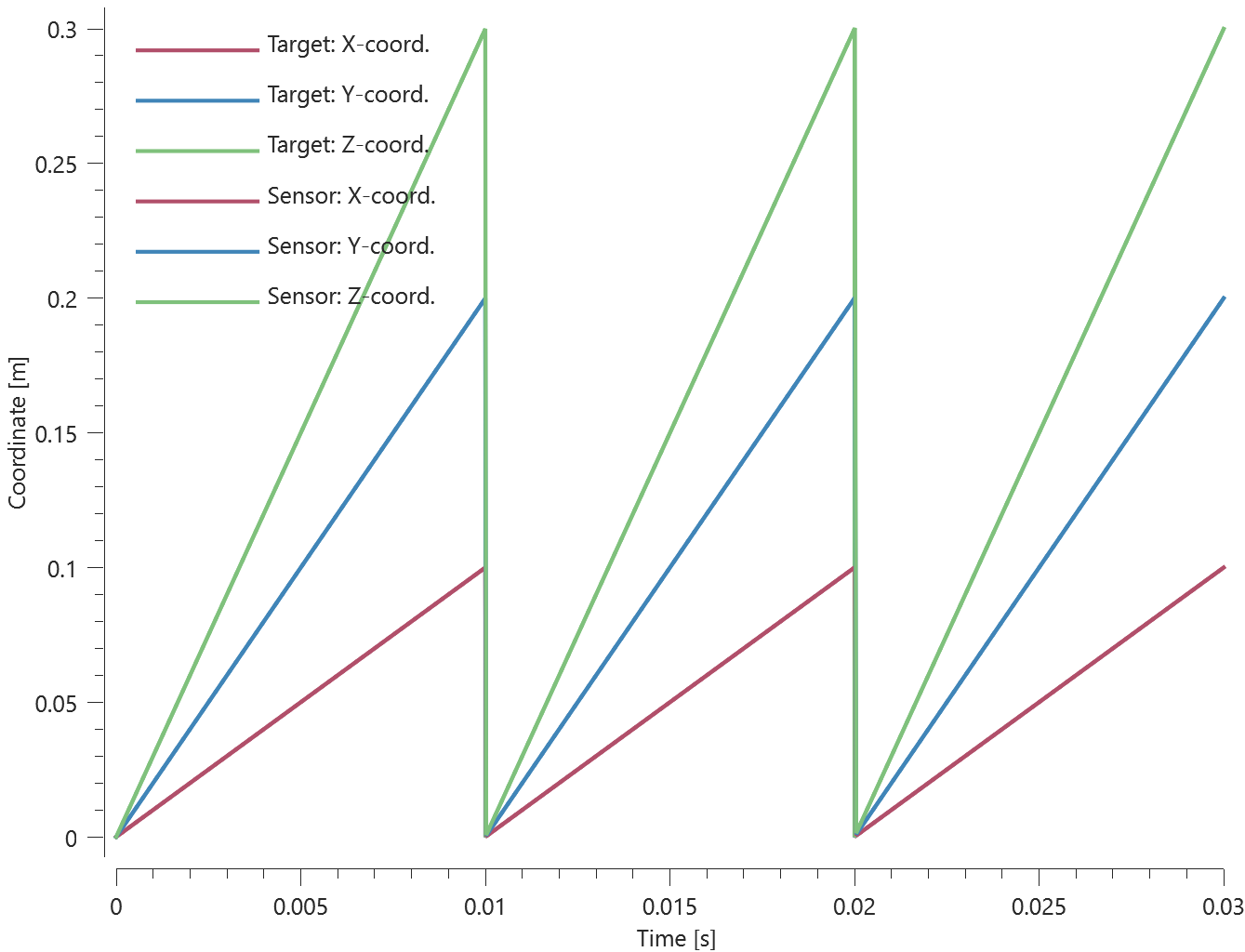

A CHEX element is given the initial velocity  ,

,  and

and  .

.

A sensor (with id = 1) is defined at the center of the element, which coincides with the origin of the global coordinate system at initiation.

A trigger function is defiend as:

The first term corresponds to the sensor displacement and  is the displacement at which teleportation is to occur, defined as:

is the displacement at which teleportation is to occur, defined as:

Parameter  is set to a third of the termination time.

is set to a third of the termination time.

Teleportation displacements are defined as  ,

,  ,

,  , meaning that the element is teleported to its initial position, and the velocities are defined to continue after teleportation.

, meaning that the element is teleported to its initial position, and the velocities are defined to continue after teleportation.

This configuration should generate two teleportations, and the sensor coordinates at termination should be:

,

,  and

and  in the X-, Y- and Z-direction.

in the X-, Y- and Z-direction.

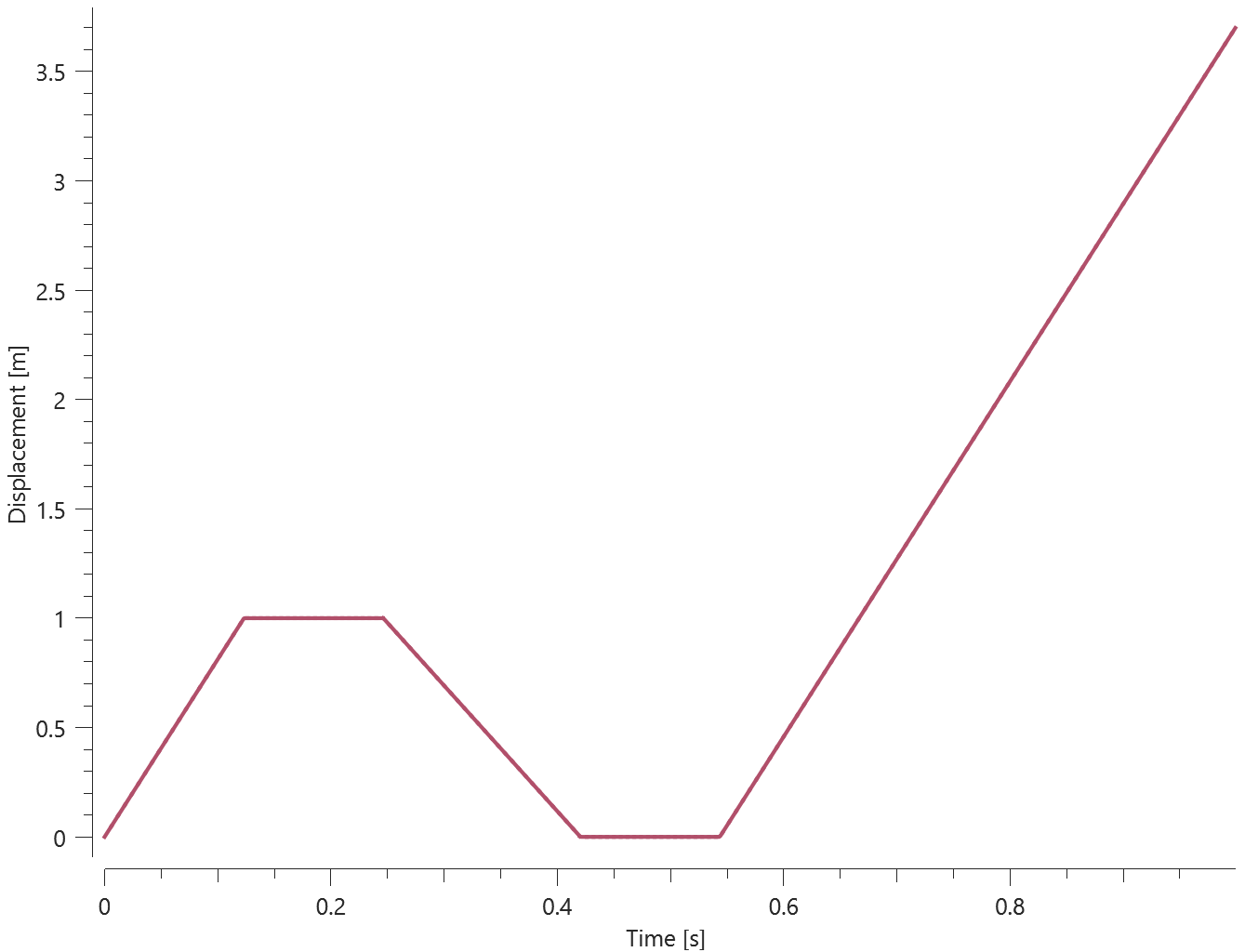

Sensor coordinates vs. time is presented in Figure 1 together with target curves.

Max, min and average values of sensor coordinates are checked.

Tests

This benchmark is associated with 1 tests.

Rotations in a local coordinate system

"Optional title"

$ coid $

$entype$, $enid$, $csysid$, $trig$, $multiple$, $velocity$

$\Delta_x$, $\Delta_y$, $\Delta_z$, $\theta_x$, $\theta_y$, $\theta_z$, $\Delta v_x$, $\Delta v_y$, $\Delta v_z$

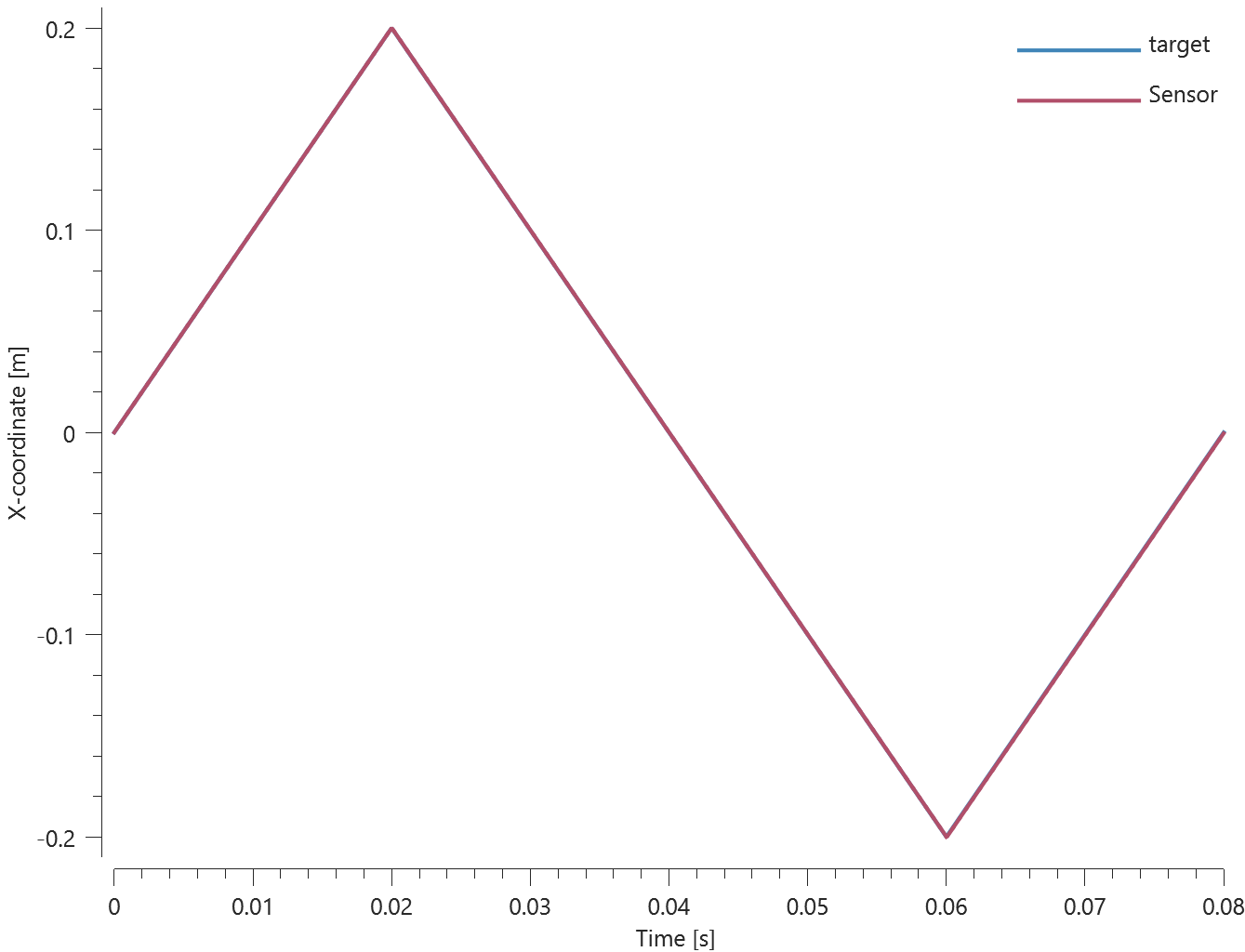

Teleportation rotations in a local coordinate system are verified in this test.

Tested parameters:  and

and  .

.

Two CHEX elements are defined in a local coordinate system, which at initiation coincides with the global coordinate system. A sensor (id = 1) is defined at the origin of the local coordinate system. The elements are given an initial velocity  in the local X-direction.

in the local X-direction.

A trigger function for teleportation is defined as:

corresponds to the absolute value of the sensor X-coordinate and

corresponds to the absolute value of the sensor X-coordinate and  is the displacement at which teleportation should occur.

is the displacement at which teleportation should occur.

Teleportation rotation is defined as  , and the velocity is defined to continue after the teleportation. This means that after rotation, the local X-direction (which is the elements velocity vector) changes direction and is now opposite the global X-direction.

, and the velocity is defined to continue after the teleportation. This means that after rotation, the local X-direction (which is the elements velocity vector) changes direction and is now opposite the global X-direction.

A second teleportation occurs once the sensor X-displacement reaches  . After this teleportation, the local X-axis coincides with the global X-axis again.

Sensor X-coordinate vs. time is presented in Figure 1 together with a target curve.

. After this teleportation, the local X-axis coincides with the global X-axis again.

Sensor X-coordinate vs. time is presented in Figure 1 together with a target curve.

Max, min and average value of sensor X-coordinate is checked.

Tests

This benchmark is associated with 1 tests.

*BC_TEMPERATURE

All features

"Optional title"

$entype$, $enid$, $cid$, $sf$, $t_{beg}$, $t_{end}$

All features of *BC_TEMPERATURE are verified in this test.

Tested parameters:  ,

,  ,

,  and

and  .

.

Eight CHEX elements are positioned as displayed in Figure 1. The temperature of the four elements in the left column is controlled by a curve while the temperature of the elements in the right column is controlled by a function.

The curve is defined as:

The function is defined as:

is the termination time and

is the termination time and  is the maximum temperature.

is the maximum temperature.  corresponds to the X-coordinate and

corresponds to the X-coordinate and  the current time in the simulation.

the current time in the simulation.  and

and  are minimum and maximum X-coordinates of the elements in the right column.

are minimum and maximum X-coordinates of the elements in the right column.

The temperatures in the two elements at the top row are just controlled by the curve and function. In the second row, a scale factor of 0.5 is used. Activation and deactivation times are used in the third and forth row respectively.

Maximum and average temperature are checked in the elements.

Tests

This benchmark is associated with 1 tests.

One-dimensional heat conduction

"Optional title"

$entype$, $enid$, $cid$, $sf$, $t_{beg}$, $t_{end}$

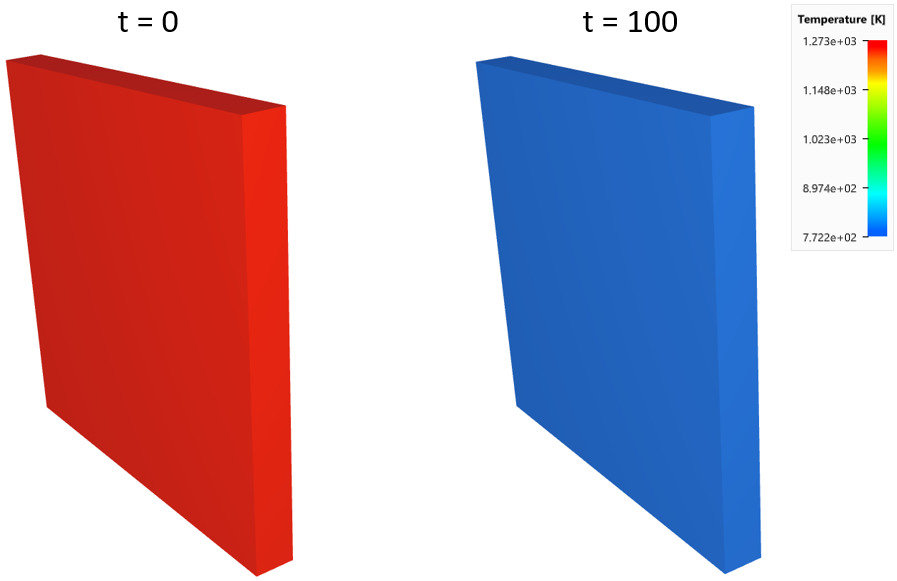

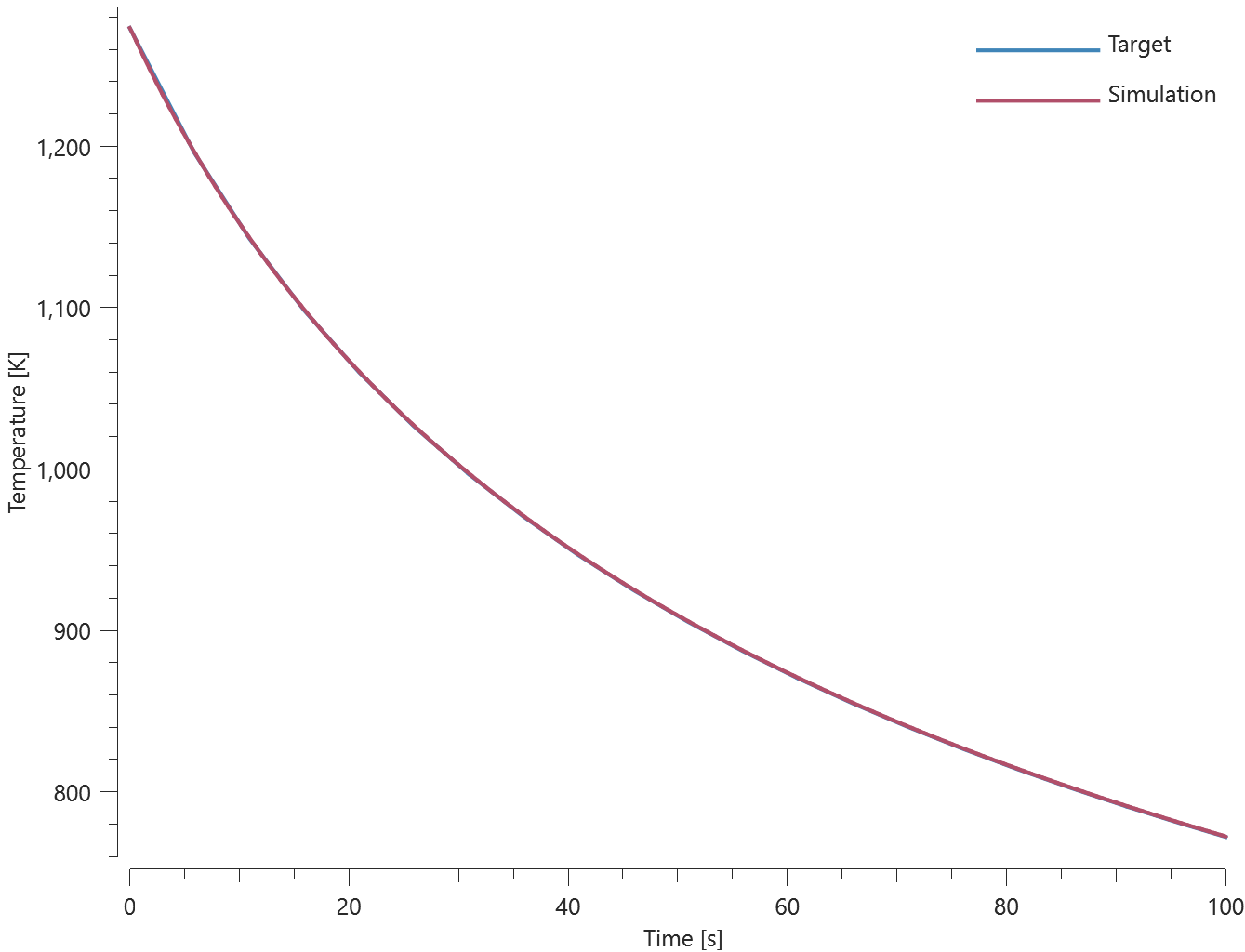

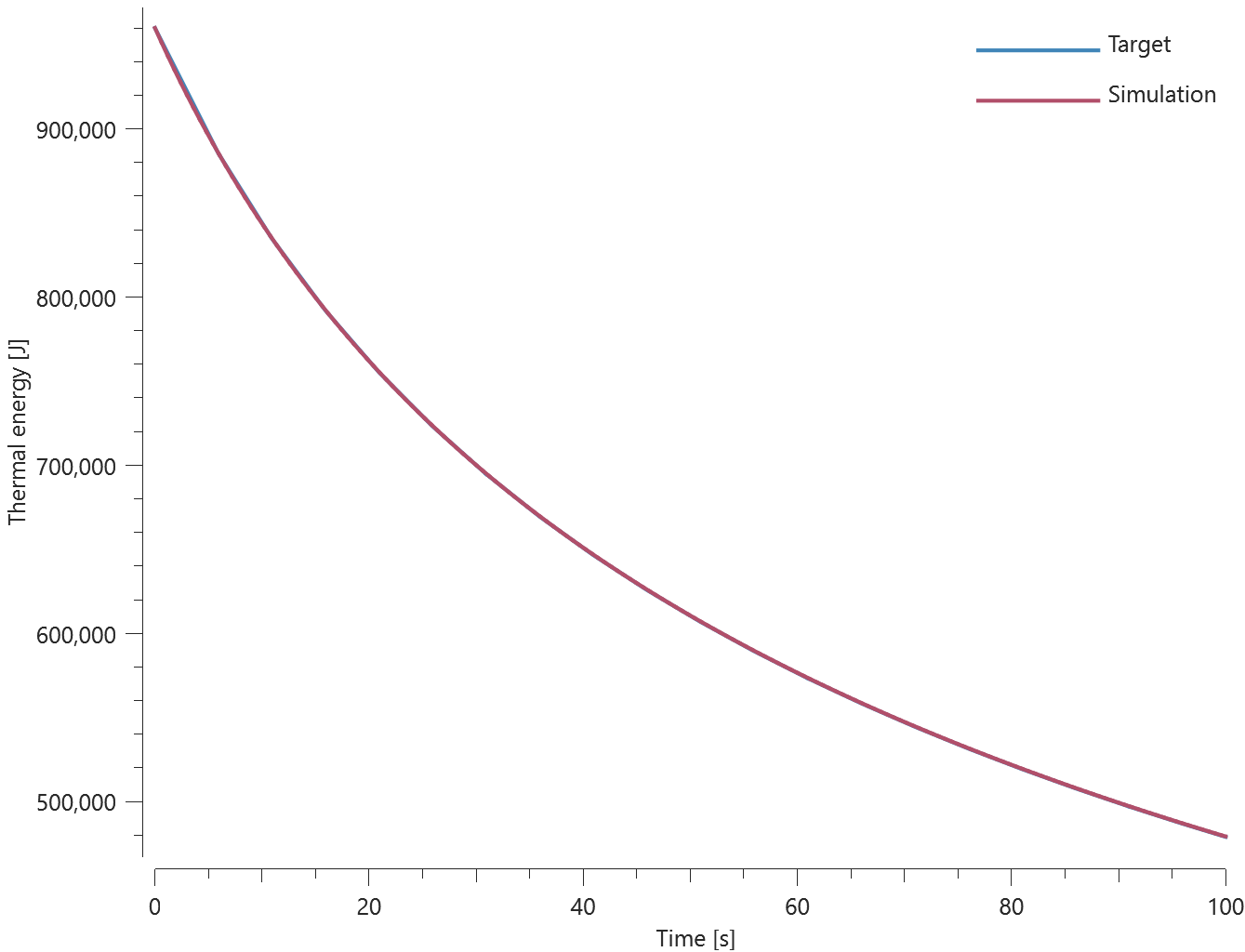

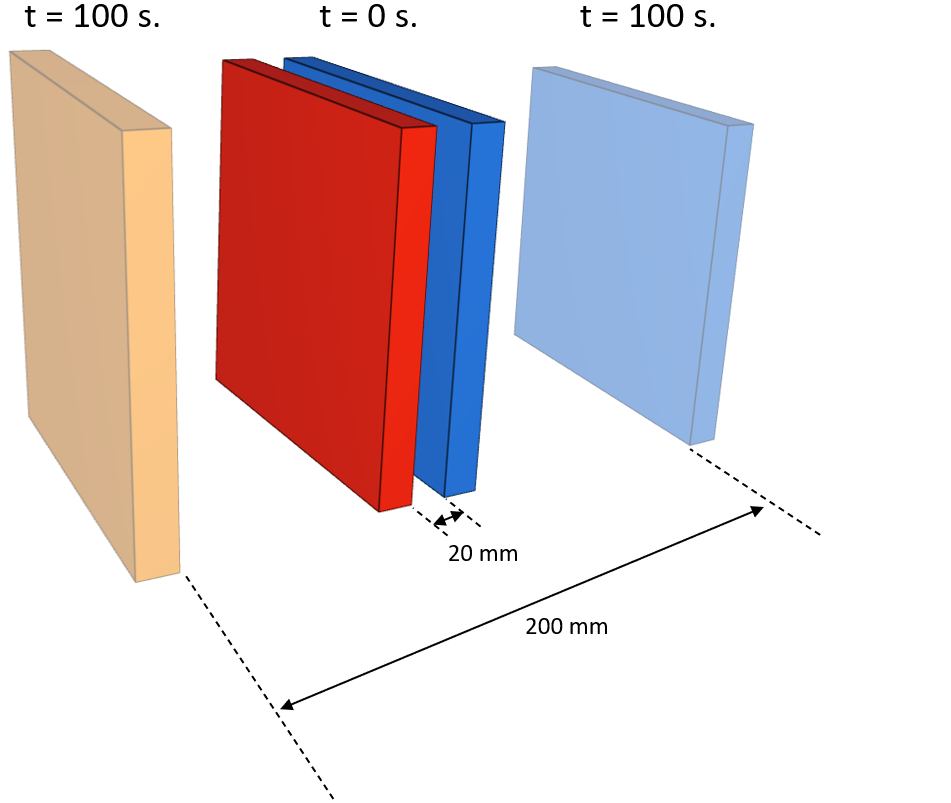

One-dimensional heat conduction is verified in this test.

Tested parameters:  ,

,  and

and  .

.

Prescribed temperatures are imposed at the ends of a rod with an initial uniform temperature, causing the temperature along the rod to change due to conduction. The initial and final temperature in a sensor located at the blue mark in Figure 1 is compared to analytical results.

Temperature at initiation and termination is checked.

Tests

This benchmark is associated with 1 tests.

*CHANGE_P-ORDER

Cantilever beams

"Optional title"

$entype$, $enid$, $order$, $gid$

This test shows that higher order elements are superior to linear elements in the case of bending.

Tested parameters:  ,

,  and

and  .

.

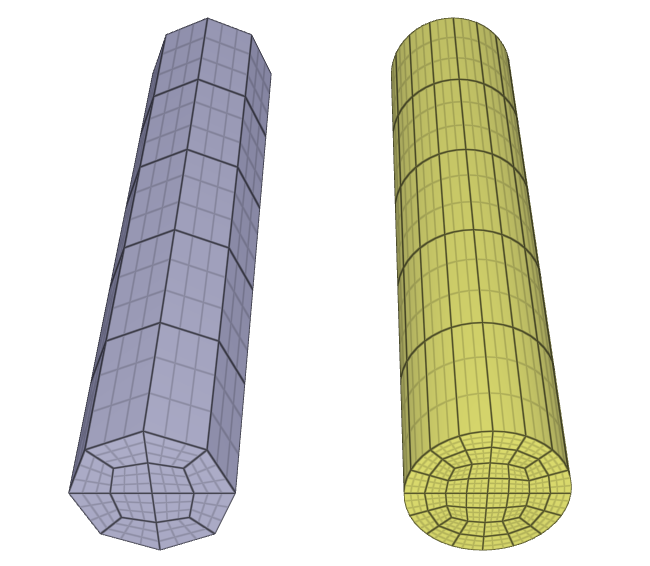

Two cantilever beams are subjected to a transverse point load at the unconstrained end. One of the beams is modeled with five LHEX elements and the other with five CHEX elements, as visible in Figure 1.

The displacements of the ends vs. time from the simulation are plotted in Figure 2 together with an analytical value of max deflection obtained from Euler-Bernoulli beam theory.

Tests

This benchmark is associated with 1 tests.

Domain of higher order elements

"Optional title"

$entype$, $enid$, $order$, $gid$

Conversion to higher order elements within a specified geometry is verified in this test.

Tested parameters:  ,

,  ,

,  and

and  .

.

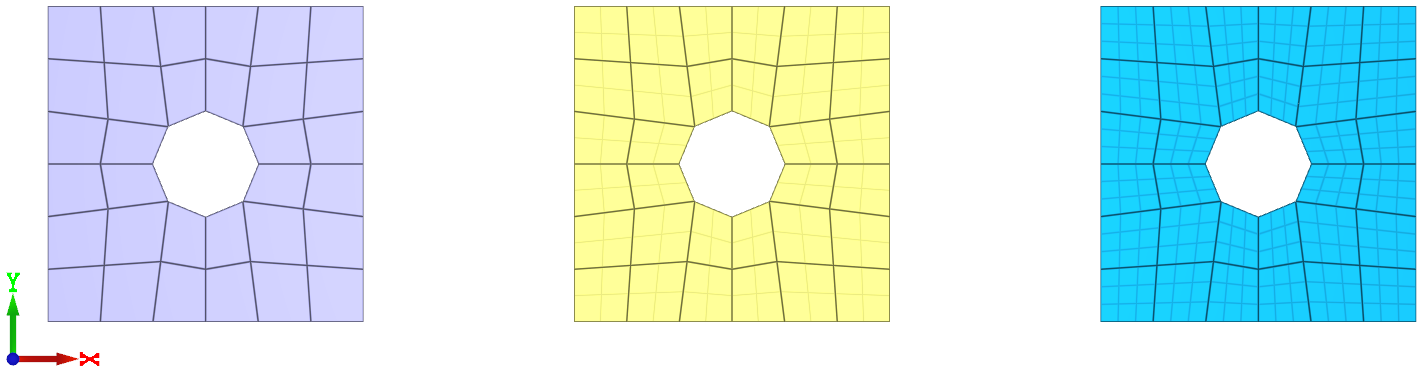

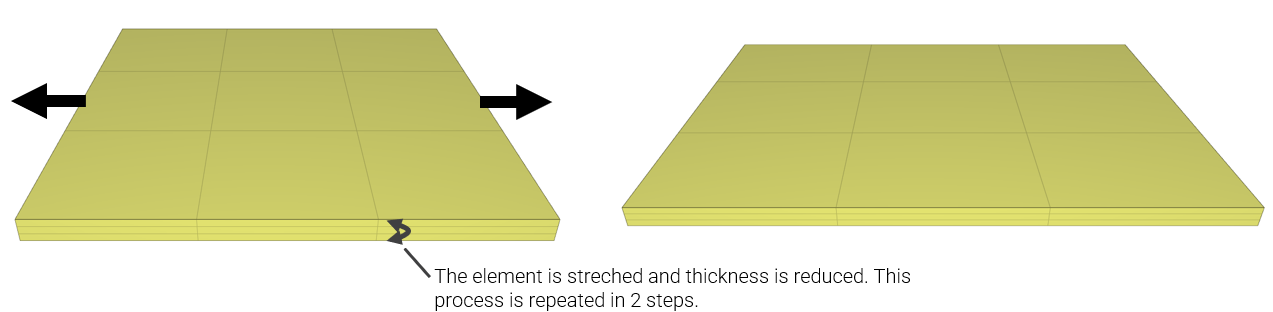

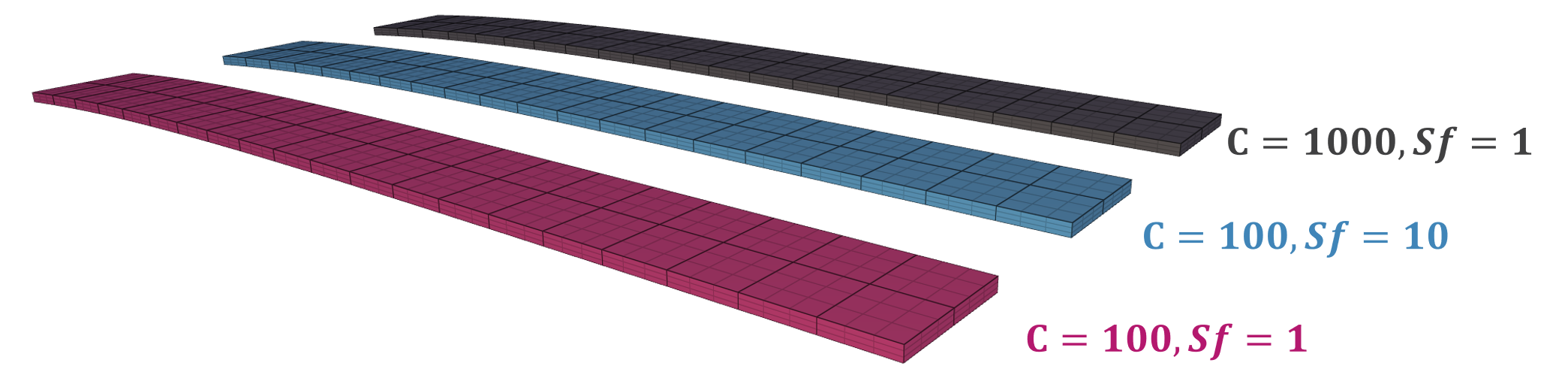

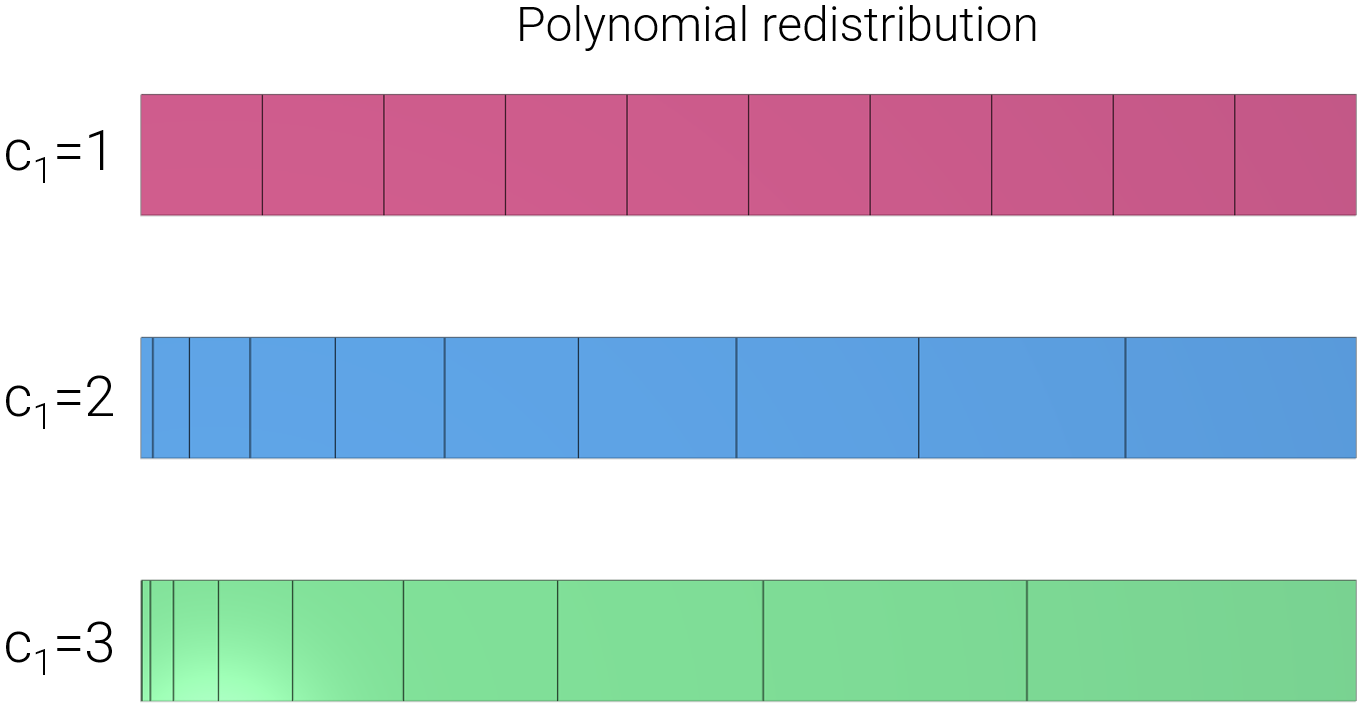

Three square plates modeled with LHEX elements are positioned as displayed in Figure 1. A geometry (*GEOMETRY_PIPE) is defined with its axial direction aligned with the center of the plates. The diameter of the geometry is smaller than the side length of the plates, meaning that only a part of the plates is inside the geometry. Elements within the geometry are converted to the higher order elements in two of the plates.

The coordinates of a node in each plate are checked.

Tests

This benchmark is associated with 1 tests.

Higher order elements

"Optional title"

$entype$, $enid$, $order$, $gid$

Conversion from linear elements to higher order elements with *CHANGE_P-ORDER is verified in this test.

Tested parameters:  ,

,  and

and  .

.

Three plates meshed with LHEX elements are used in this test. Each plate is assigned a unique polynomial order (1,2 or 3) in *CHANGE_P-ORDER. The elements in two of the plates are therefore converted into higher order elements as visible in Figure 1.

The coordinates of a node in each plate are checked.

Tests

This benchmark is associated with 1 tests.

*CHANGE_PART_ID

Elements inside a geometry

"Optional title"

coid

pid$_{from}$, pid$_{to}$, gid

Tested parameters: coid, pid , pid

, pid , gid.

, gid.

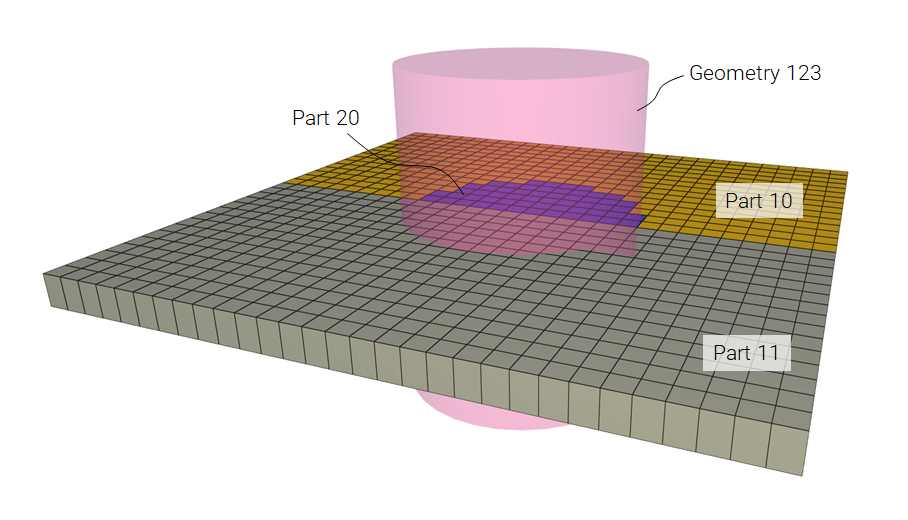

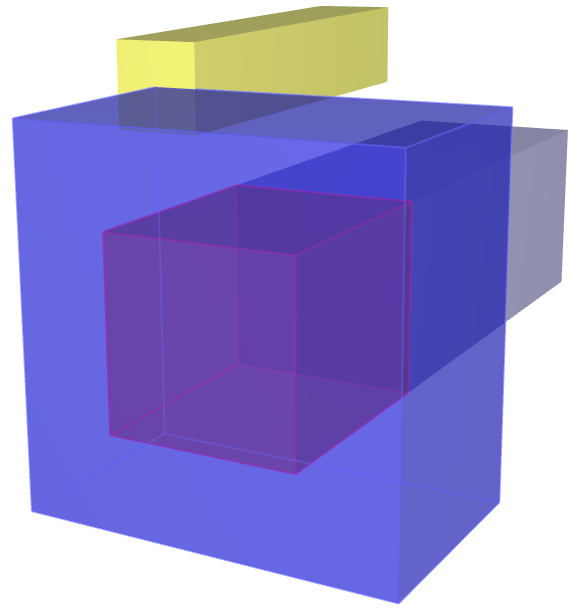

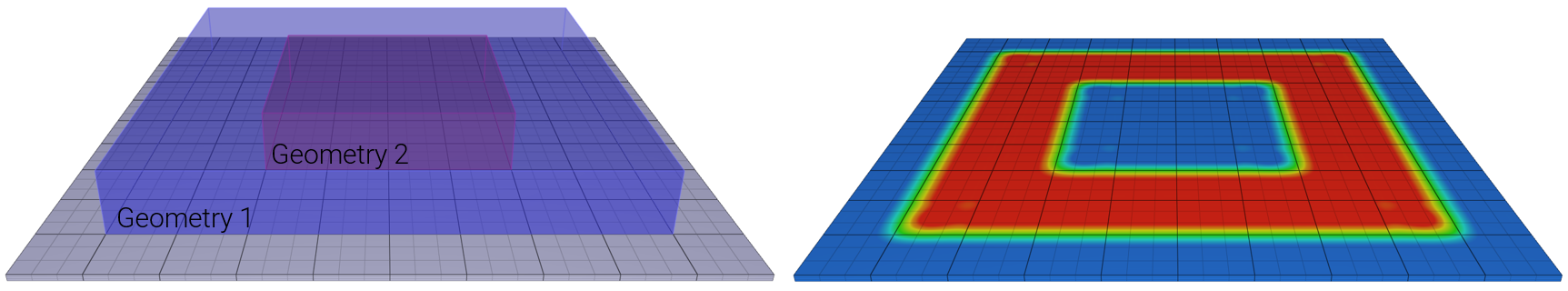

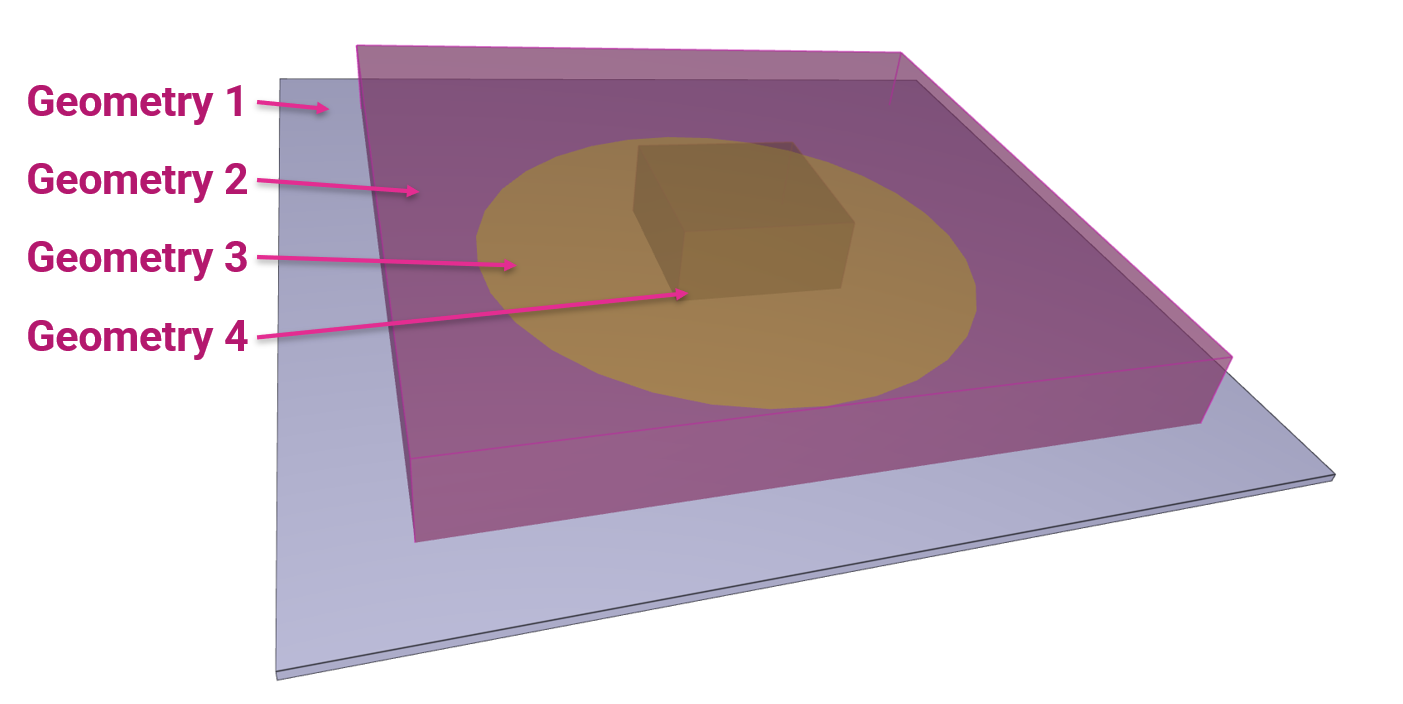

The model tests the command *CHANGE_PART_ID. The test consists of two parts and a geometry.

With the use of the command *CHANGE_PART_ID the elements of Part 10 that are inside Geometry 123 will be moved to Part 20.

See Figure 1.

The physical mass of part 10, 11 & 20 is checked for version control.

Tests

This benchmark is associated with 1 tests.

Included files

"Optional title"

coid

pid$_{from}$, pid$_{to}$, gid

Tested parameters: coid, pid , pid

, pid , gid.

, gid.

The model tests that the command *CHANGE_PART_ID is functioning within included files when using offsets to part ID:s.

The test is similar to the test "*INCLUDE - Offset" and should give the same result.

Targets:

-First cube should rotate 1 lap about X-axis.

-Second cube should move downwards 1 m in Z-direction.

Tests

This benchmark is associated with 1 tests.

*COMPONENT_BOLT

Defined in global and local coordinate systems

"Optional title"

$coid$, $pid_1$, $pid_2$, $pid_3$, $pid_4$, $csysid$, $tid$

$D$, $L$, $h$, $t$

Dimensions and positioning of bolts defined with *COMPONENT_BOLT are verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  , h and

, h and  .

.

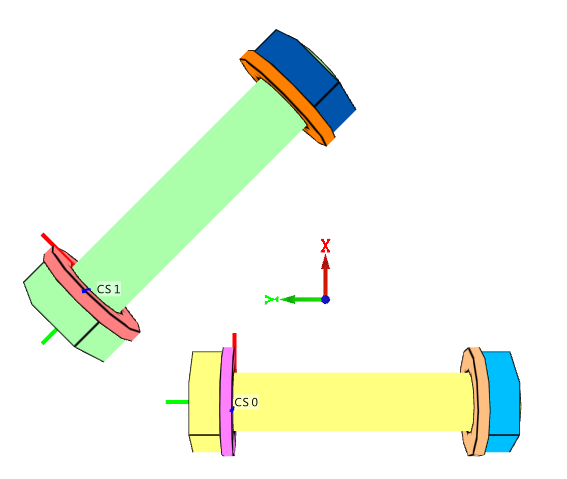

Two bolts are created using *COMPONENT_BOLT. One is created in the global coordinate system and the other in a local coordinate system. Both the origin and the axes in the local coordinate system differs from the global system, as visible in Figure 1.

Coordinates for a number of nodes are checked.

Tests

This benchmark is associated with 1 tests.

Positioning with table

"Optional title"

$coid$, $pid_1$, $pid_2$, $pid_3$, $pid_4$, $csysid$, $tid$

$D$, $L$, $h$, $t$

Positioning of bolts with the command *TABLE is verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  , h and

, h and  .

.

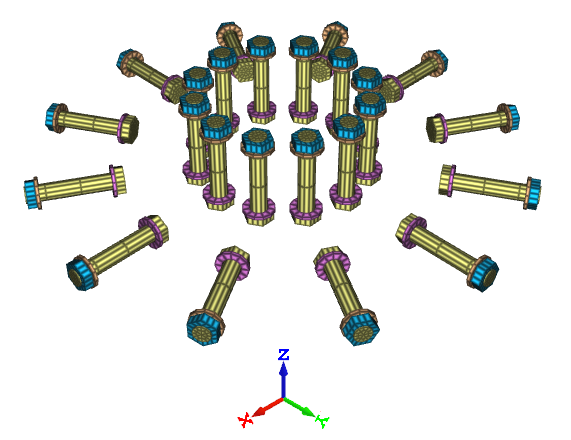

A number of bolts are positioned as displayed in Figure 1 by using the command *TABLE.

Coordinates for some of the nodes are checked.

Tests

This benchmark is associated with 1 tests.

*COMPONENT_BOX

Defined in global and local coordinate systems

"Optional title"

$coid$, $pid$, $N_x$, $N_y$, $N_z$, $csysid$

$x_1$, $y_1$, $z_1$, $x_2$, $y_2$, $z_2$

Dimensions and positioning of boxes defined with *COMPONENT_BOX are verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

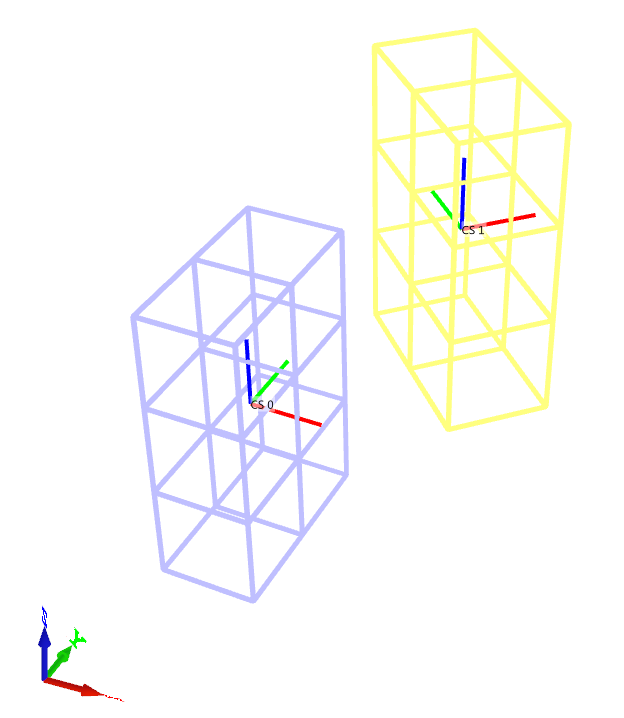

Two boxes are created using *COMPONENT_BOX. One is created in the global coordinate system and the other one in a local coordinate system. Both the origin and the axes in the local coordinate system differs from the global system, as visible in Figure 1.

Coordinates for a number of nodes are checked.

Tests

This benchmark is associated with 1 tests.

*COMPONENT_BOX_IRREGULAR

Defined in global and local coordinate systems

"Optional title"

$coid$, $pid$, $N_1$, $N_2$, $N_3$, $csysid$

$x_1$, $y_1$, $z_1$, $x_2$, $y_2$, $z_2$

$x_3$, $y_3$, $z_3$, $x_4$, $y_4$, $z_4$

$x_5$, $y_5$, $z_5$, $x_6$, $y_6$, $z_6$

$x_7$, $y_7$, $z_7$, $x_8$, $y_8$, $z_8$

$id1$, $x_{id1}$, $y_{id1}$, $z_{id1}$, $id2$, $x_{id2}$, $y_{id2}$, $z_{id2}$

$.$

$idm$, $x_{idm}$, $y_{idm}$, $z_{idm}$, $idn$, $x_{idn}$, $y_{idn}$, $z_{idn}$

Dimensions and positioning of boxes defined with *COMPONENT_BOX_IRREGULAR are verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

Two boxes are created using *COMPONENT_BOX_IRREGULAR. One is created in the global coordinate system and the other one in a local coordinate system. Both the origin and the axes in the local coordinate system differs from the global system, as visible in Figure 1.

Coordinates for a number of nodes are checked.

Tests

This benchmark is associated with 1 tests.

*COMPONENT_CYLINDER

Defined in global and local coordinate systems

"Optional title"

$coid$, $pid$, $N_1$, $N_2$, $csysid$

$x_1$, $y_1$, $z_1$, $x_2$, $y_2$, $z_2$, $R_1$, $R_2$

Dimensions and positioning of cylinders defined with *COMPONENT_CYLINDER are verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

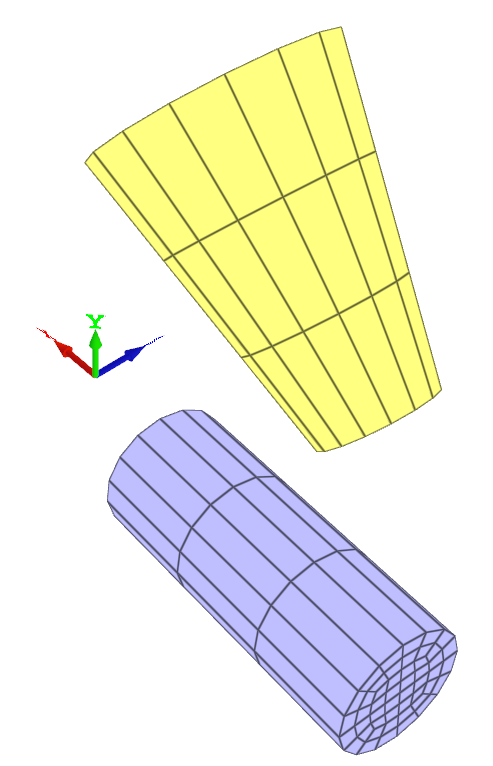

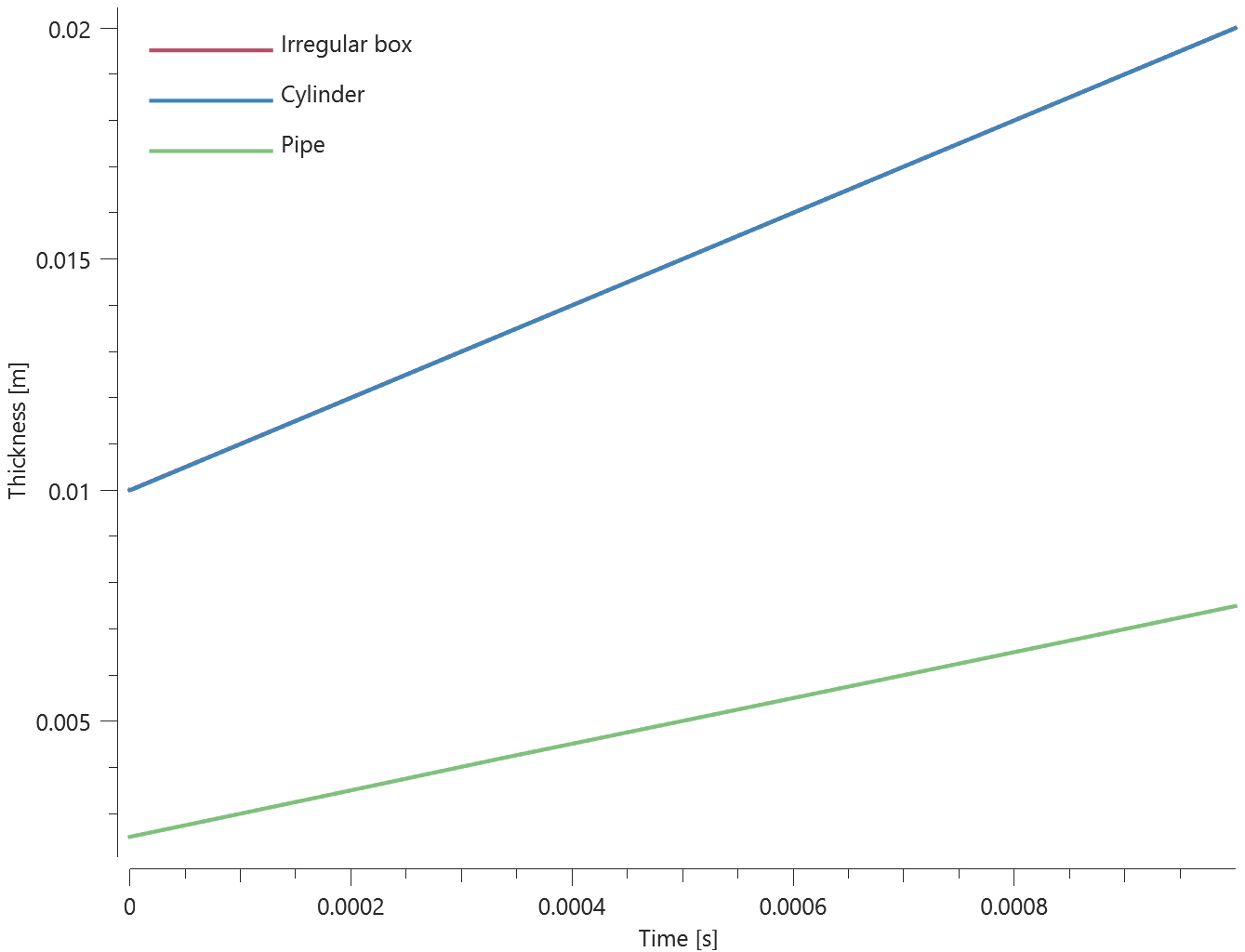

Two cylinders are created using *COMPONENT_CYLIDNER. One is created in the global coordinate system and the other one in a local coordinate system. Both the origin and the axes in the local coordinate system differs from the global system, as visible in Figure 1. The cylinder in the local coordinate system is tapered, verifying that parameters  and

and  works.

works.

Coordinates for a number of nodes are checked.

Tests

This benchmark is associated with 1 tests.

*COMPONENT_PIPE

Defined in global and local coordinate systems

"Optional title"

$coid$, $pid$, $N_1$, $N_2$, $N_3$, $csysid$, $\alpha_c$

$x_1$, $y_1$, $z_1$, $x_2$, $y_2$, $z_2$, $R_1$, $R_2$

$R_3$, $R_4$

Dimensions and positioning of pipes defined with *COMPONENT_PIPE are verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

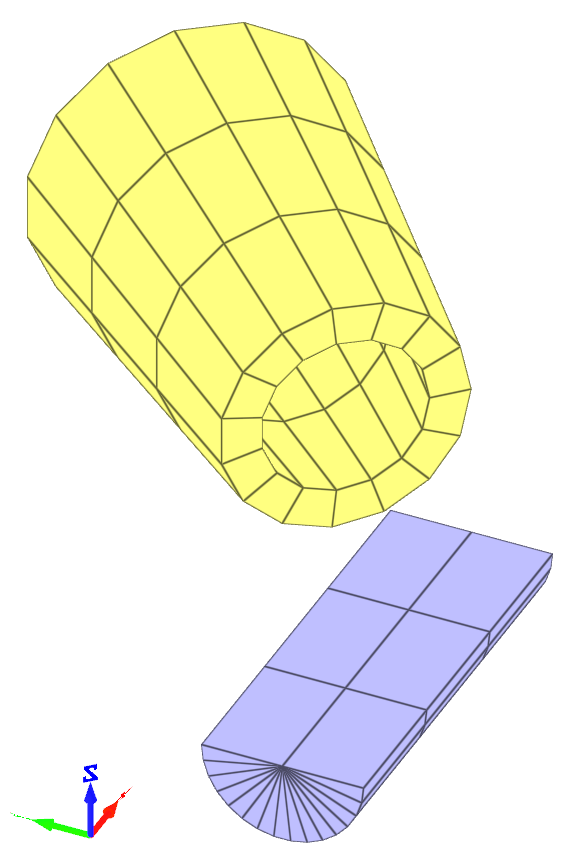

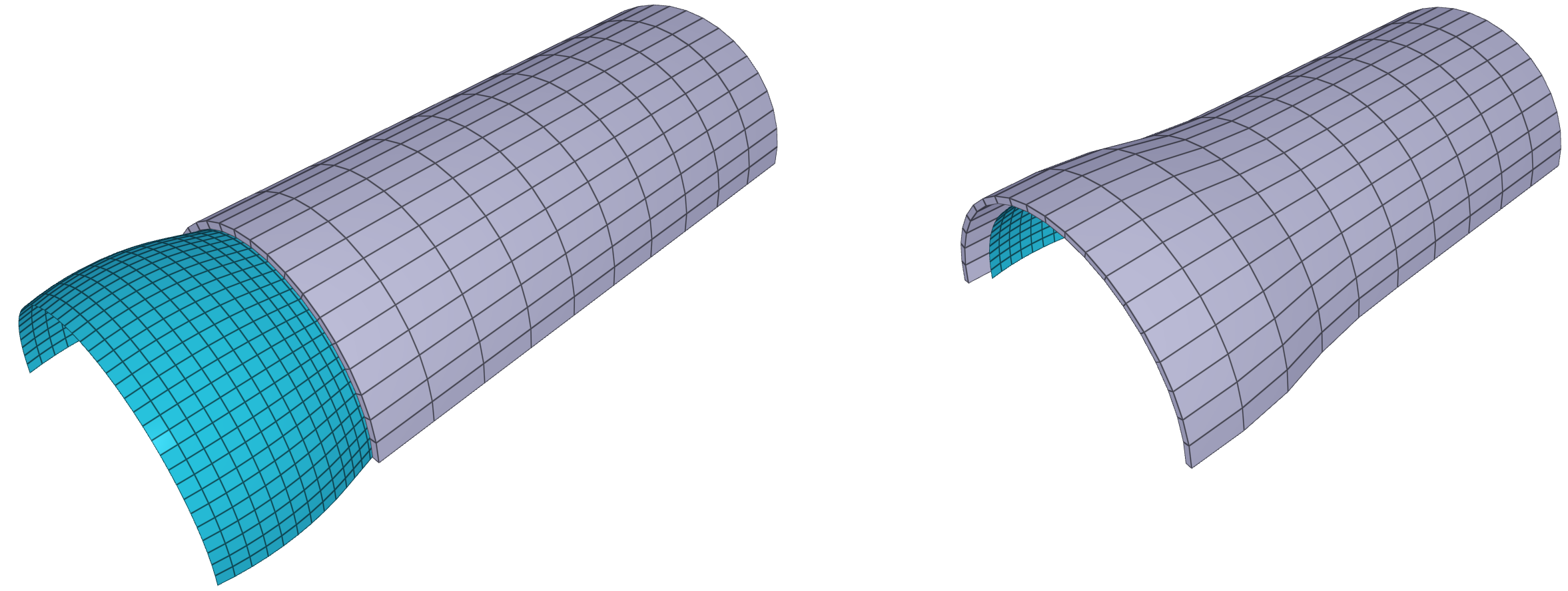

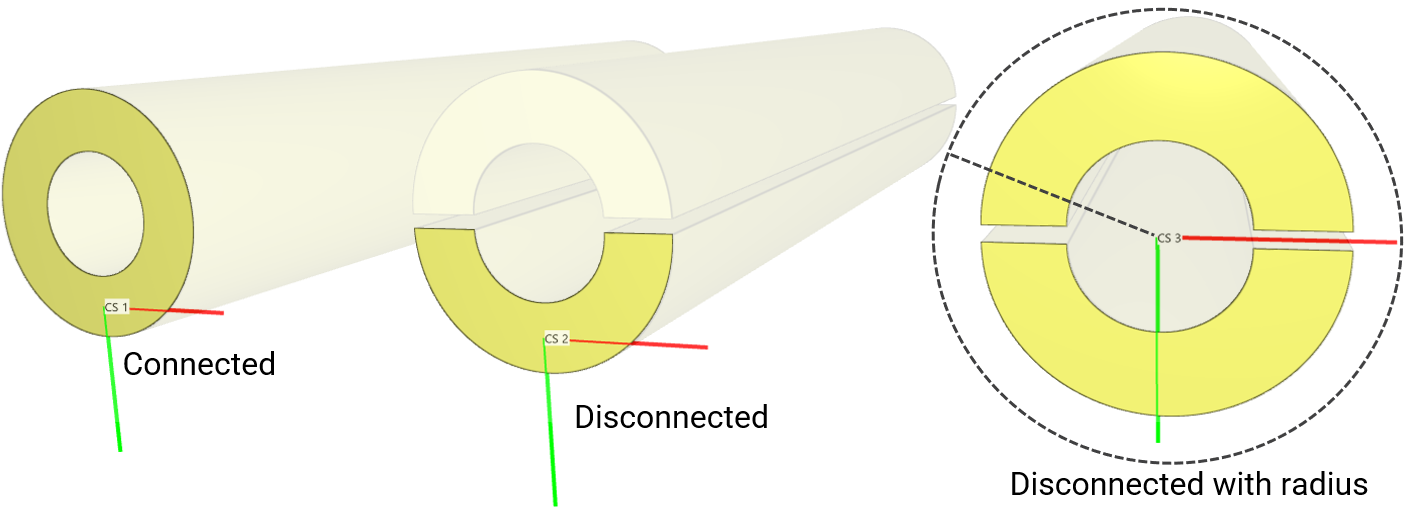

Two pipes are created using *COMPONENT_PIPE. One is created in the global coordinate system and the other one in a local coordinate system. Both the origin and the axes in the local coordinate system differs from the global system, as visible in Figure 1.

Parameter  is set to 180 deg. for the pipe defined in the global coordinate system. Parameter

is set to 180 deg. for the pipe defined in the global coordinate system. Parameter  ,

,  ,

,  and

and  are set so that the pipe in the local coordinate system is tapered and hollow.

are set so that the pipe in the local coordinate system is tapered and hollow.

Coordinates for a number of nodes are checked.

Tests

This benchmark is associated with 1 tests.

*COMPONENT_REBAR

Bending

"Optional title"

$coid$, $pid$, $N_x$, $N_y$, $N_z$, $csysid$

$x_1$, $y_1$, $z_1$, $x_2$, $y_2$, $z_2$, $h$

A rebar element with length  , diameter

, diameter  (

( >>

>>  ) and Young's modulus

) and Young's modulus  is fixed at both ends. A transverse displacement,

is fixed at both ends. A transverse displacement,  (

( ), is defined at the center of the element, causing the element to bend.

), is defined at the center of the element, causing the element to bend.

The load required to deflect the element to the defined displacement is calculated as:

is the second moment of area, defined as:

is the second moment of area, defined as:

The reaction force in each support should therefore be  . The reaction forces at termination are checked.

. The reaction forces at termination are checked.

Tests

This benchmark is associated with 1 tests.

Defined in global and local coordinate systems

"Optional title"

$coid$, $pid$, $N_x$, $N_y$, $N_z$, $csysid$

$x_1$, $y_1$, $z_1$, $x_2$, $y_2$, $z_2$, $h$

Dimensions and positioning of rebar grids defined with *COMPONENT_REBAR are verified in this test.

Two rebar grids are created using *COMPONENT_REBAR. One is created in the global coordinate system and the other one in a local coordinate system. Both the origin and the axes in the local coordinate system differs from the global system. The rebar grids consist of one cell in the X-direction, two cells in the Y-direction and three cells in the Z-diretion, as visible in Figure 1.

Coordinates for a number of nodes are checked.

Tests

This benchmark is associated with 1 tests.

*COMPONENT_SPHERE

Defined in global and local coordinate systems

"Optional title"

$coid$, $pid$, $N$, $N_c$, $csysid$, $\alpha_c$

$x_0$, $y_0$, $z_0$, $R_1$, $R_2$

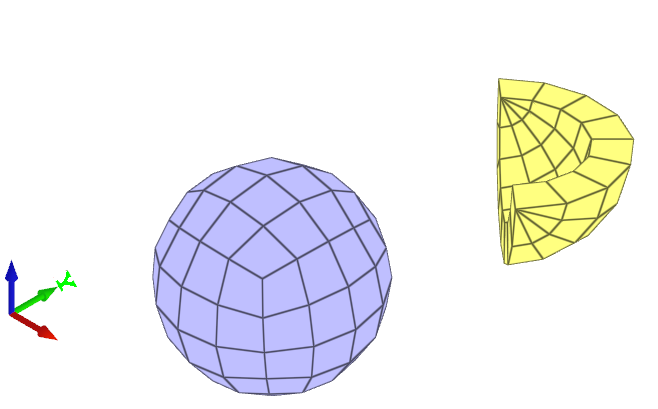

Dimensions and positioning of spheres defined with *COMPONENT_SPHERE are verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  .

.

A sphere and a slice of a sphere are created using *COMPONENT_SPHERE. The sphere is defined in the global coordinate system and the slice in a local coordinate system. Both the origin and the axes in the local coordinate system differs from the global system, as visible in Figure 1. Parameter  is set to 180 deg. in the slice.

is set to 180 deg. in the slice.

Coordinates for a number of nodes are checked.

Tests

This benchmark is associated with 1 tests.

*CONNECTOR_DAMPER

Axially loaded damper

"Optional title"

coid

pid$_{1}$, pid$_{2}$, csysid, $R$, $h$, $m$, $\eta$, $k_{max}$

cid$_{axial}$, cid$_{shear}$, cid$_{bend}$, cid$_{rate}$

Tested parameters: coid, pid , pid

, pid , csysid,

, csysid,  , h,

, h,  ,

,  ,

,  , cid

, cid , cid

, cid , cid

, cid , cid

, cid .

.

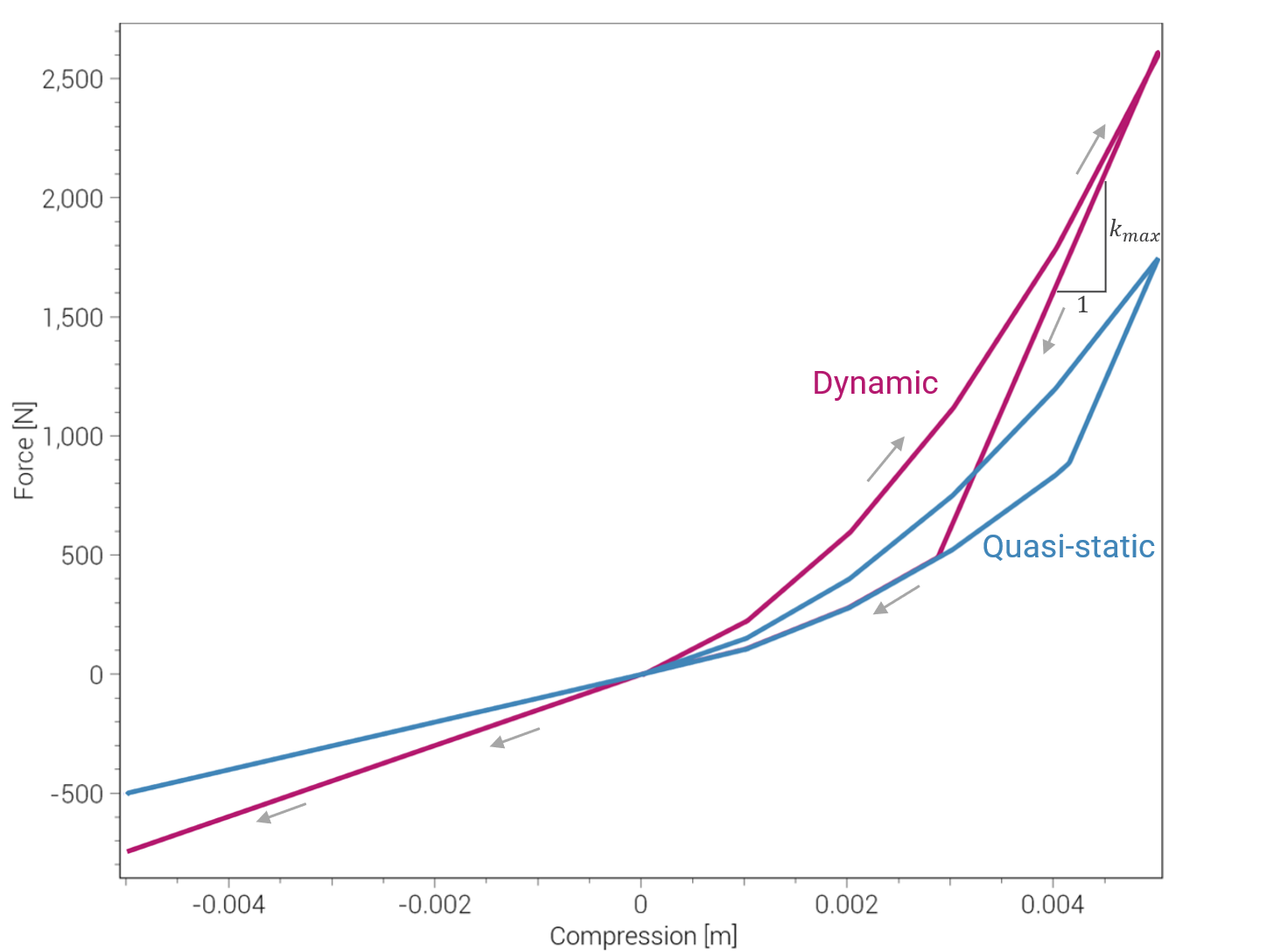

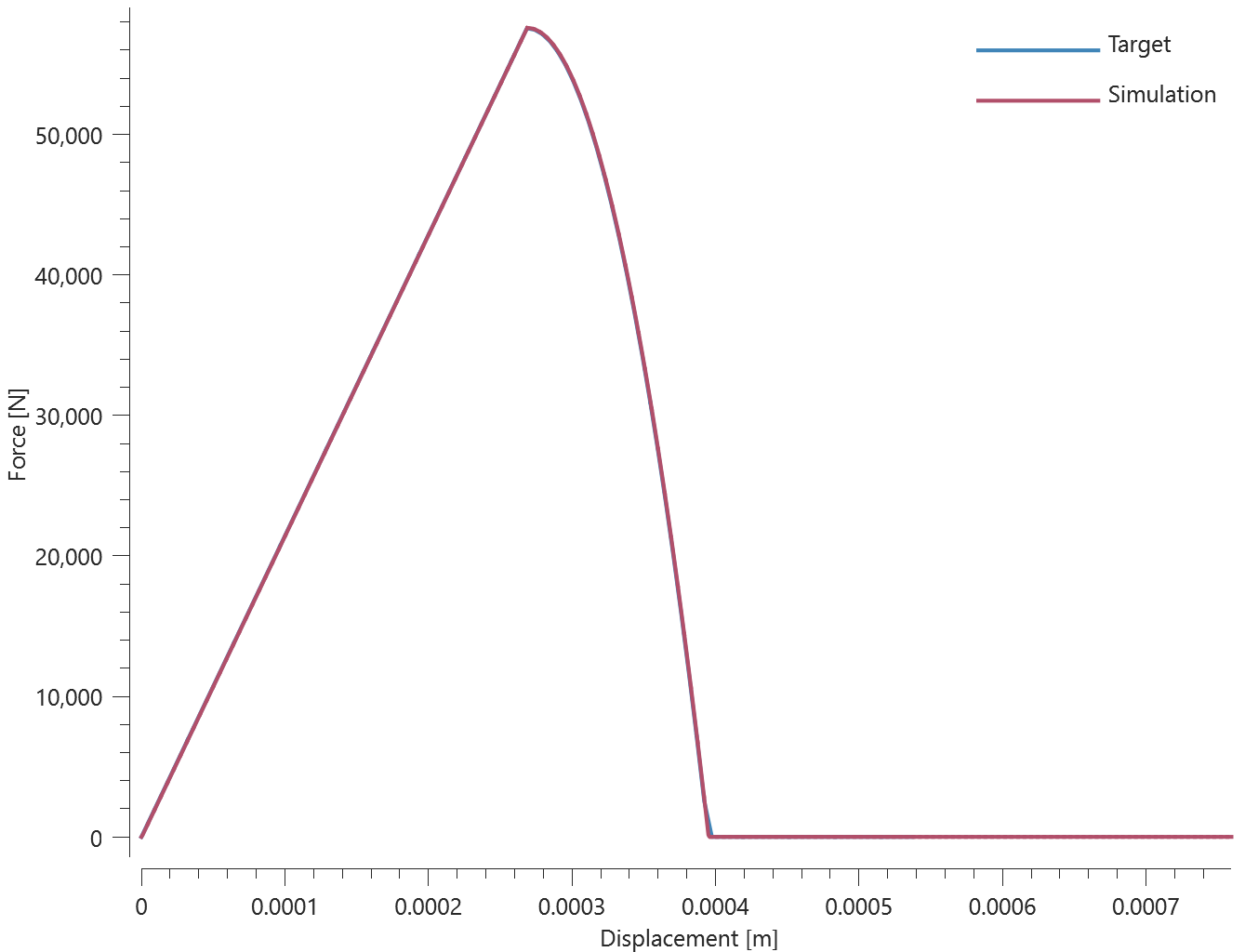

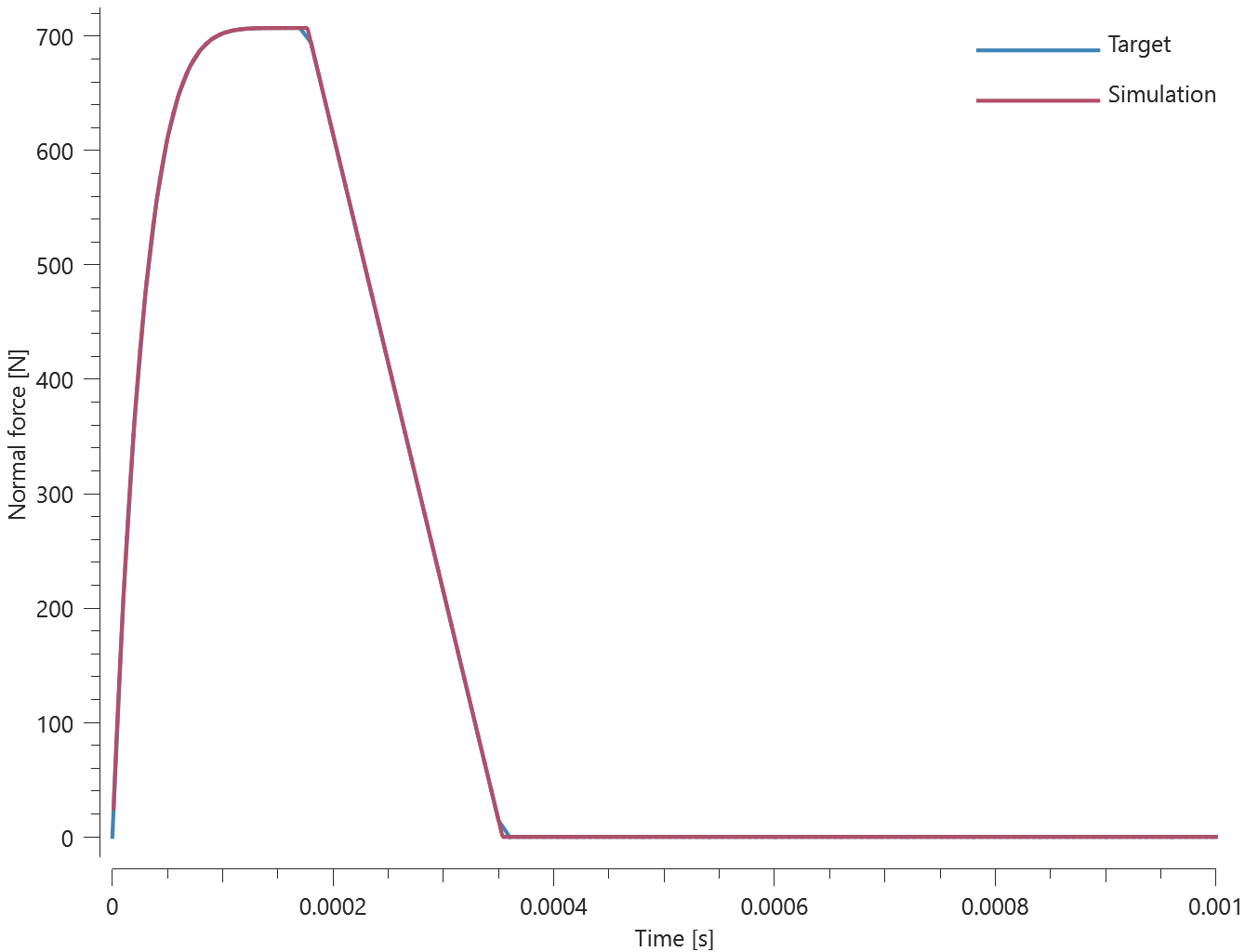

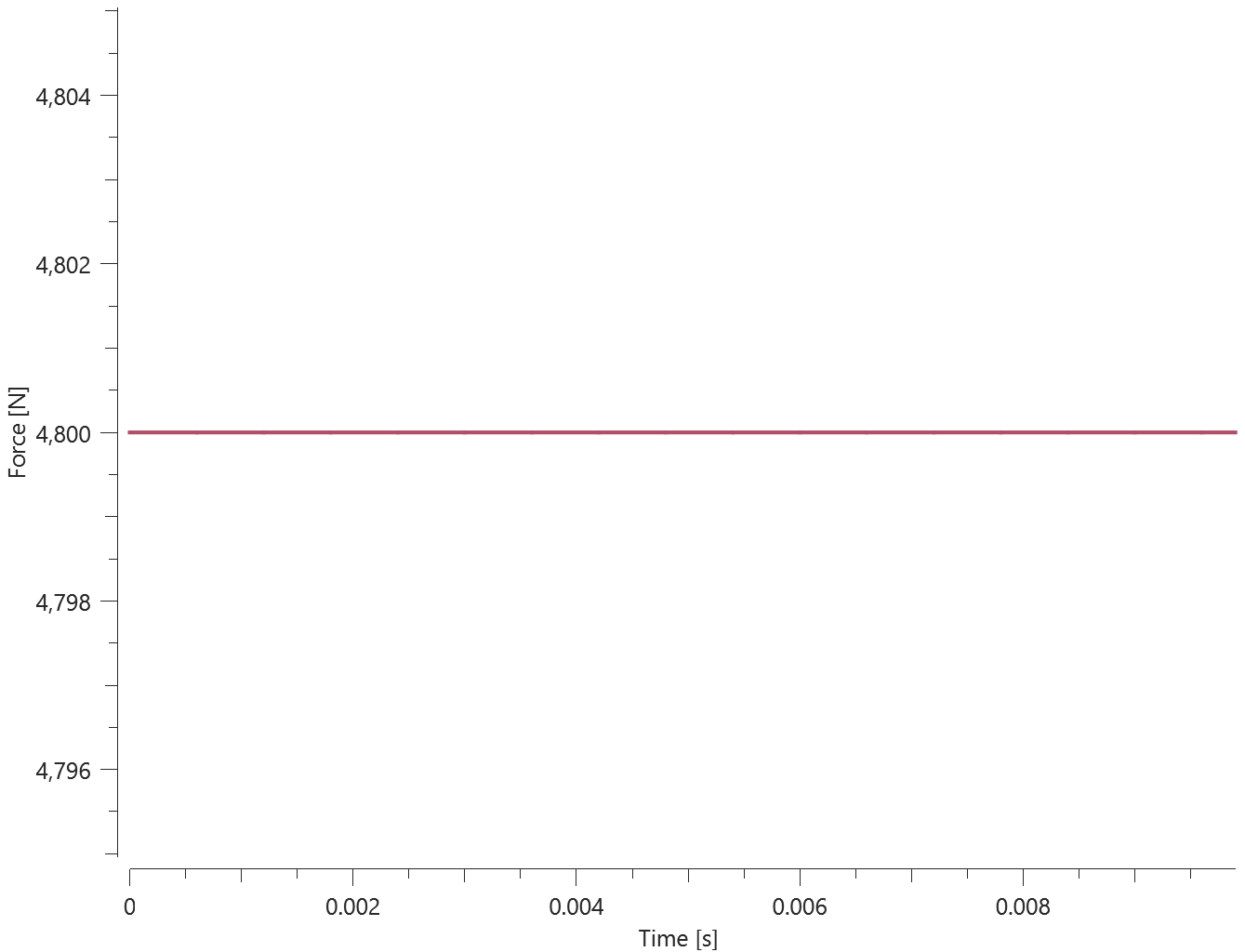

This model tests the command *CONNECTOR_DAMPER. It consists of two tests, one with quasi-static and one with a dynamic response.

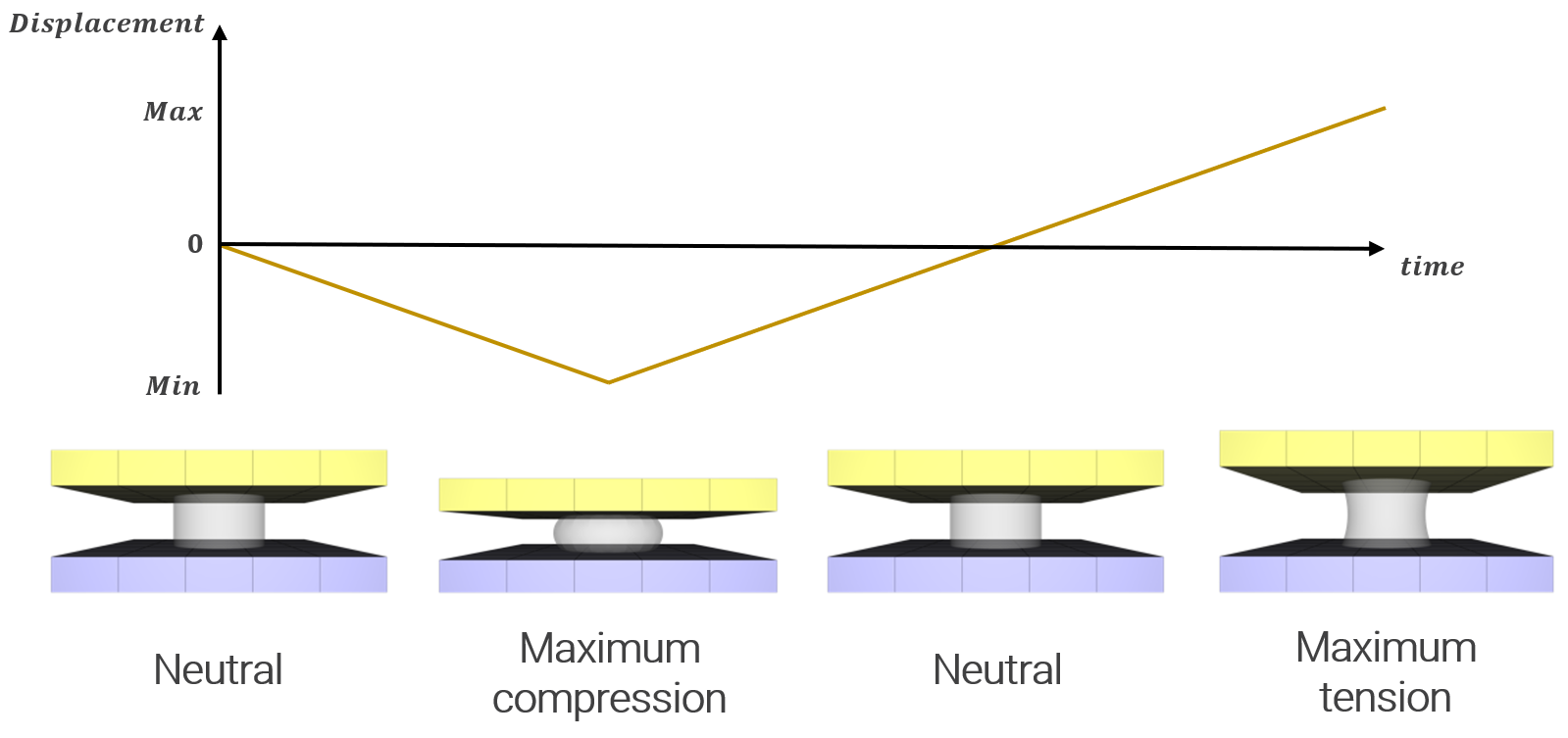

An axially loaded damper is positioned between two plates with the command *CONNECTOR_DAMPER. It is first compressed and then loaded in tension.

The base plate is restricted in all directions while the top plate is assigned a motion in the negative and positive Z-direction.

See Figure 1.

The damper properties are the same for both tests but the prescribed velocity of the top plate differs.

- Velocity (Quasi-static) =

- Velocity (Dynamic) =

The quasi-static as well as the dynamic response of the dampers can be seen in Figure 2.

Maximum and minimum normal force and displacement in Z direction is checked for version control.

Tests

This benchmark is associated with 2 tests.

*CONNECTOR_GLUE_LINE

Combined stress

"Optional title"

$coid$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $pid$, $tol$, $\Delta$, $w$

$h$, $\rho$, $E$, $\nu$, $\sigma_f$, $\tau_f$, $G_I$, $G_{II}$

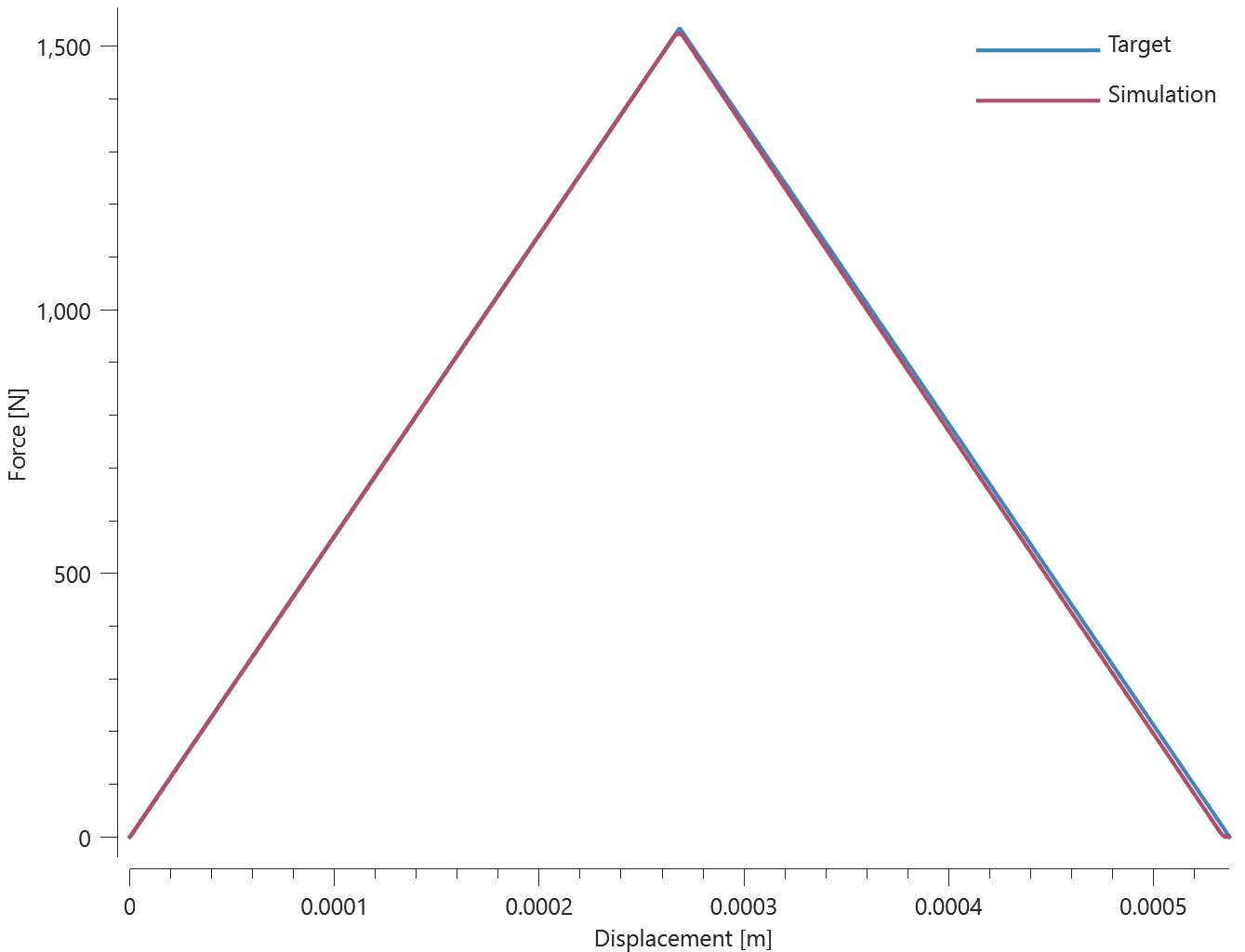

This test is similair to the test "*CONNECTOR_GLUE_LINE - Normal stress". In the current test, the glue is subjected to a combination of normal and shear stress instead.

Tested parameters:  , h,

, h,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

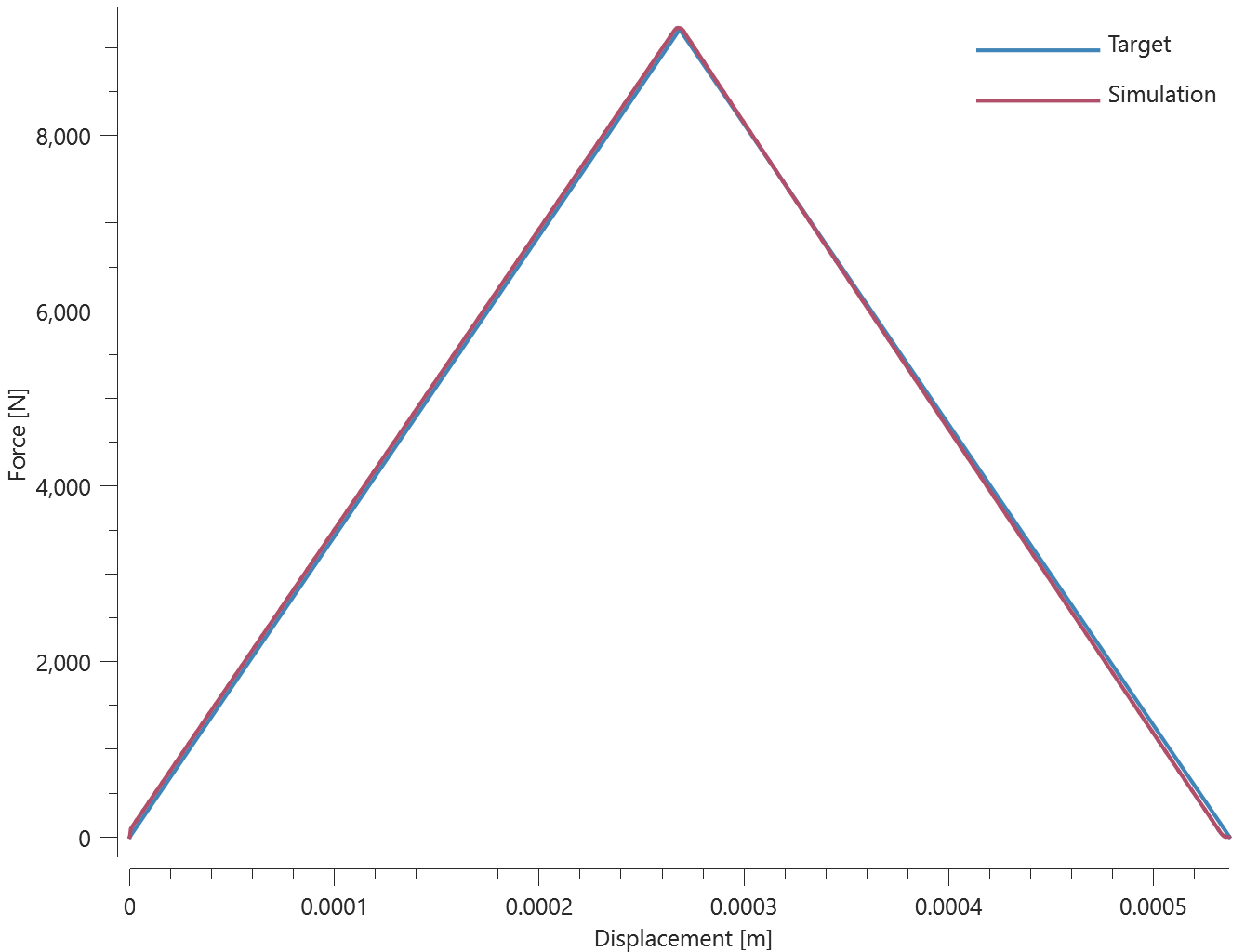

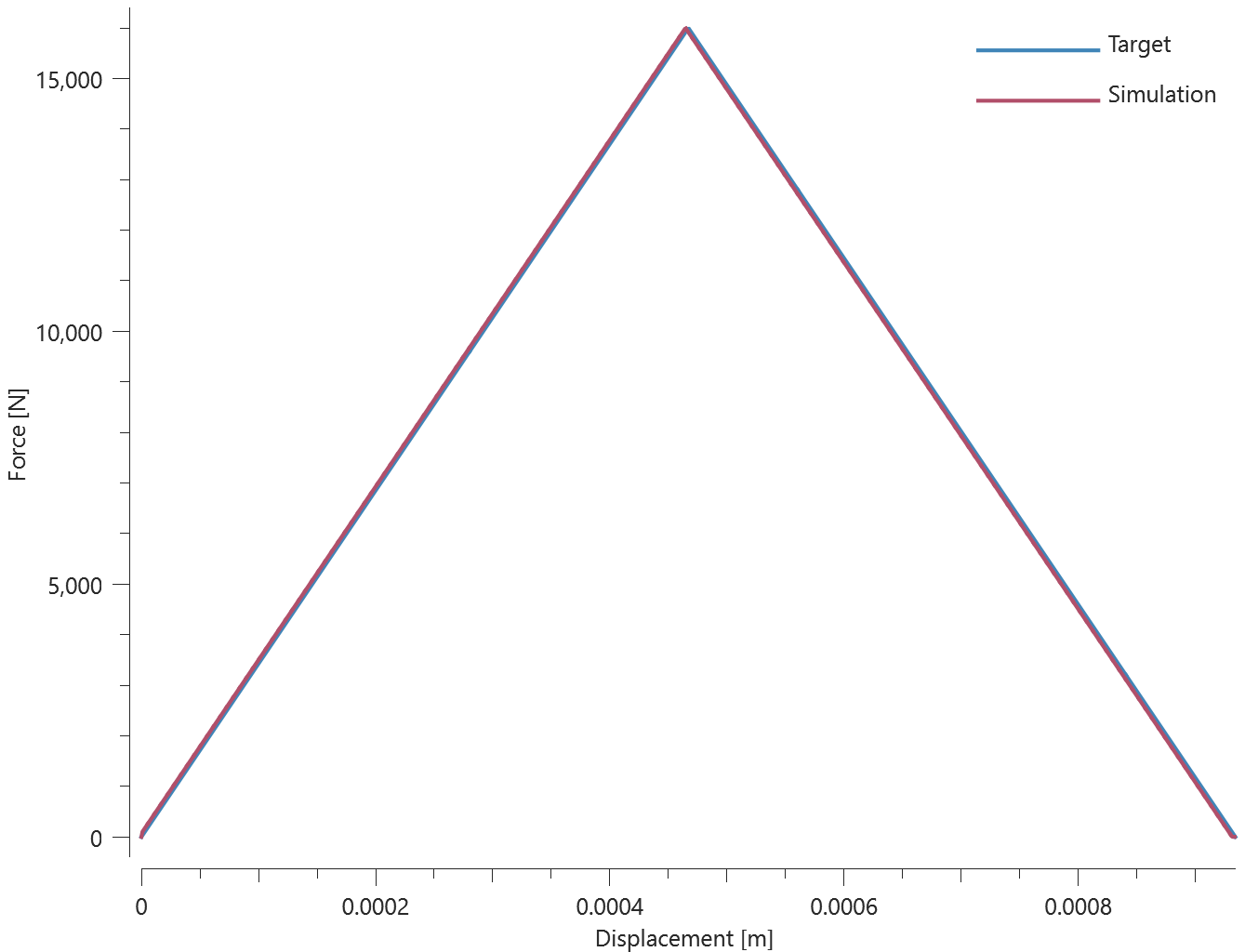

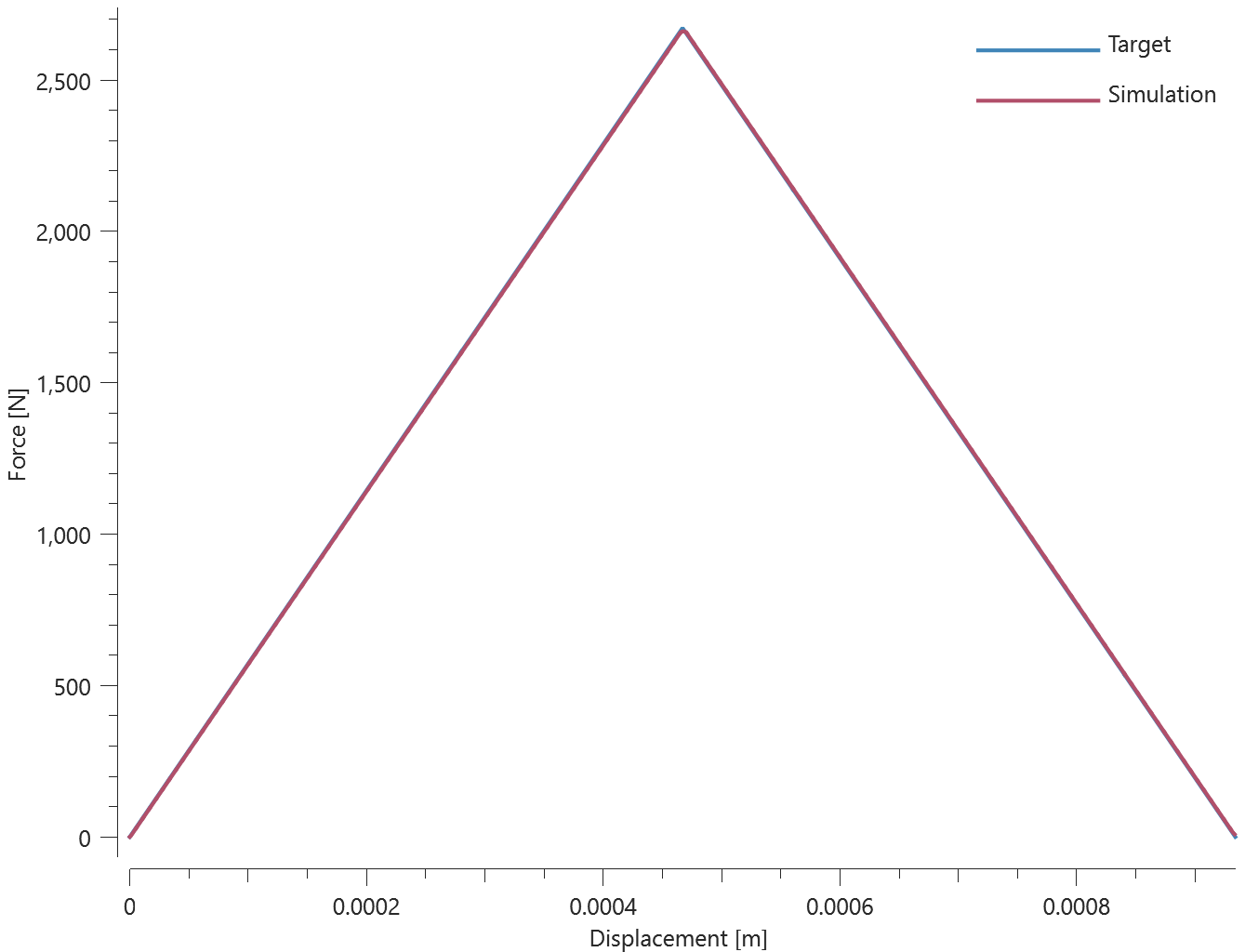

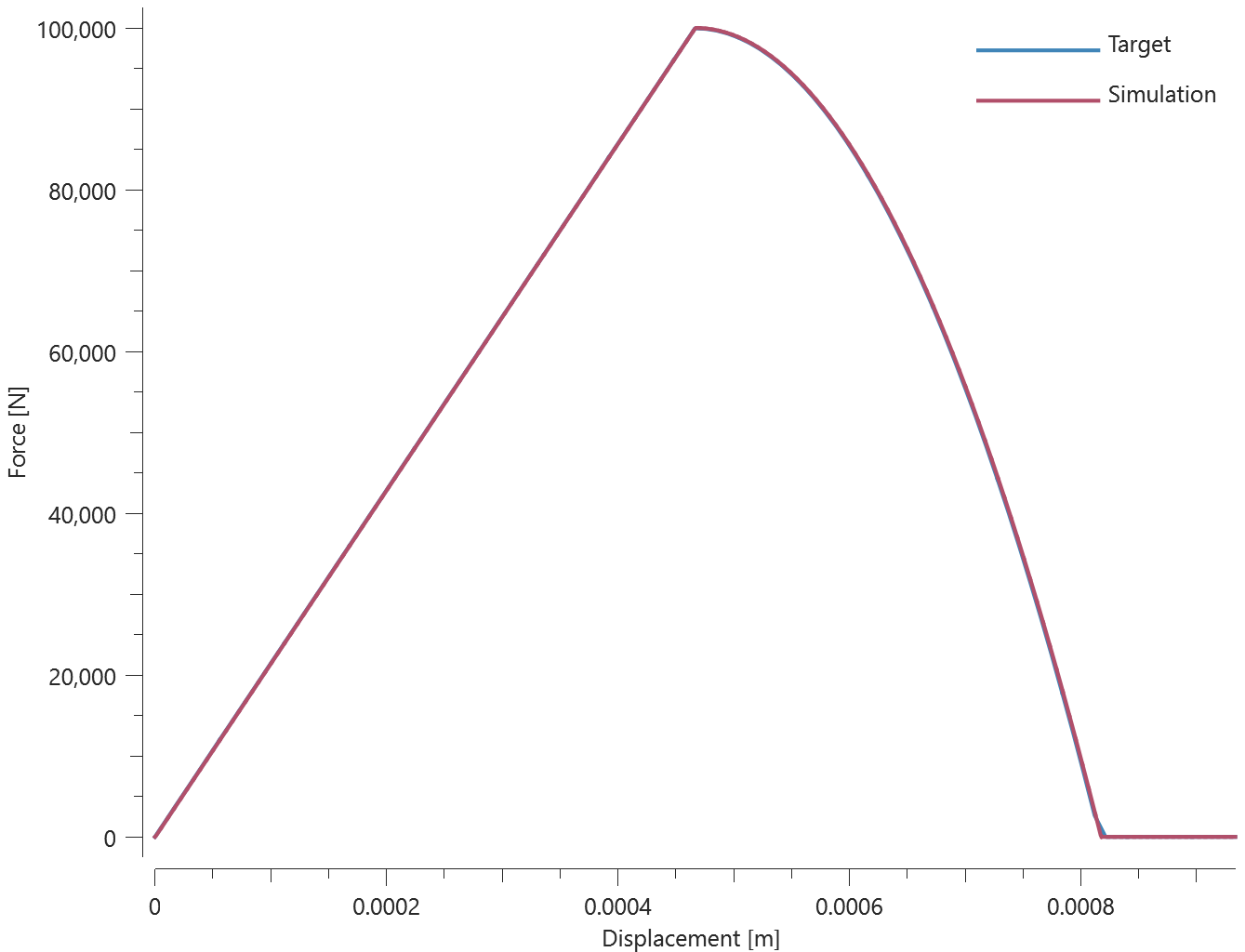

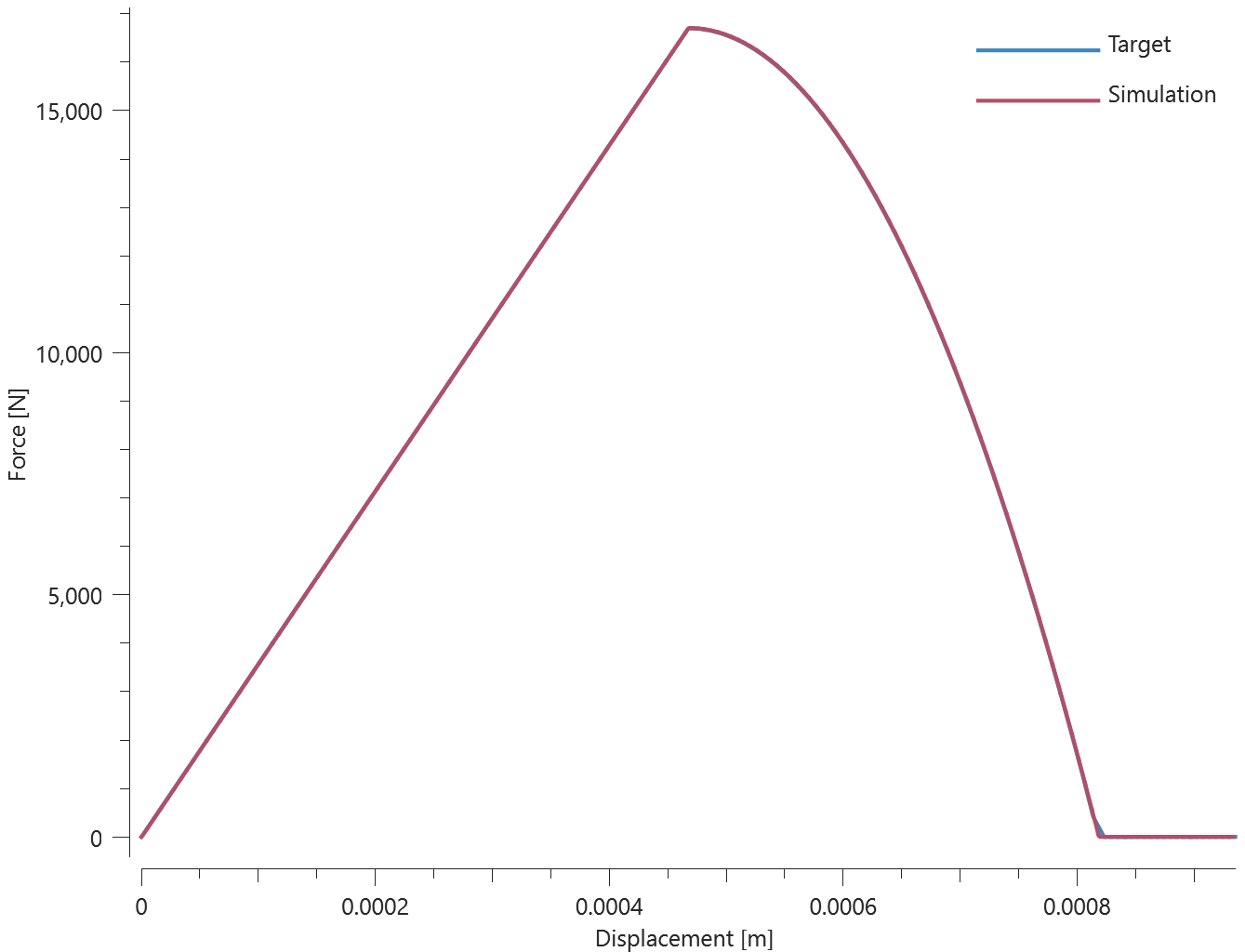

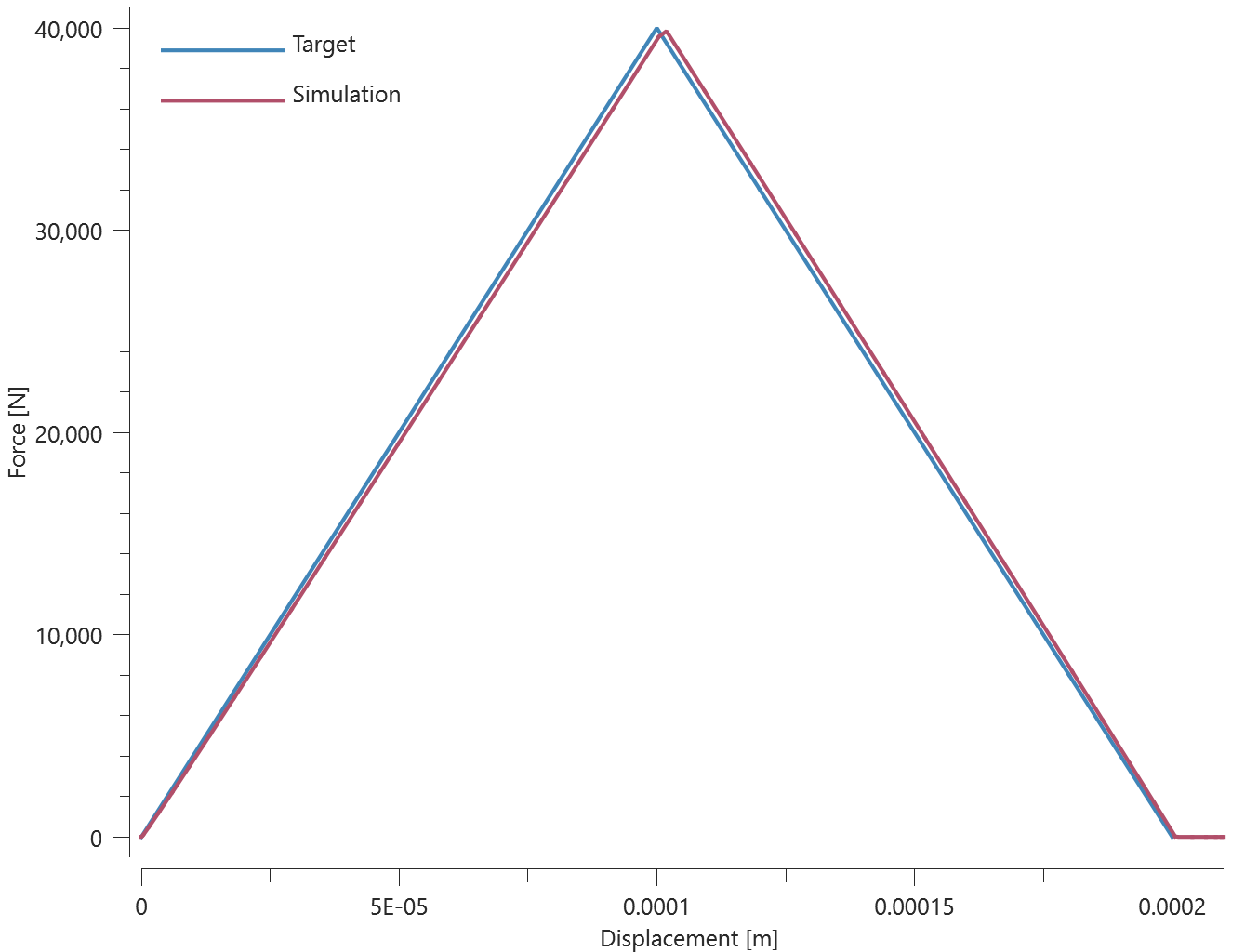

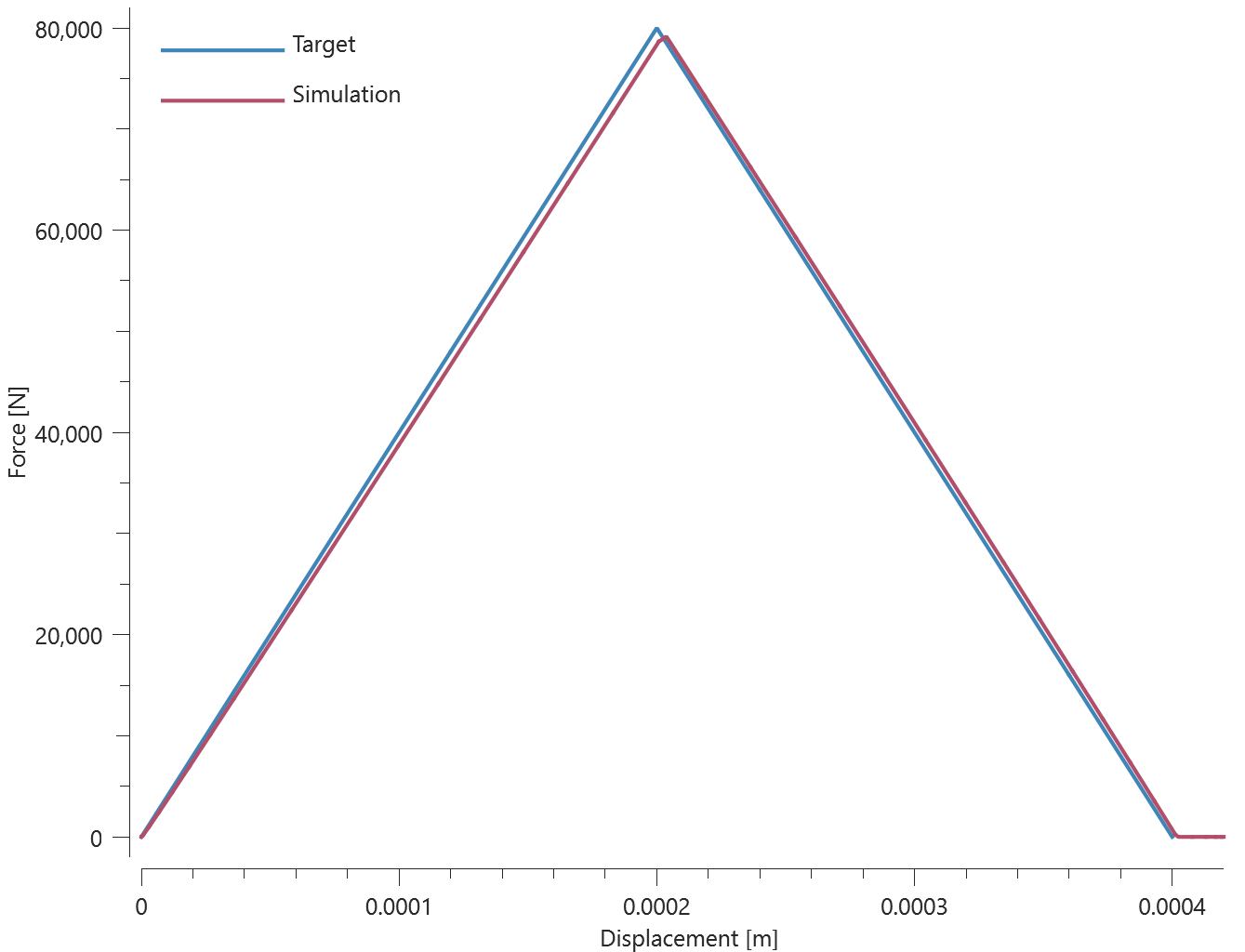

Forces vs. displacements are presented in Figure 1 and Figure 2 together with target curves of the analytical solutions.

Maximum and average value of the forces, delamination energy and area are checked.

Tests

This benchmark is associated with 1 tests.

Normal stress

"Optional title"

$coid$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $pid$, $tol$, $\Delta$, $w$

$h$, $\rho$, $E$, $\nu$, $\sigma_f$, $\tau_f$, $G_I$, $G_{II}$

The glue properties of *CONNECTOR_GLUE_LINE in a state of normal stress is verified in this test.

Tested parameters:  , h,

, h,  ,

,  ,

,  and

and  .

.

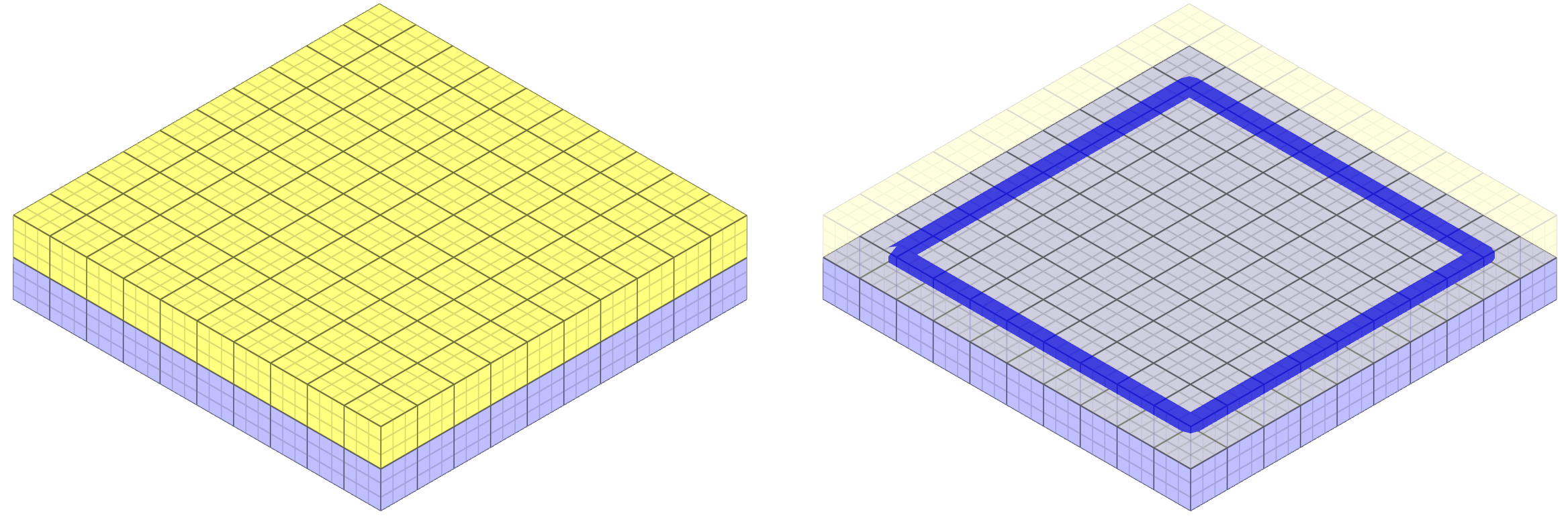

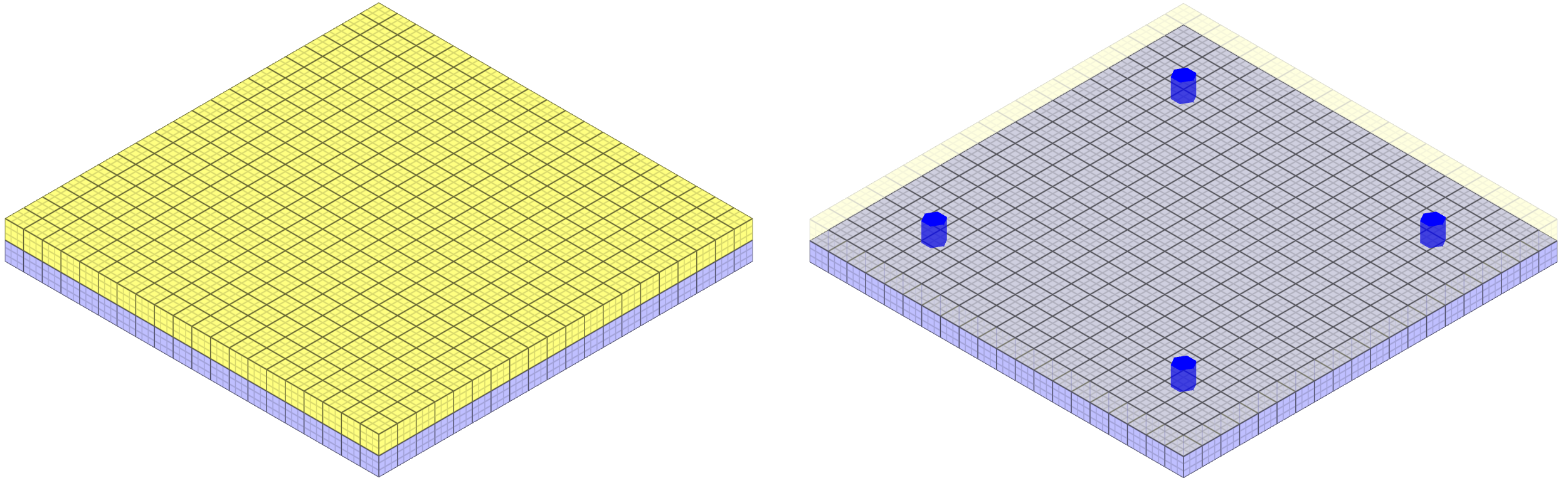

Two quadratic plates with length 100 mm and thickness 10 mm are glued together with *CONNECTOR_GLUE_LINE. The glue line has a width of 5 mm and a thickness of 1 mm. The glue line runs 10 mm from the edges around the plate, as illustrated in Figure 1.

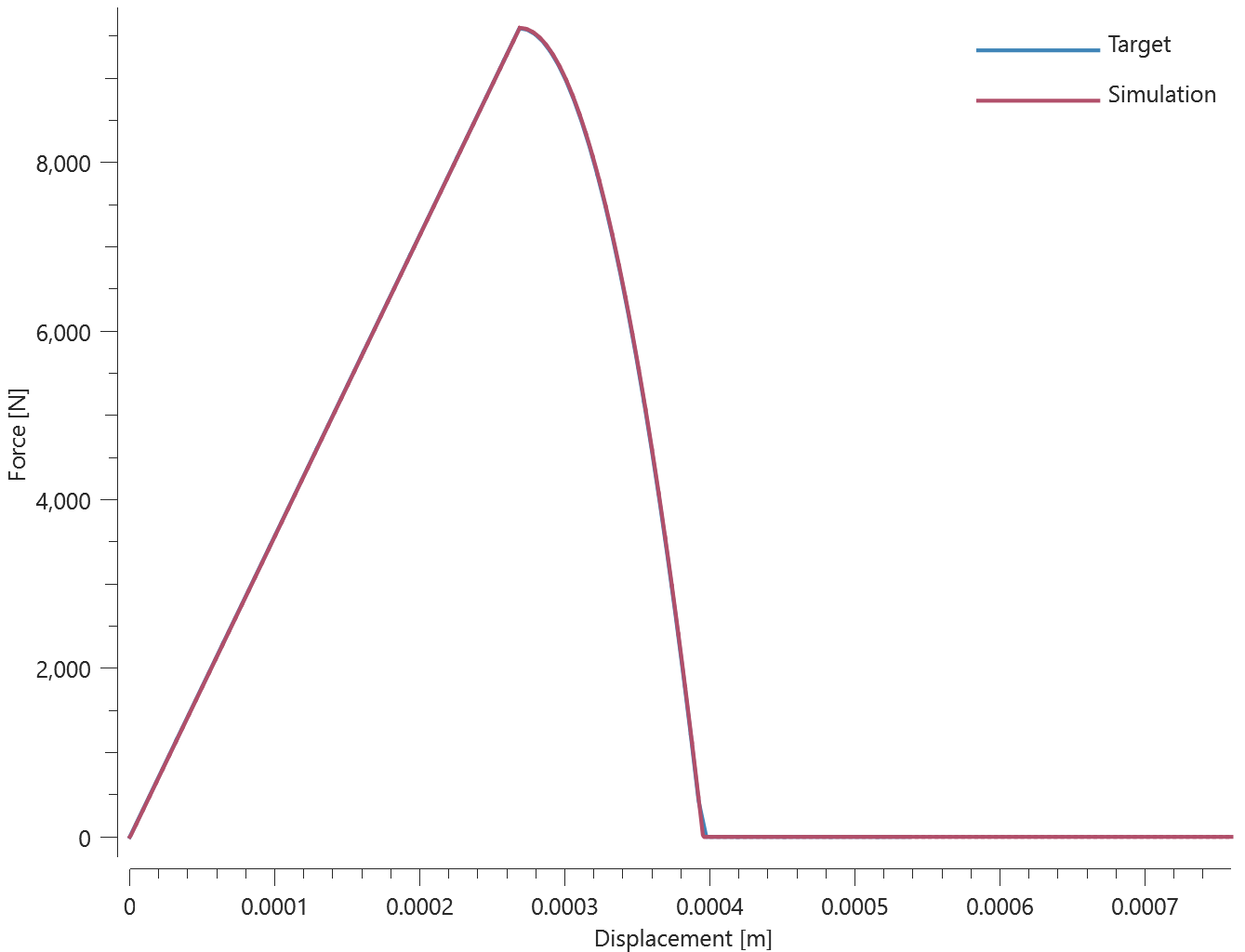

Prescribed motions causing a state of normal stress in the glue are imposed on the plates. Force vs. displacement from the simulation is presented in Figure 2 together with a target curve of the analytical solution.

Maximum and average value of the force, delamination energy and area are checked.

Tests

This benchmark is associated with 1 tests.

Shear stress

"Optional title"

$coid$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $pid$, $tol$, $\Delta$, $w$

$h$, $\rho$, $E$, $\nu$, $\sigma_f$, $\tau_f$, $G_I$, $G_{II}$

This test is similair to the test "*CONNECTOR_GLUE_LINE - Normal stress". In the current test, the glue is subjected to a state of shear stress instead.

Tested parameters:  , h,

, h,  ,

,  ,

,  and

and  .

.

Force vs. displacement from the simulation is presented in Figure 1 together with a target curve of the analytical solution.

Maximum and average value of the force, delamination energy and area are checked.

Tests

This benchmark is associated with 1 tests.

*CONNECTOR_GLUE_SURFACE

Combined stress

"Optional title"

$coid$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $tol$

$h$, $\rho$, $E$, $\nu$, $\sigma_f$, $\tau_f$, $G_I$, $G_{II}$

This test is similair to the test "*CONNECTOR_GLUE_SURFACE - Normal stress". In the current test, the glue is subjected to a combination of normal and shear stress instead.

Tested parameters: h,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

Forces vs. displacements are presented in Figure 1 and Figure 2 together with target curves of the analytical solutions.

Maximum and average value of the forces, delamination energy and area are checked.

Tests

This benchmark is associated with 1 tests.

Normal stress

"Optional title"

$coid$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $tol$

$h$, $\rho$, $E$, $\nu$, $\sigma_f$, $\tau_f$, $G_I$, $G_{II}$

The glue properties of *CONNECTOR_GLUE_SURFACE in a state of normal stress is verified in this test.

Tested parameters: h,  ,

,  ,

,  and

and  .

.

Two quadratic plates with length 100 mm and thickness 10 mm are glued together with *CONNECTOR_GLUE_SURFACE. Prescribed motions causing a state of normal stress in the glue are imposed on the plates.

Force vs. displacement from the simulation is presented in Figure 1 together with a target curve of the analytical solution.

Maximum and average value of the force, delamination energy and area are checked.

Tests

This benchmark is associated with 1 tests.

Shear stress

"Optional title"

$coid$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $tol$

$h$, $\rho$, $E$, $\nu$, $\sigma_f$, $\tau_f$, $G_I$, $G_{II}$

This test is similair to the test "*CONNECTOR_GLUE_SURFACE - Normal stress". In the current test, the glue is subjected to a state of shear stress instead.

Tested parameters: h,  ,

,  ,

,  and

and  .

.

Force vs. displacement from the simulation is presented in Figure 1 together with a target curve of the analytical solution.

Maximum and average value of the force, delamination energy and area are checked.

Tests

This benchmark is associated with 1 tests.

*CONNECTOR_RIGID

Connection in motion

"Optional title"

$coid$, $entype$, $enid$

*CONNECTOR_RIGID is verified in this test.

Tested parameters:  and

and  .

.

Two rigid elements are connected with a rigid connection. One of the elements is set in motion. The displacement and velocity in the other element is checked at termination.

Tests

This benchmark is associated with 1 tests.

*CONNECTOR_SPOT_WELD

Combined stress

"Optional title"

$coid$

$entype$, $enid$, $tid$, $tol$,

$R$, $h$, $m$, $k$, $F_t$, $F_s$, $W_t$, $W_s$

This test is similair to the test "*CONNECTOR_SPOT_WELD - Normal stress". In the current test, the spot welds are subjected to a combination of normal and shear stress instead.

Tested parameters:  , h,

, h,  ,

,  ,

,  ,

,  and

and  .

.

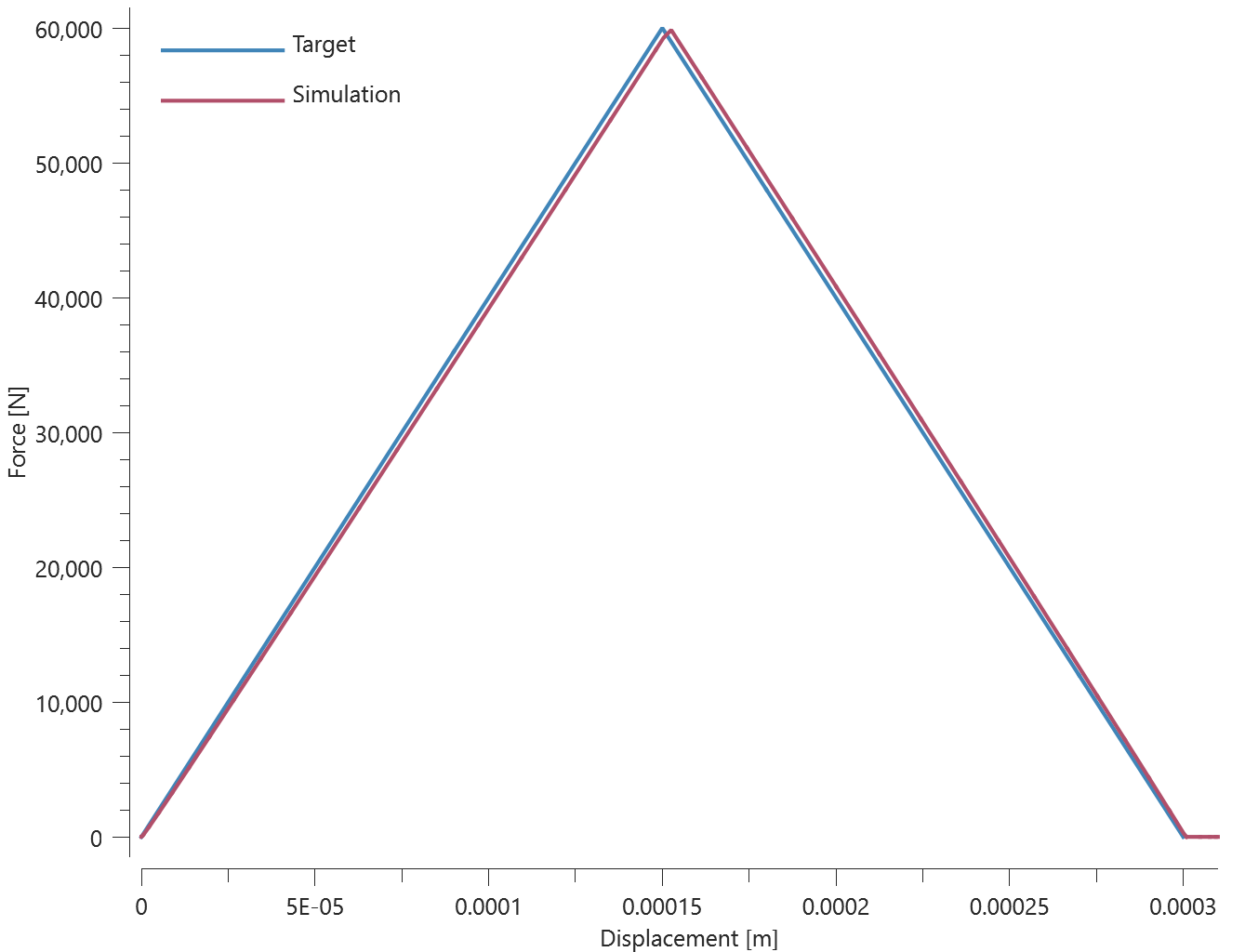

The resultant force vs. displacement from the simulation is presented in Figure 1 together with a target curve of the analytical solution.

Maximum and average value of the force and dissipated energy are checked.

Tests

This benchmark is associated with 1 tests.

Normal stress

"Optional title"

$coid$

$entype$, $enid$, $tid$, $tol$,

$R$, $h$, $m$, $k$, $F_t$, $F_s$, $W_t$, $W_s$

The spot weld properties of *CONNECTOR_SPOT_WELD in a state of normal stress is verified in this test.

Tested parameters:  , h,

, h,  ,

,  and

and  .

.

Two quadratic plates with length 200 mm and thickness 10 mm are connected to each other by four spot welds defined with *CONNECTOR_SPOT_WELD as illustrated in Figure 1.

Prescribed motions causing a state of normal stress in the spot welds are imposed on the plates. Force vs. displacement from the simulation is presented in Figure 2 together with a target curve of the analytical solution.

Maximum and average value of the force and dissipated energy are checked.

Tests

This benchmark is associated with 1 tests.

Shear stress

"Optional title"

$coid$

$entype$, $enid$, $tid$, $tol$,

$R$, $h$, $m$, $k$, $F_t$, $F_s$, $W_t$, $W_s$

This test is similair to the test "*CONNECTOR_SPOT_WELD - Normal stress". In the current test, the spot welds are subjected to a state of shear stress instead.

Tested parameters:  , h,

, h,  ,

,  and

and  .

.

Force vs. displacement from the simulation is presented in Figure 1 together with a target curve of the analytical solution.

Maximum and average value of the force and dissipated energy are checked.

Tests

This benchmark is associated with 1 tests.

*CONNECTOR_SPOT_WELD_NODE

Normal stress

"Optional title"

coid, nid, pid, N, entype, enid

This test is equivalent to the test "*CONNECTOR_SPOT_WELD - Normal stress". The only difference is the input format, in which *CONNECTOR_SPOT_WELD_NODE is used to define the connector location of the spot welds from Node ID. The command is used in combination with *PROP_SPOT_WELD.

All parameters used are the same as in the test "*CONNECTOR_SPOT_WELD - Normal stress", which means that the same result is expected.

Tests

This benchmark is associated with 1 tests.

*CONNECTOR_SPR

Combined stress

"Optional title"

$coid$, $pid_s$, $pid_m$, $csysid$

$R$, $h$, $m$, $f_n^{max}$, $f_t^{max}$, $d_n^{max}$, $d_t^{max}$, $\xi_n$

$\xi_t$, $a_1$, $a_2$, $a_3$

This test is similair to the test "*CONNECTOR_SPR - Normal stress". In the current test, the rivet is subjected to a combination of normal and shear stress instead.

Tested parameters:  , h,

, h,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

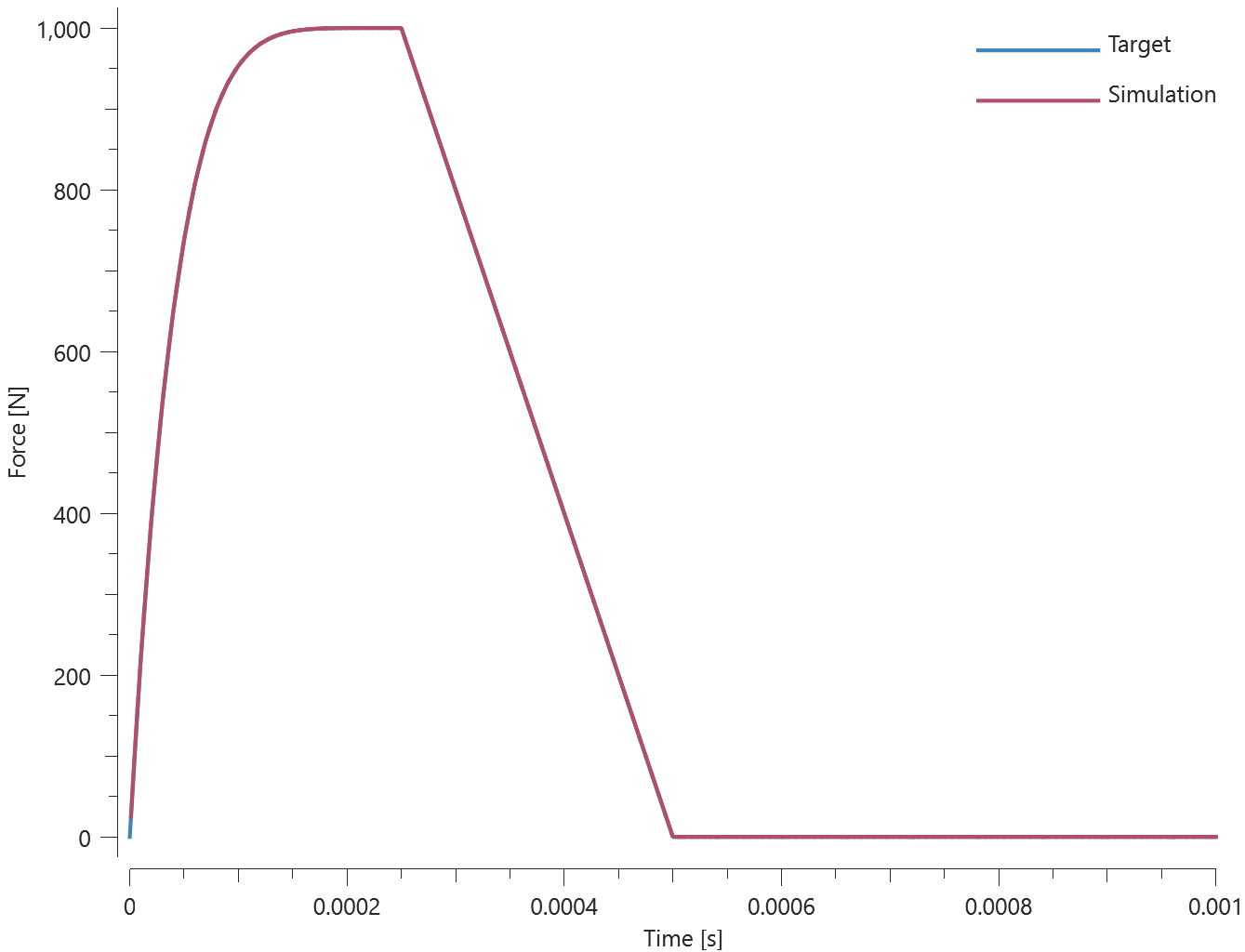

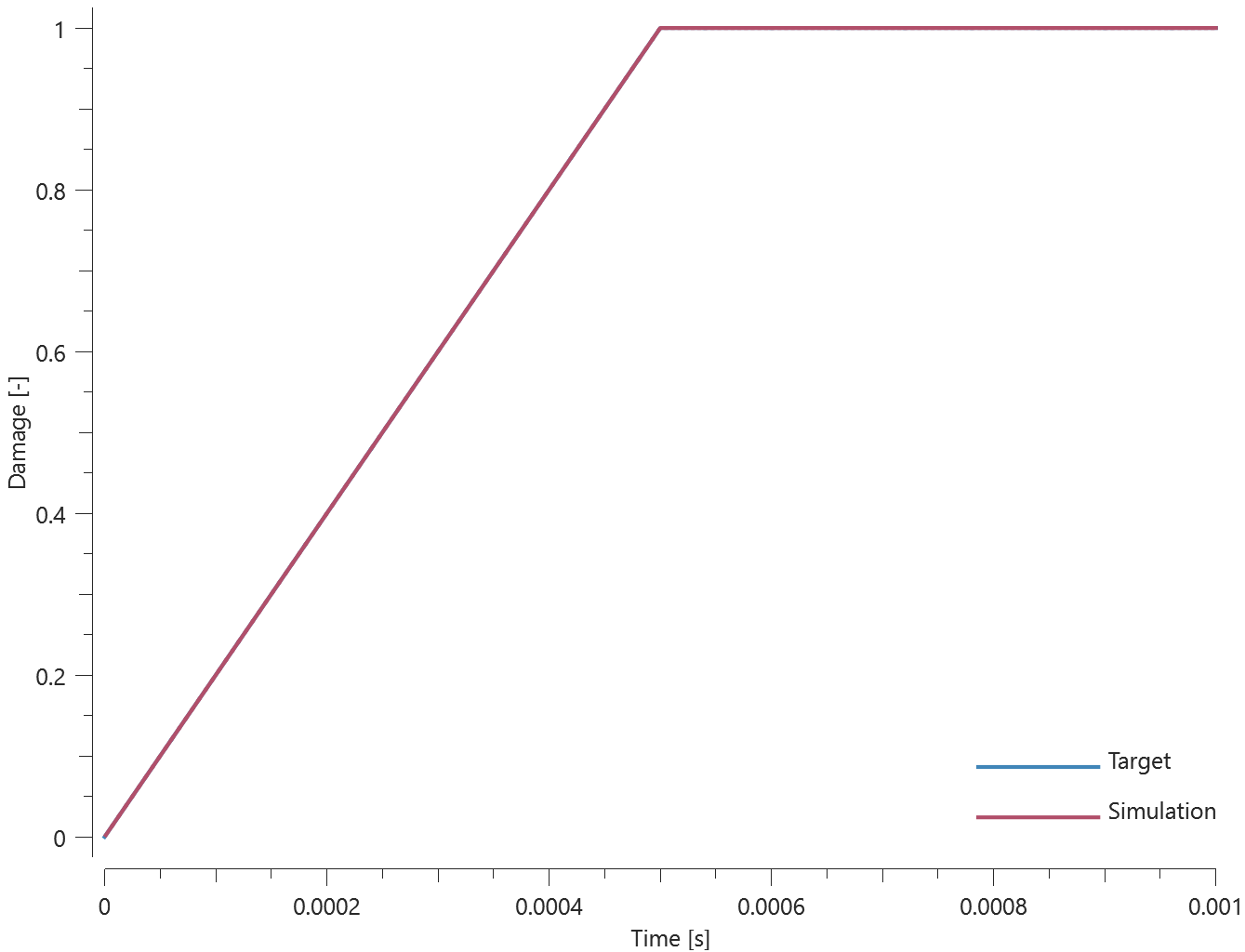

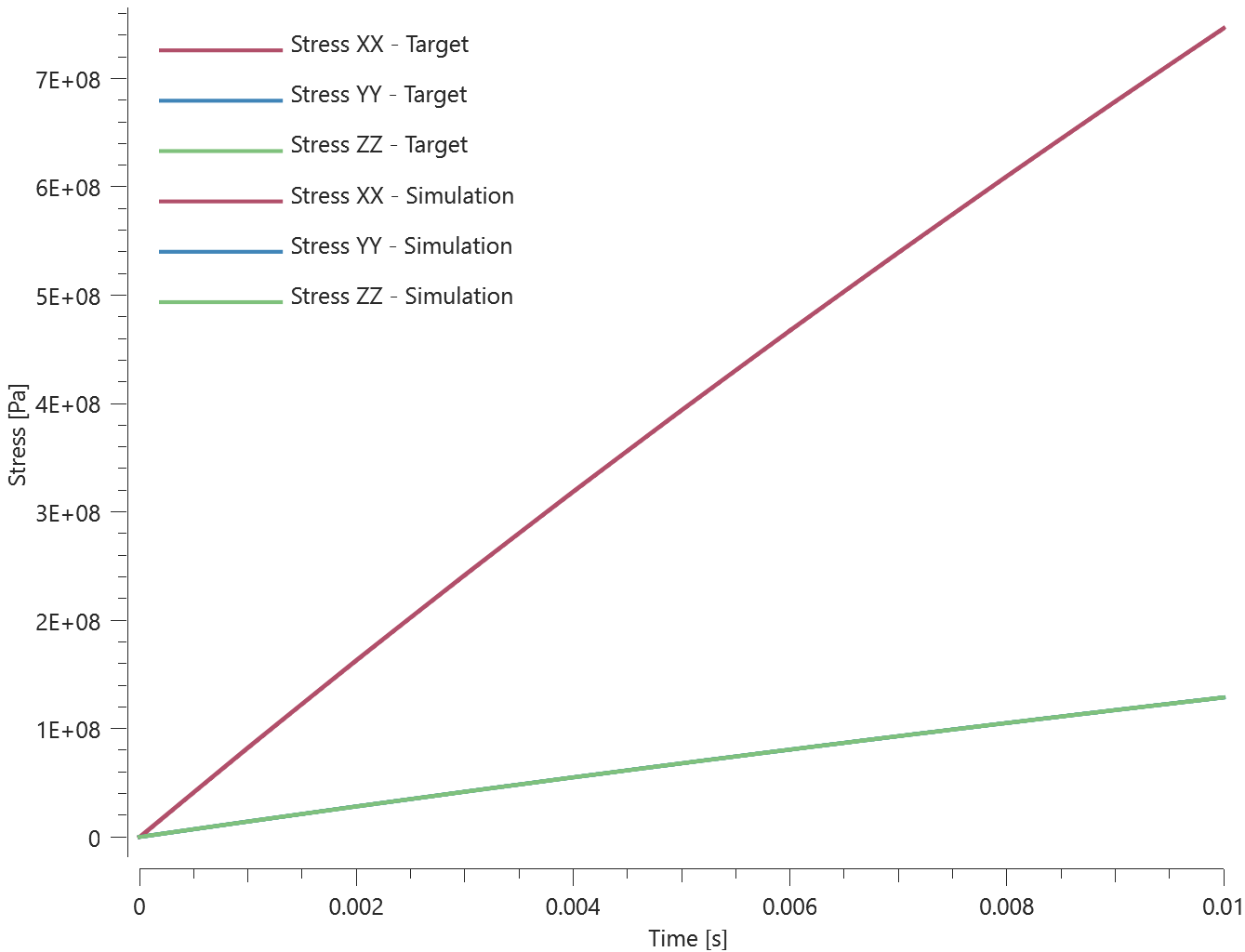

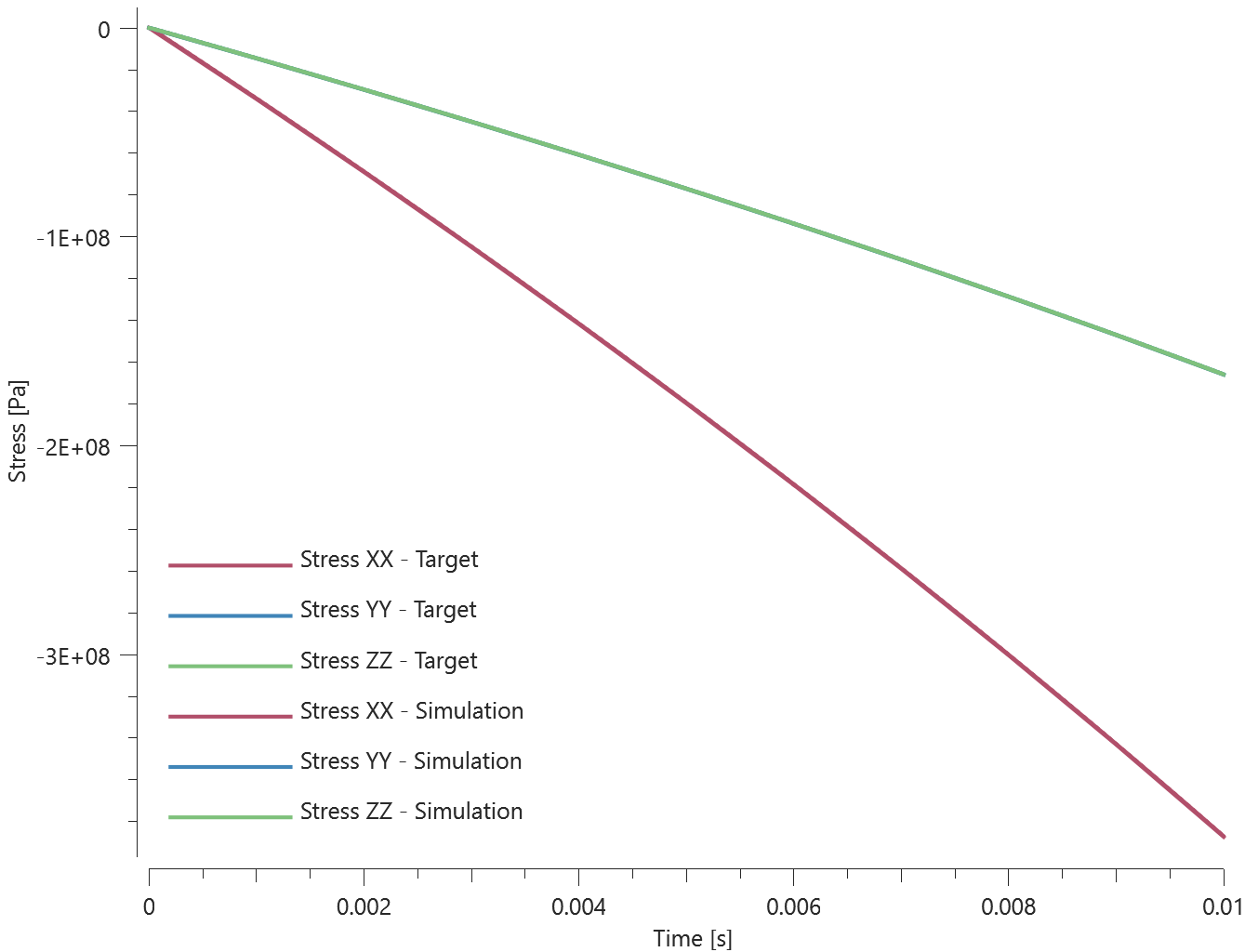

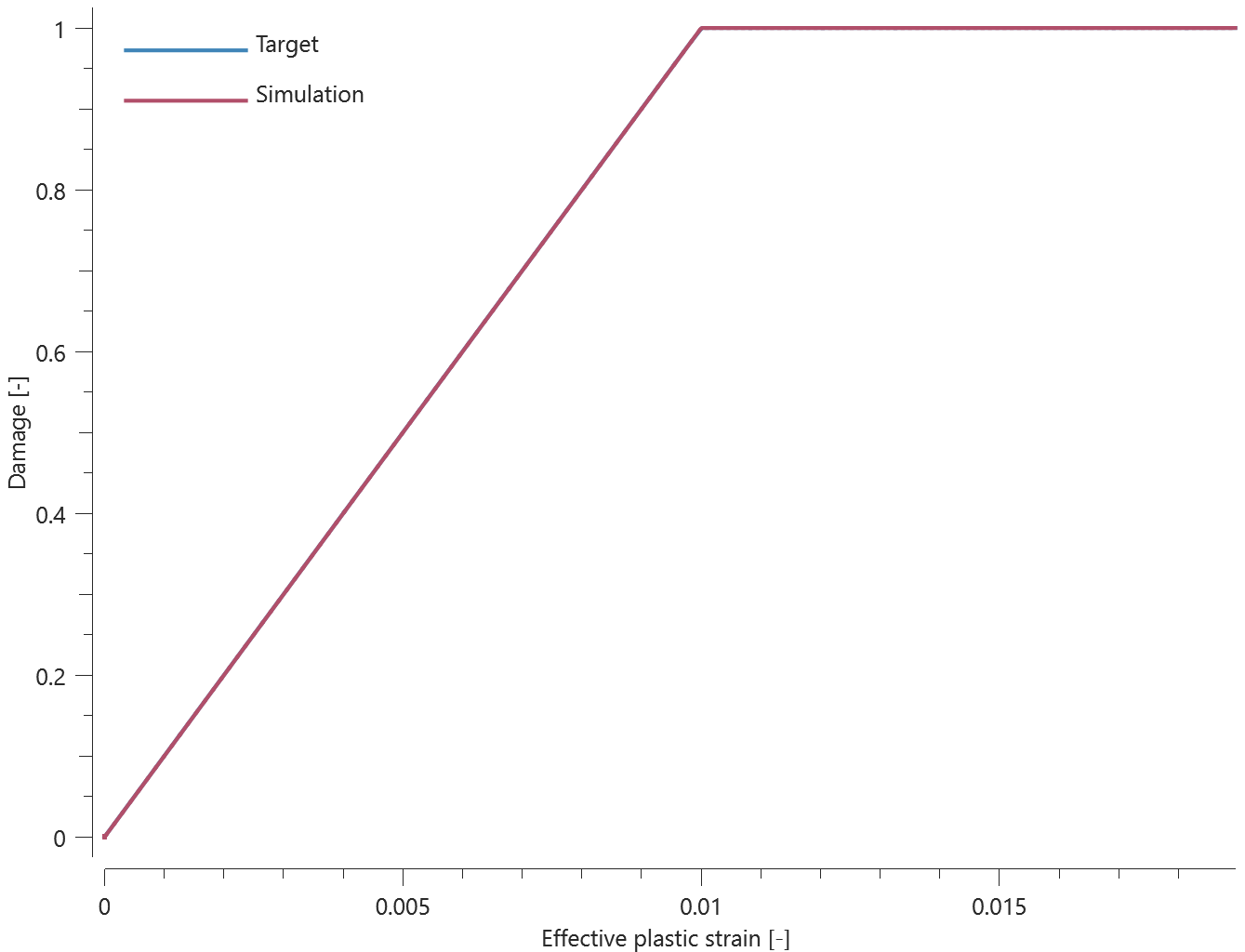

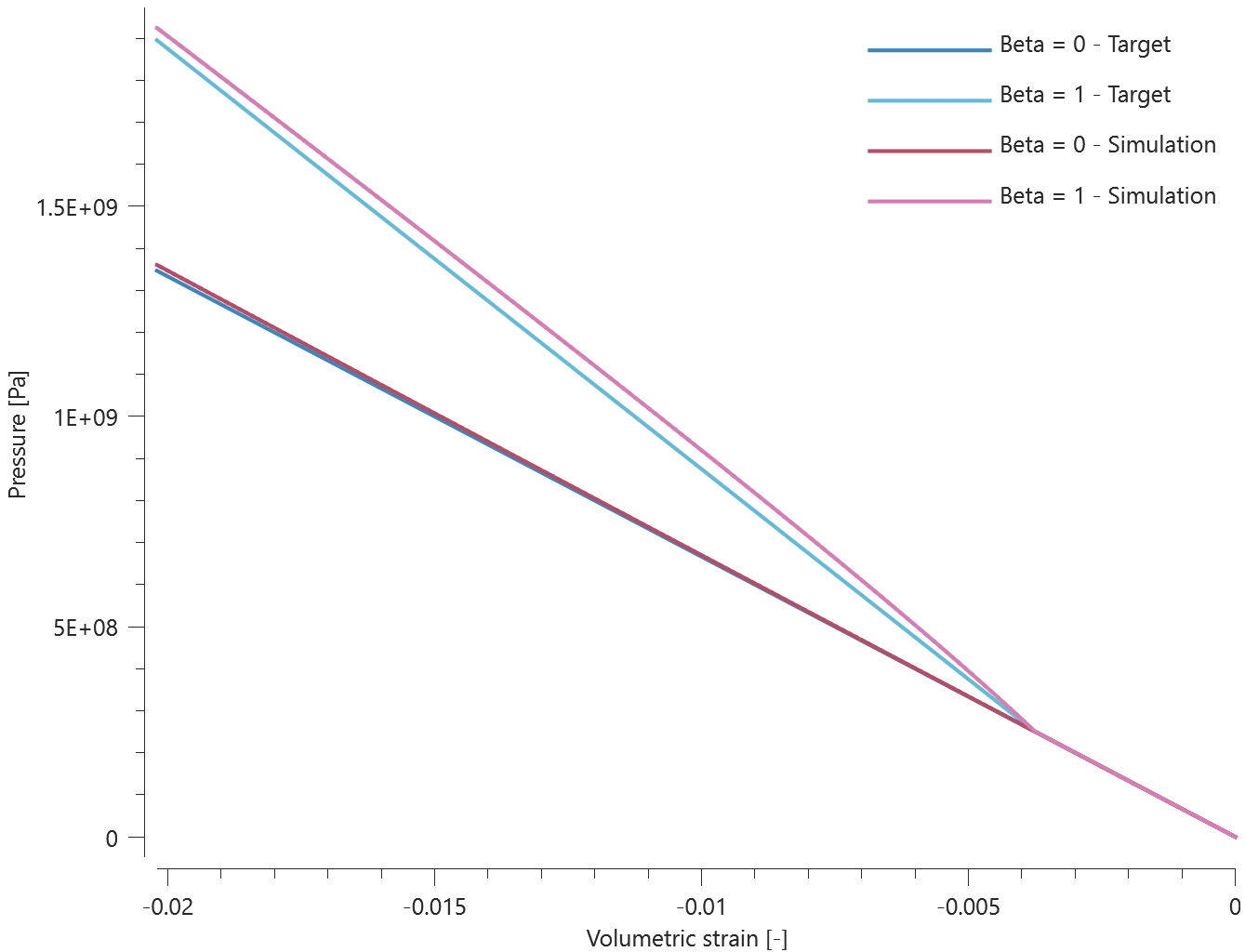

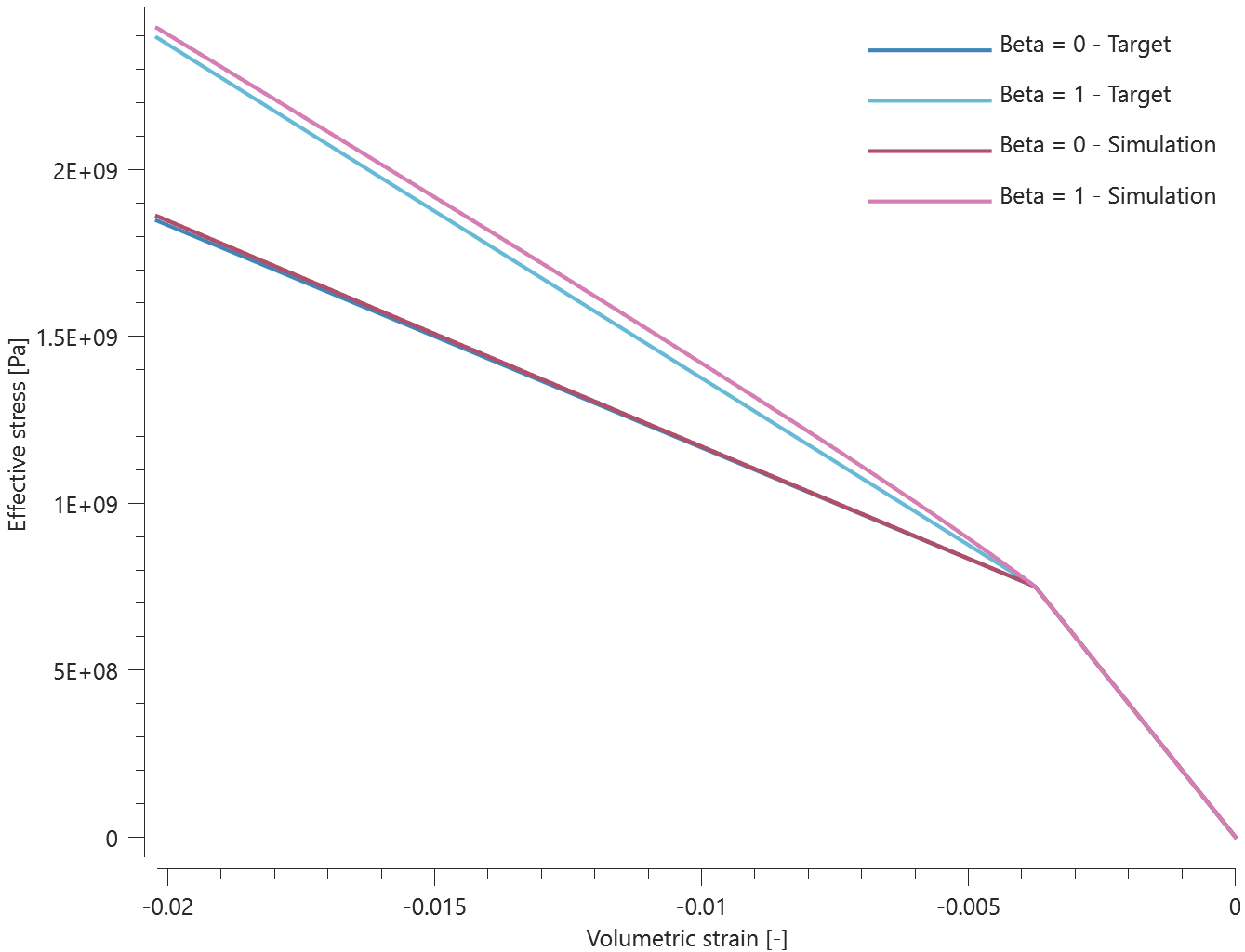

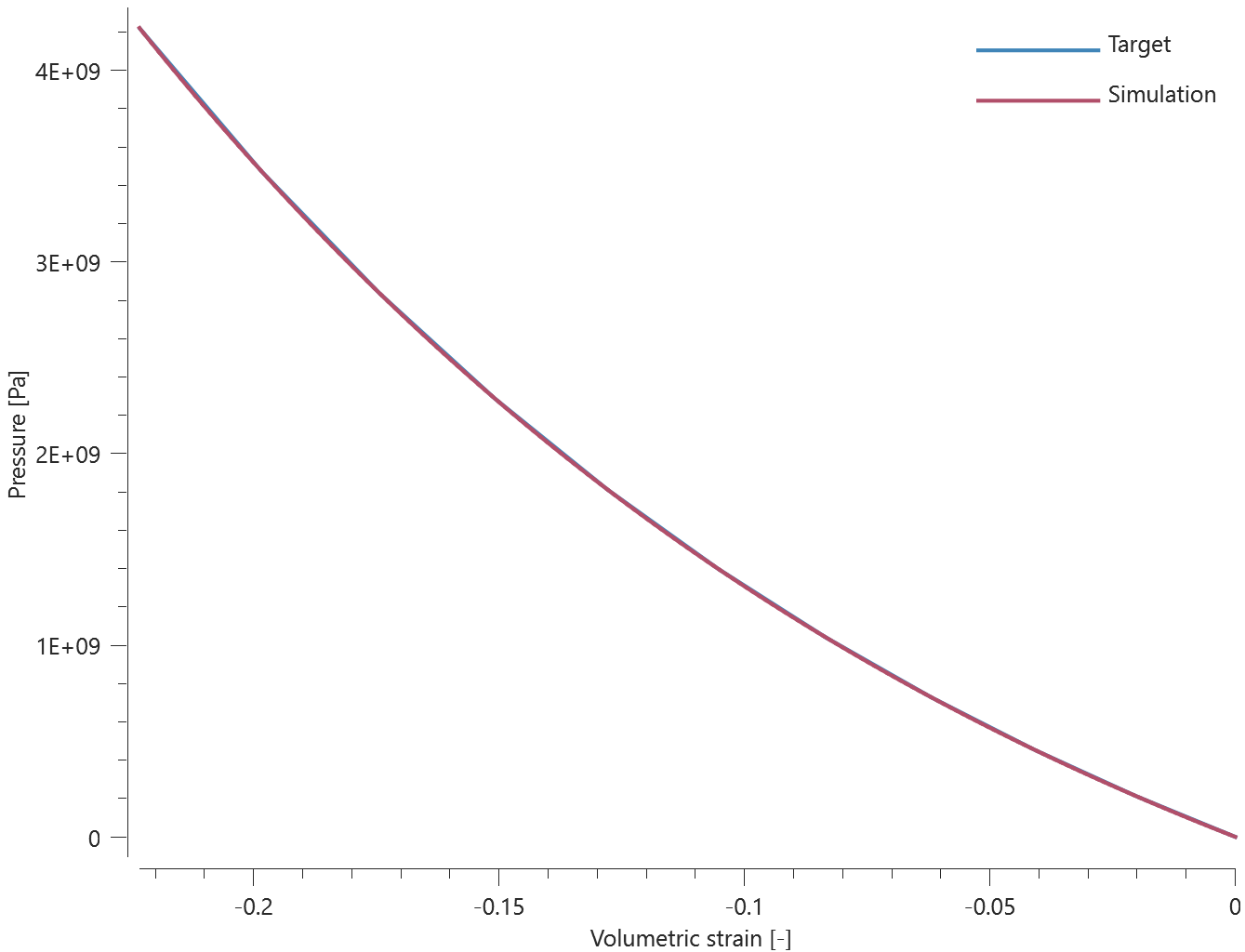

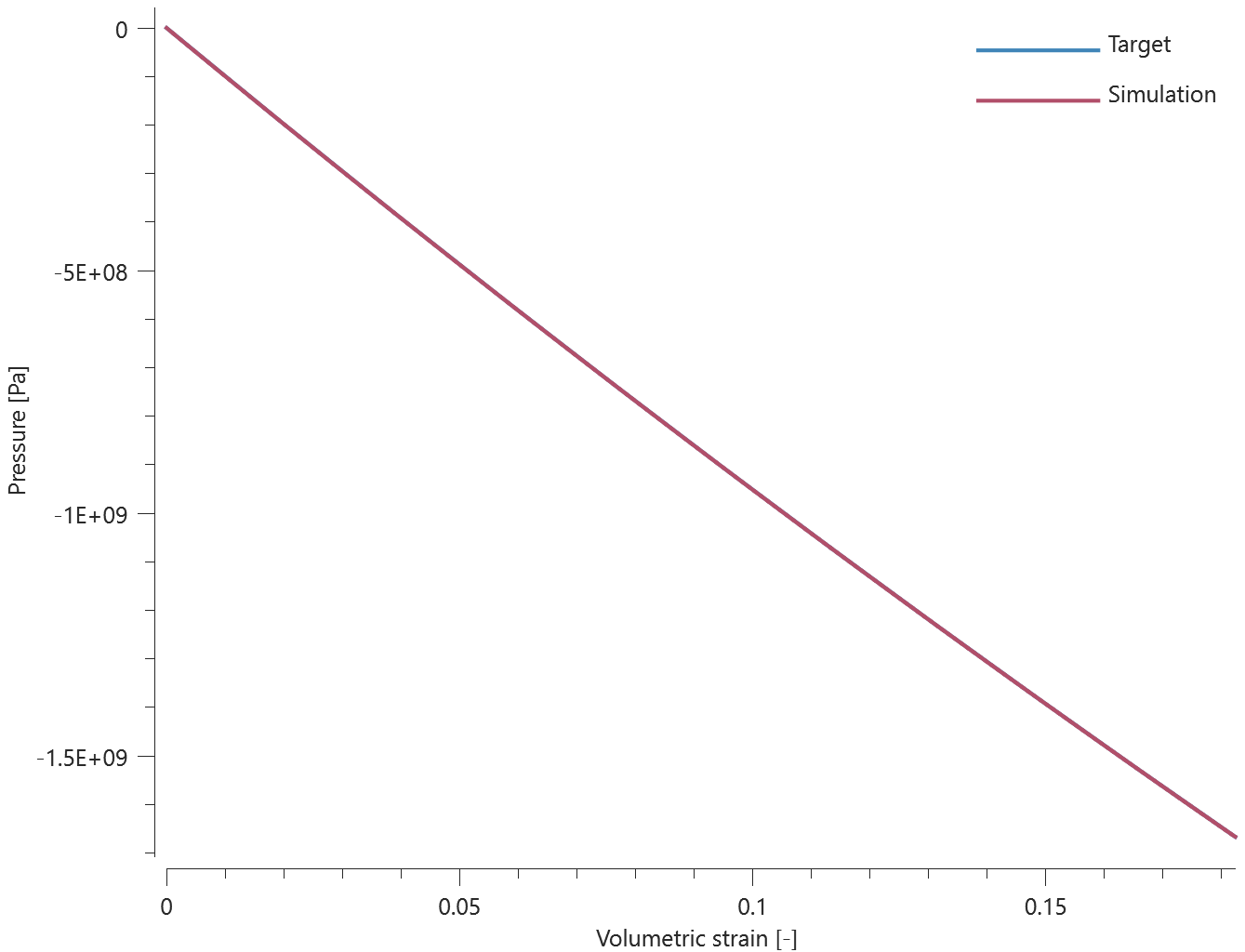

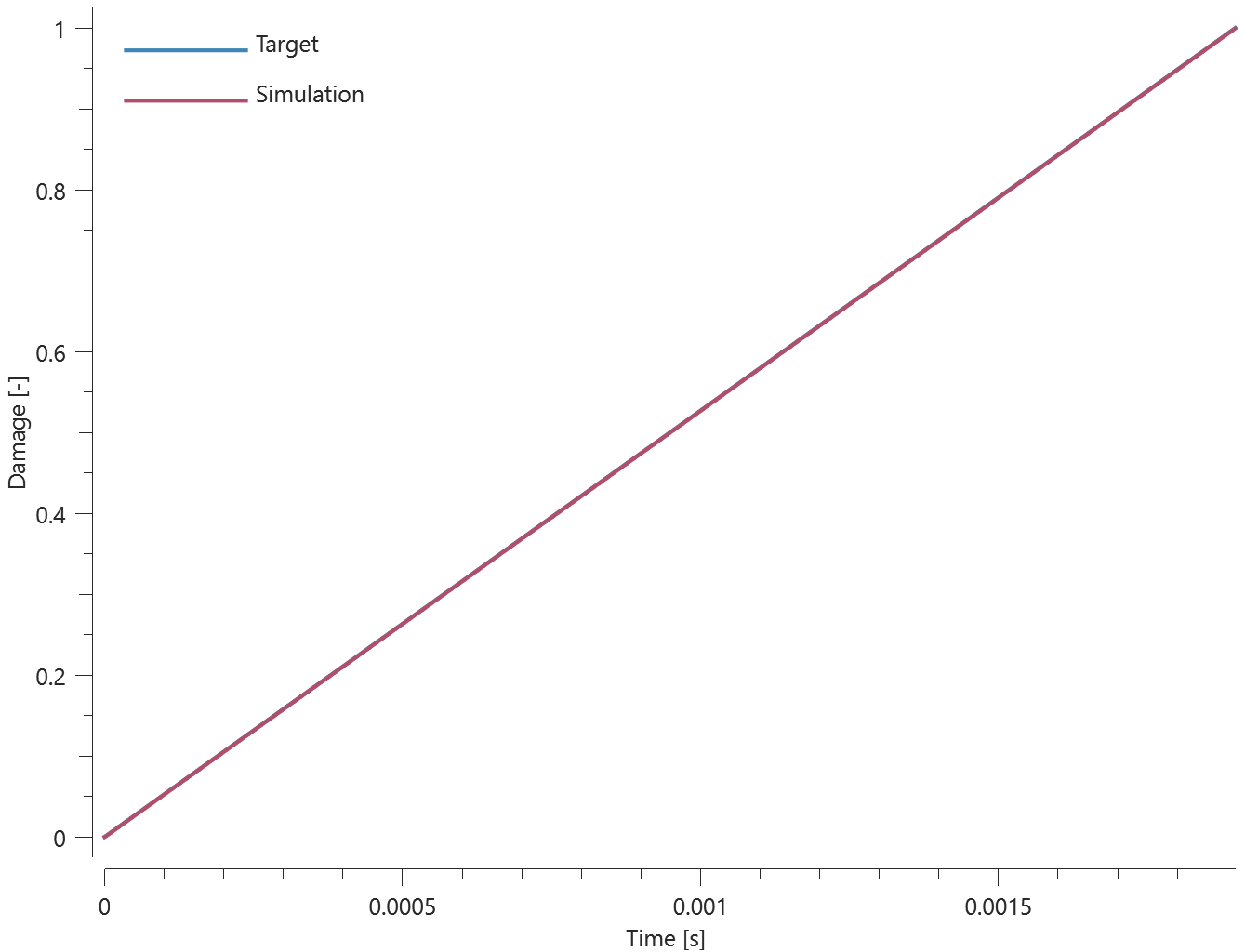

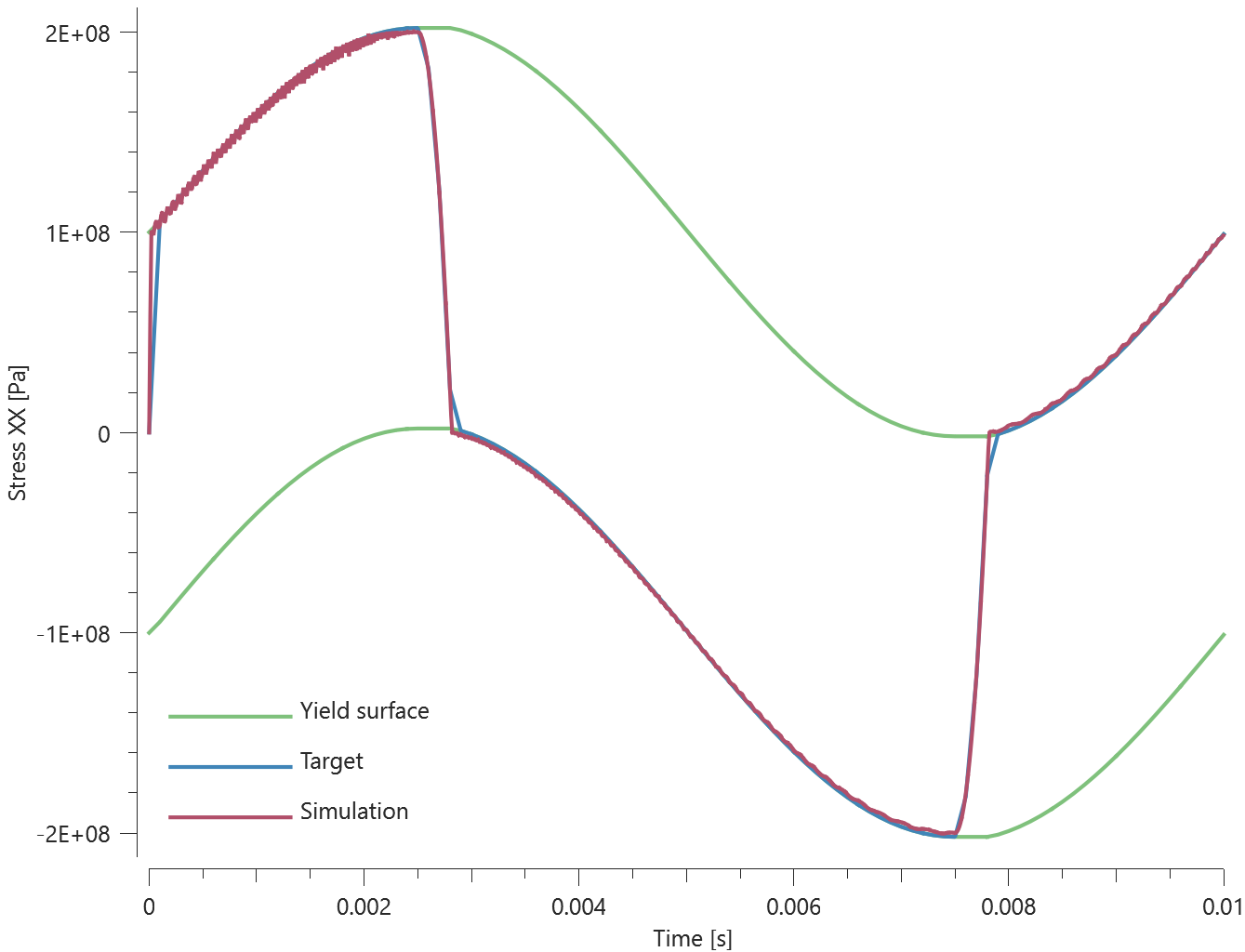

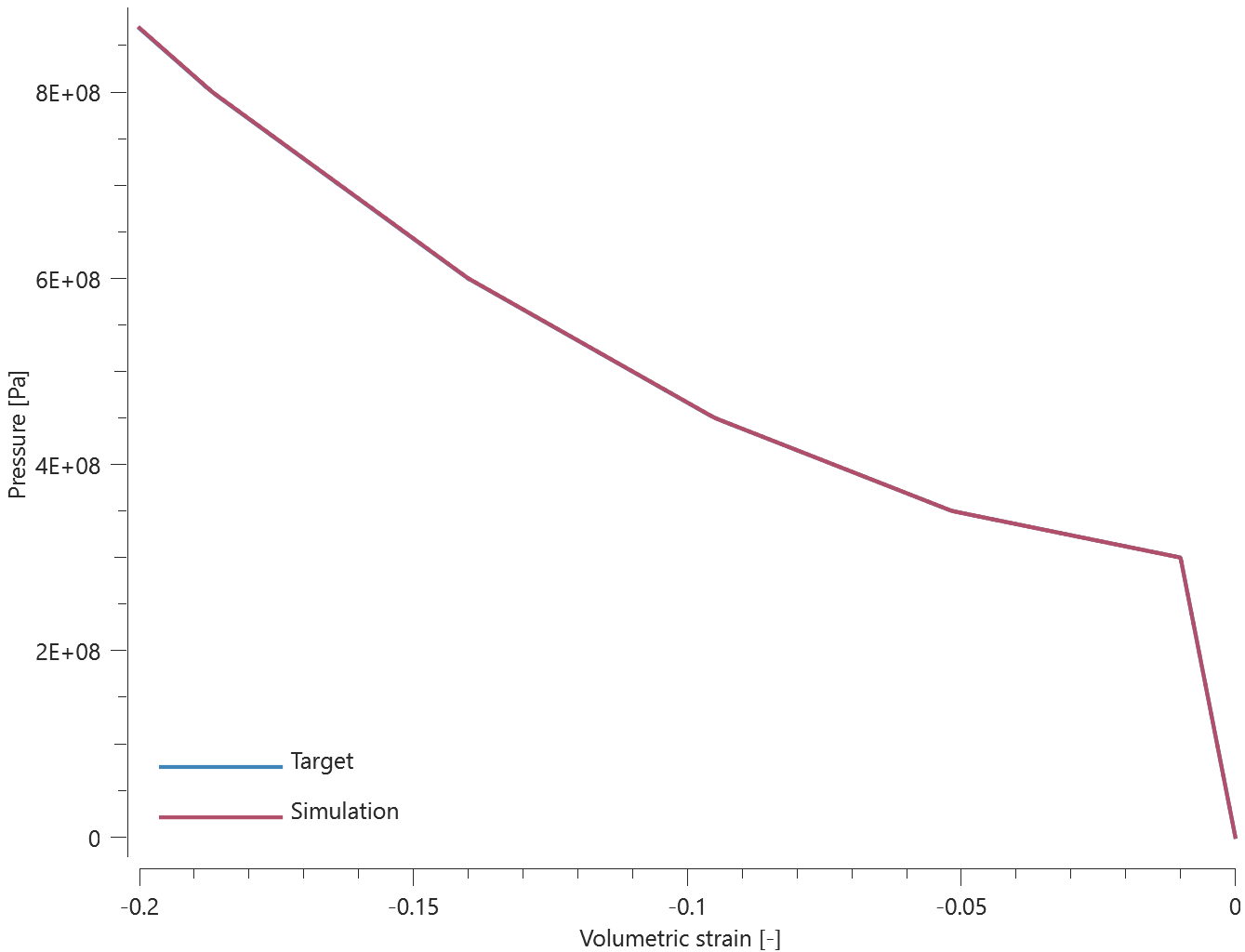

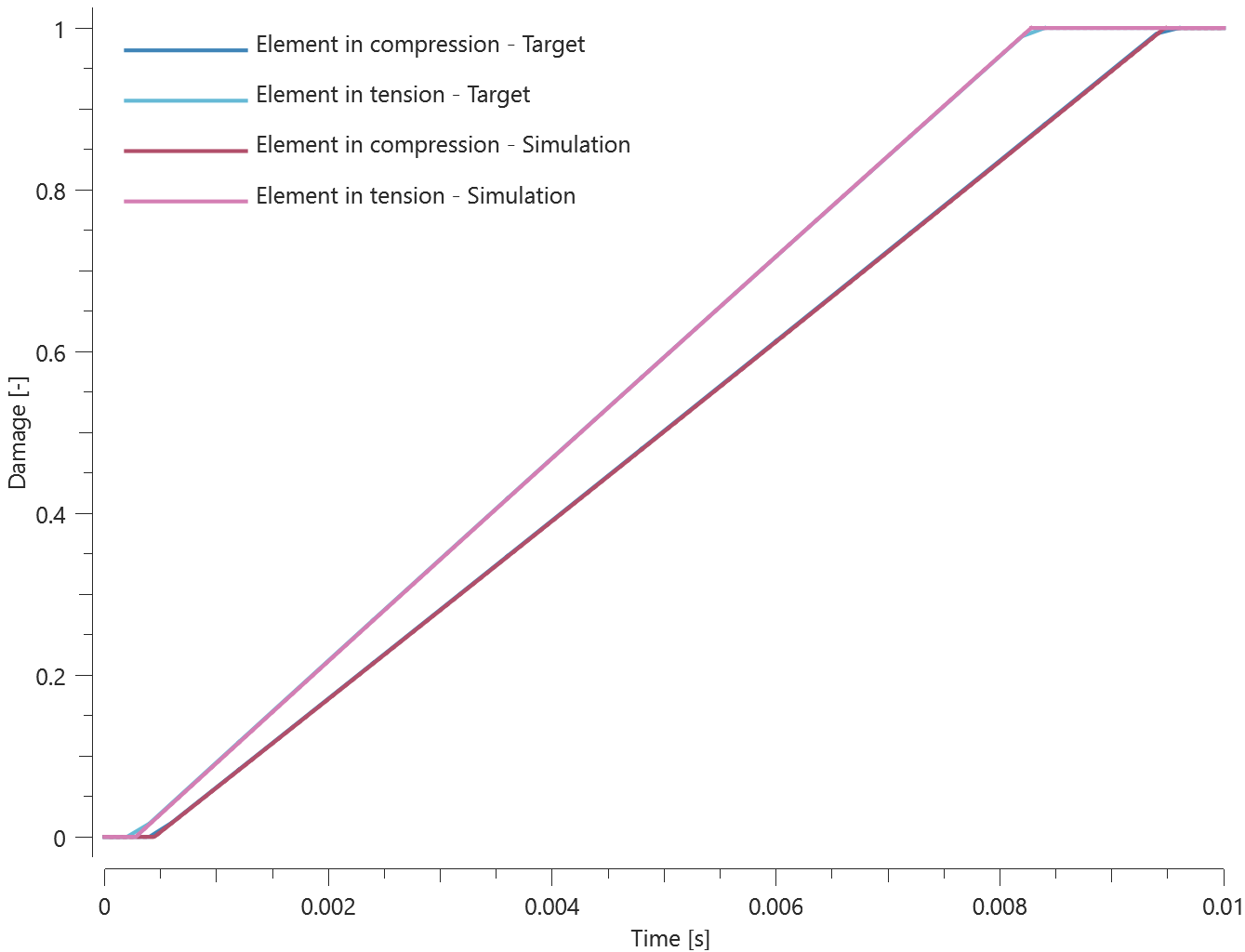

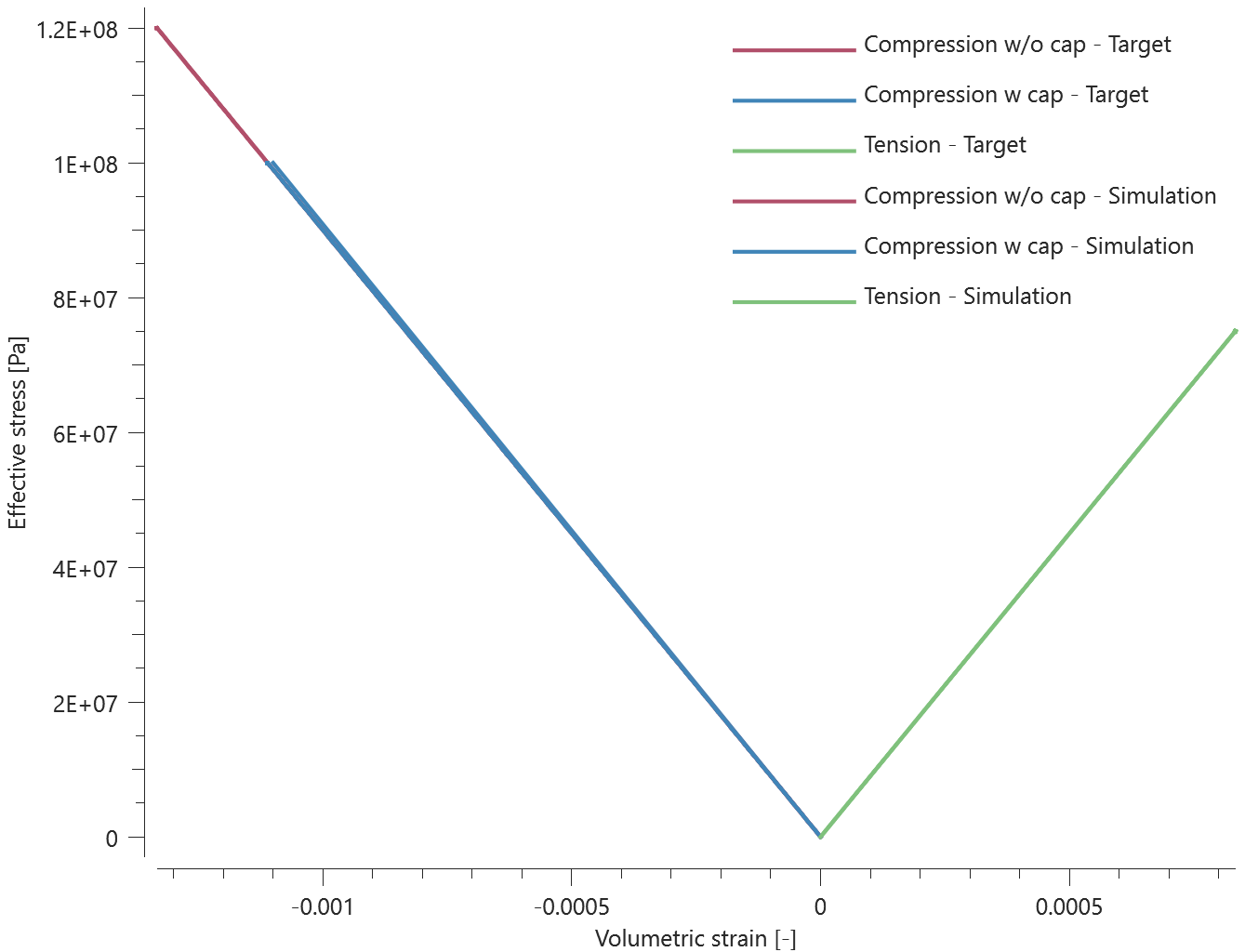

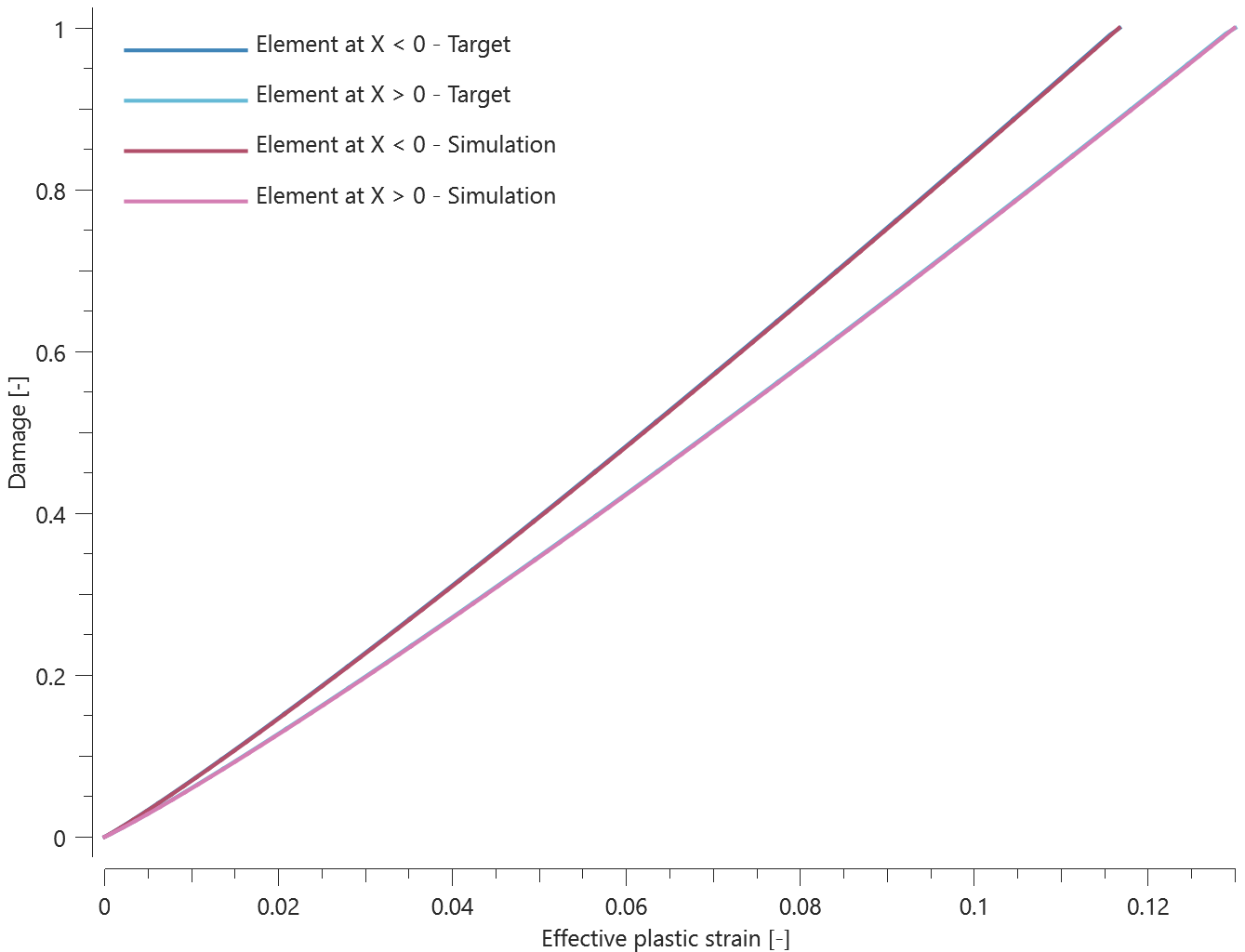

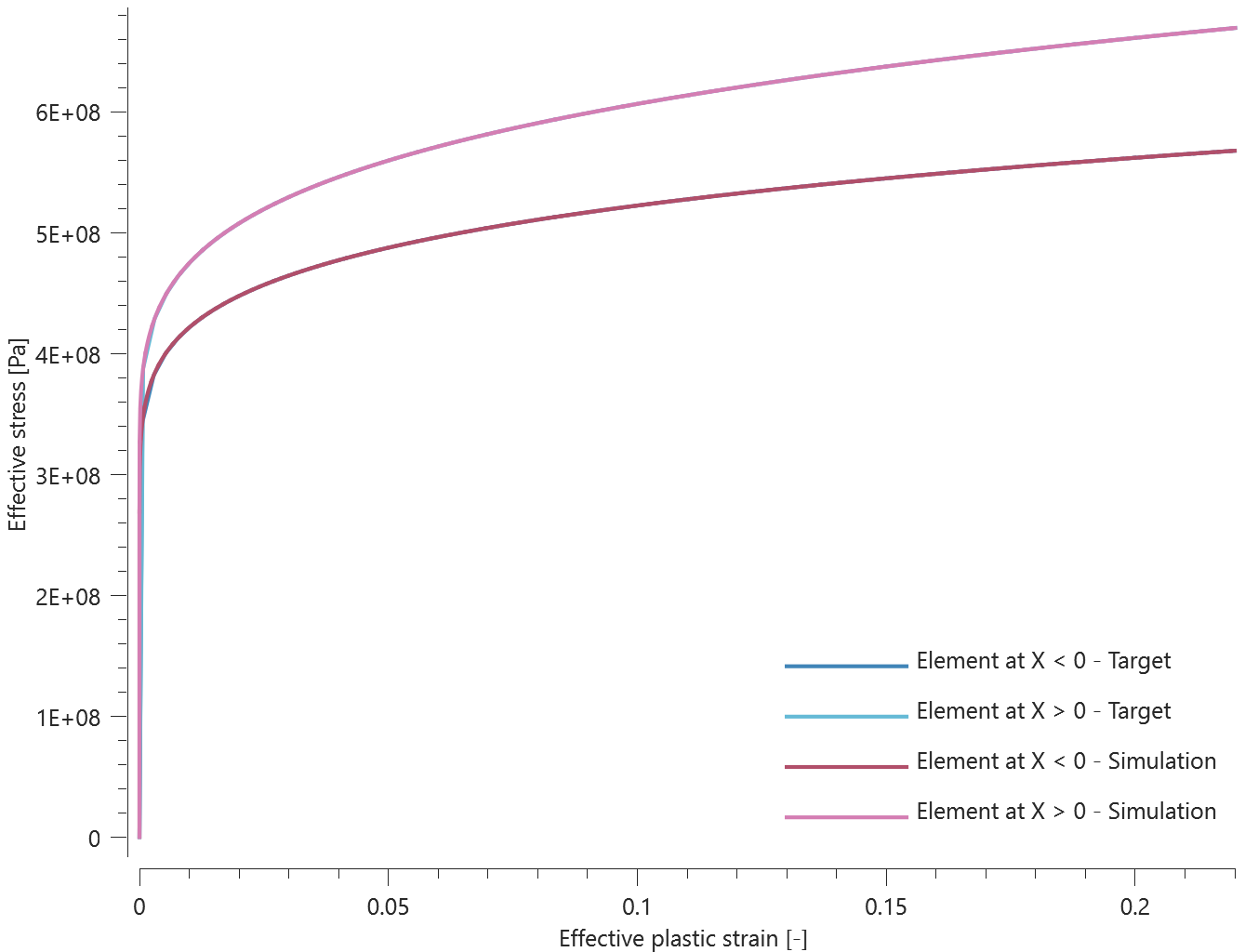

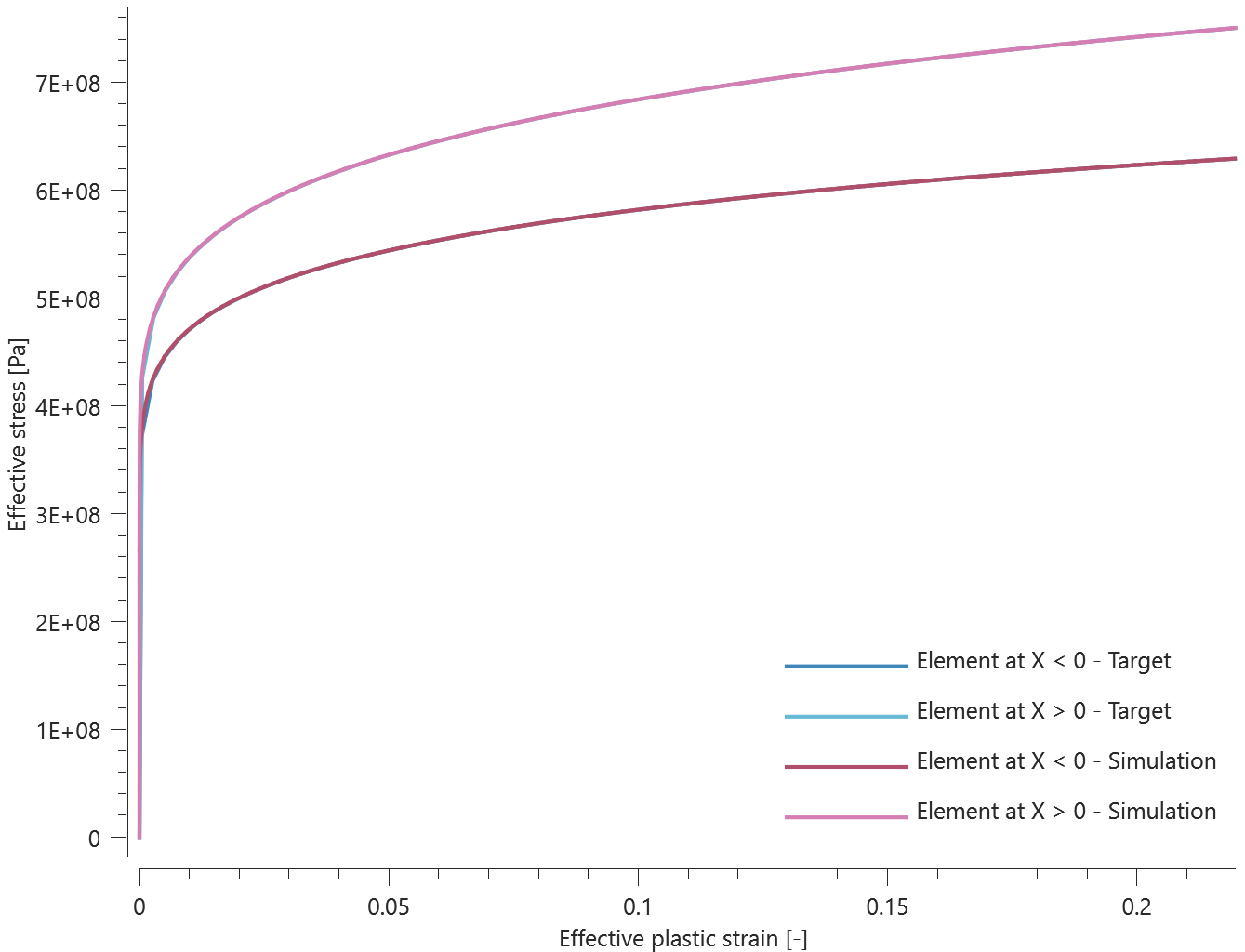

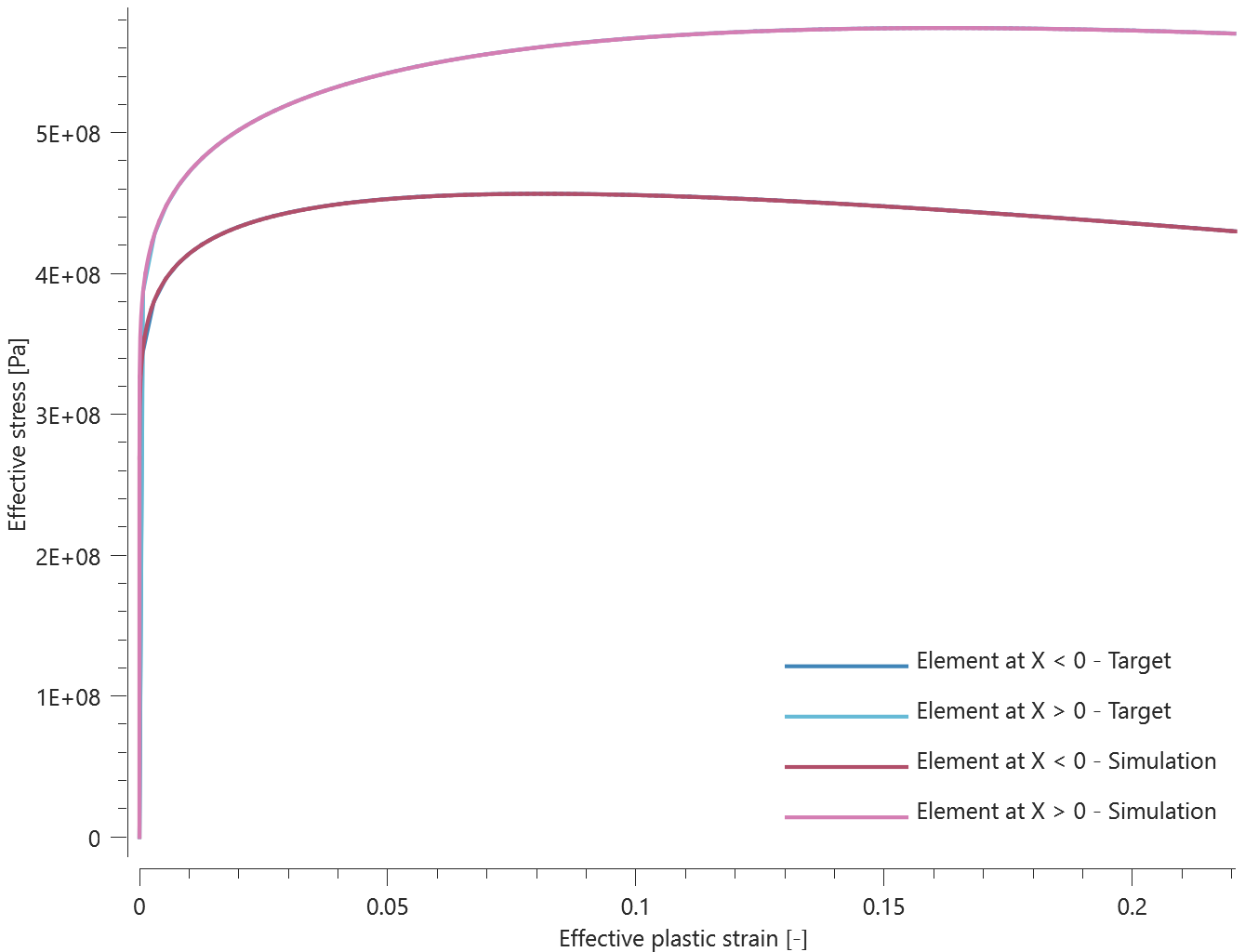

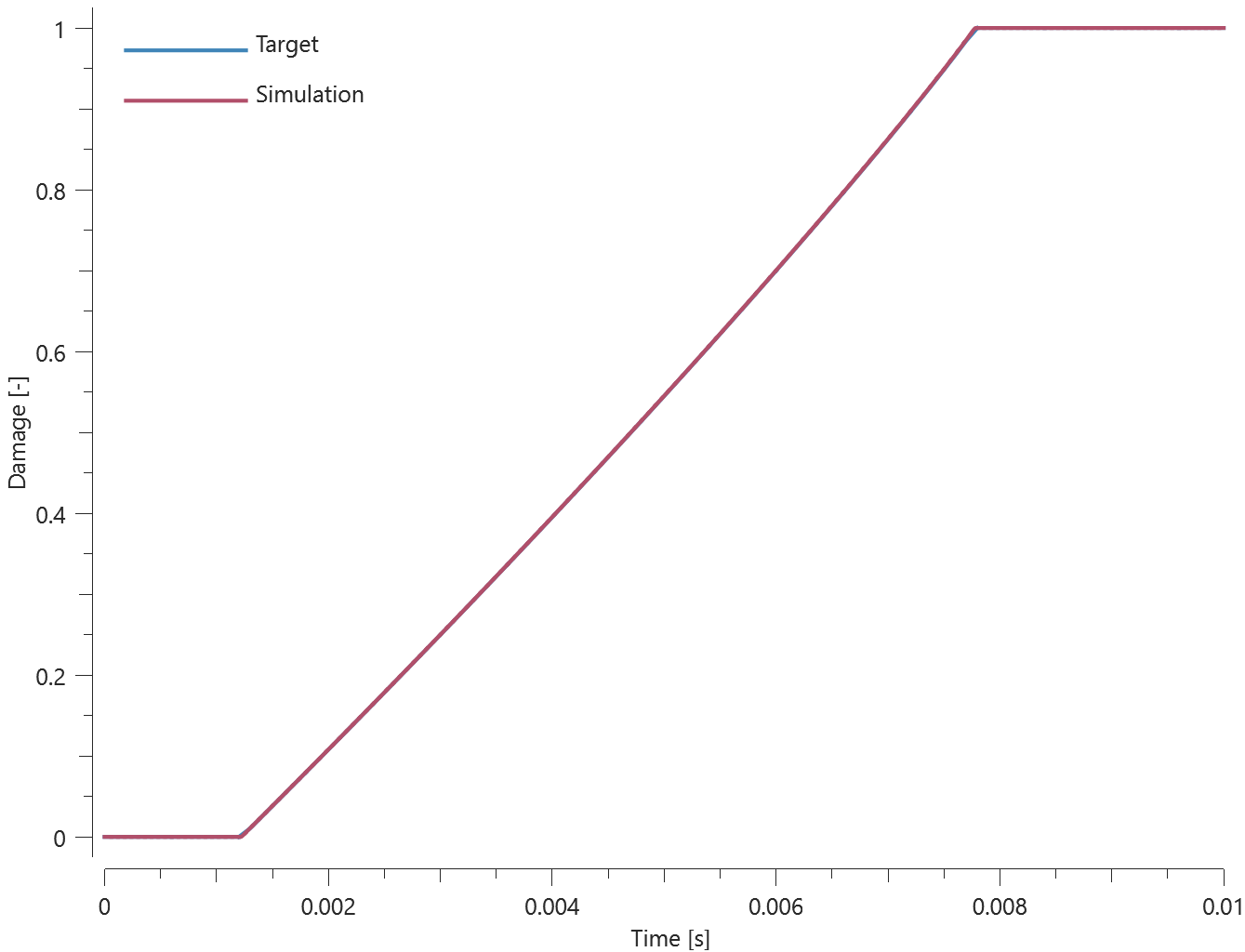

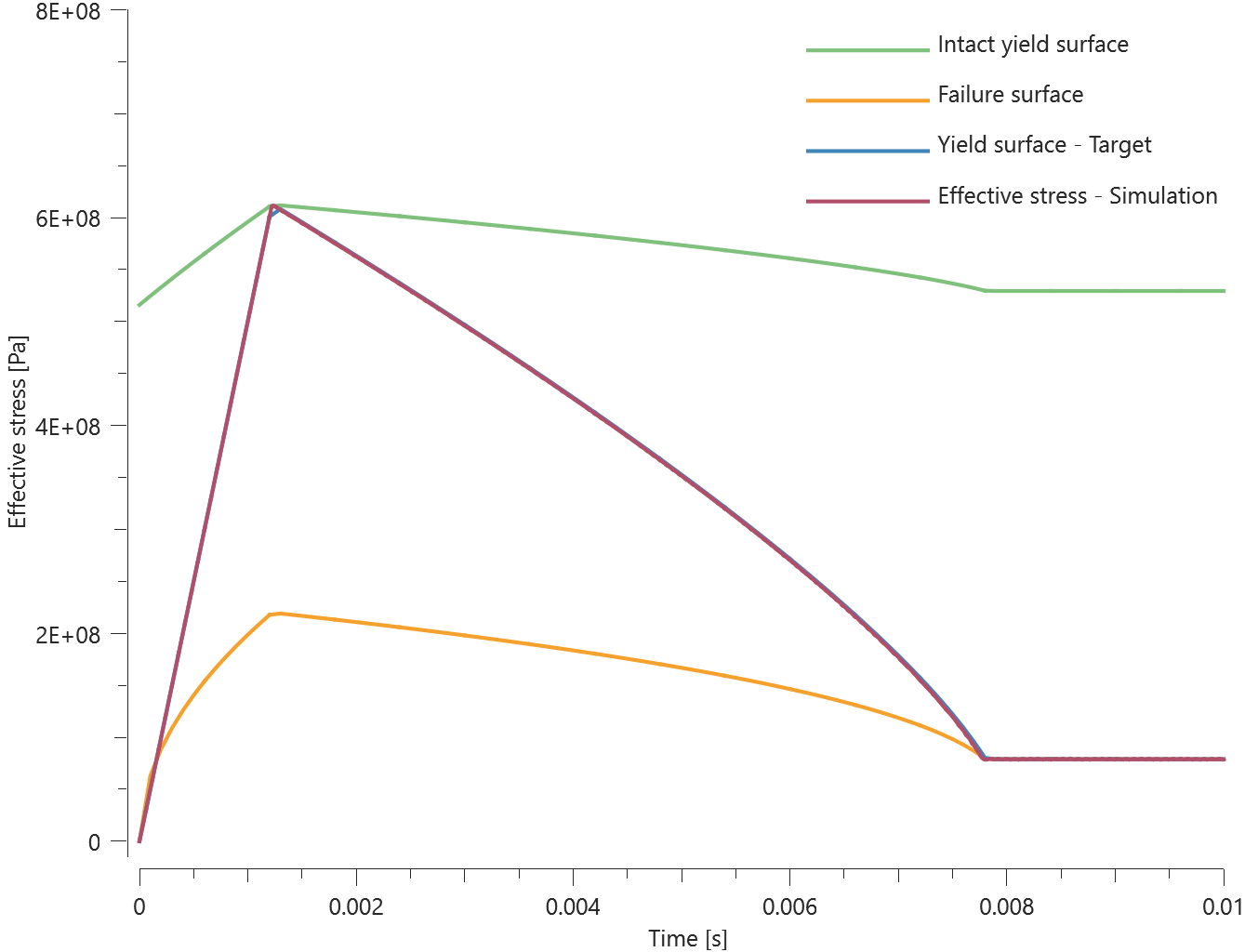

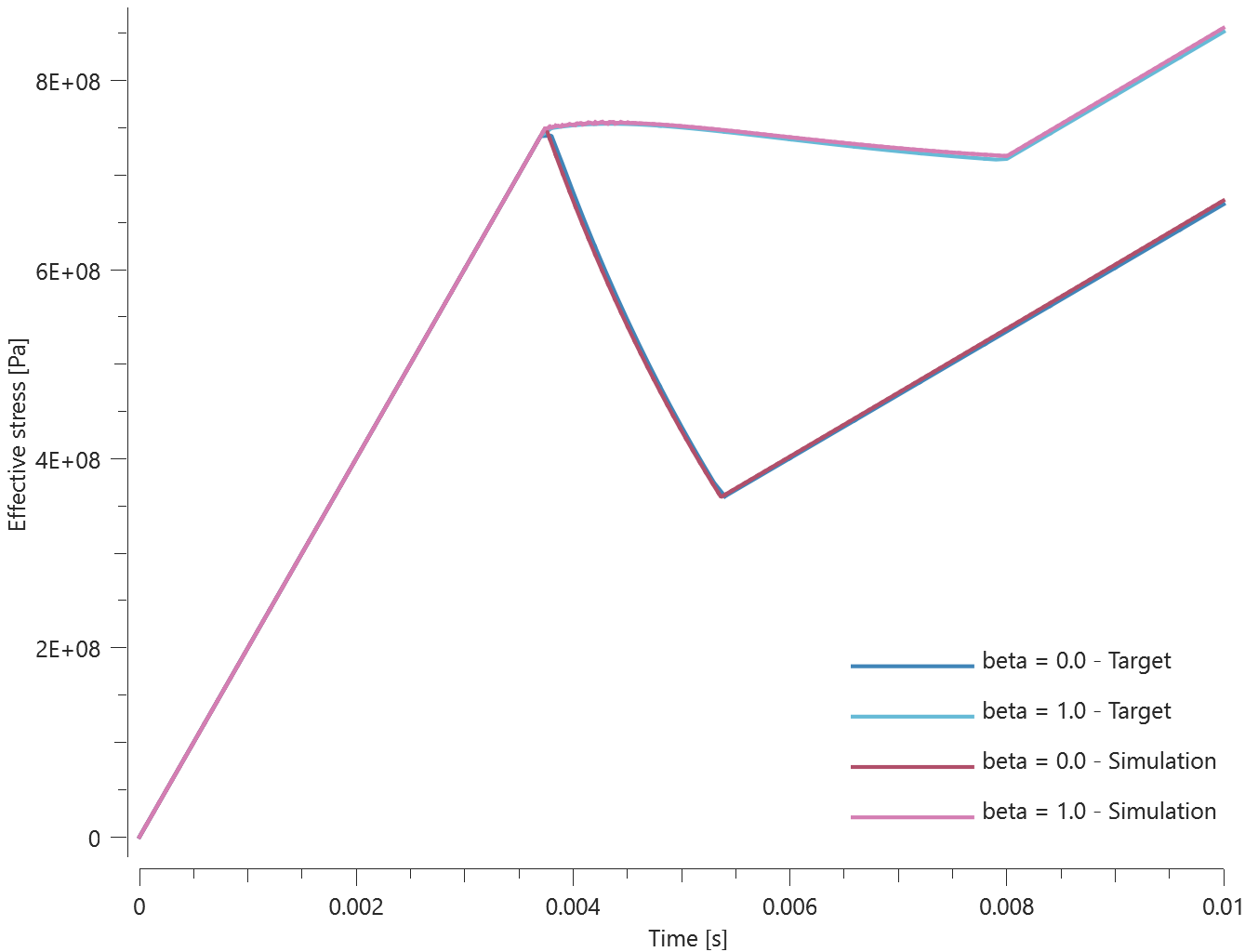

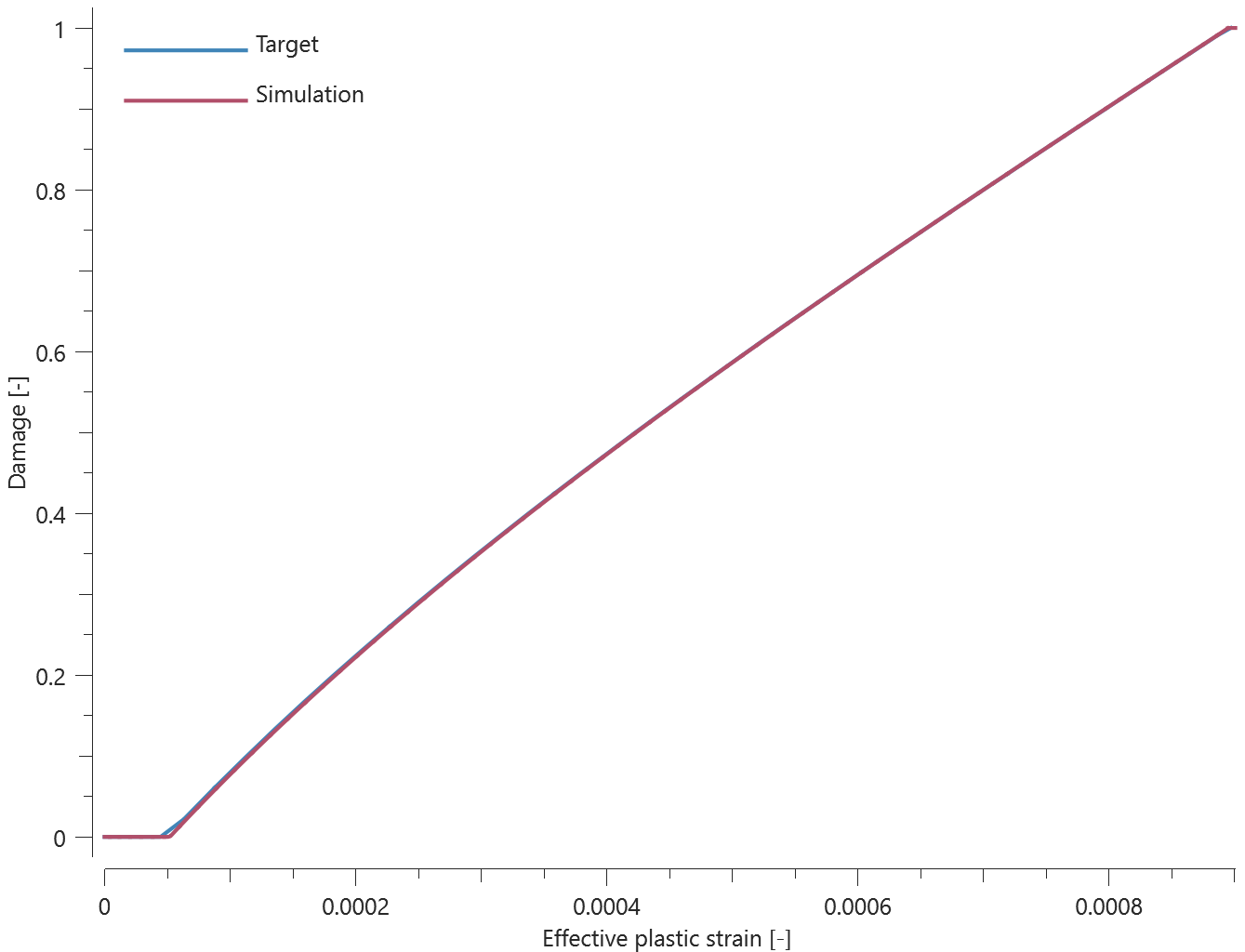

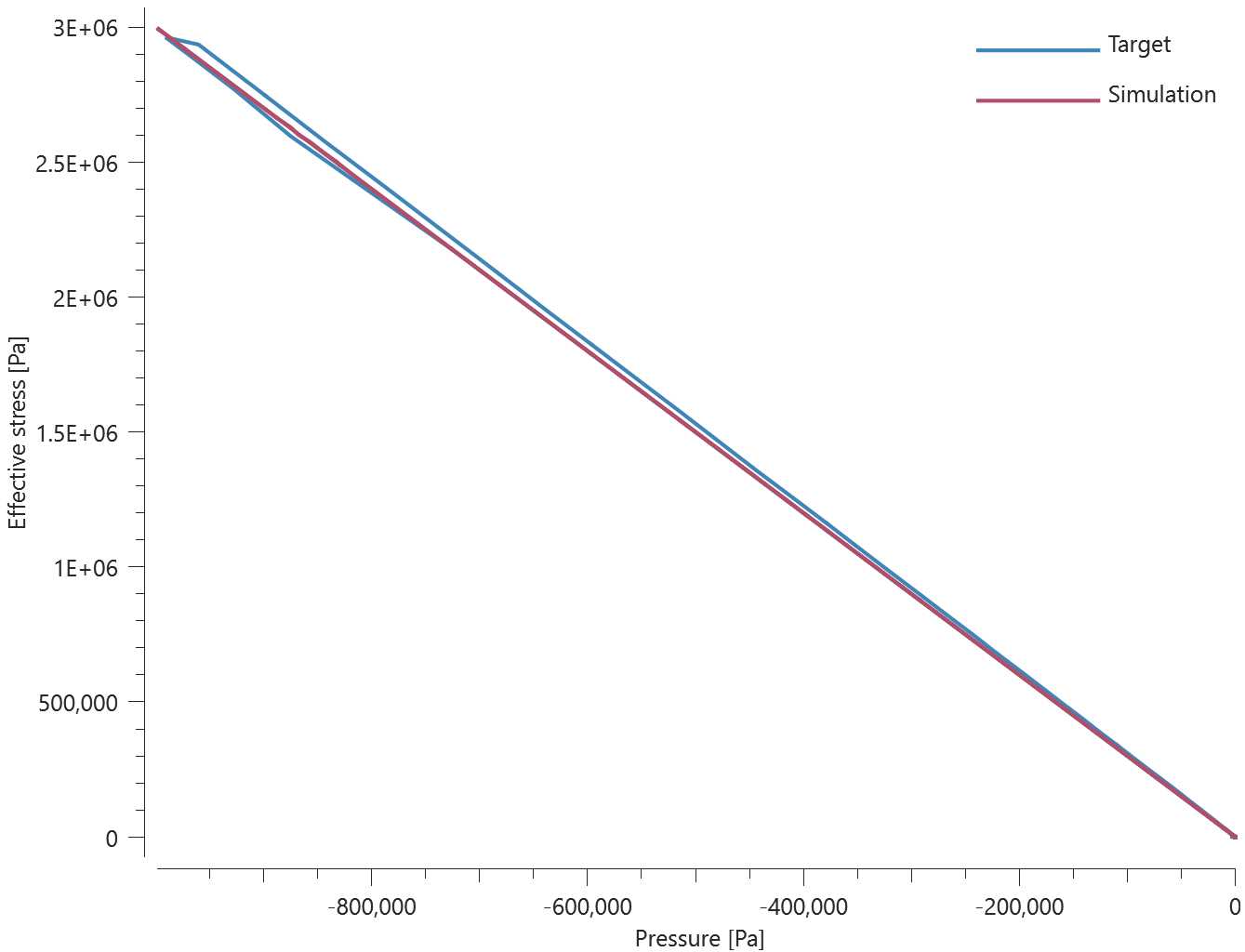

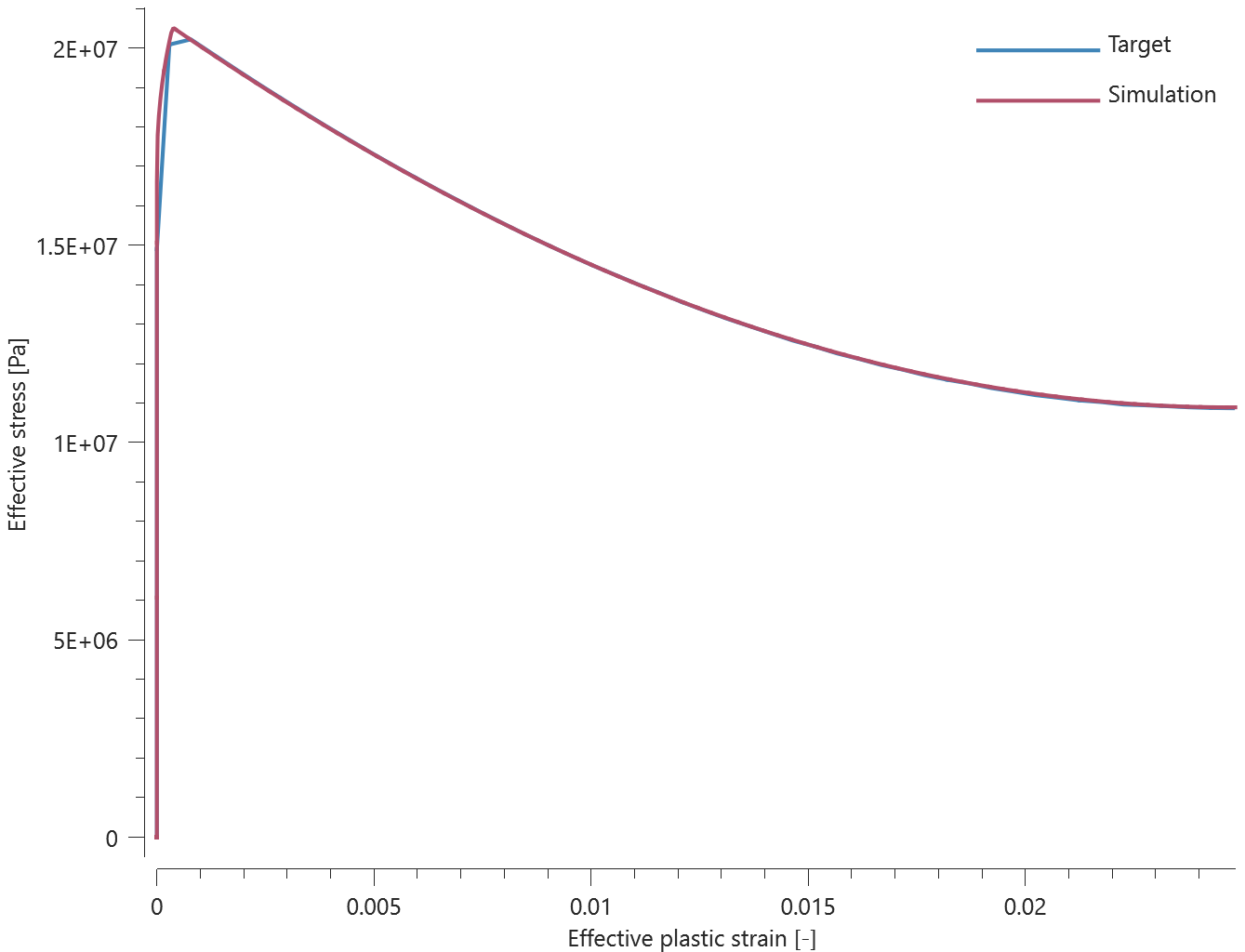

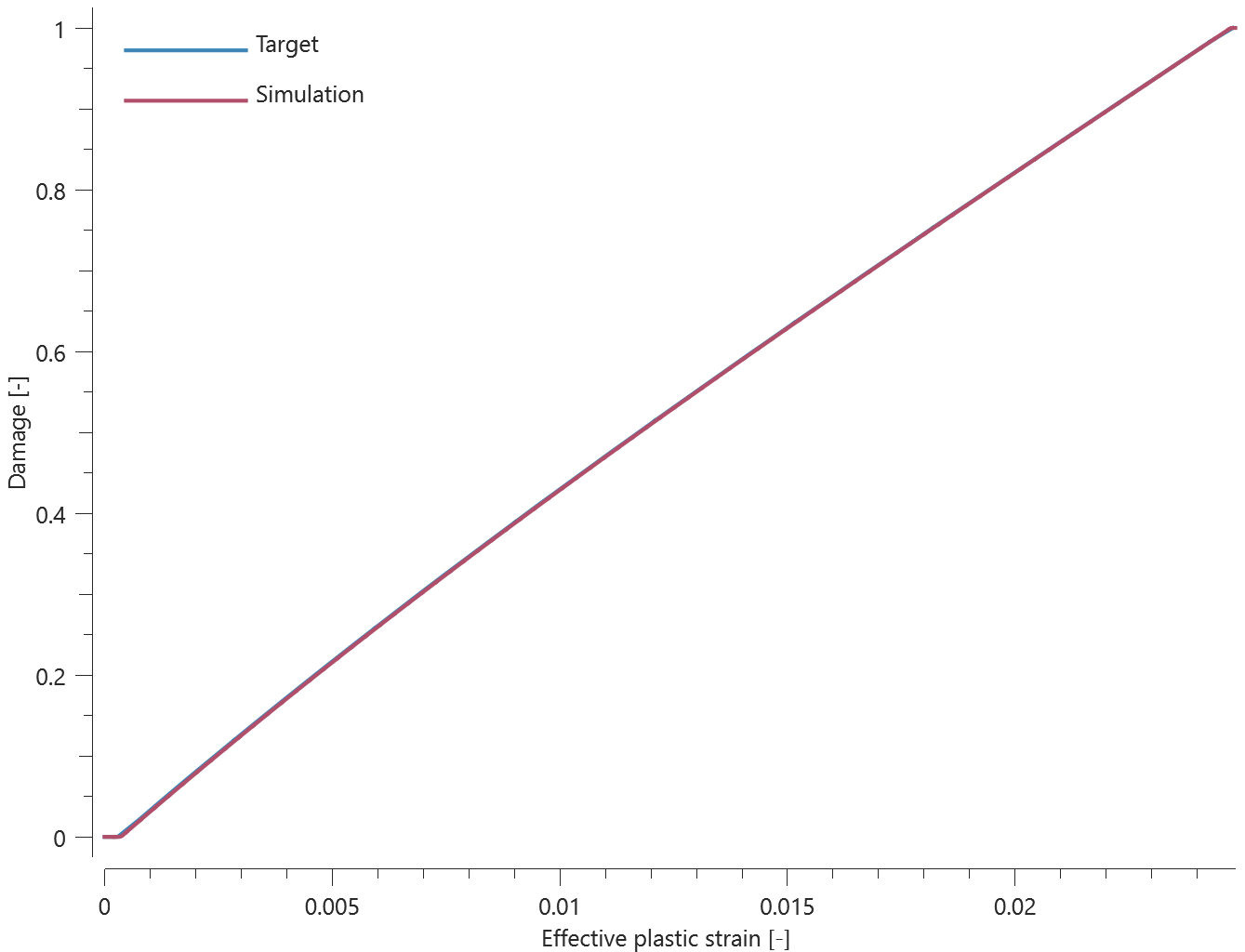

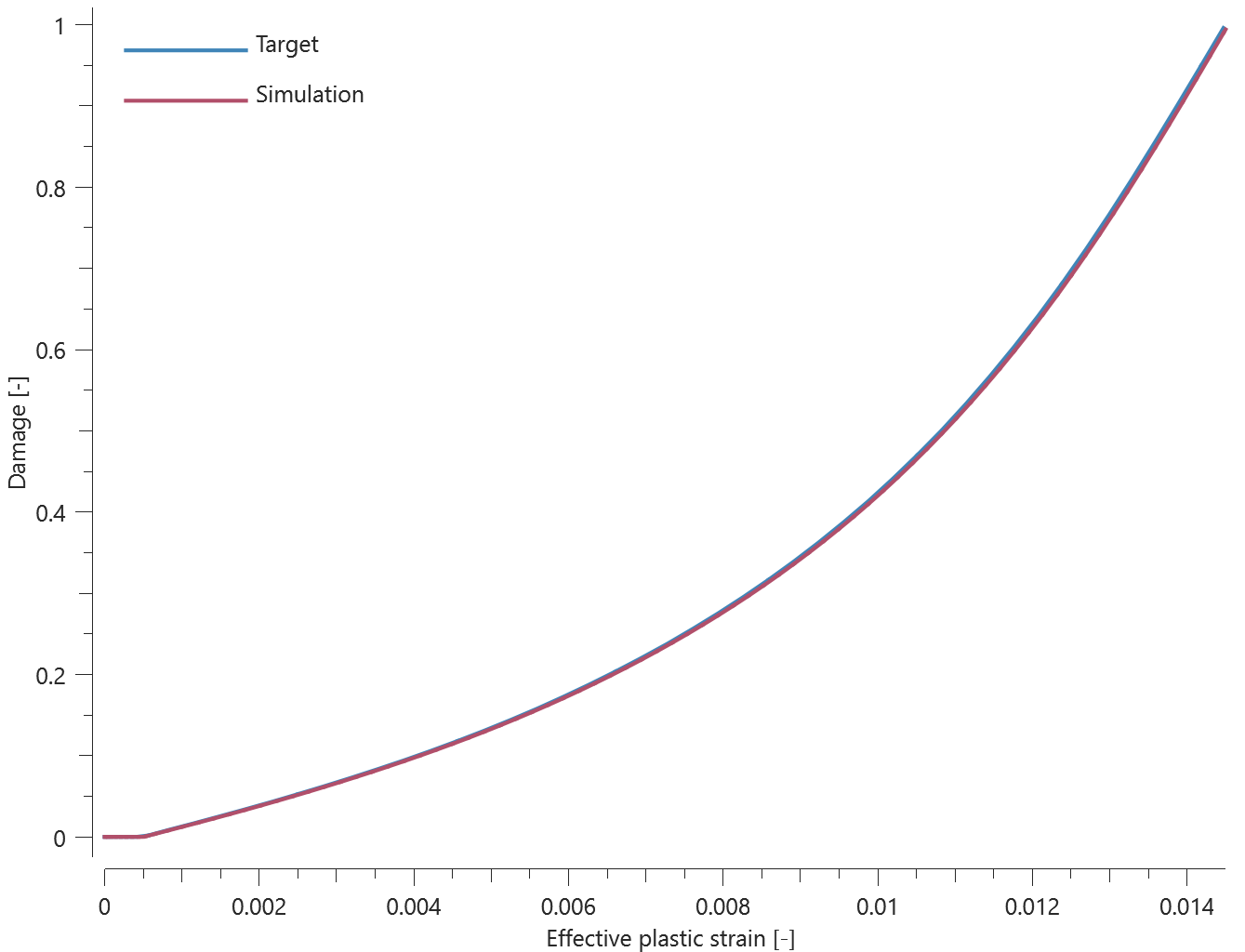

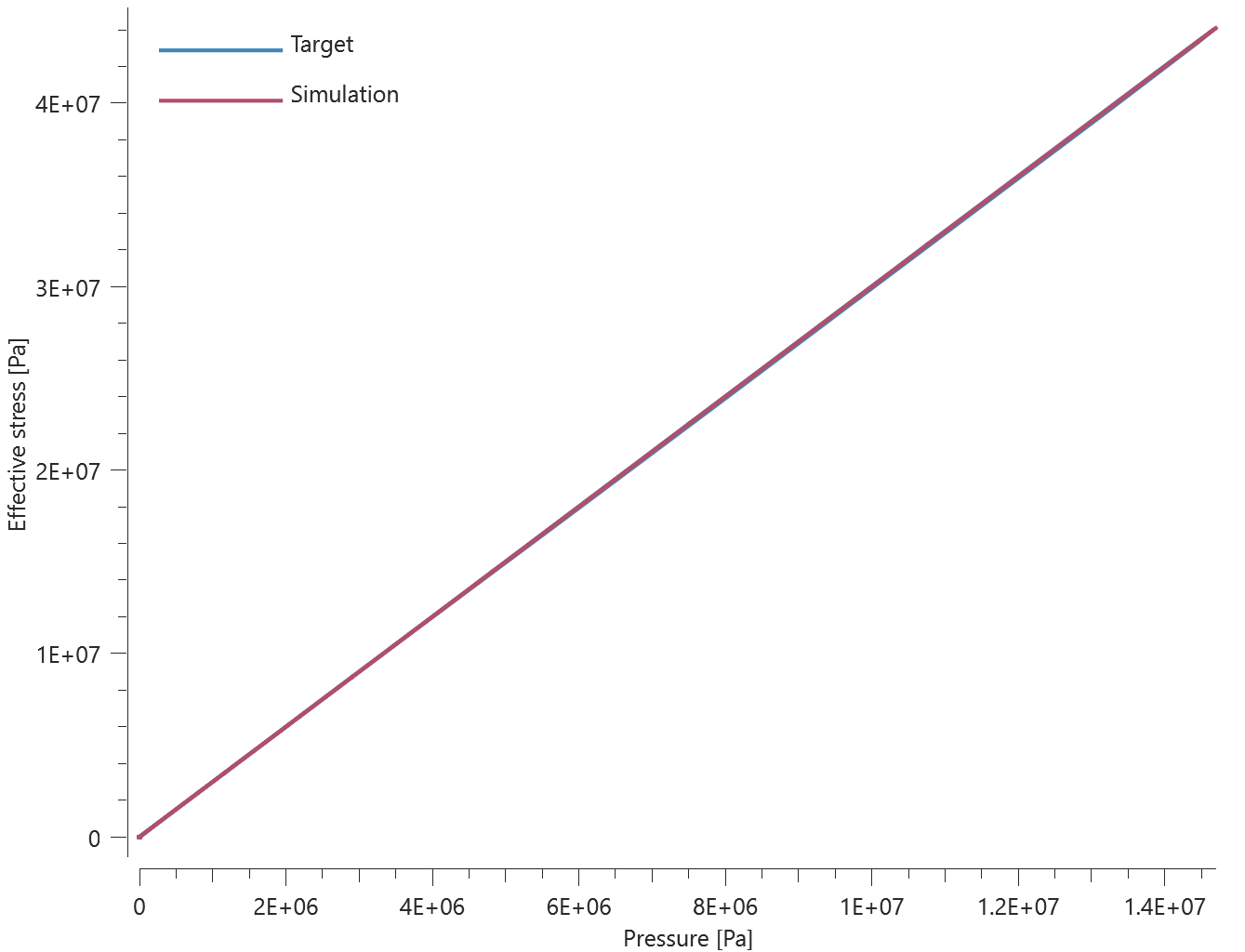

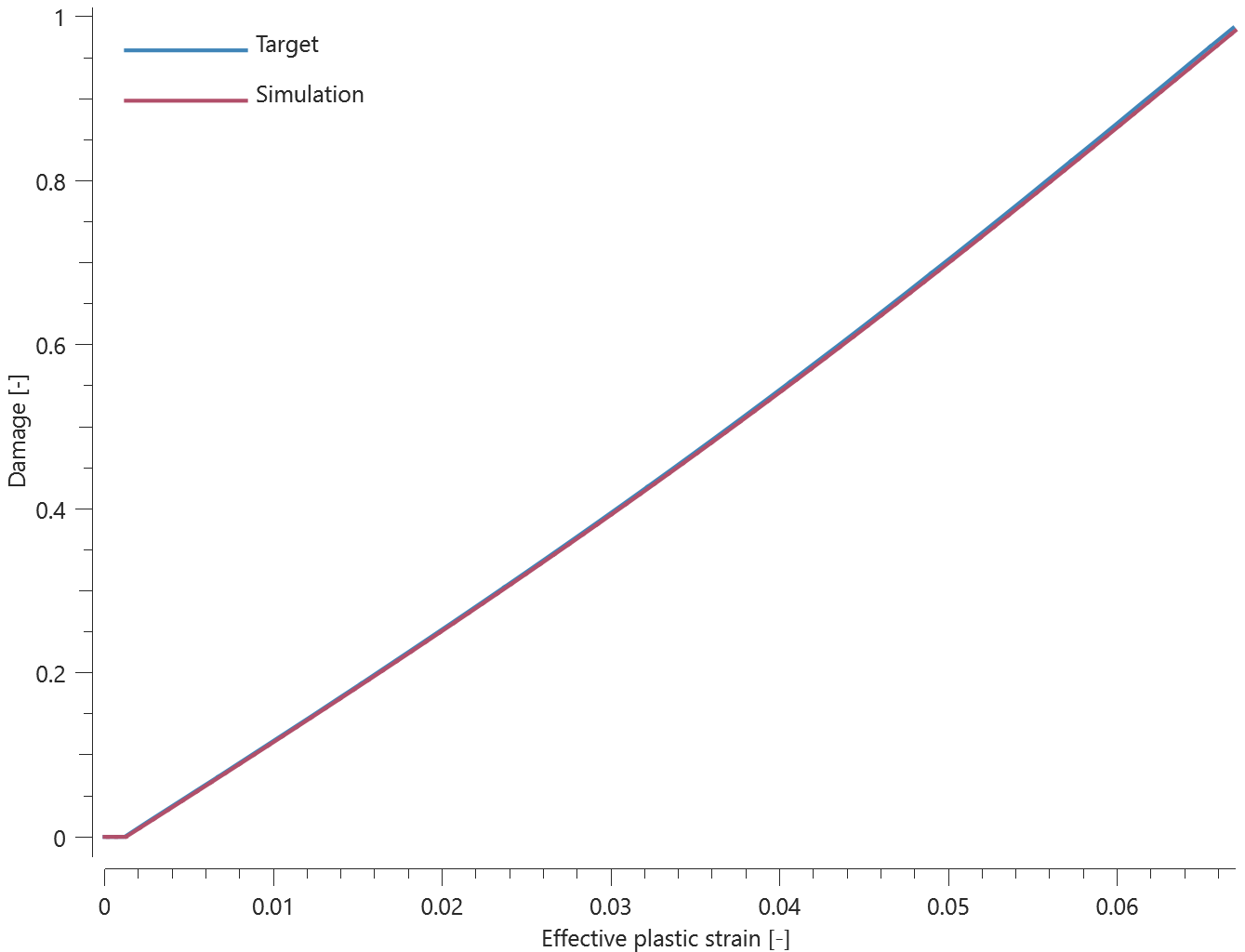

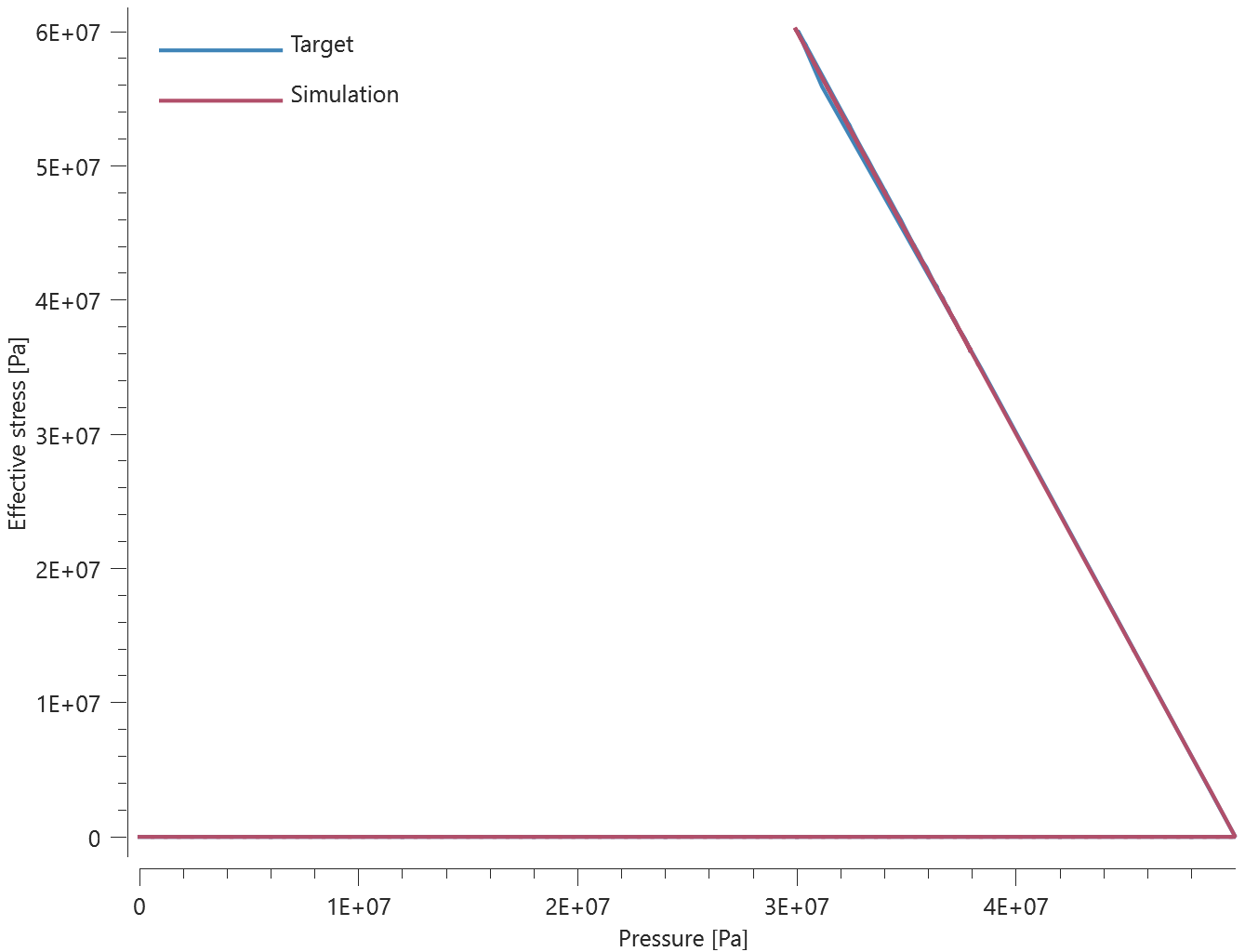

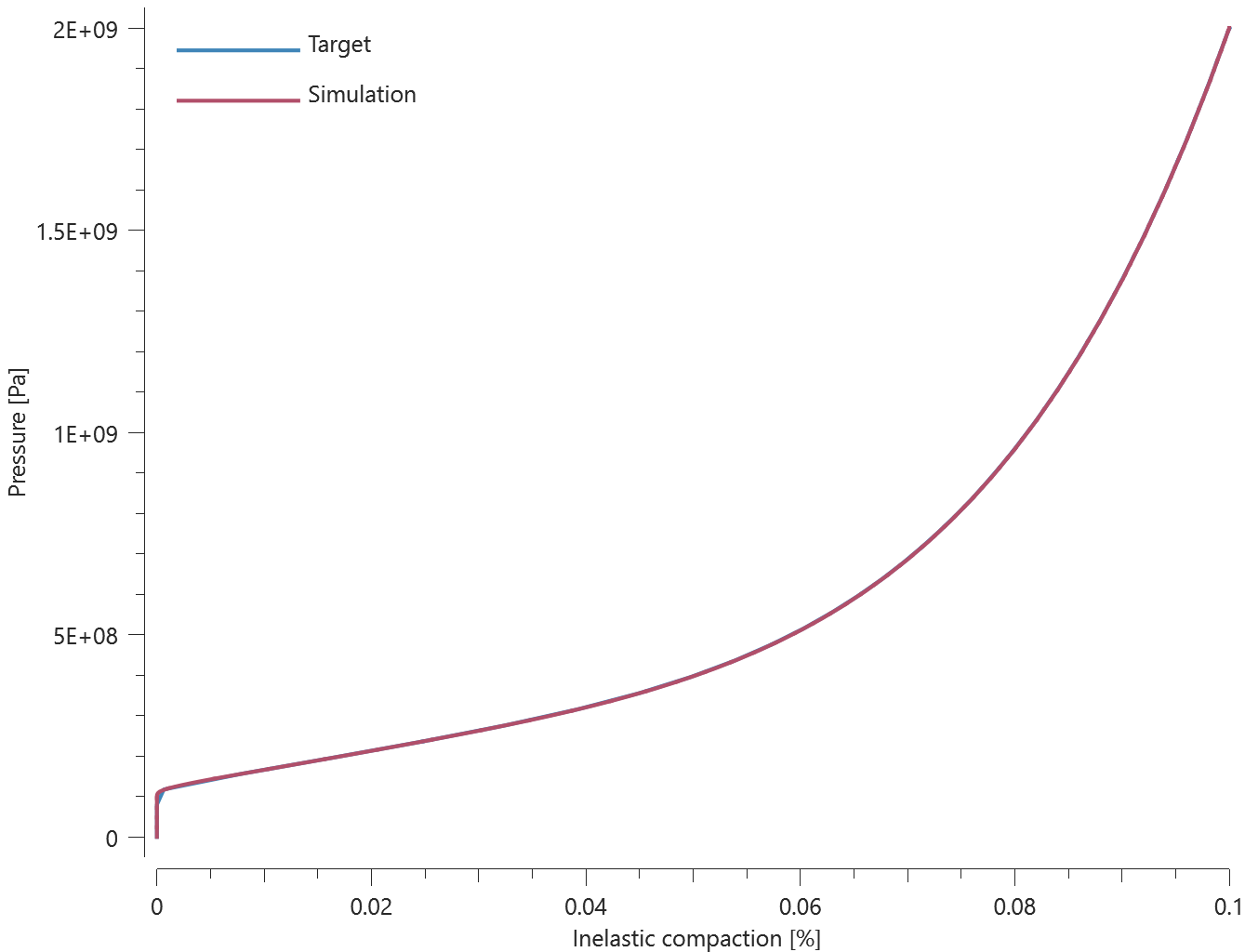

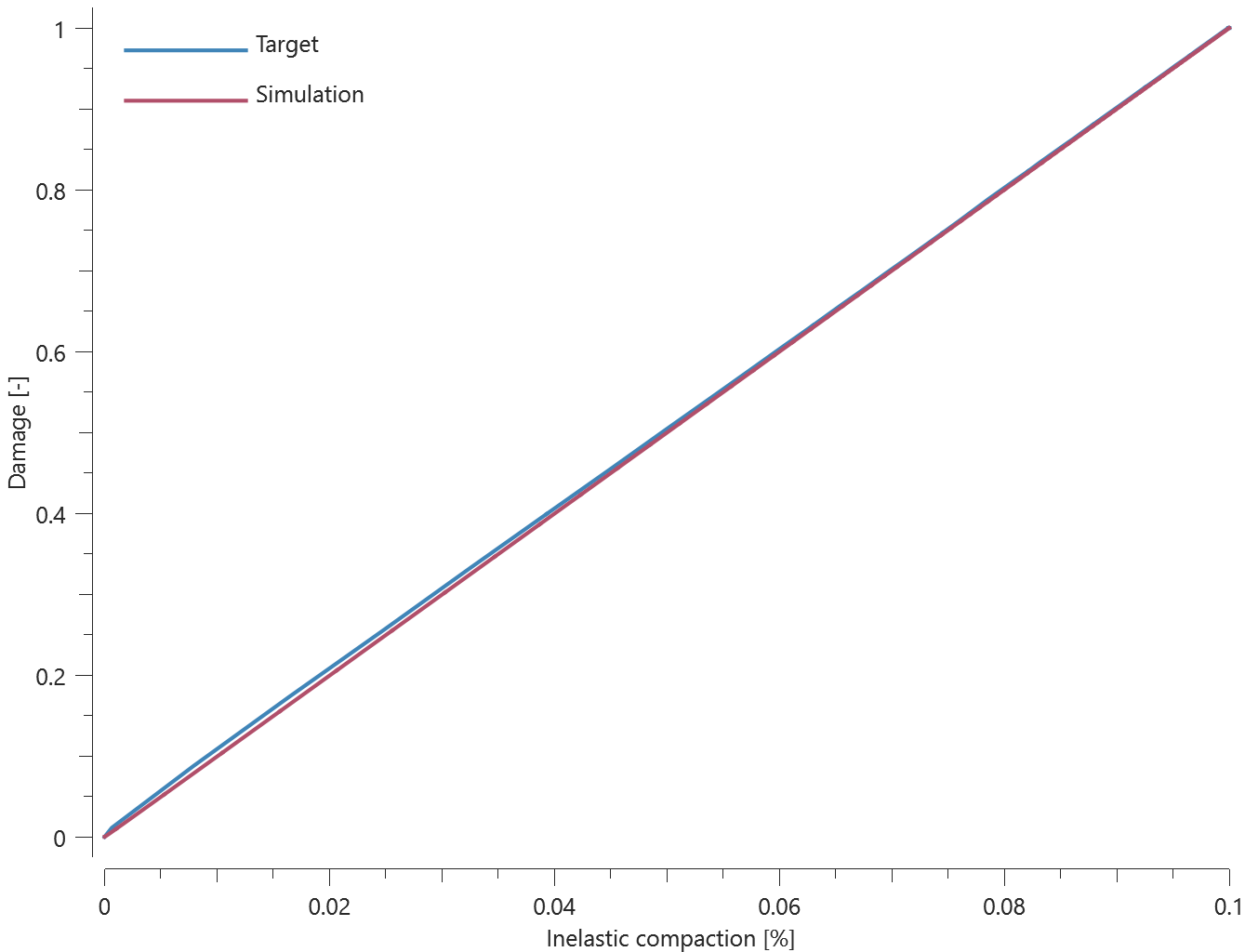

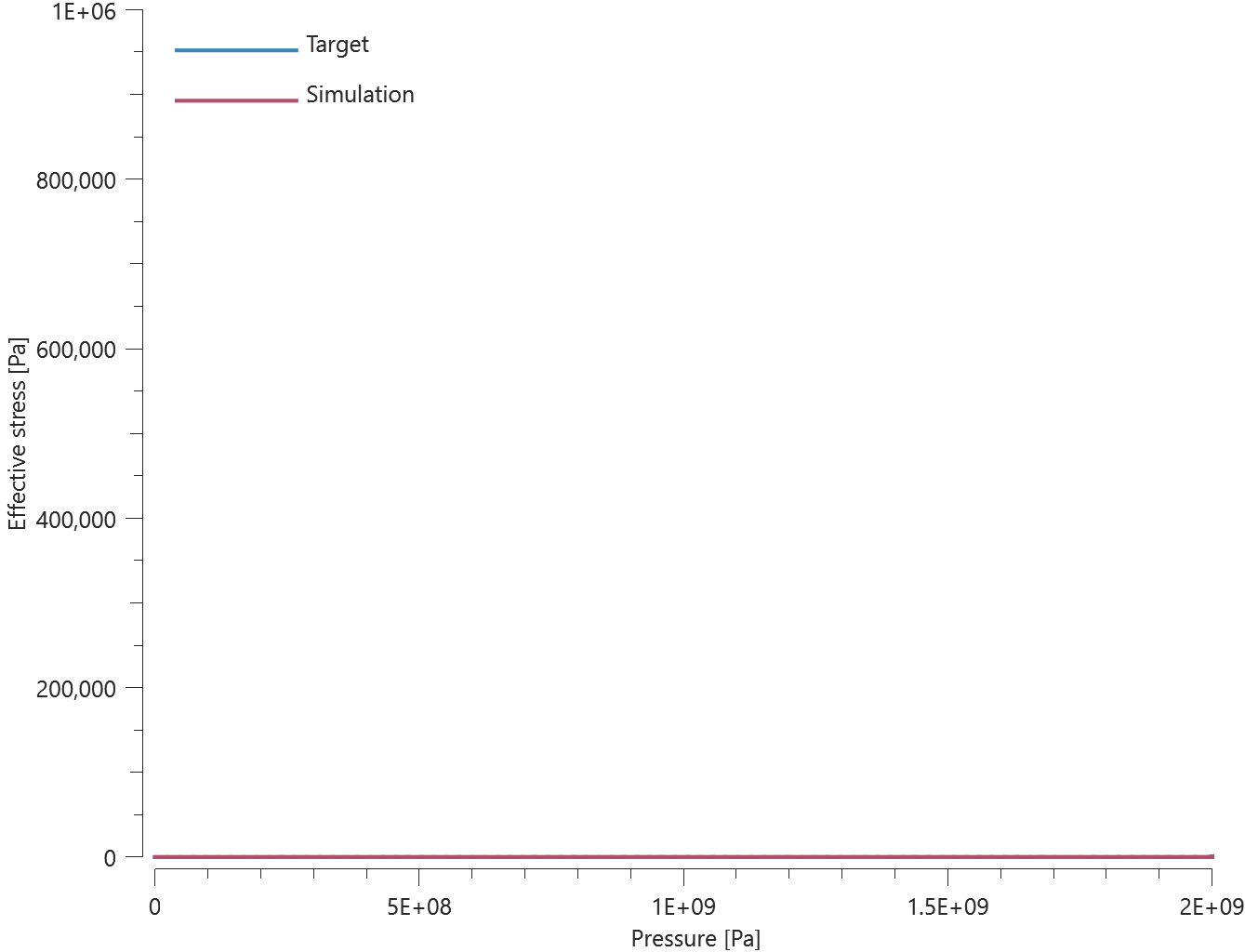

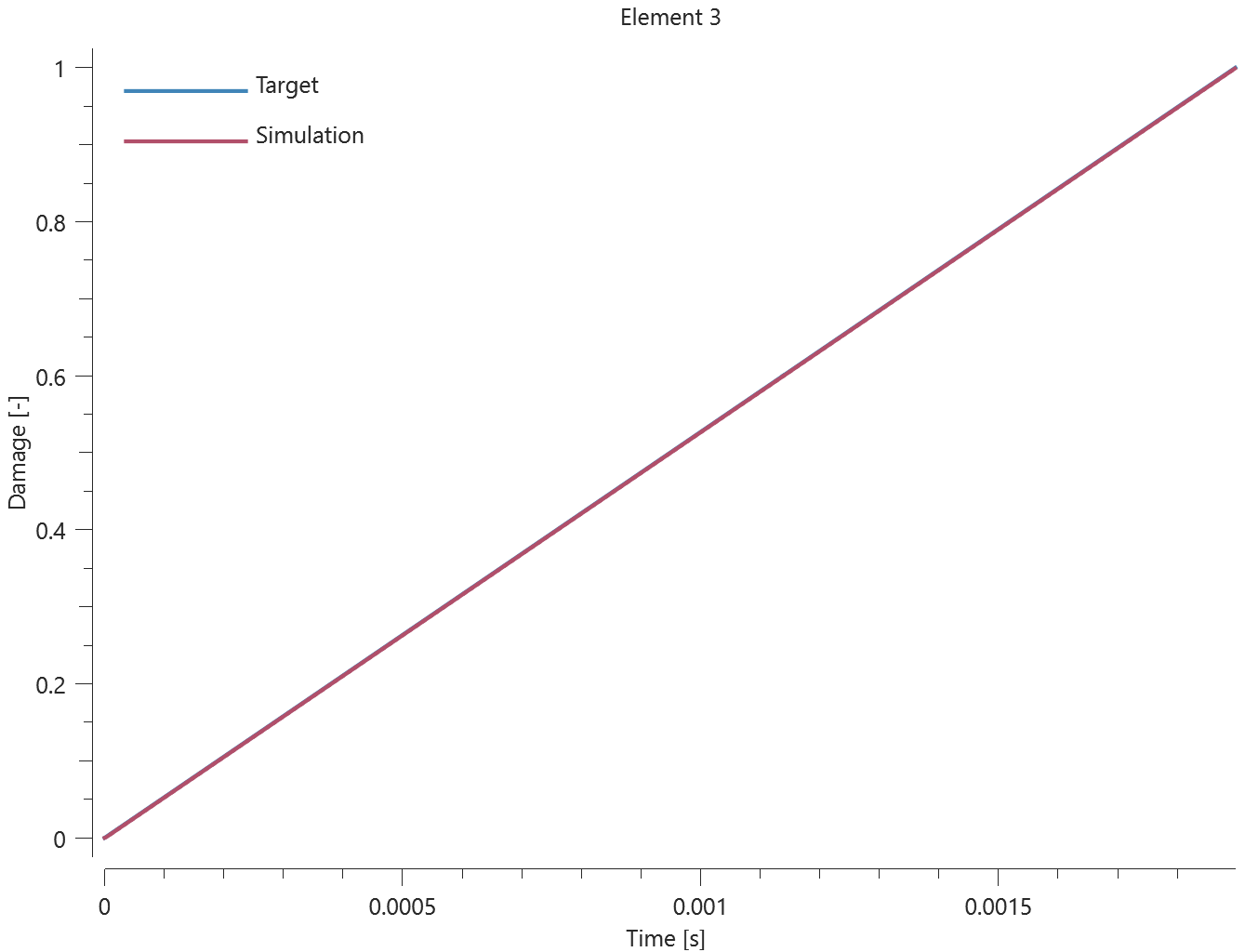

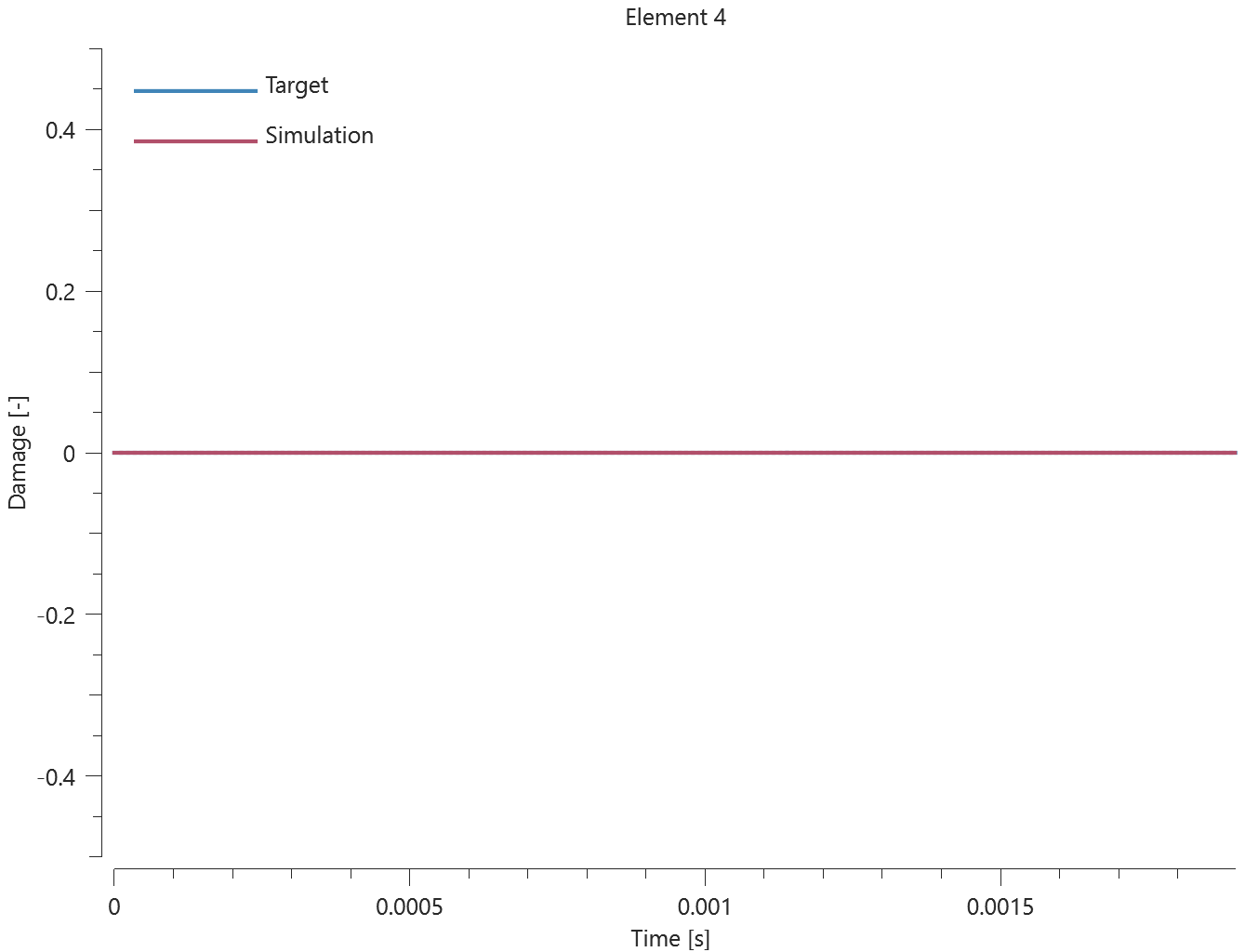

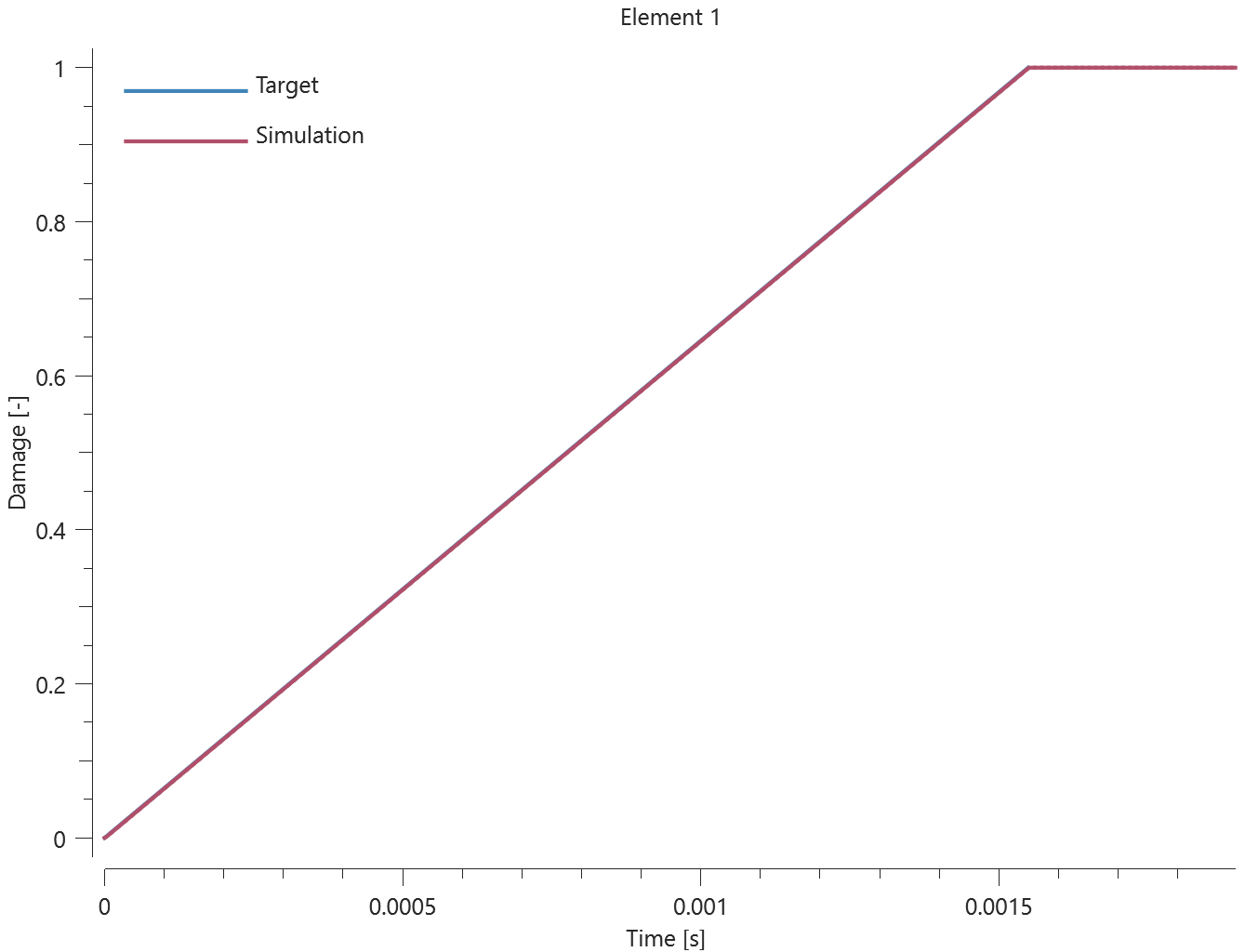

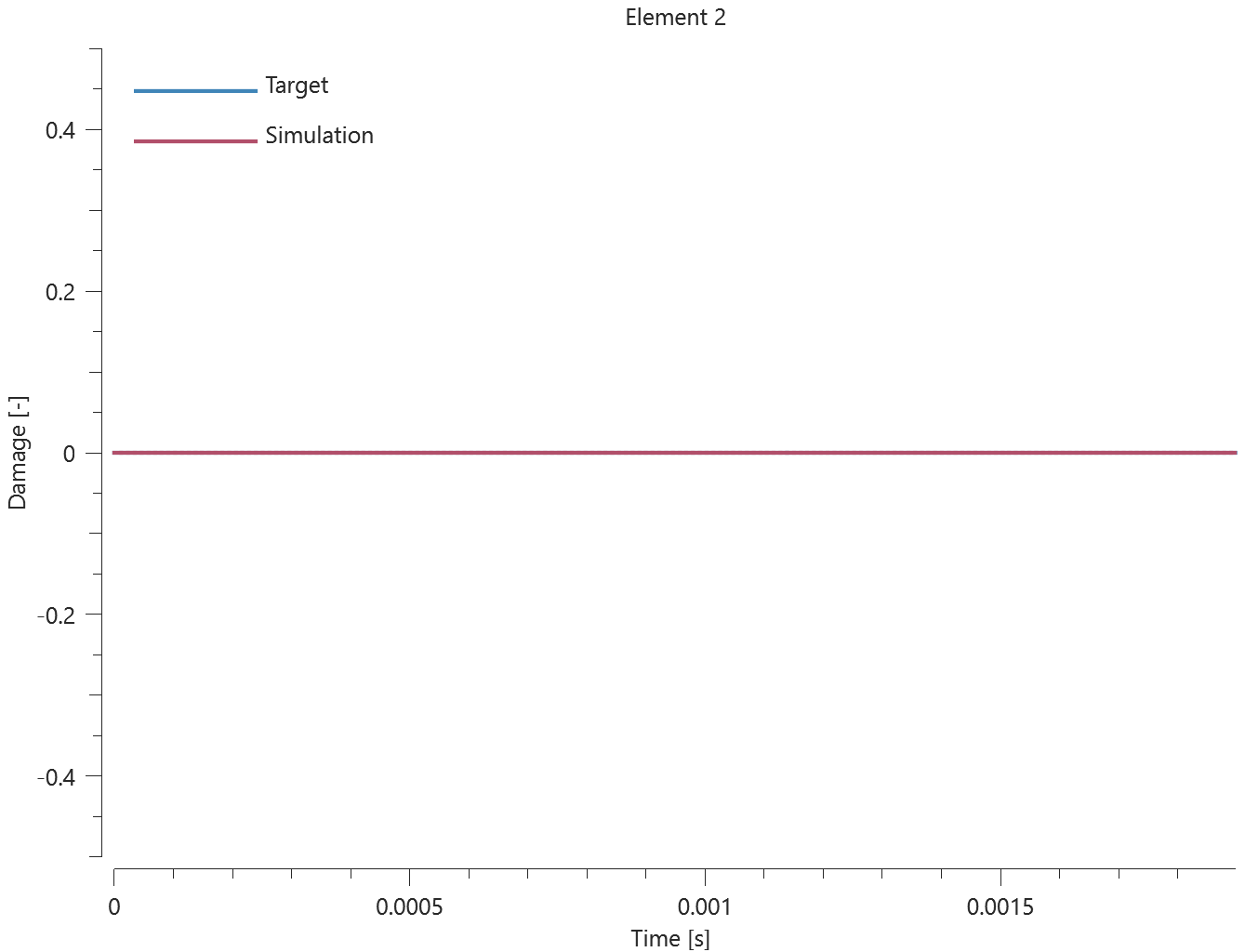

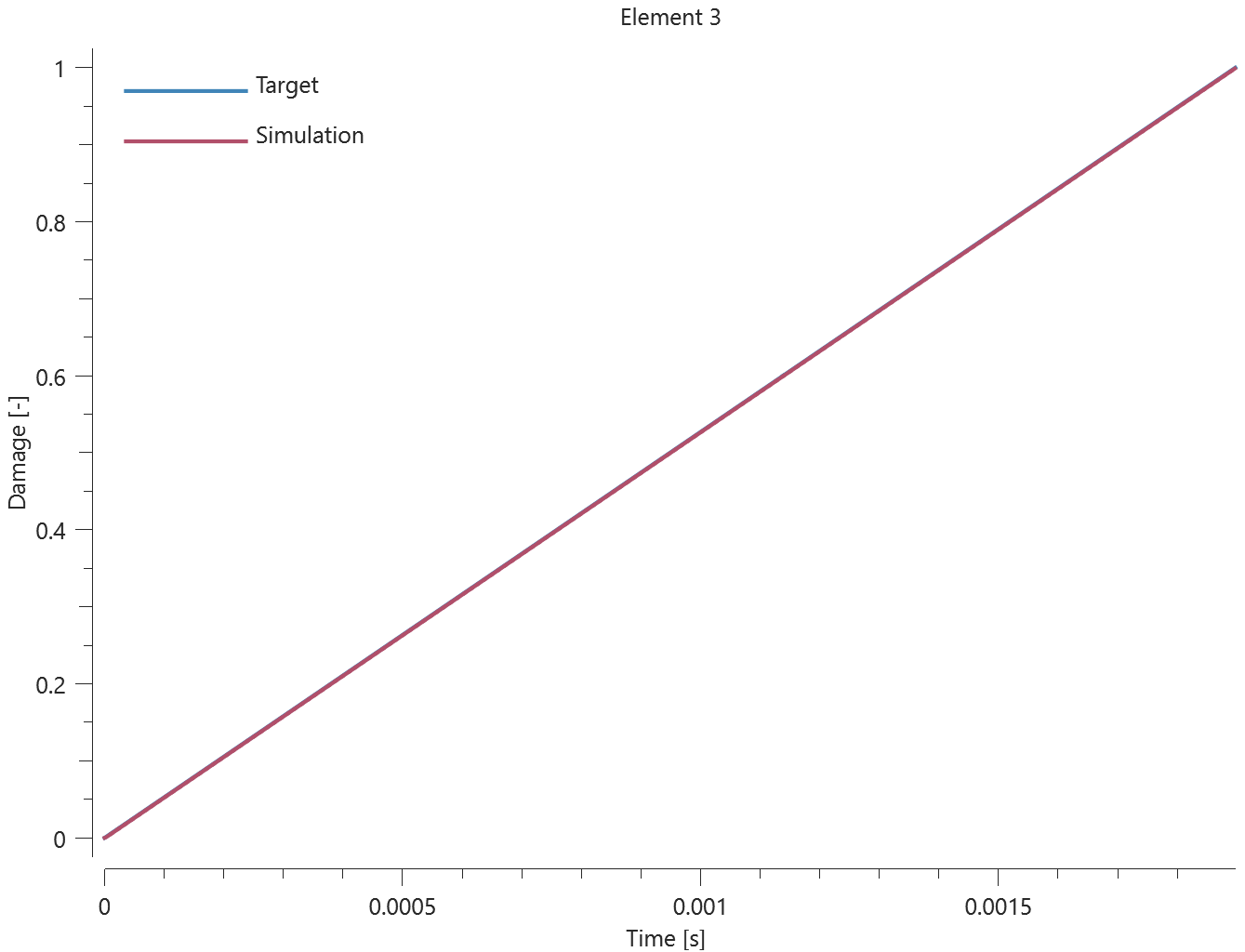

Forces vs. time and damage vs. time from the simulation are presented in Figure 1, 2 and 3 together with target curves from a verification script.

Maximum and average forces and damage in the rivet are checked in spr.out. The dissipated energy is also checked for version control.

Tests

This benchmark is associated with 1 tests.

Normal stress

"Optional title"

$coid$, $pid_s$, $pid_m$, $csysid$

$R$, $h$, $m$, $f_n^{max}$, $f_t^{max}$, $d_n^{max}$, $d_t^{max}$, $\xi_n$

$\xi_t$, $a_1$, $a_2$, $a_3$

The rivet properties of *CONNECTOR_SPR in a state of normal stress is verified in this test.

Tested parameters:  , h,

, h,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

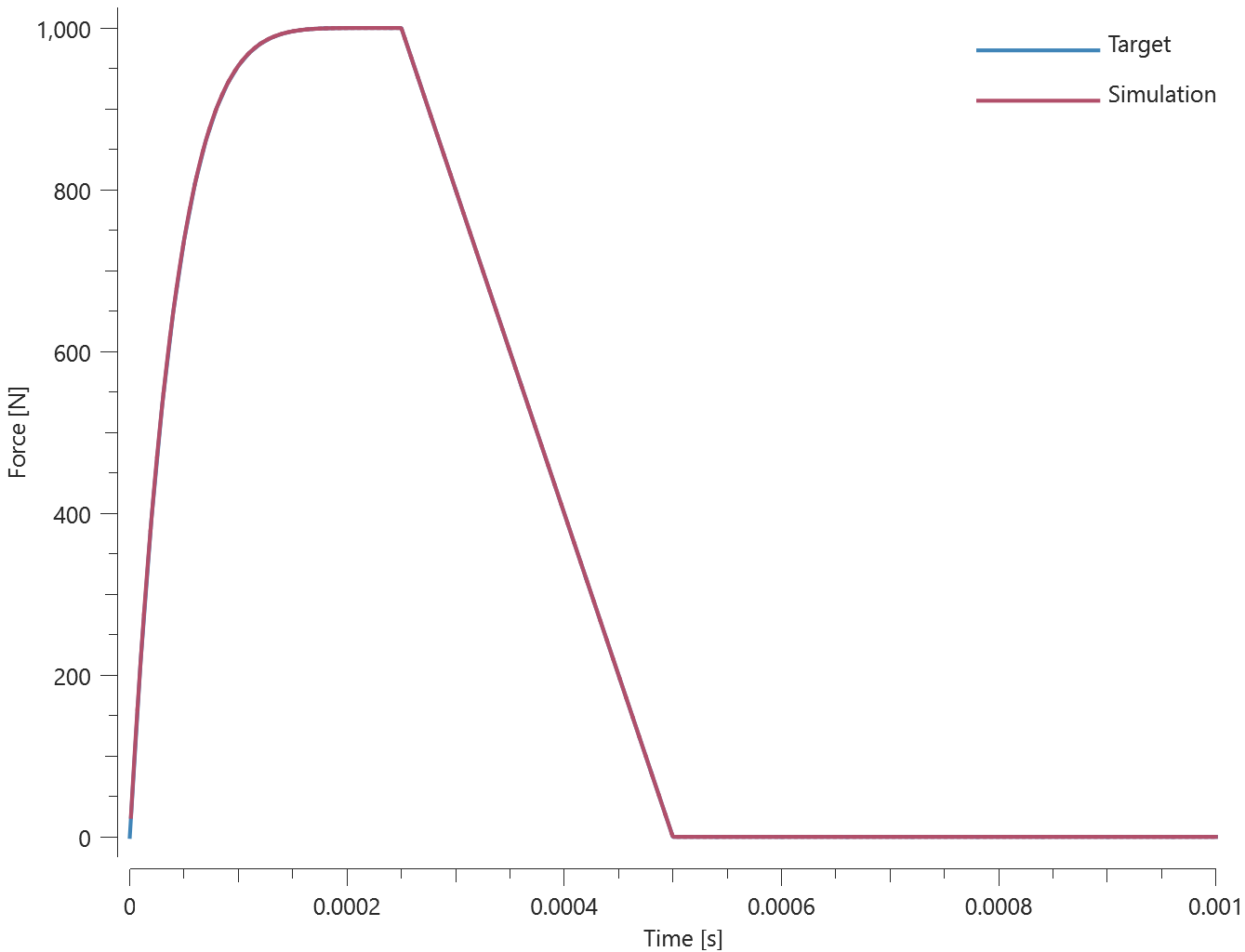

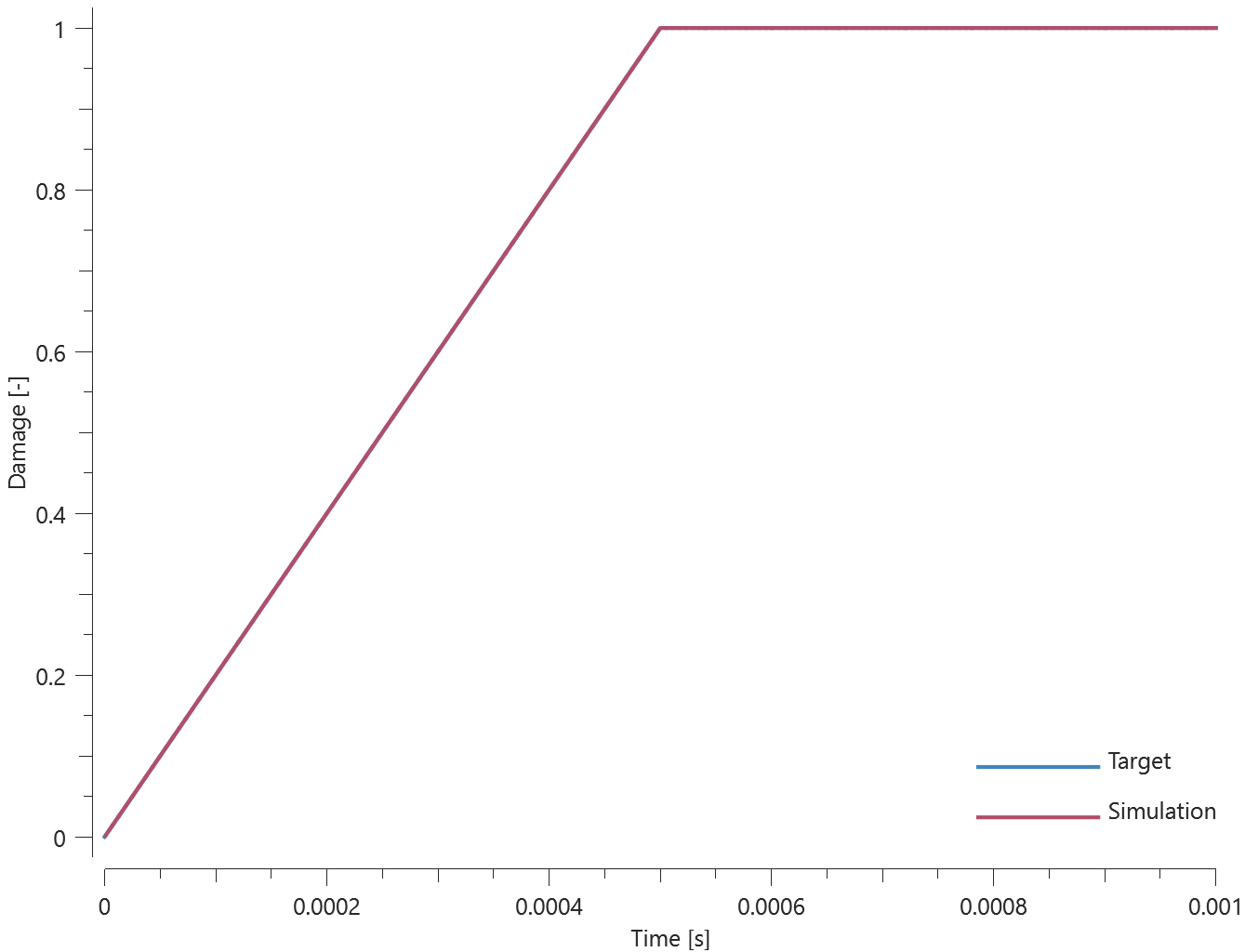

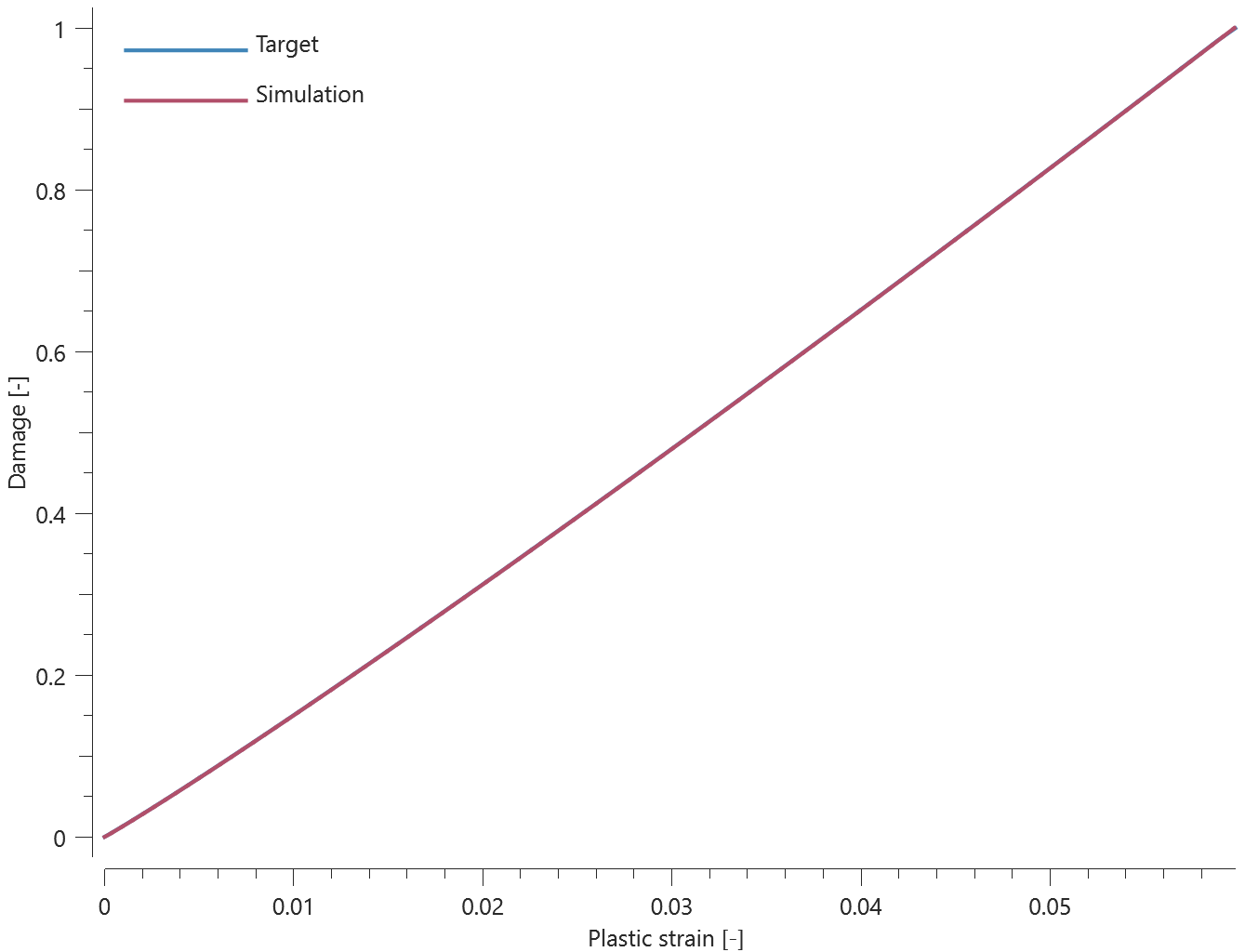

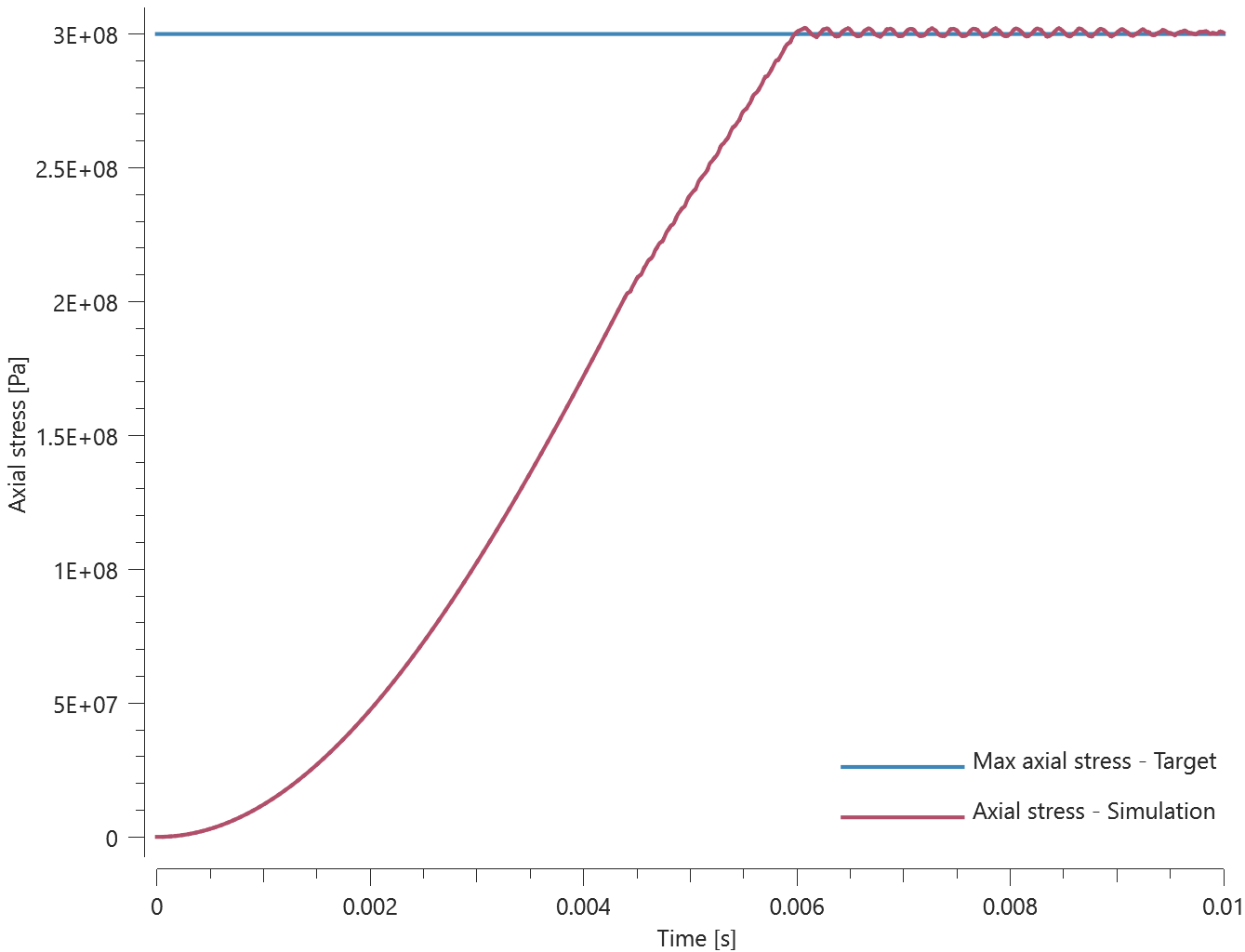

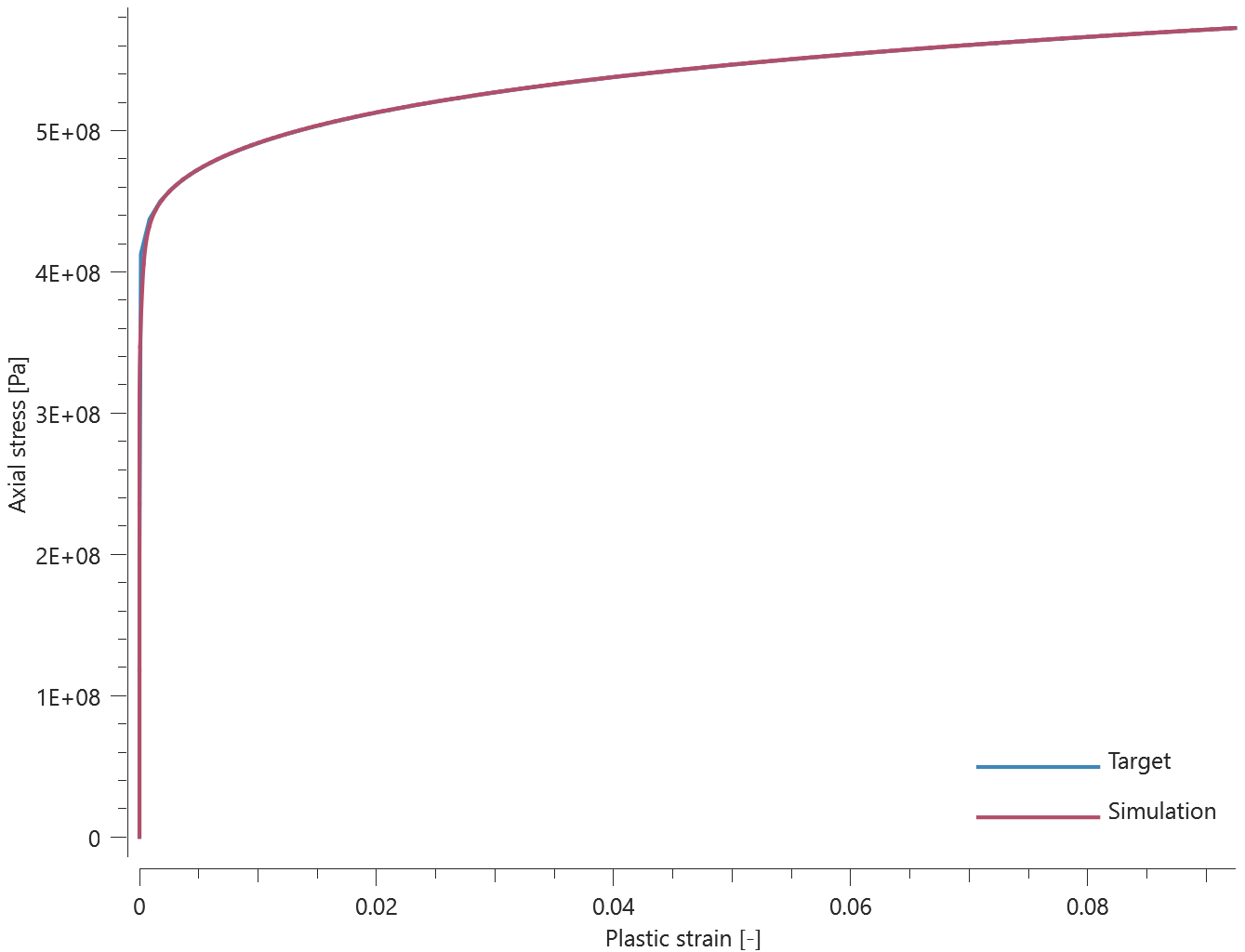

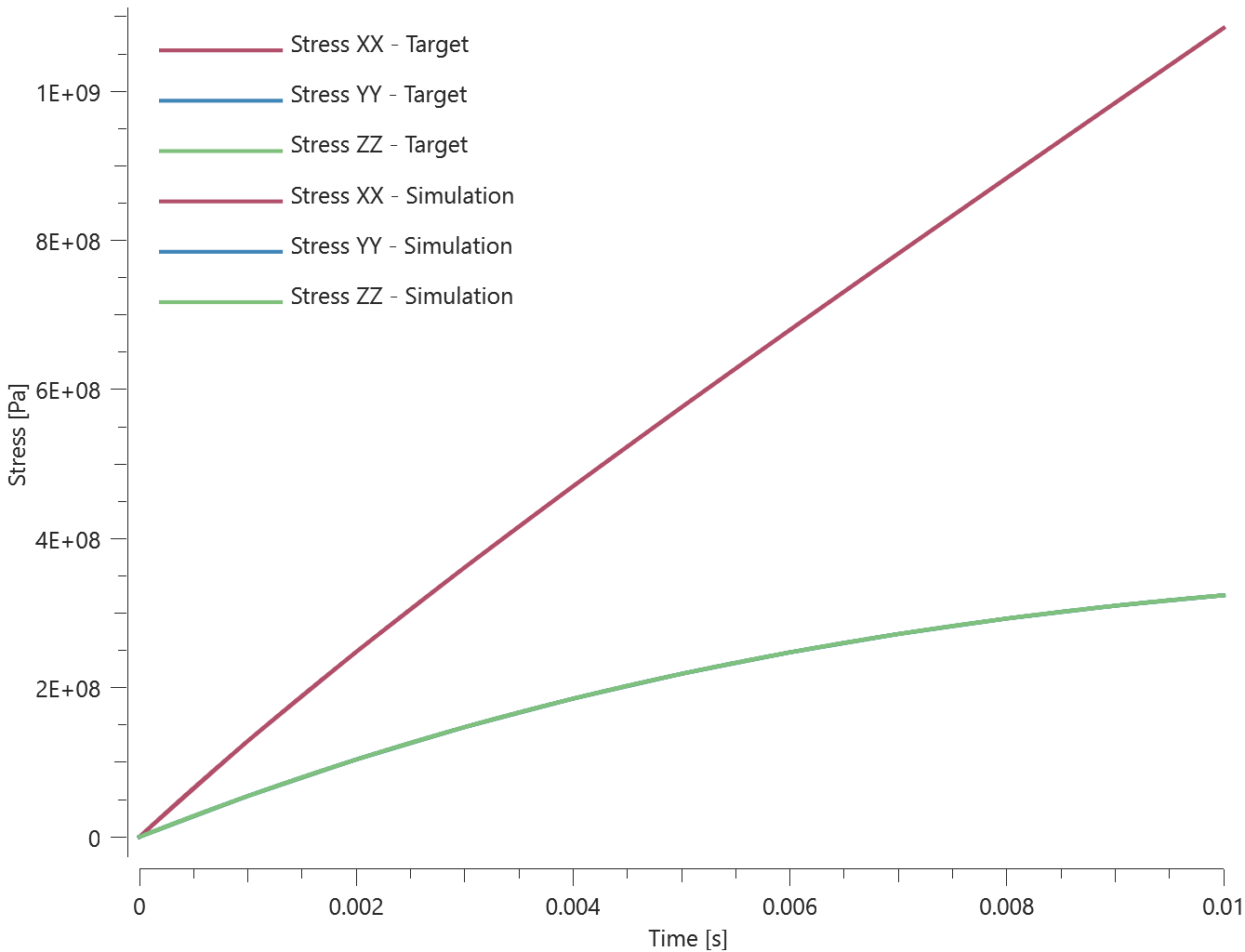

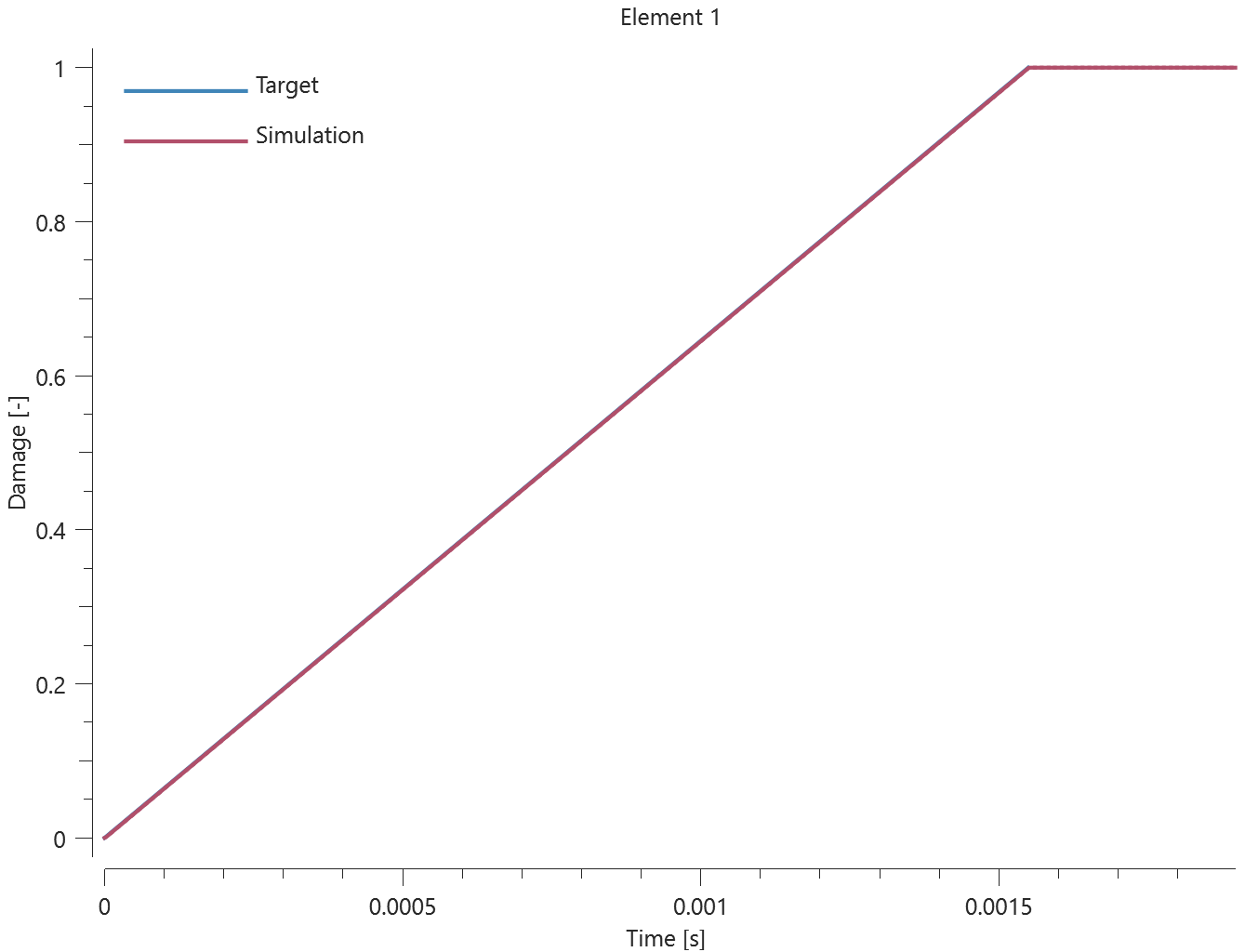

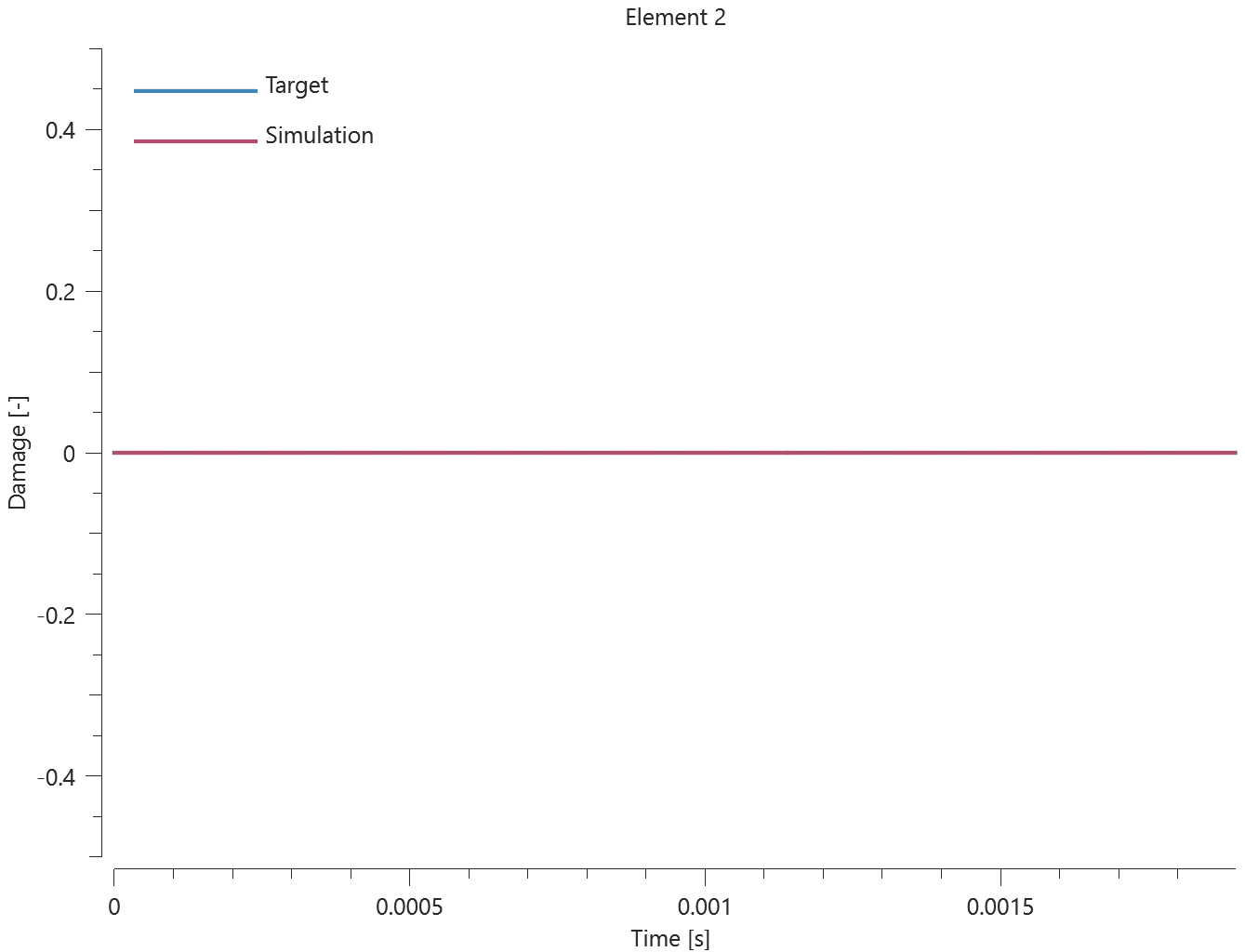

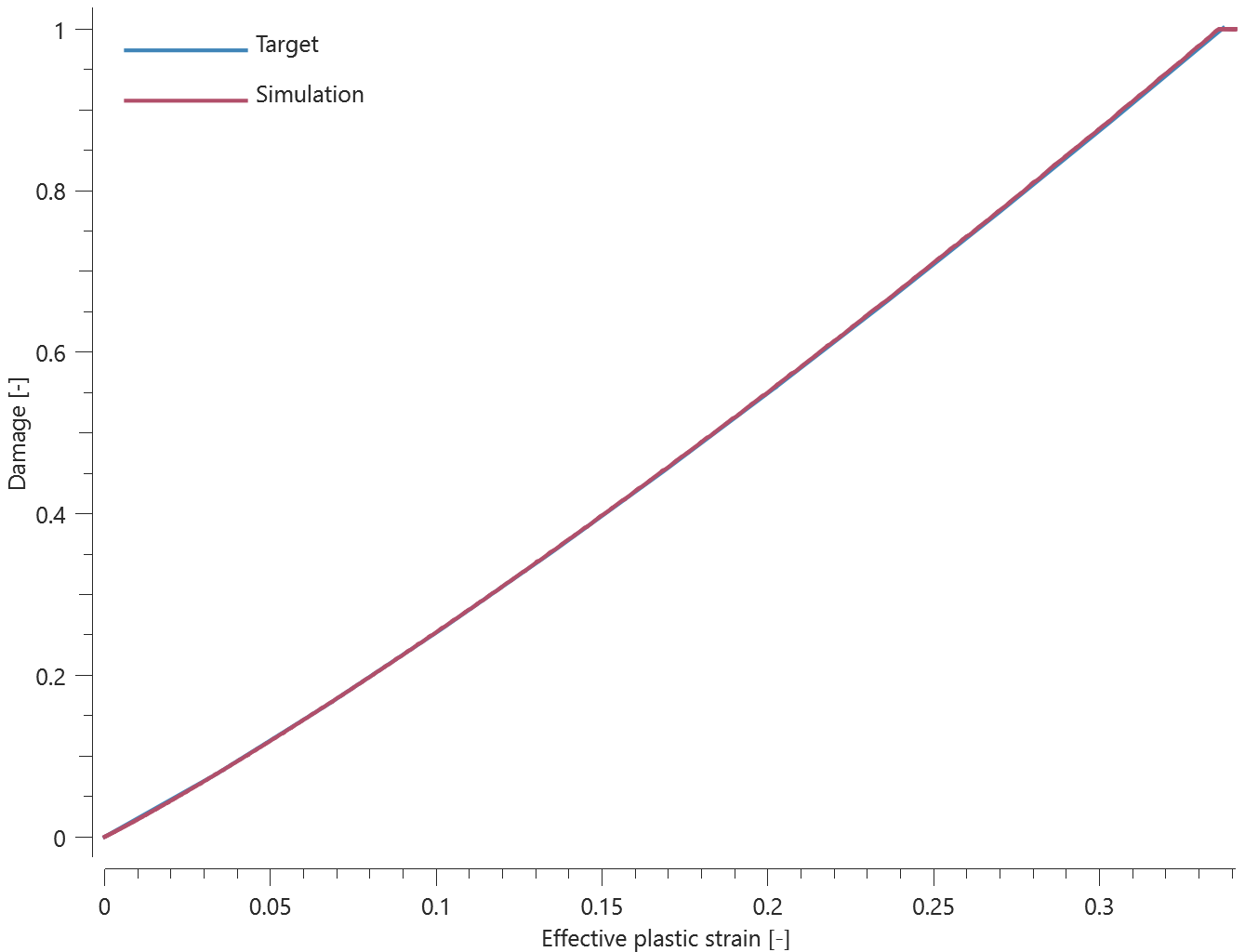

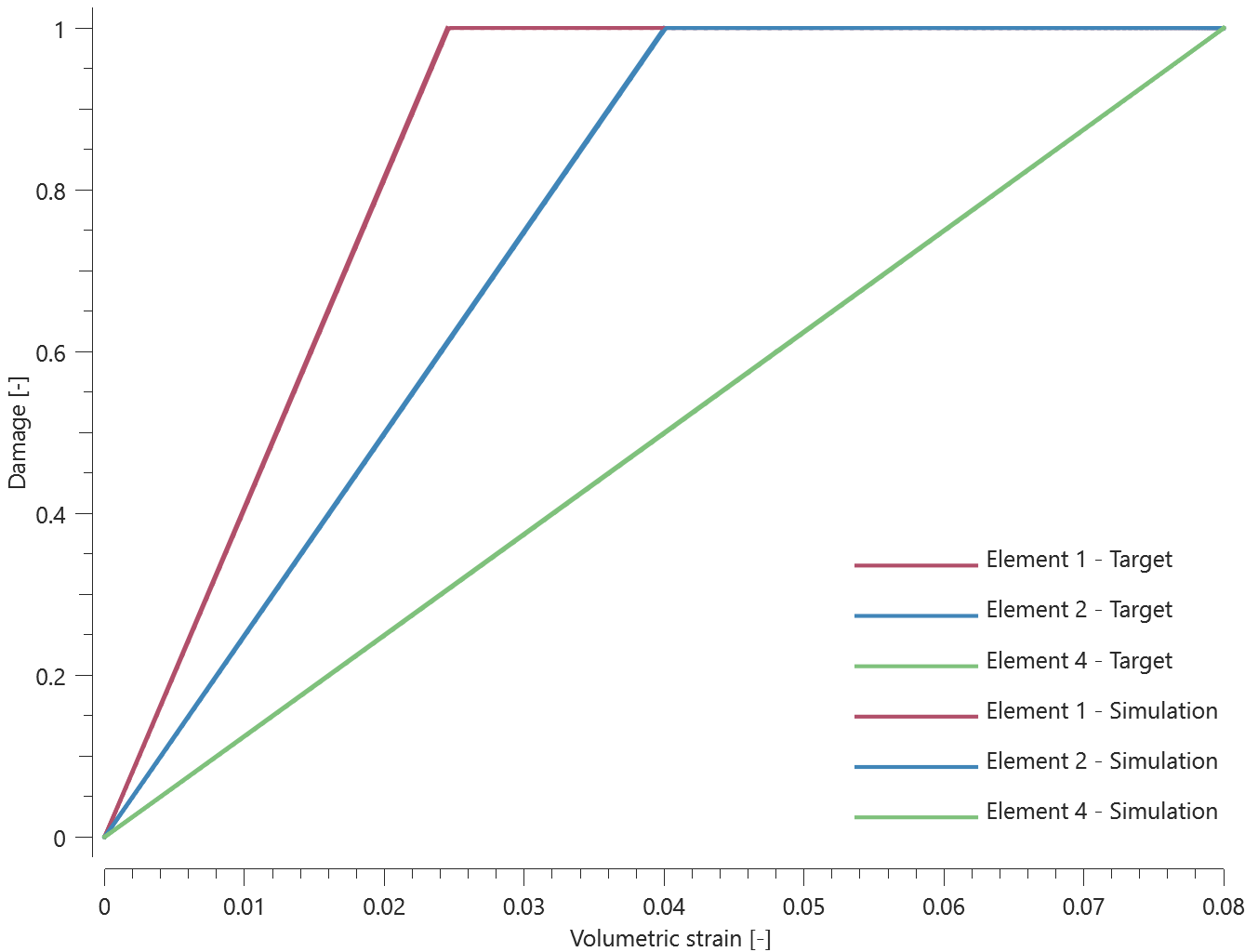

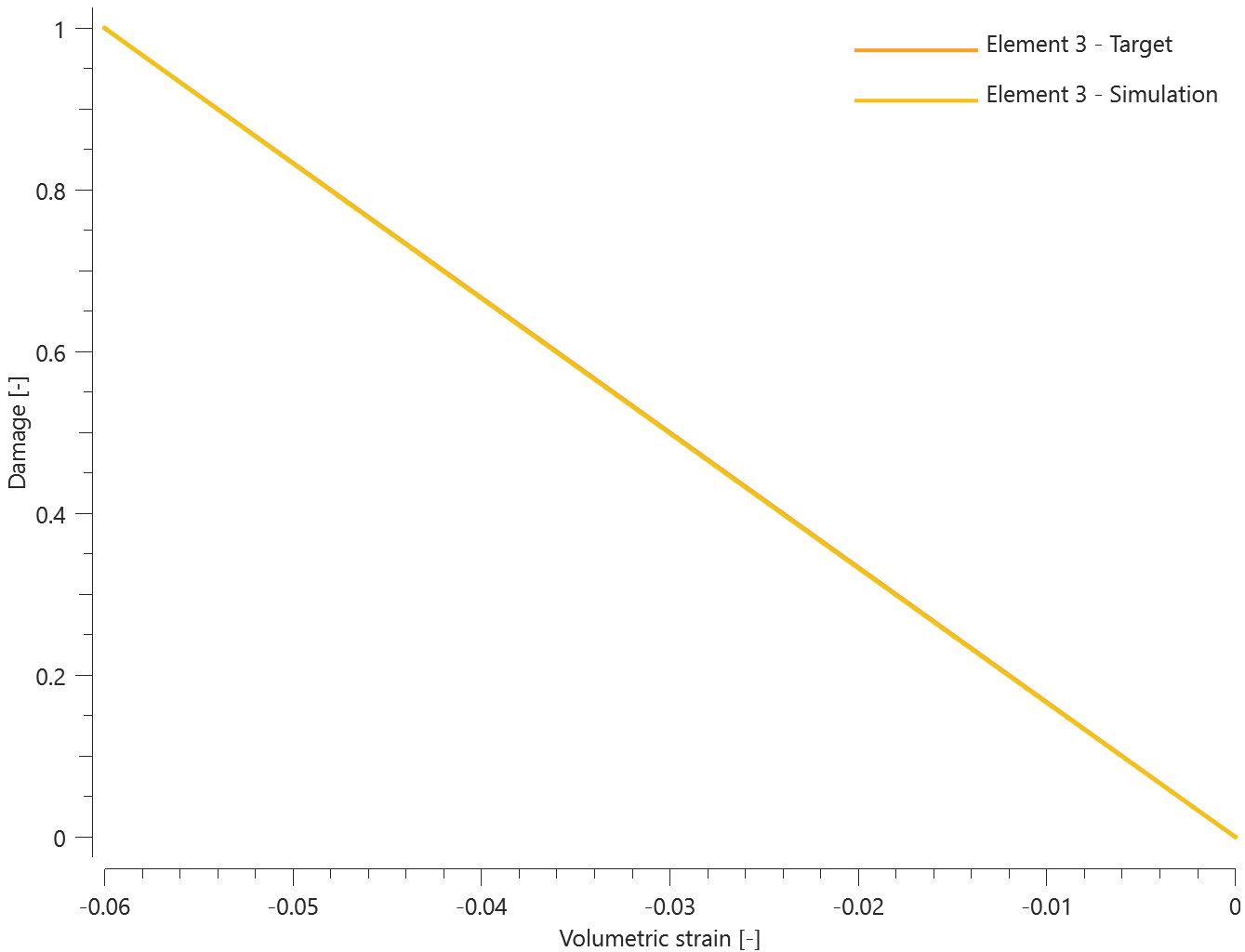

Two plates are connected to each other by a self-piercing rivet. Prescribed motions causing a state of normal stress in the rivet are imposed on the plates. Force vs. time and damage vs. time from the simulation are presented in Figure 1 and 2 together with target curves from a verification script.

Maximum and average force and damage in the rivet are checked in spr.out. The dissipated energy is also checked for version control.

Tests

This benchmark is associated with 1 tests.

Shear stress

"Optional title"

$coid$, $pid_s$, $pid_m$, $csysid$

$R$, $h$, $m$, $f_n^{max}$, $f_t^{max}$, $d_n^{max}$, $d_t^{max}$, $\xi_n$

$\xi_t$, $a_1$, $a_2$, $a_3$

This test is similair to the test "*CONNECTOR_SPR - Normal stress". In the current test, the rivet is subjected to a state of shear stress instead.

Tested parameters:  , h,

, h,  ,

,  ,

,  ,

,  ,

,  and

and  .

.

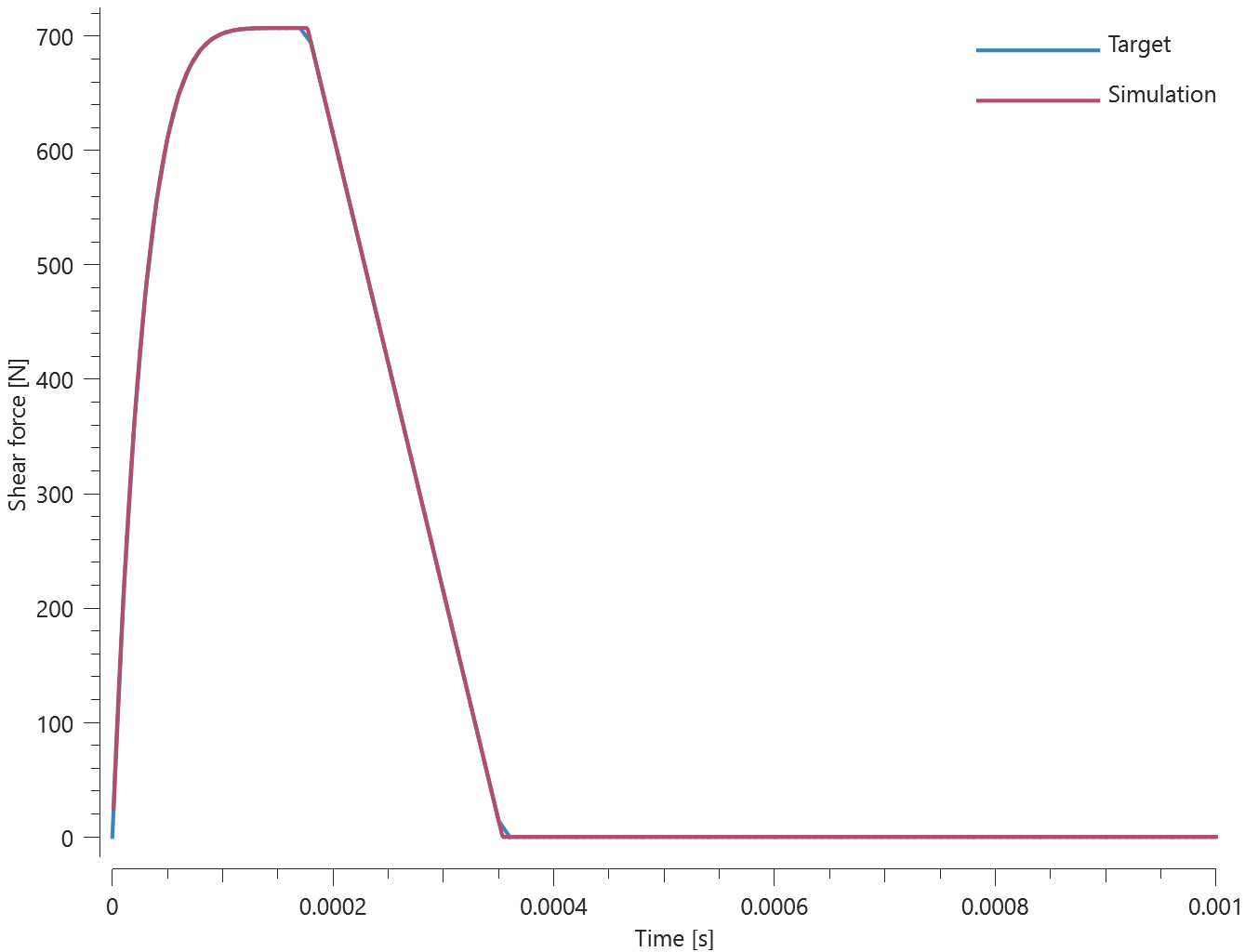

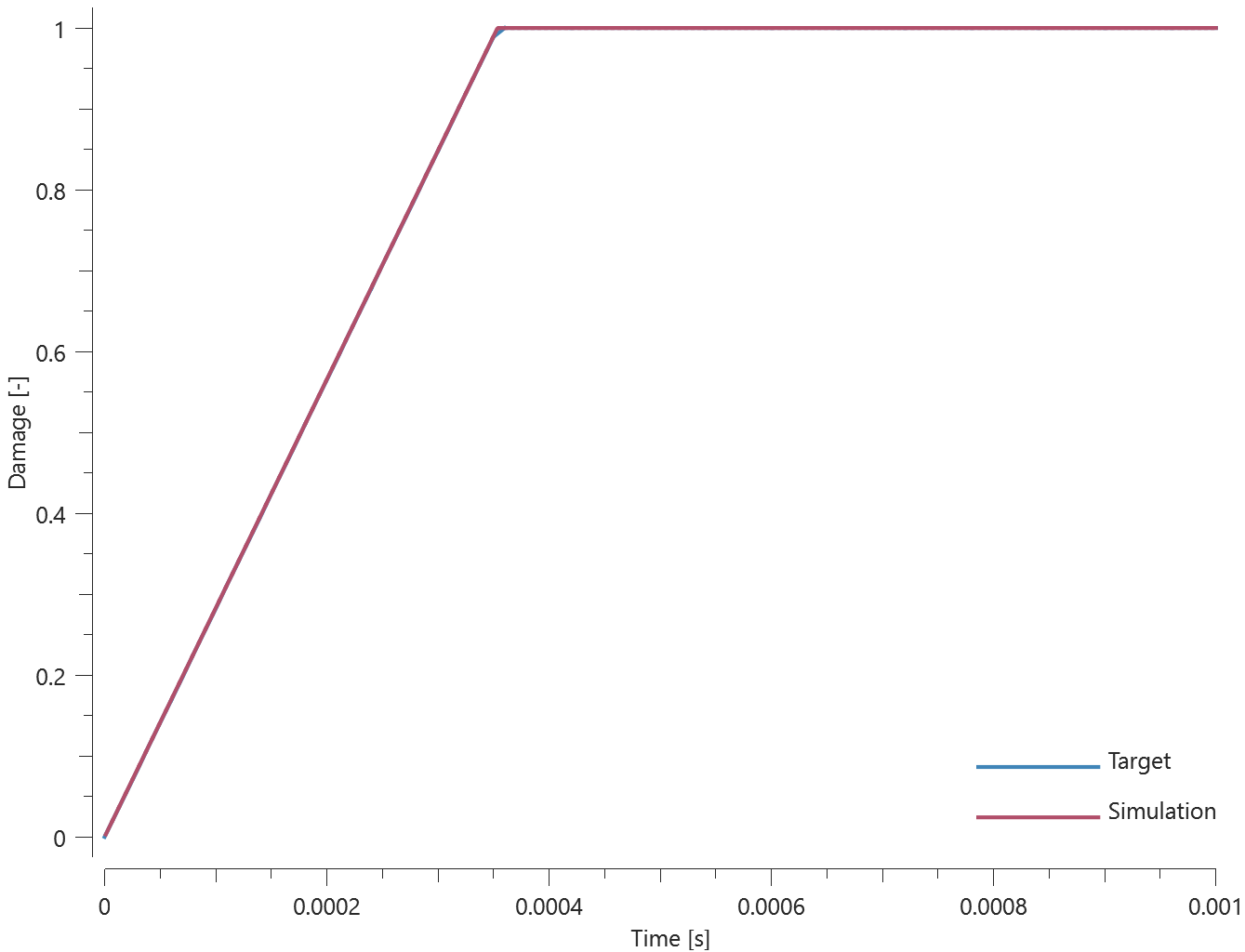

Force vs. time and damage vs. time from the simulation are presented in Figure 1 and 2 together with target curves from a verification script.

Maximum and average force and damage in the rivet are checked in spr.out. The dissipated energy is also checked for version control.

Tests

This benchmark is associated with 1 tests.

*CONNECTOR_SPRING

Intrinsic operations (dnorm, dnorm_min, dnorm_max)

$coid$, $N_1$, $N_2$, $m$, $k$, $\xi$, $F_{fail}$, $direc$, $l_{0}$

Intrinsic operations (dnorm, dnorm_min, dnorm_max) are verified in this test.

Tested parameters: coid, /mathmode.png) ,

, /mathmode01.png) ,

, /mathmode02.png) ,

, /mathmode03.png) .

.

The model contains three springs with different functions defining elastic force versus elongation. The springs are clamped at one end and are given a prescribed displacement at the other end.

The springs have the following properties:

Spring 1:

|-/\/\/\/\-O /mathmode04.png) prescribed displacement

prescribed displacement

/mathmode05.png)

/eq_1.png)

Spring 2:

|-/\/\/\/\-O /mathmode06.png) prescribed displacement

prescribed displacement

/mathmode07.png)

/eq_101.png)

Spring 3:

|-/\/\/\/\-O /mathmode08.png) prescribed displacement

prescribed displacement

/mathmode09.png)

/eq_102.png)

The prescribed displacement of the free nodes is presented in Table 1.

/longtable.png)

Force vs. time for the springs is presented in Figure 1.

/connector_spring_intrinsic_operations.png)

The spring forces are checked at termination.

Tests

This benchmark is associated with 1 tests.

Linear springs

$coid$, $N_1$, $N_2$, $m$, $k$, $\xi$, $F_{fail}$, $direc$, $l_{0}$

Linear stiffness and damping in *CONNECTOR_SPRING are verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  and

and  .

.

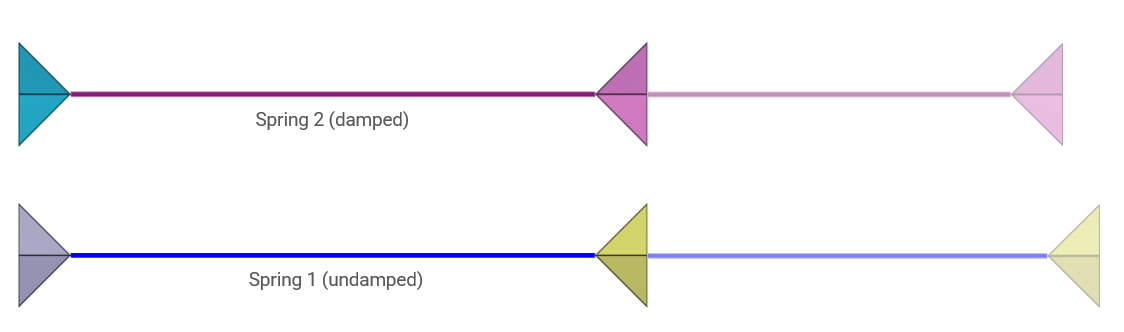

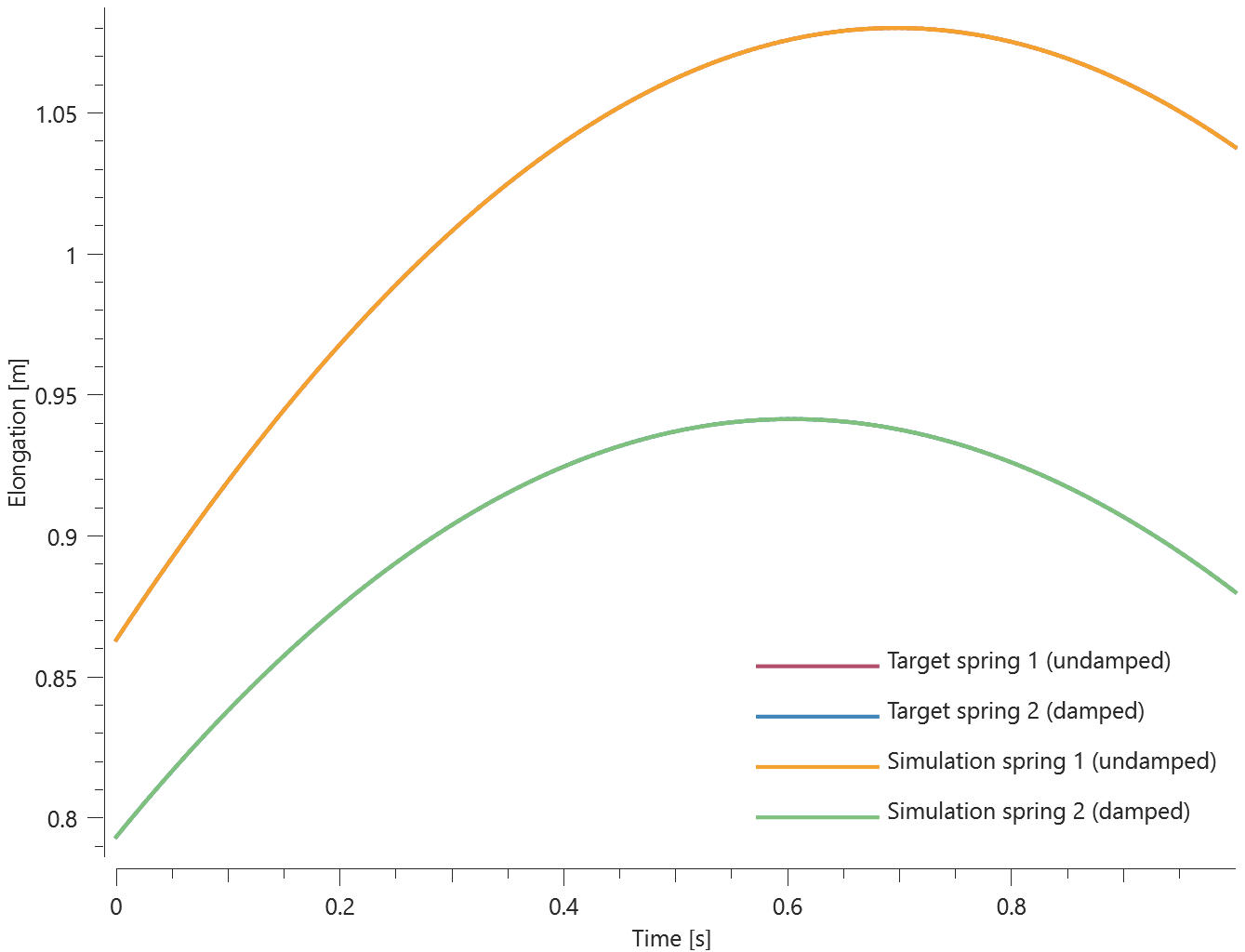

The model contains two springs with constant stiffness  and mass

and mass  . The node mass is

. The node mass is  . The springs are clamped at one end and are given an initial velocity

. The springs are clamped at one end and are given an initial velocity  at the other end. Spring 1 is undamped and spring 2 is damped. The absolute damping

at the other end. Spring 1 is undamped and spring 2 is damped. The absolute damping  is defined as a fraction

is defined as a fraction  of the critical damping of the springs highest eigenfrequency

of the critical damping of the springs highest eigenfrequency  .

.

Analytical displacement, spring 1 (undamped):

Displacement at time  , spring 1:

, spring 1:

Analytical displacement, spring 2 (damped):

Displacement at time  , spring 2:

, spring 2:

The spring displacements are checked at termination.

Tests

This benchmark is associated with 1 tests.

Nonlinear springs

$coid$, $N_1$, $N_2$, $m$, $k$, $\xi$, $F_{fail}$, $direc$, $l_{0}$

Non-linear stiffness and damping in *CONNECTOR_SPRING are verified in this test.

Tested parameters:  ,

,  ,

,  ,

,  and

and  .

.

The model contains two springs with non-linear force-displacement and damping properties. The springs are clamped at one end and given a prescribed velocity  at the other end. Velocity and displacement at a given moment

at the other end. Velocity and displacement at a given moment  takes trivial values.

takes trivial values.

The force at  , spring 1:

, spring 1:

The force at  , spring 2:

, spring 2:

The spring forces are checked at termination.

Tests

This benchmark is associated with 1 tests.

State file output

$coid$, $N_1$, $N_2$, $m$, $k$, $\xi$, $F_{fail}$, $direc$, $l_{0}$

This model tests the unloaded spring length, parameter  in *CONNECTOR_SPRING , which is used when importing results in subsequent simulations.

The test consists of 2 steps. The *CONNECTOR_SPRING command with parameter

in *CONNECTOR_SPRING , which is used when importing results in subsequent simulations.

The test consists of 2 steps. The *CONNECTOR_SPRING command with parameter  is automatically generated by the solver engine in the state file impetus_state_spring1.k at termination.

is automatically generated by the solver engine in the state file impetus_state_spring1.k at termination.

The model contains two springs with constant stiffness  and mass

and mass  . The node mass is

. The node mass is  .

The springs are clamped at one end and are given an initial velocity

.

The springs are clamped at one end and are given an initial velocity  at the other end.

Spring 1 is undamped and spring 2 is damped.

The absolute damping

at the other end.

Spring 1 is undamped and spring 2 is damped.

The absolute damping  is defined as a fraction

is defined as a fraction  of the critical damping of the springs highest eigenfrequency

of the critical damping of the springs highest eigenfrequency  .

.

Analytical displacement, spring 1 (undamped):

Displacement at time  , spring 1:

, spring 1:

Analytical displacement, spring 2 (damped):

Displacement at time  , spring 2:

, spring 2:

The test setup can be seen in Figure 1.

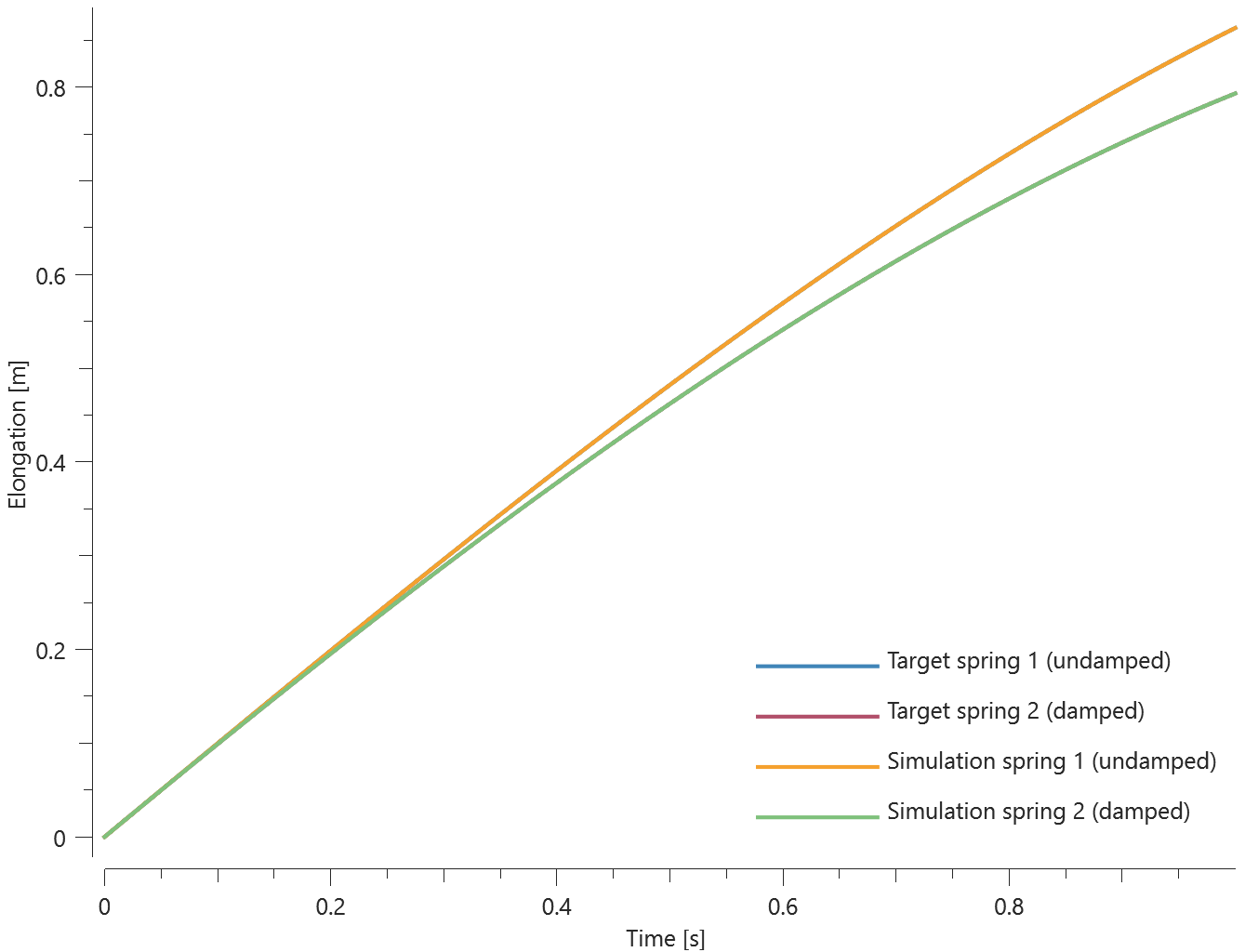

Spring elongation vs. time for step 1 can be seen in Figure 2 together with a target curve from a verification script.

Spring elongation vs. time for step 2 can be seen in Figure 3 together with a target curve from a verification script.

The spring displacements are checked for version control.

Tests

This benchmark is associated with 2 tests.

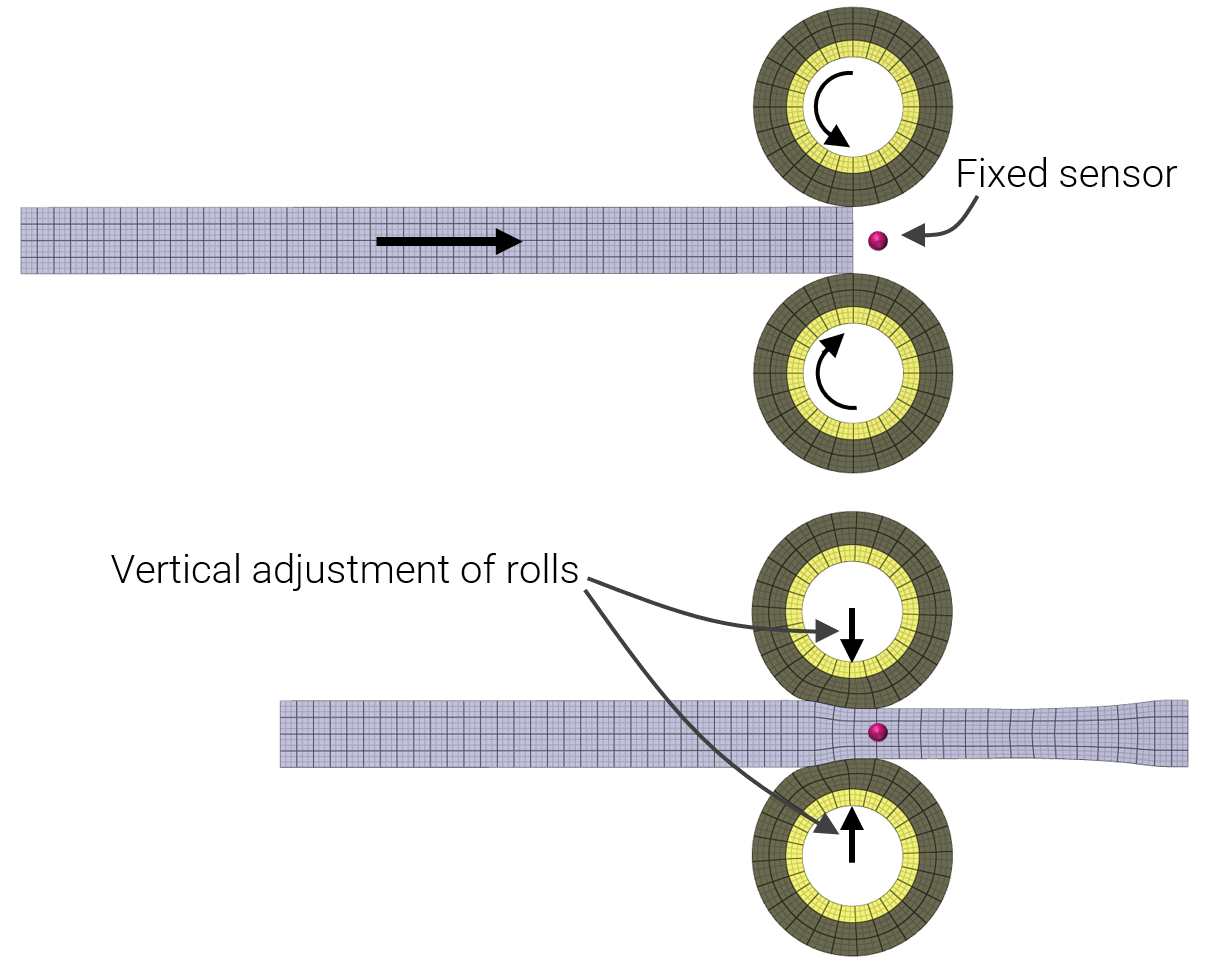

*CONTACT

Contact and friction forces between all element types

"Optional title"

$coid$, $accuracy_level$, $accuracy_edge$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $\mu$, $pfac$, $t_{beg}$, $t_{end}$

$merge$, $\xi$, $gid_0$, $gid_1$, $\delta_0^{offset}$, $\delta_0^{max}$, $\delta^{edge}$

$fid_{wear1}$, $fid_{wear2}$, $fid_{thermal}$, $\alpha_{edge}$, $one way$, $no_internal$

Contact and friction forces between all element types are verified in this test.

Tested parameters:  (automatic calculation of penalty stiffness) and

(automatic calculation of penalty stiffness) and  .

.

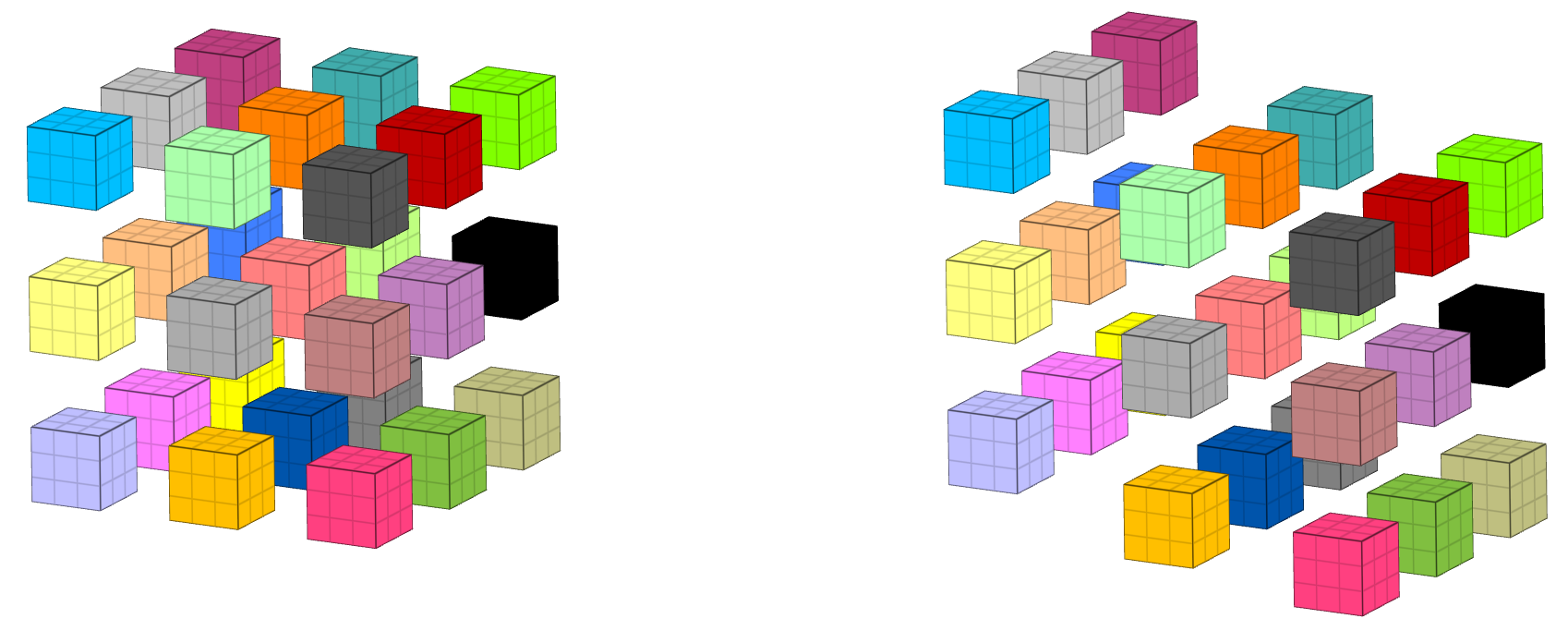

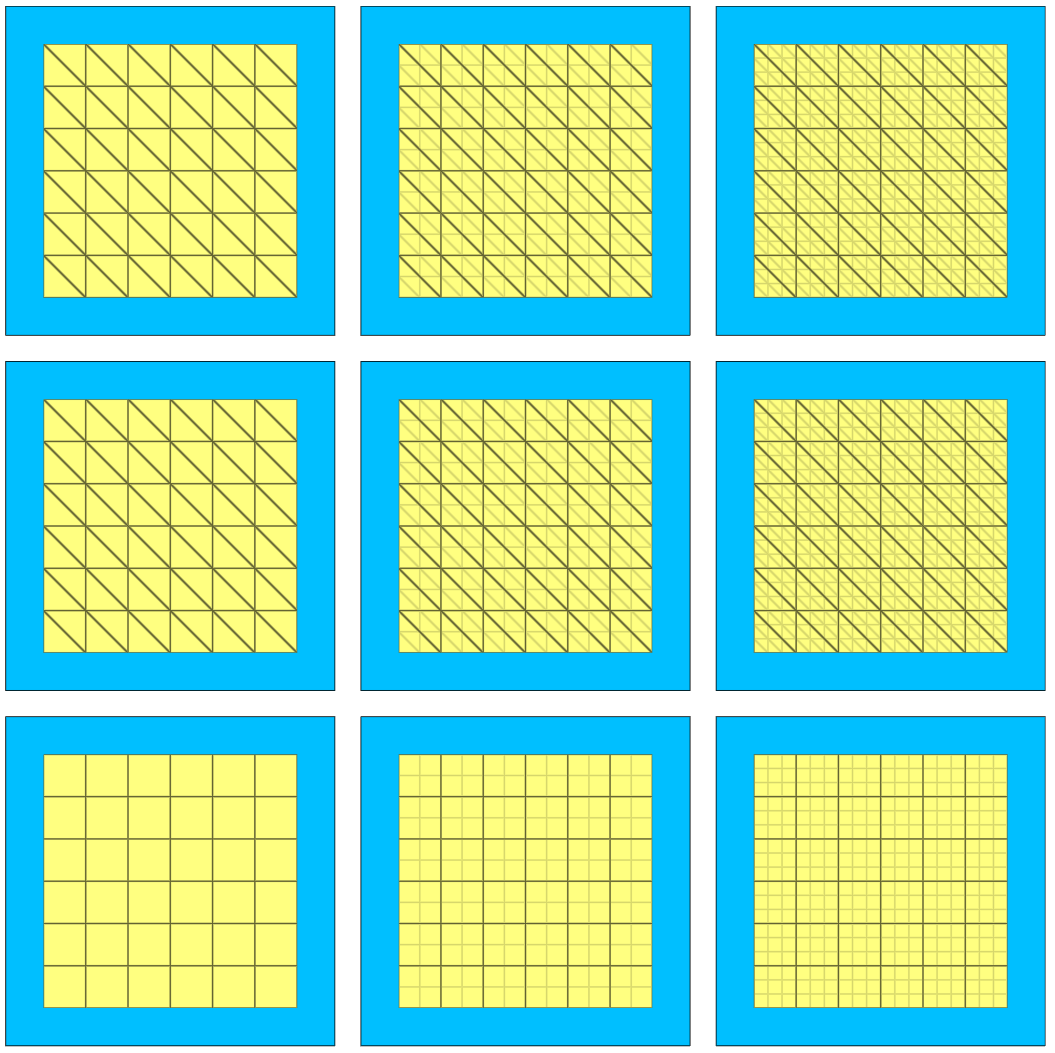

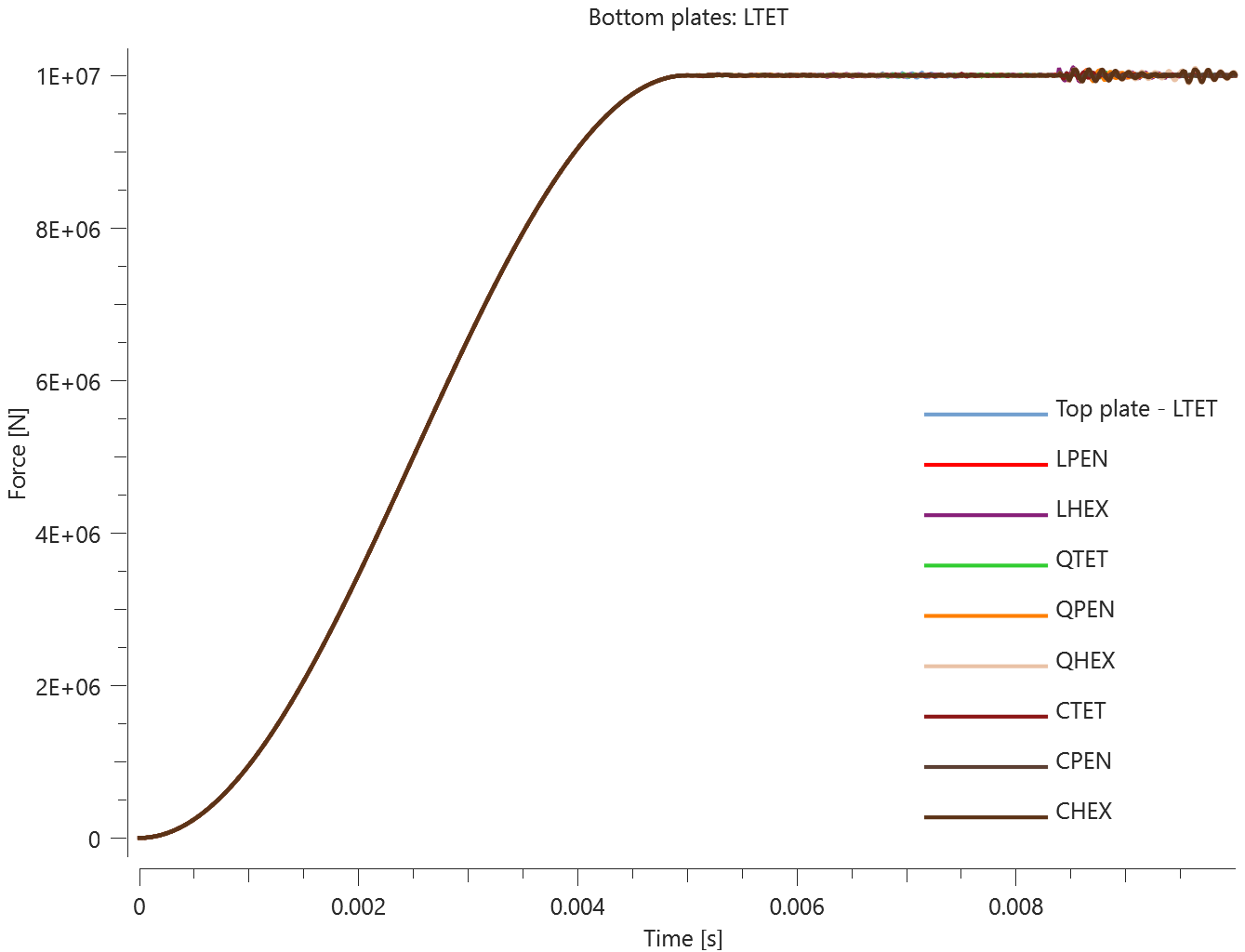

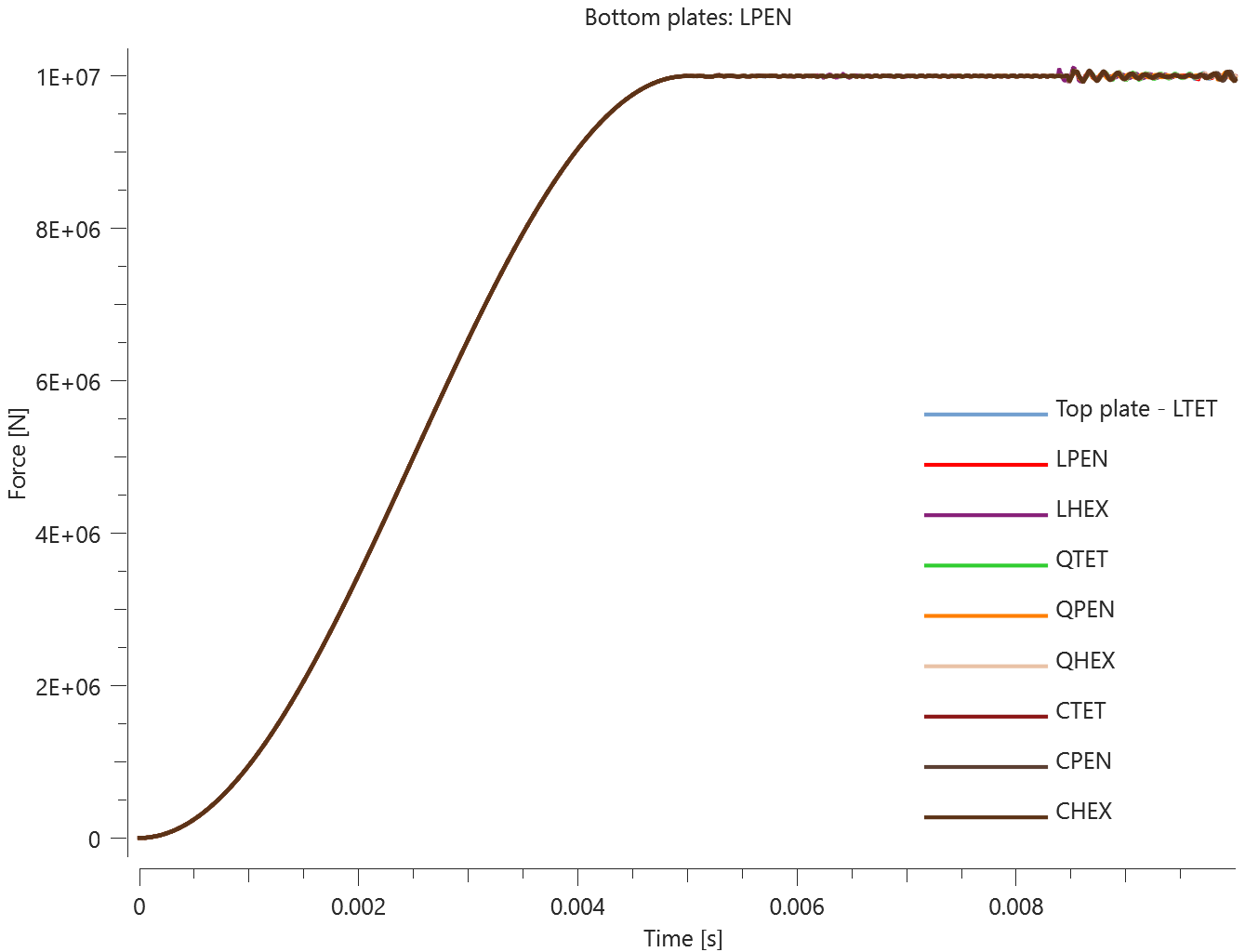

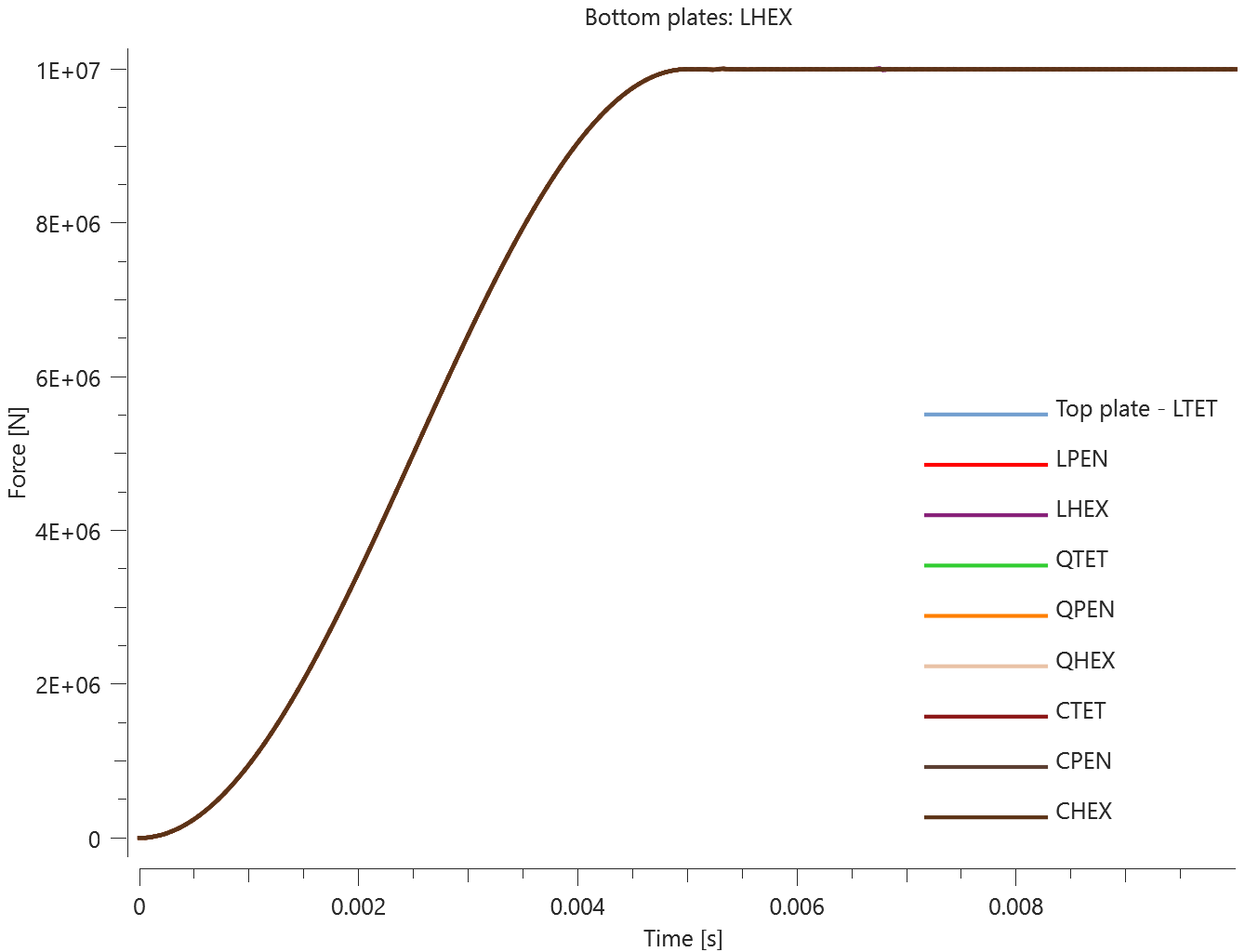

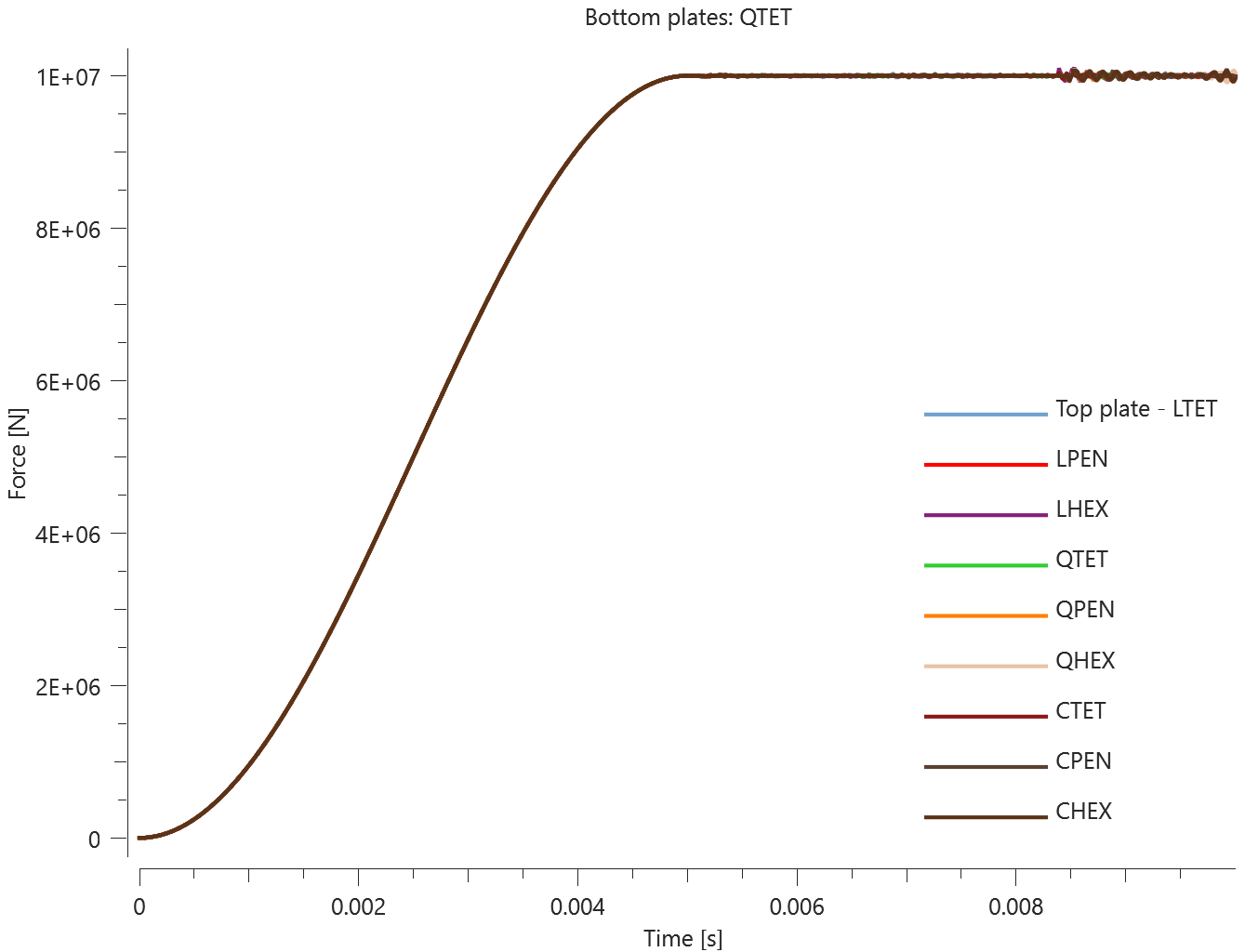

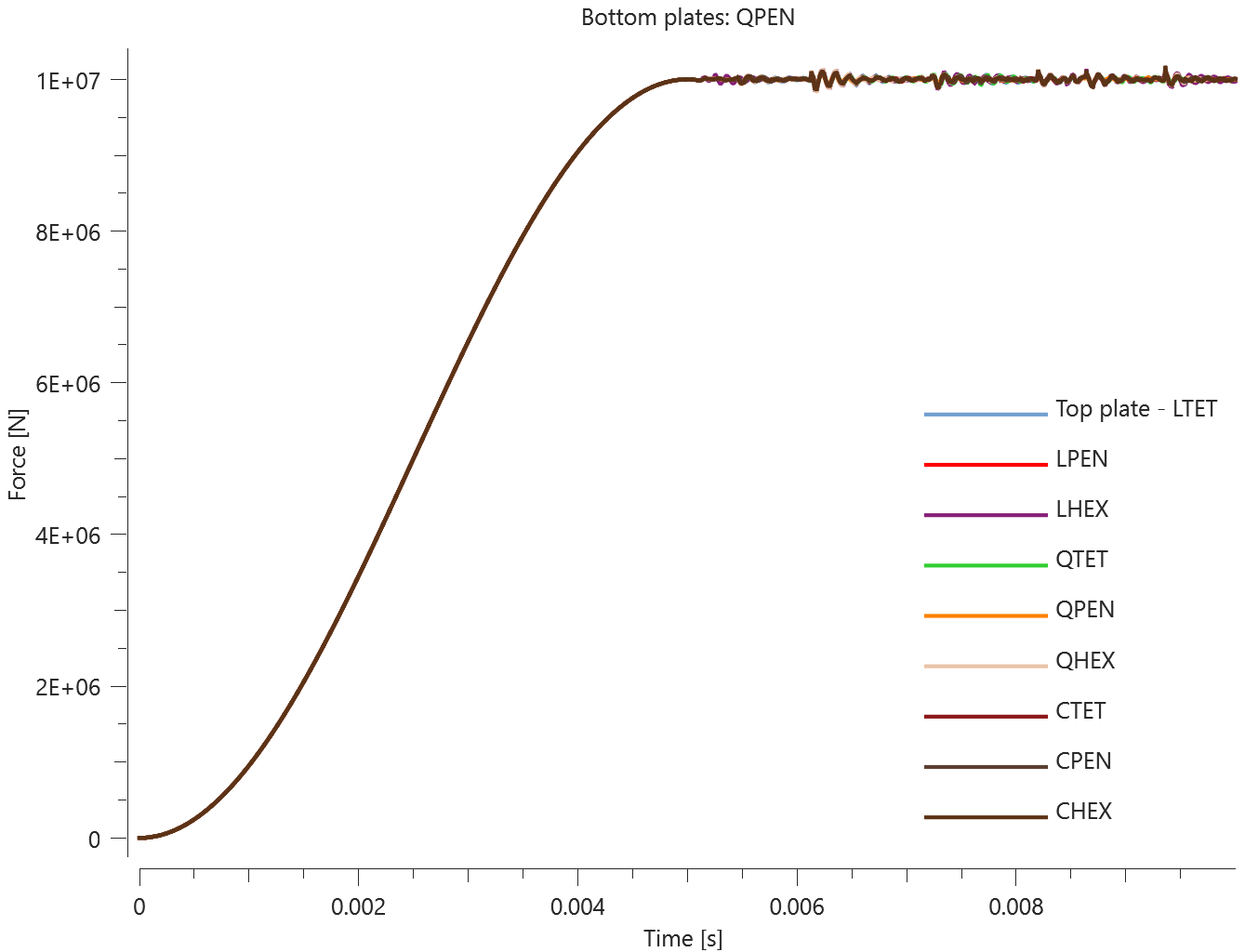

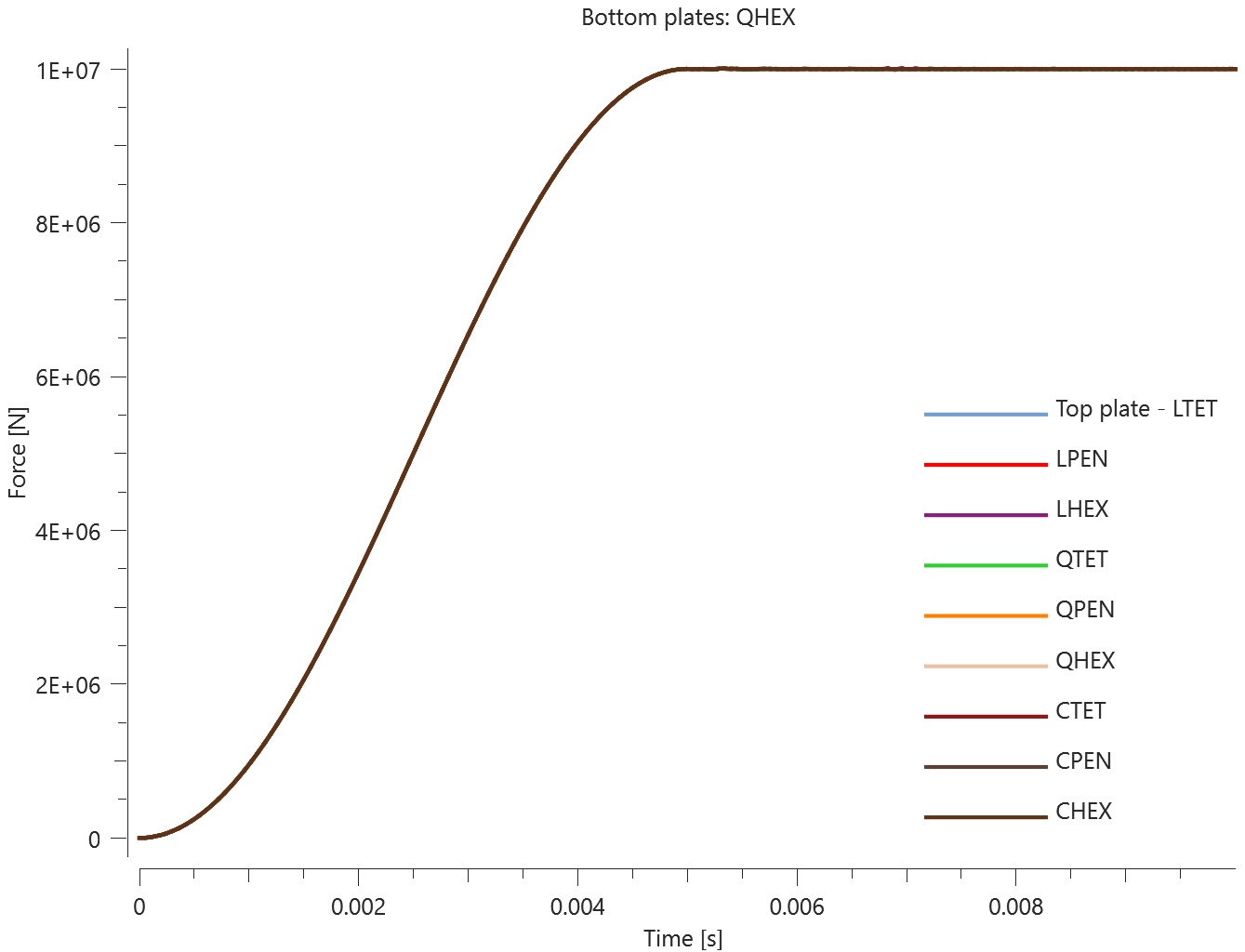

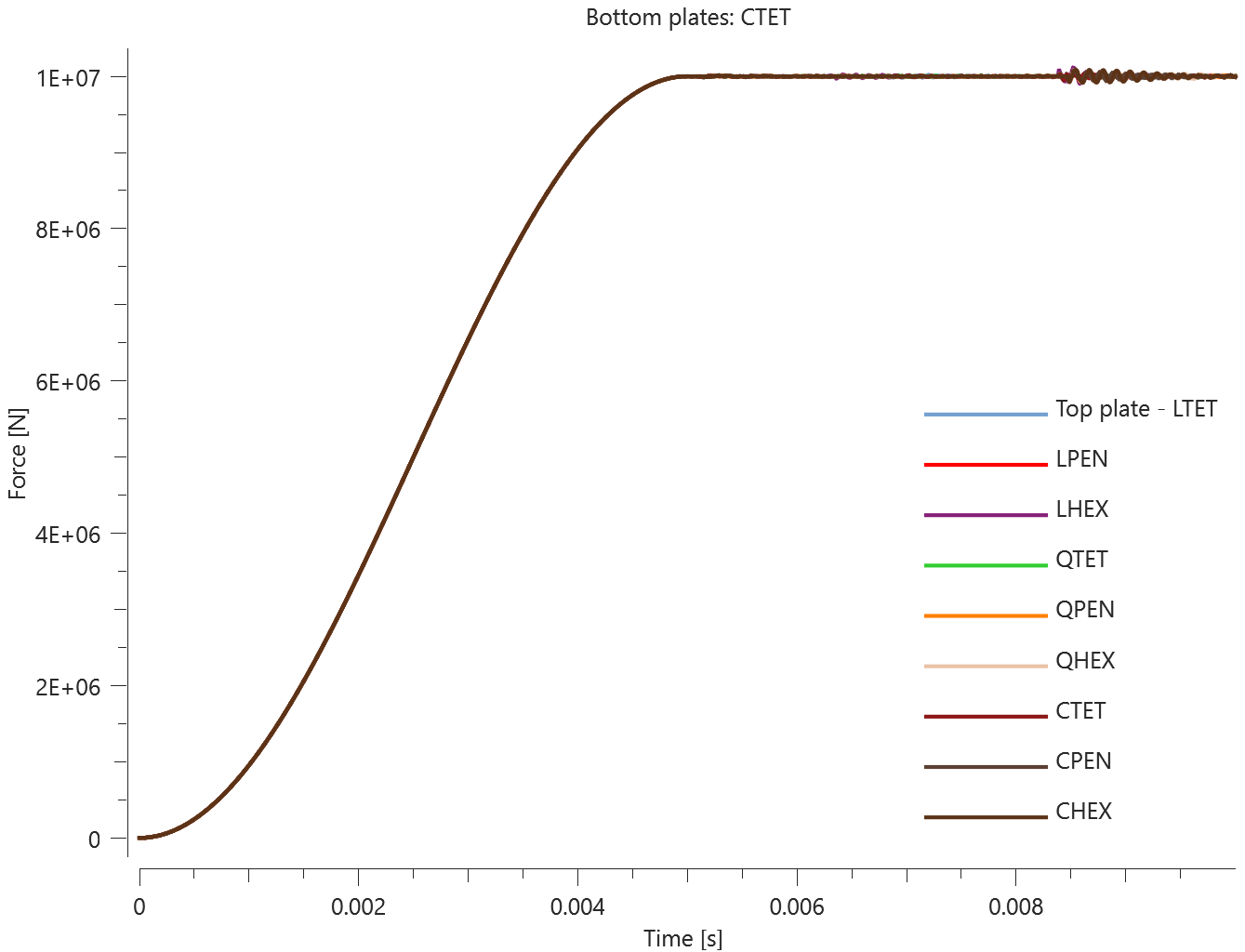

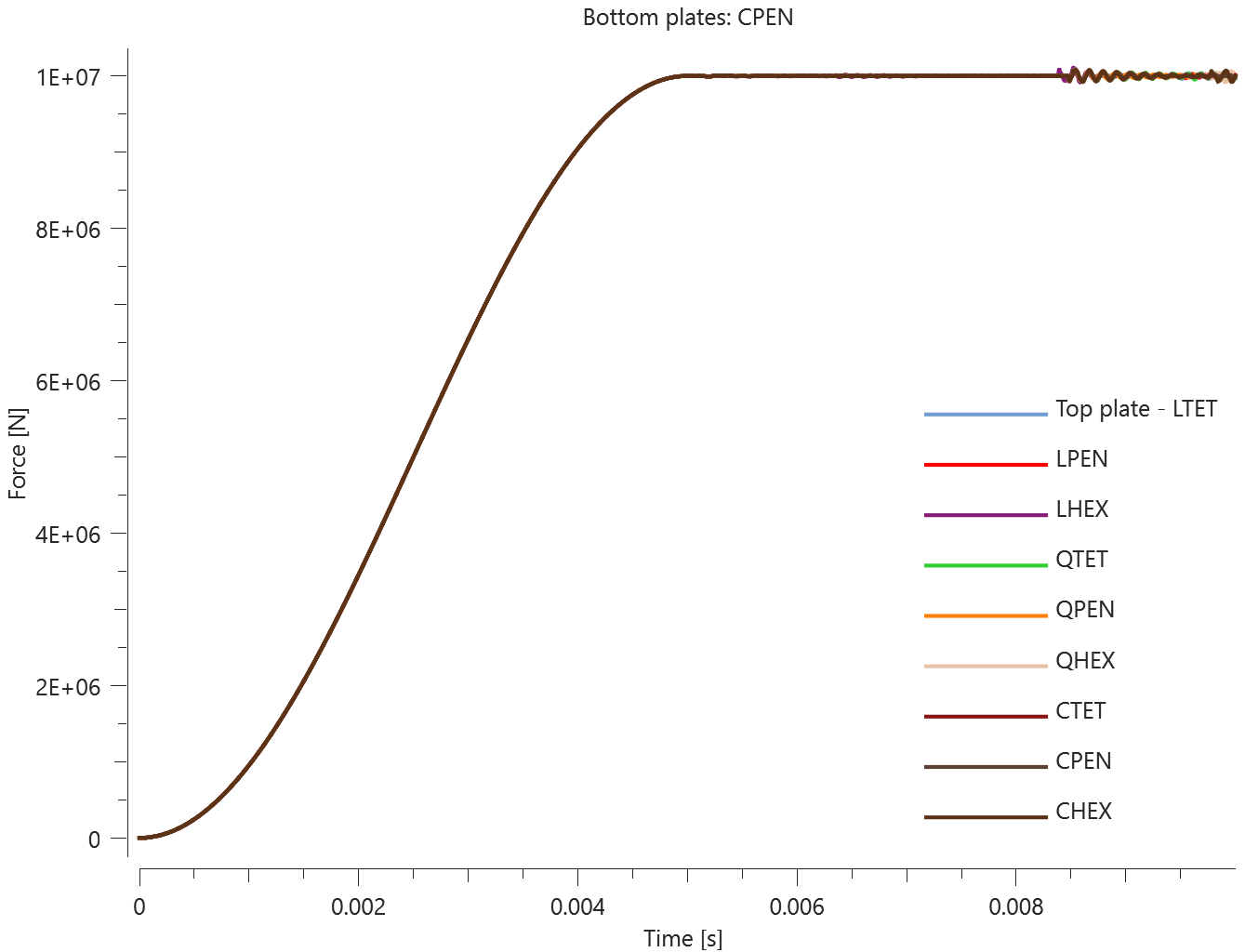

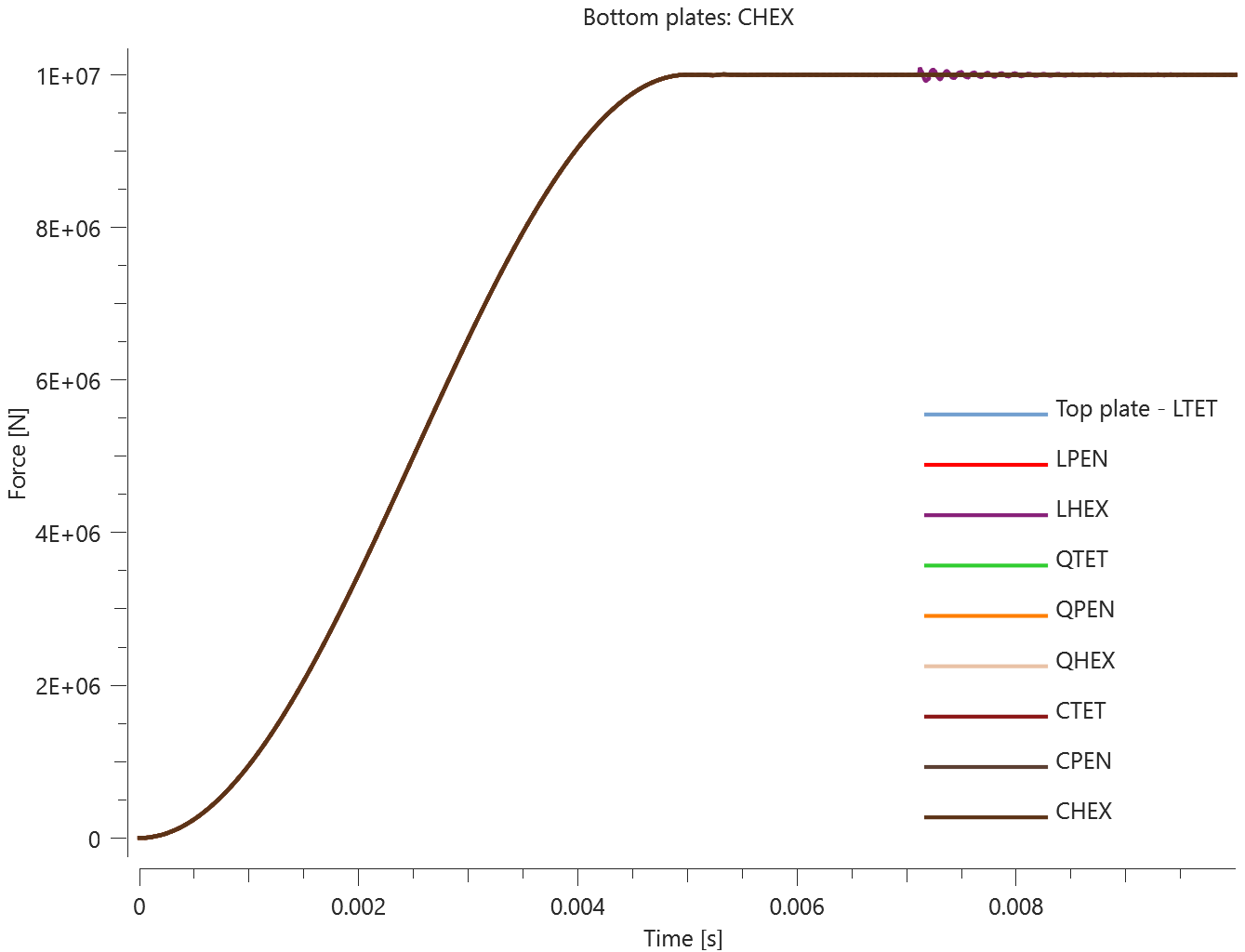

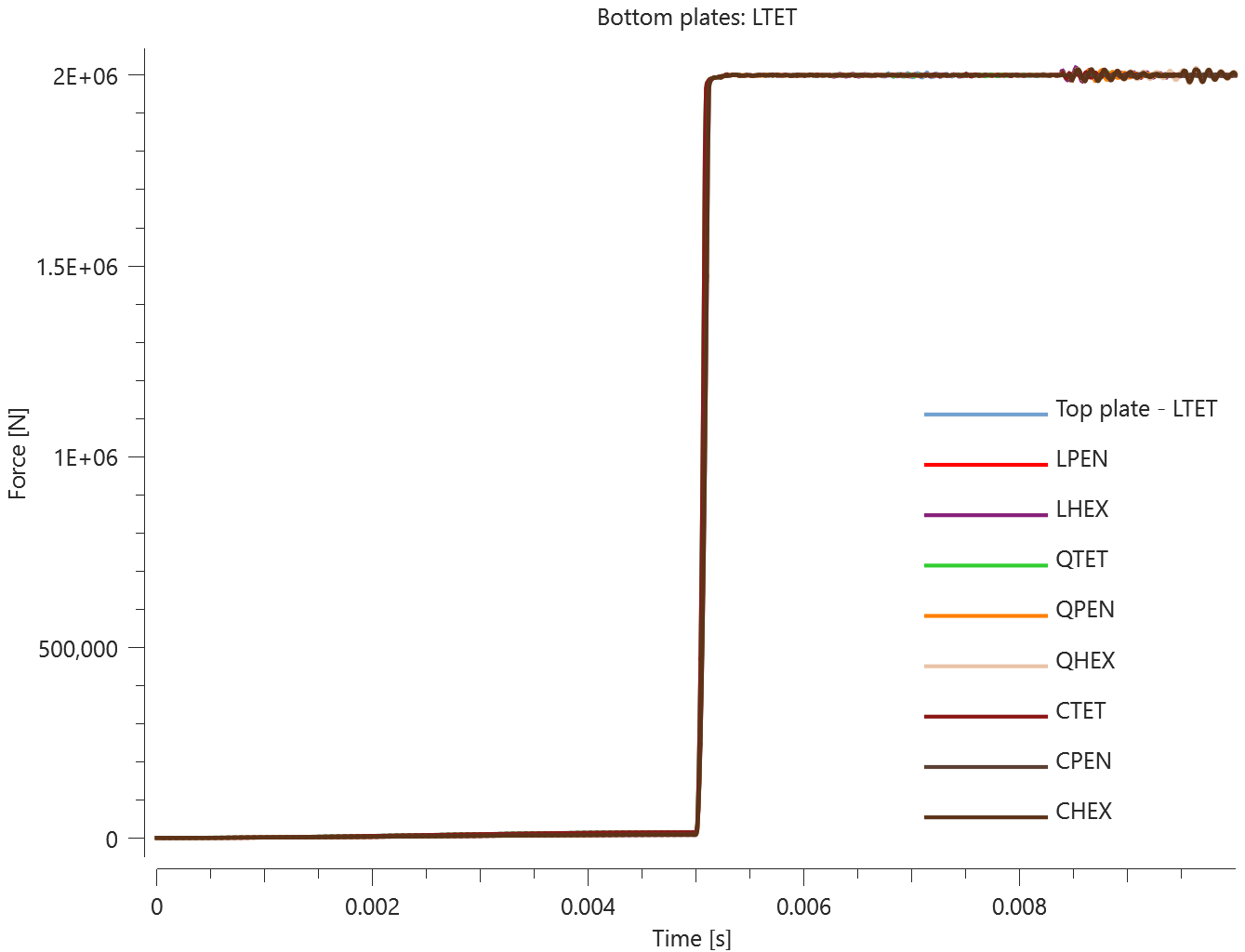

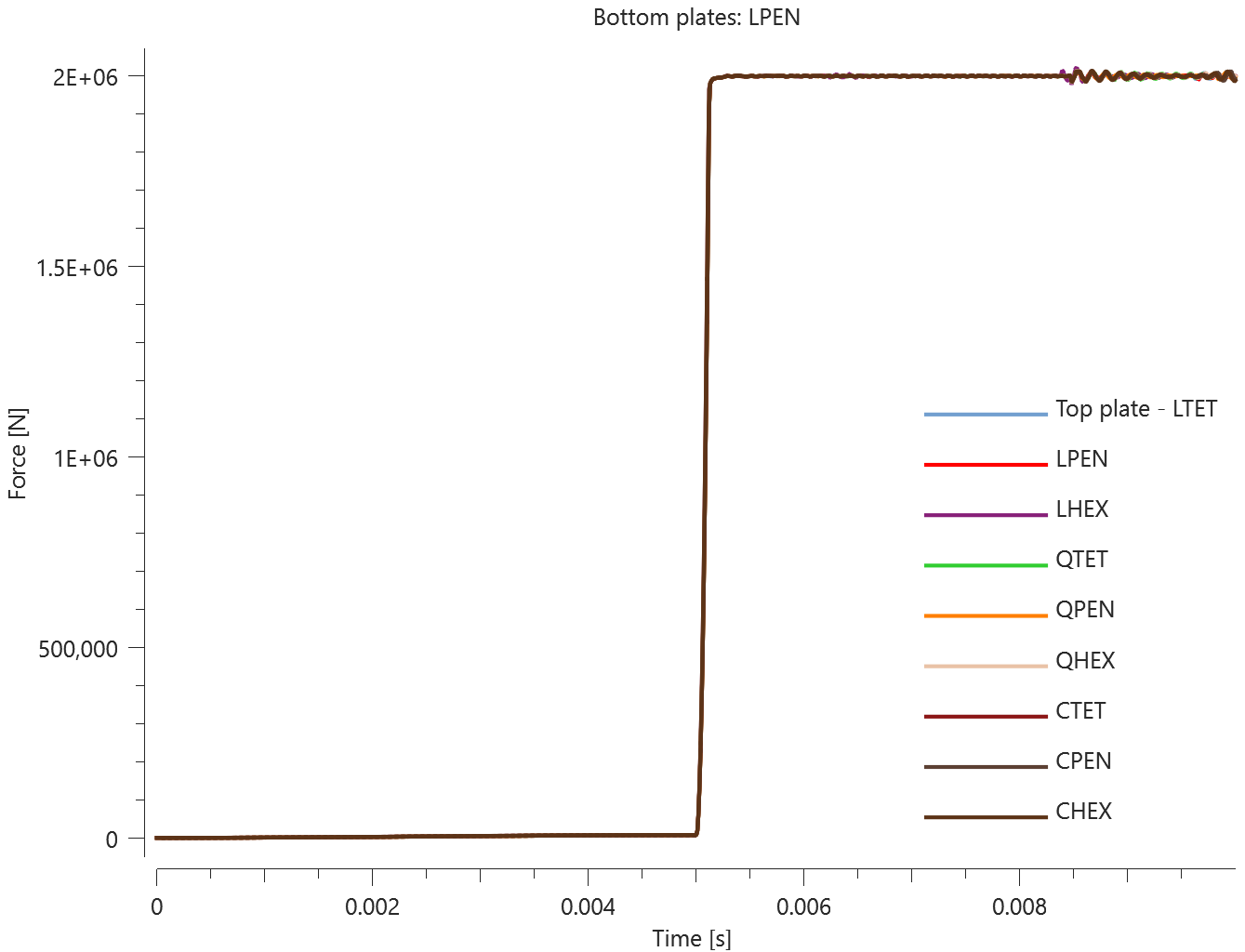

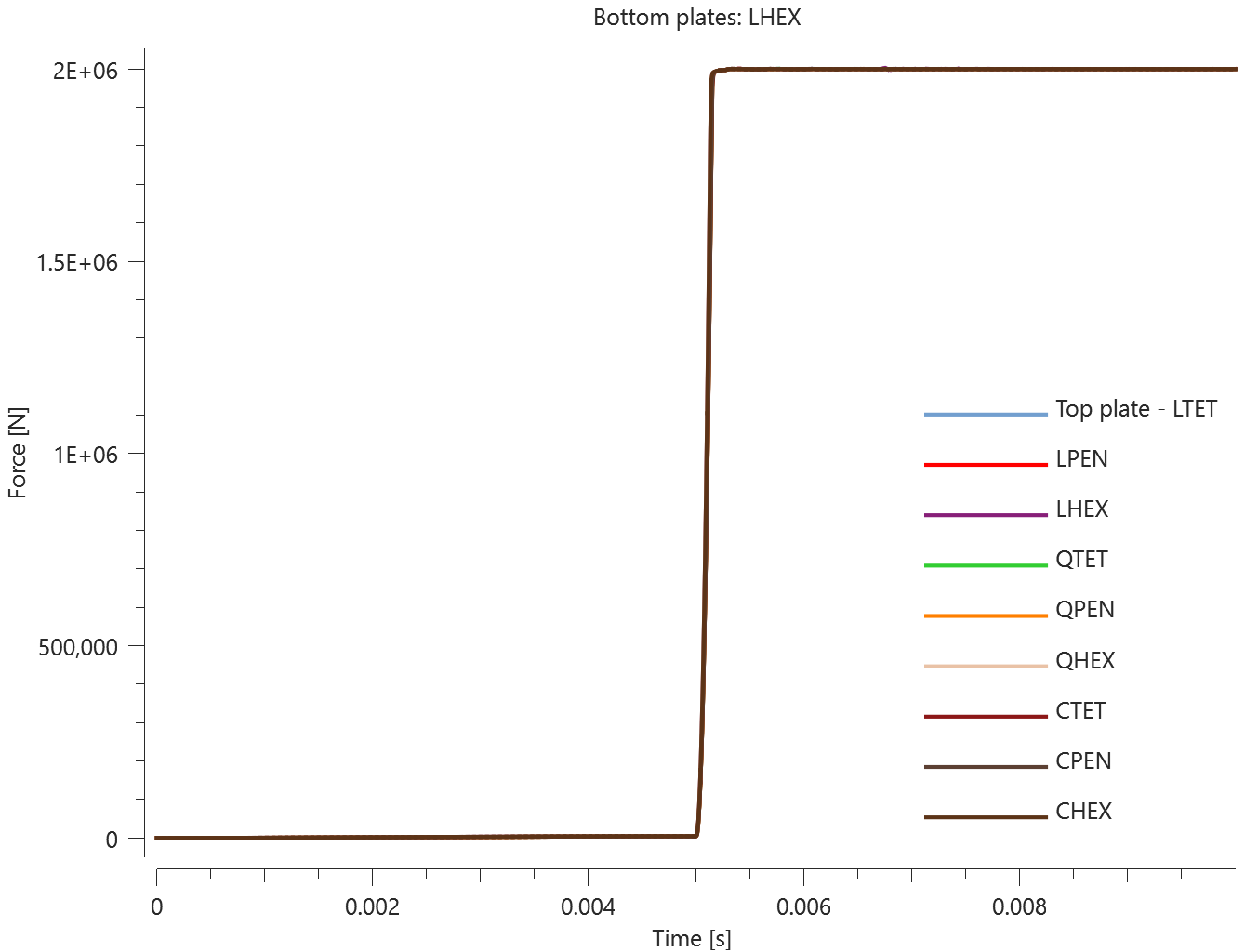

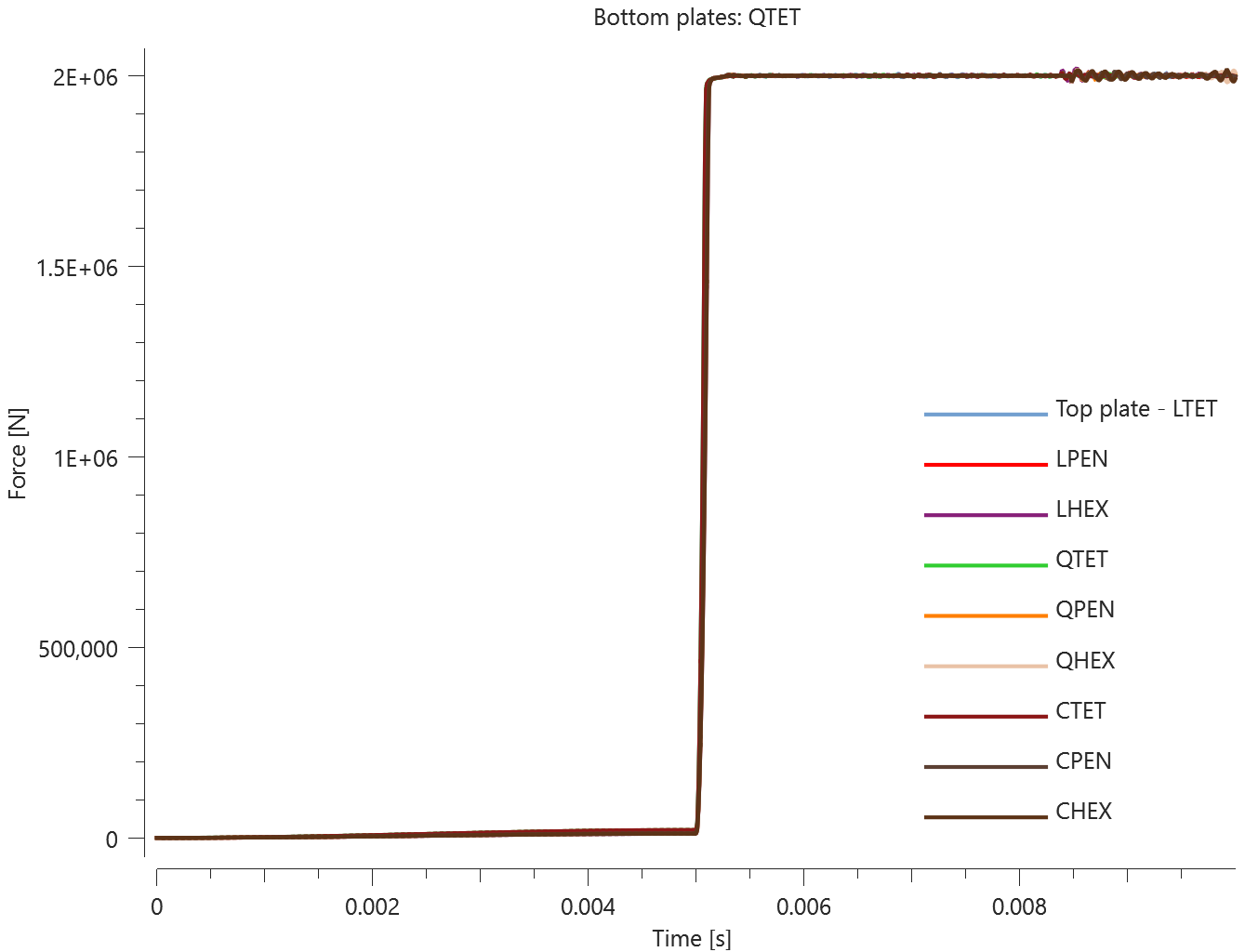

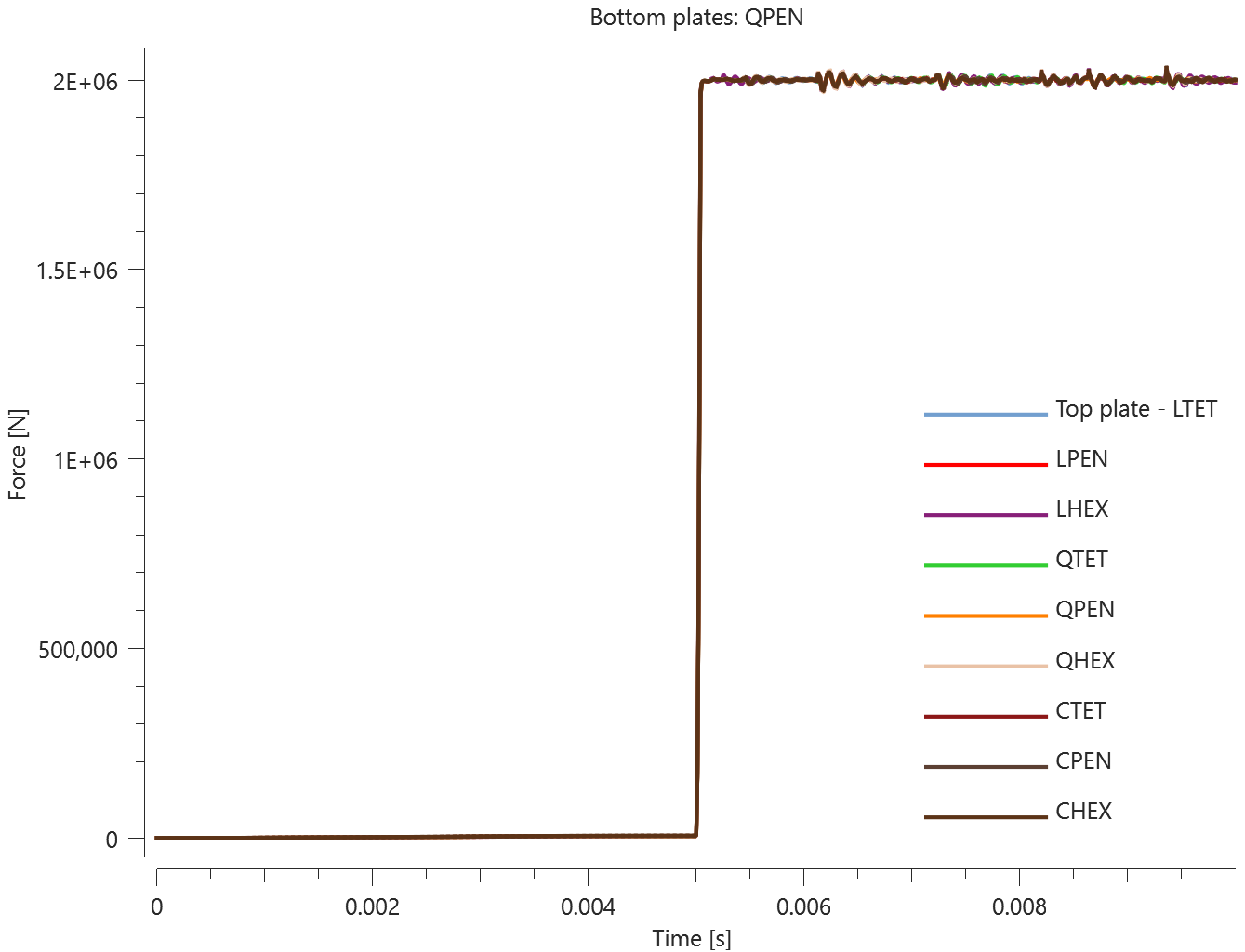

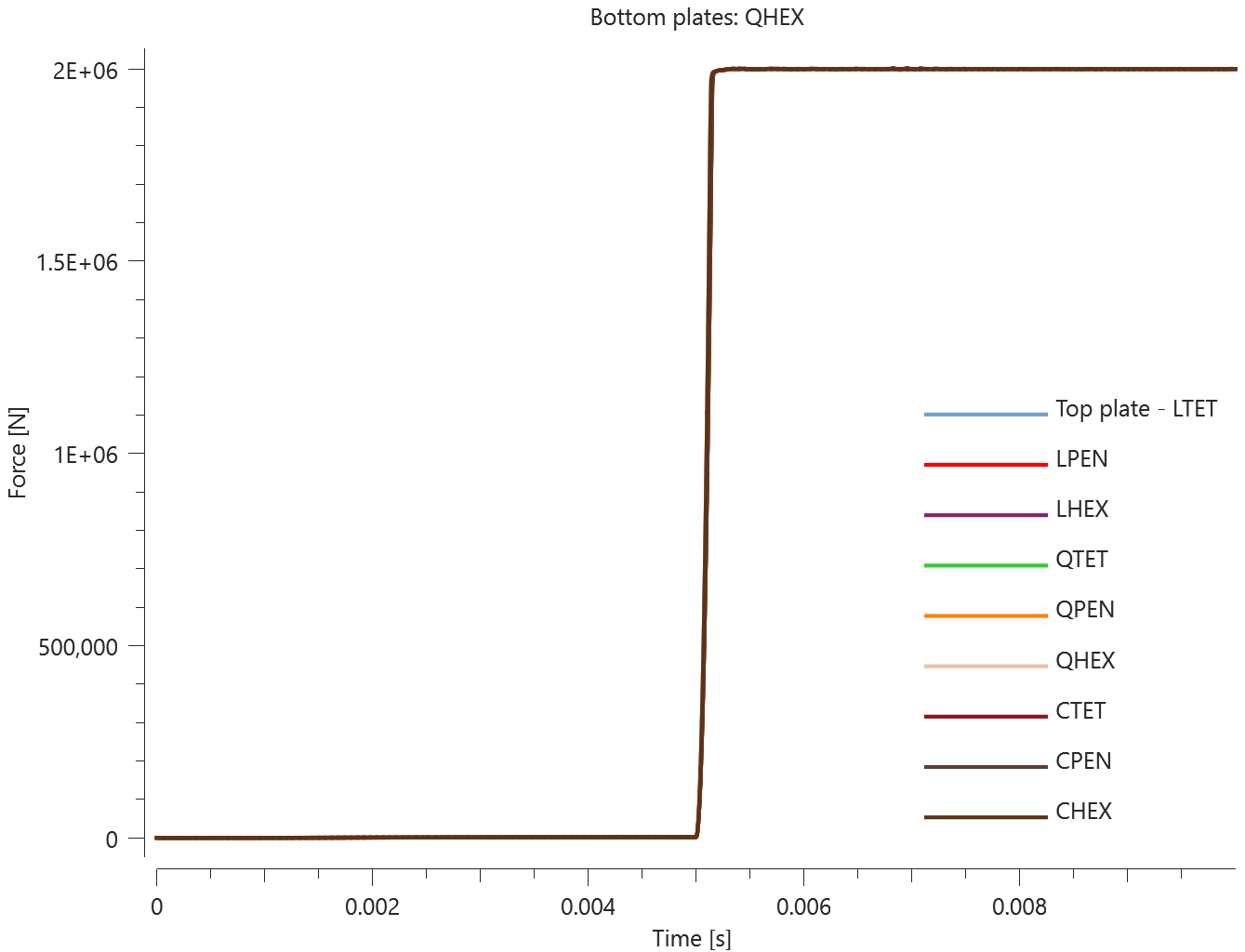

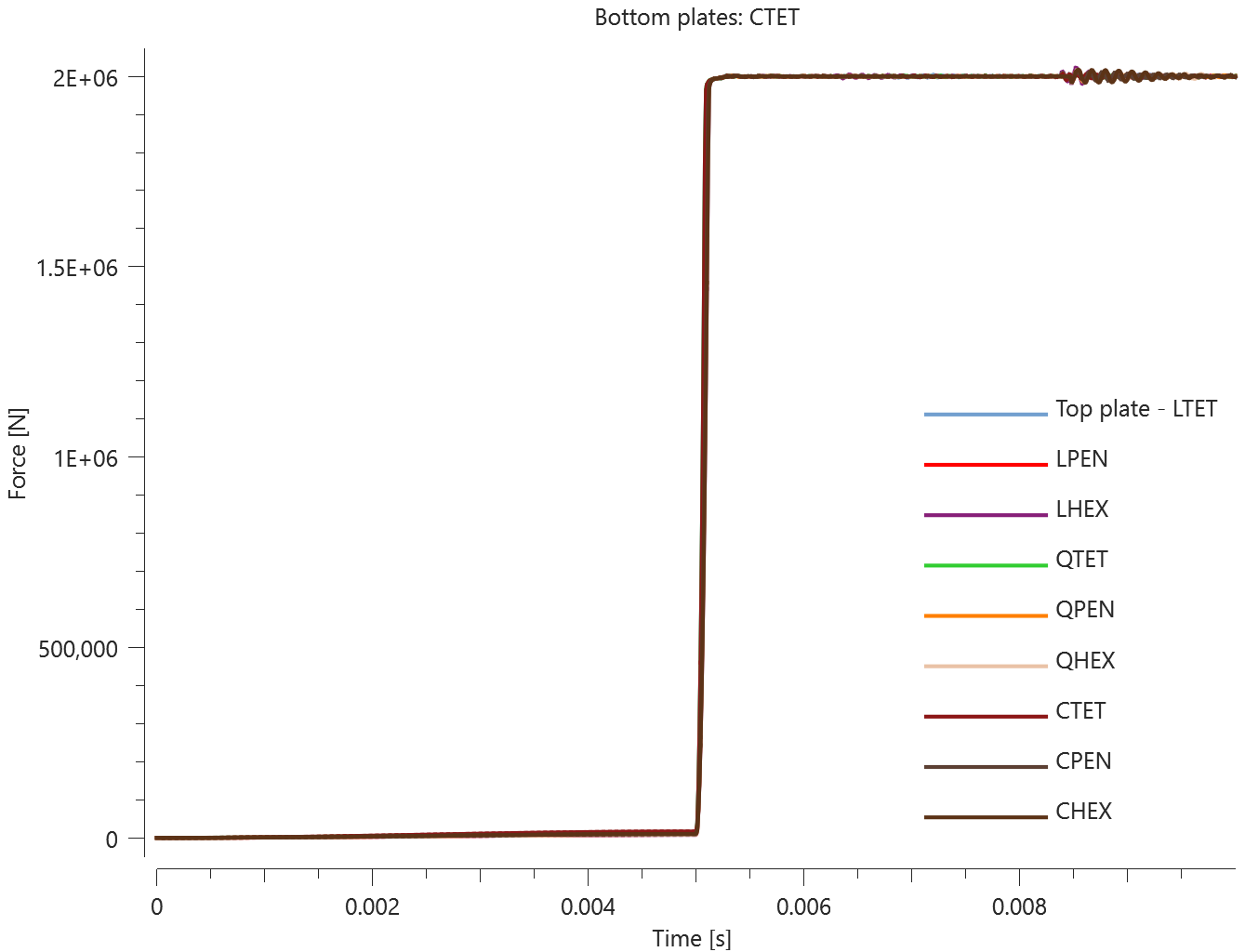

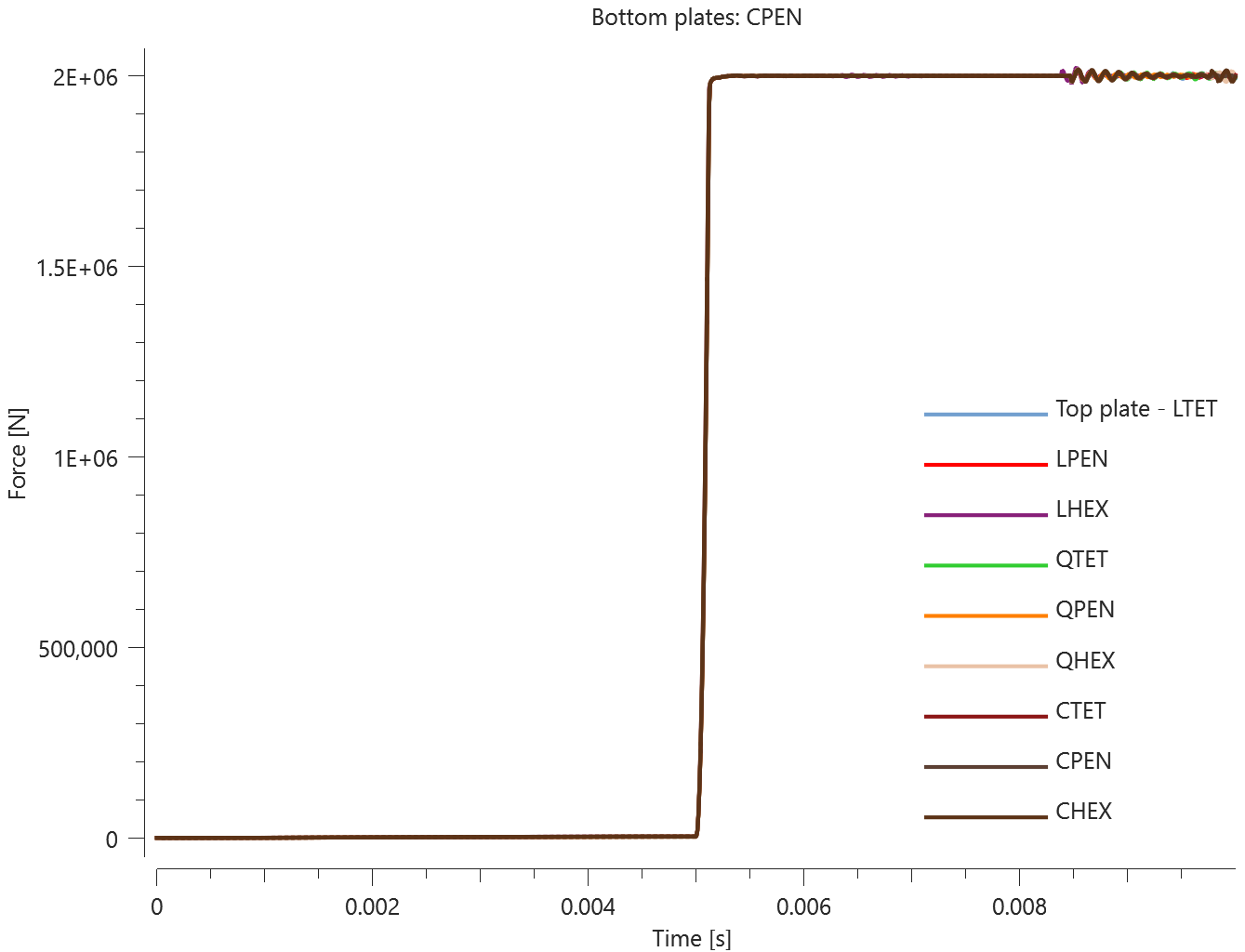

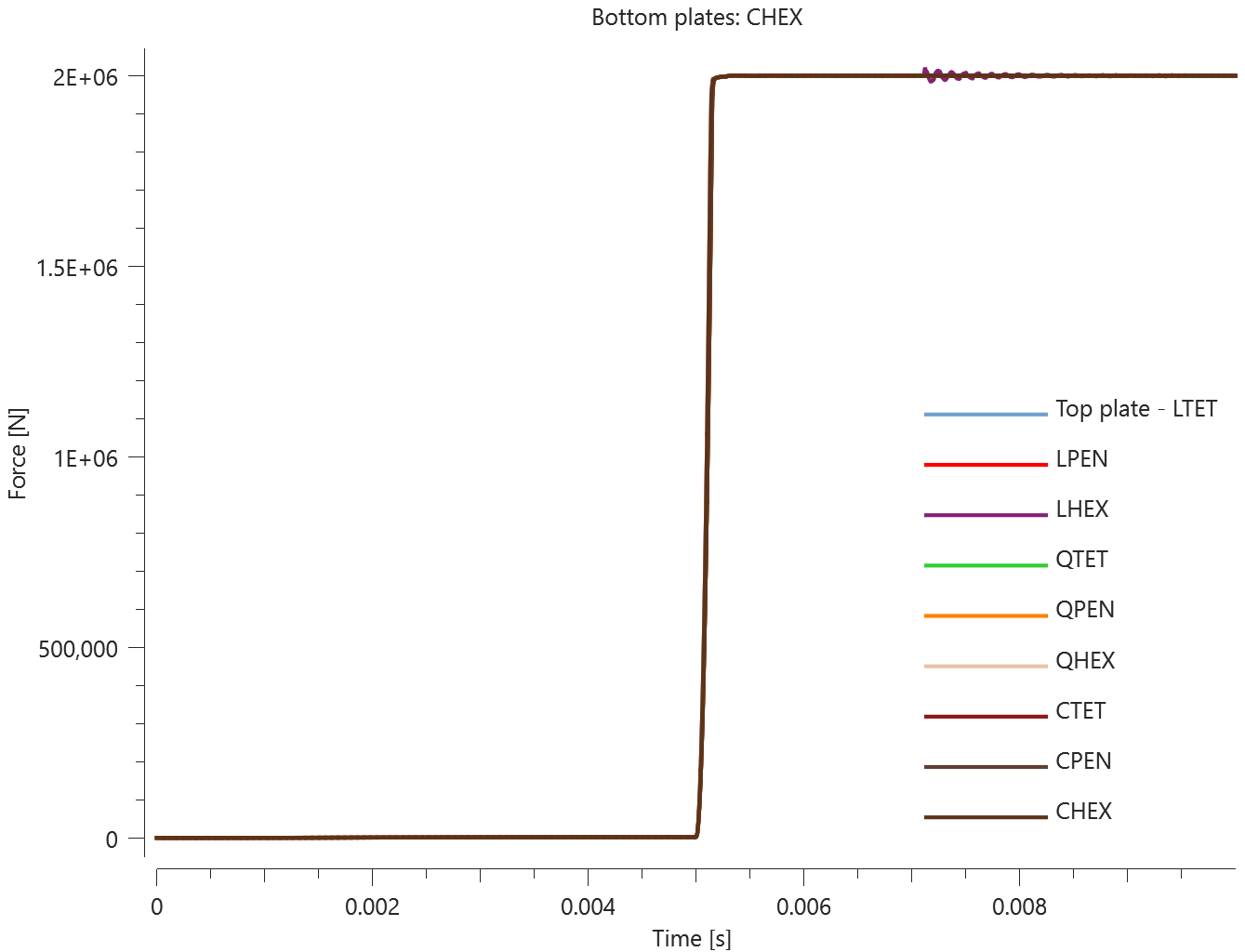

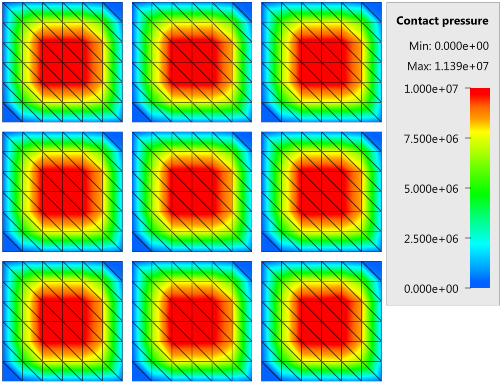

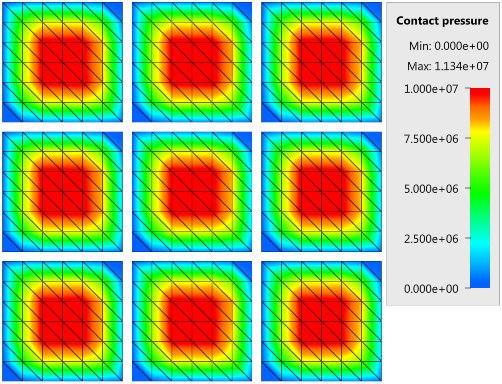

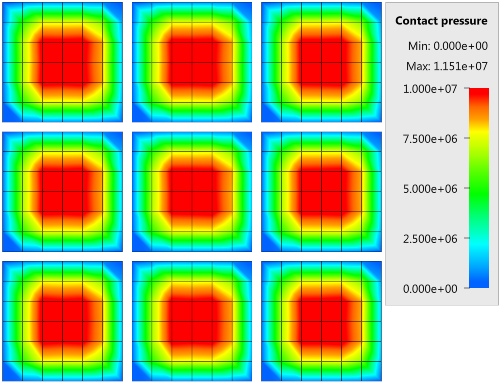

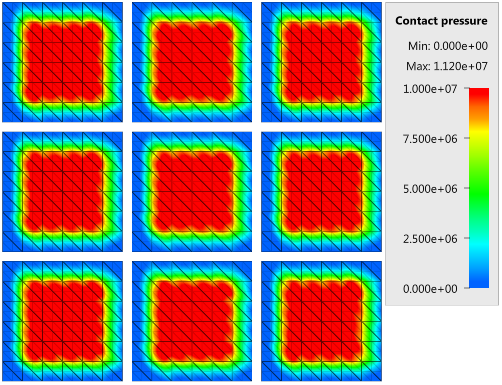

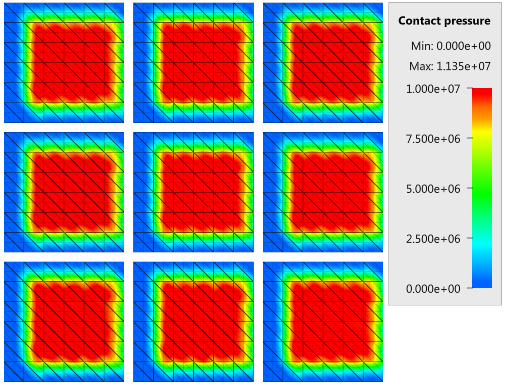

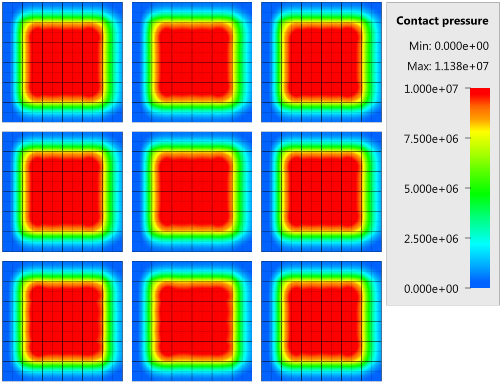

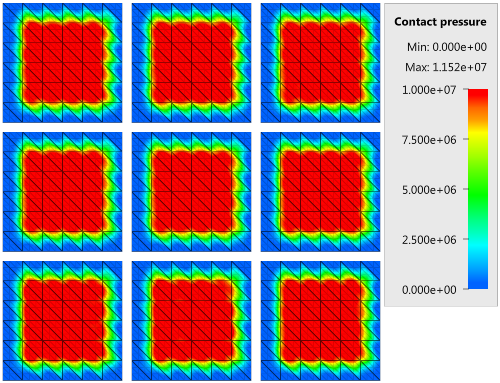

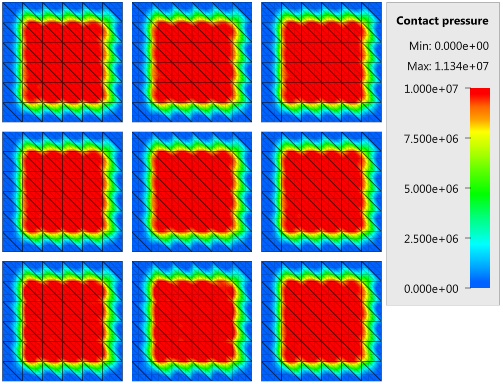

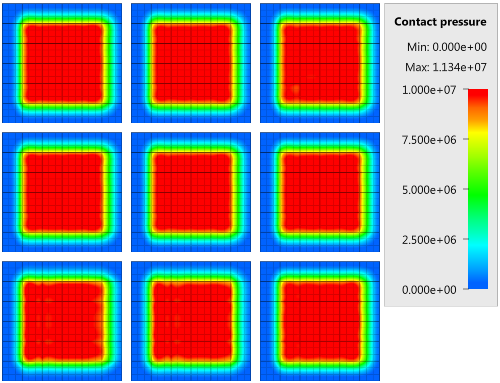

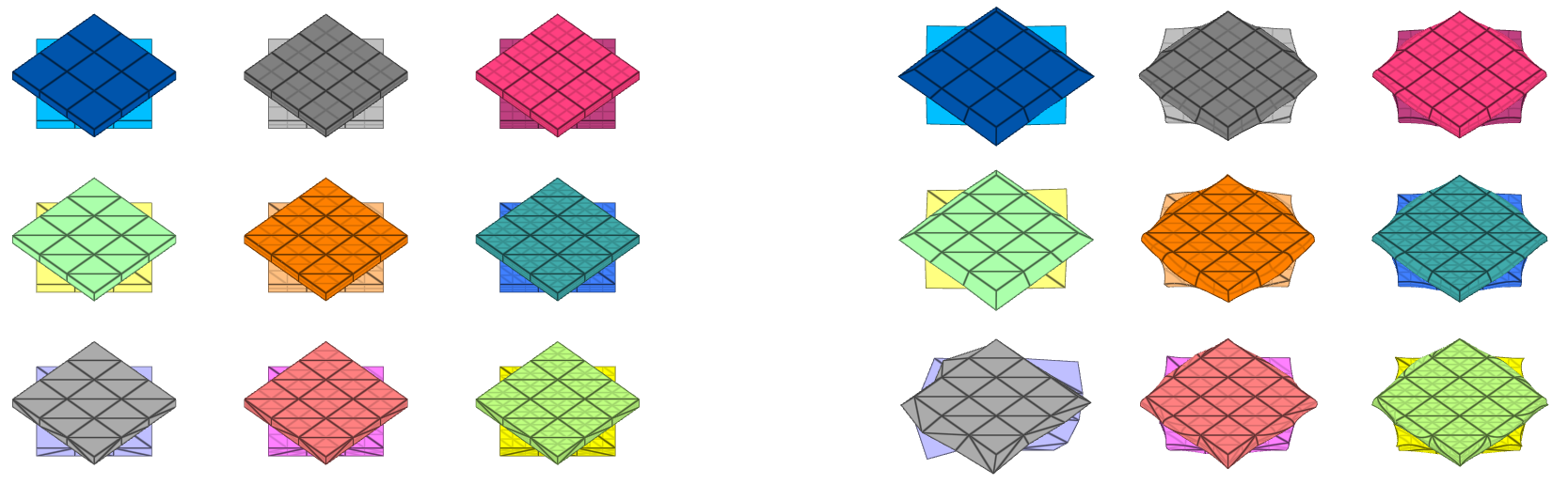

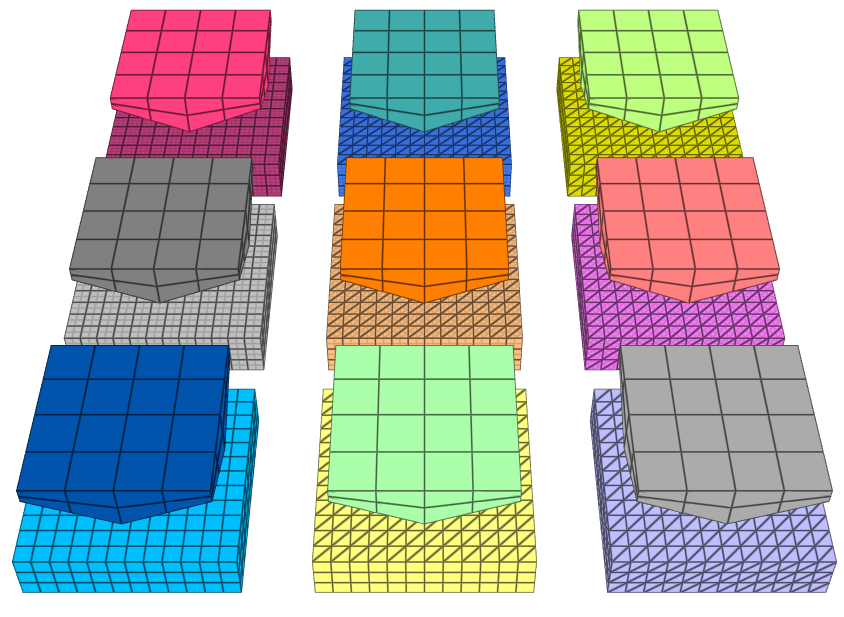

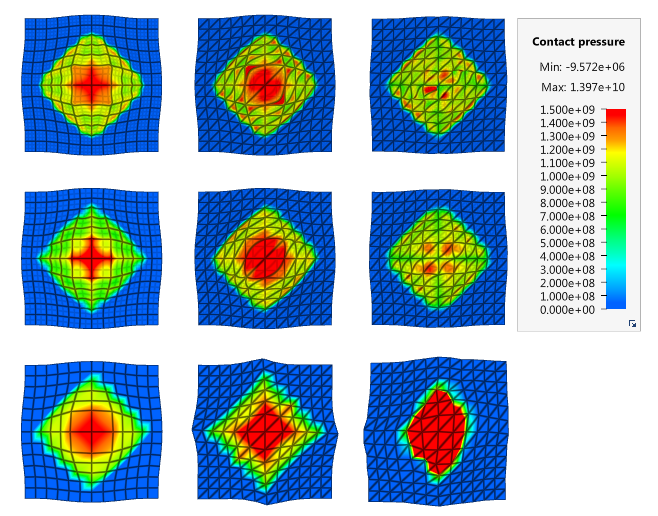

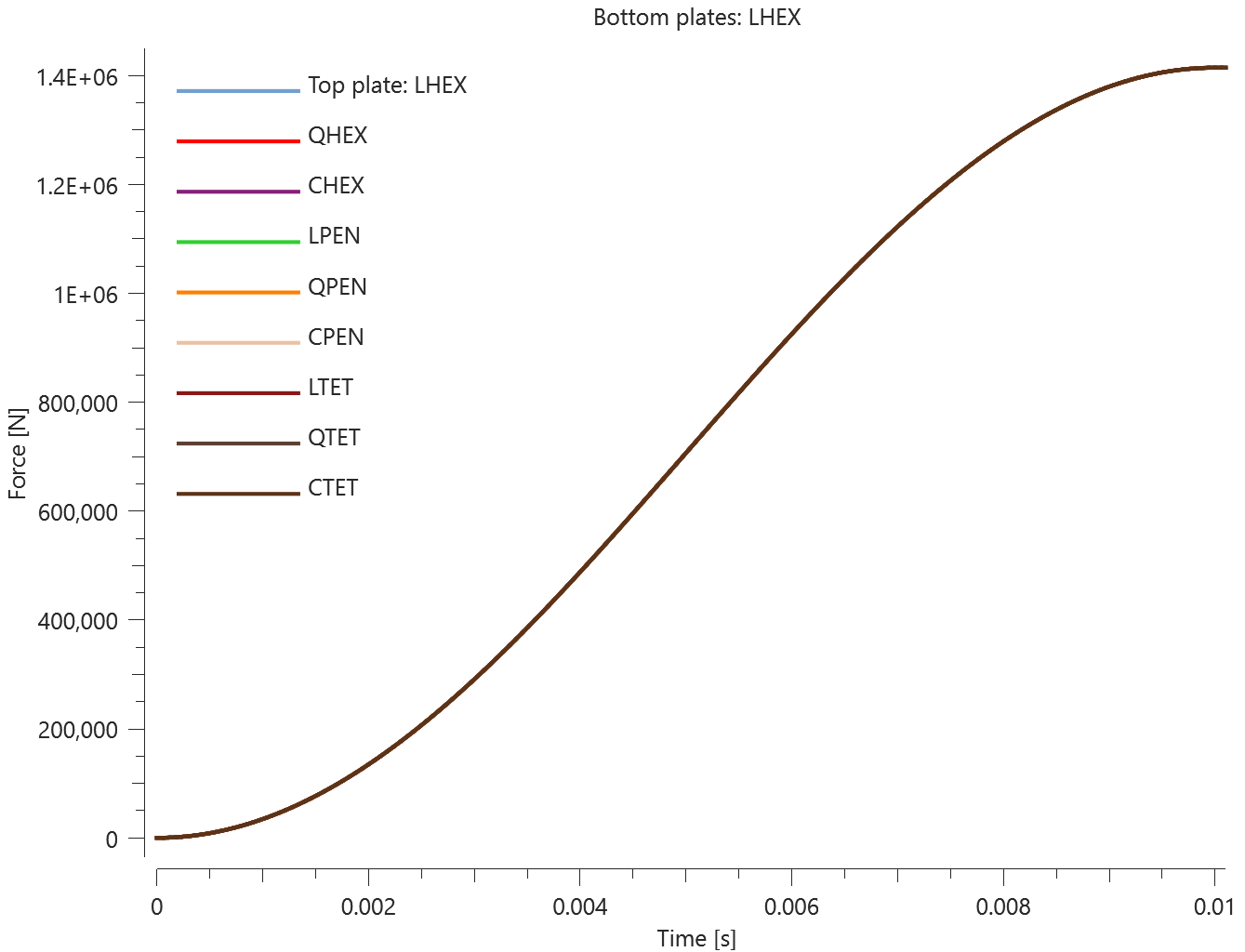

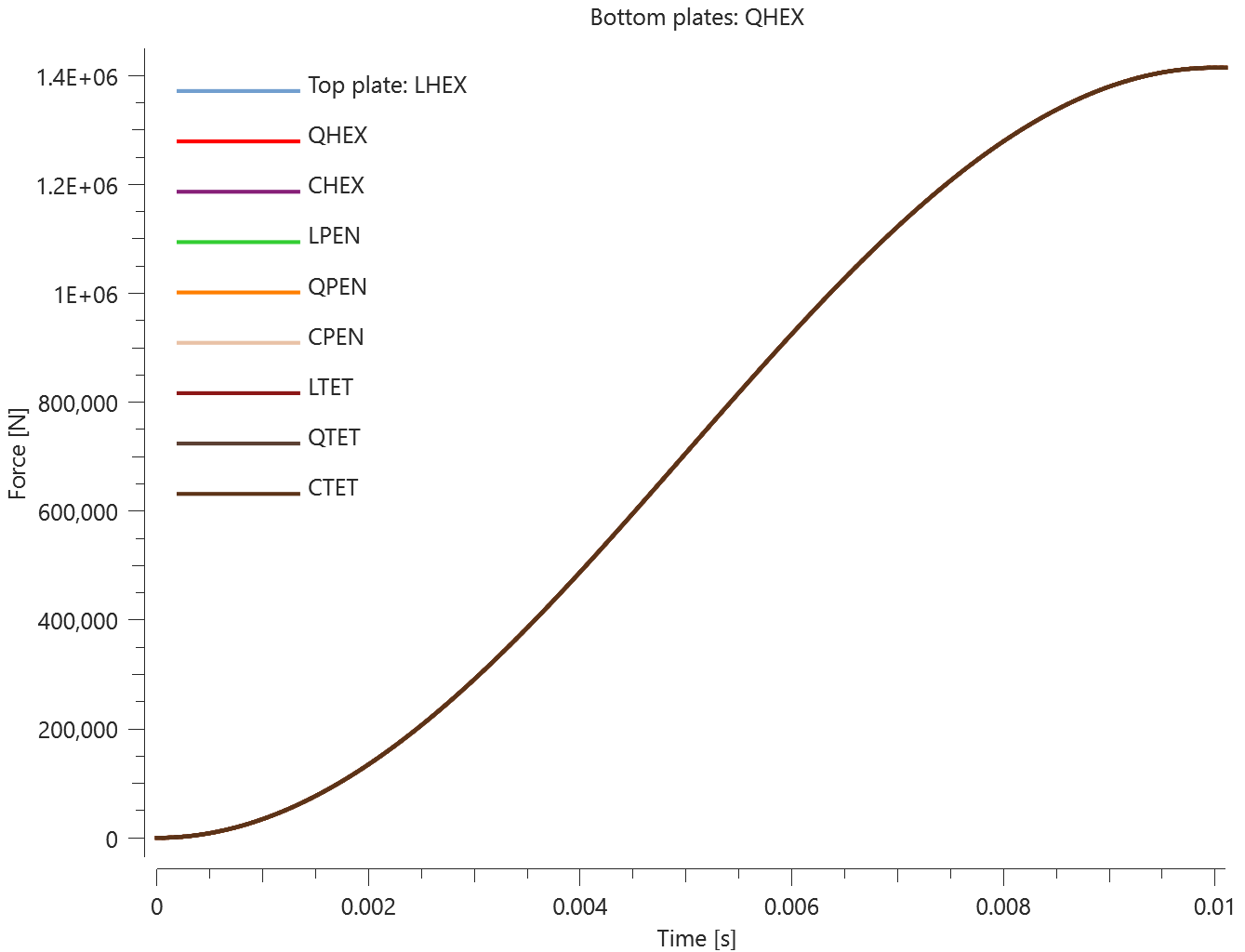

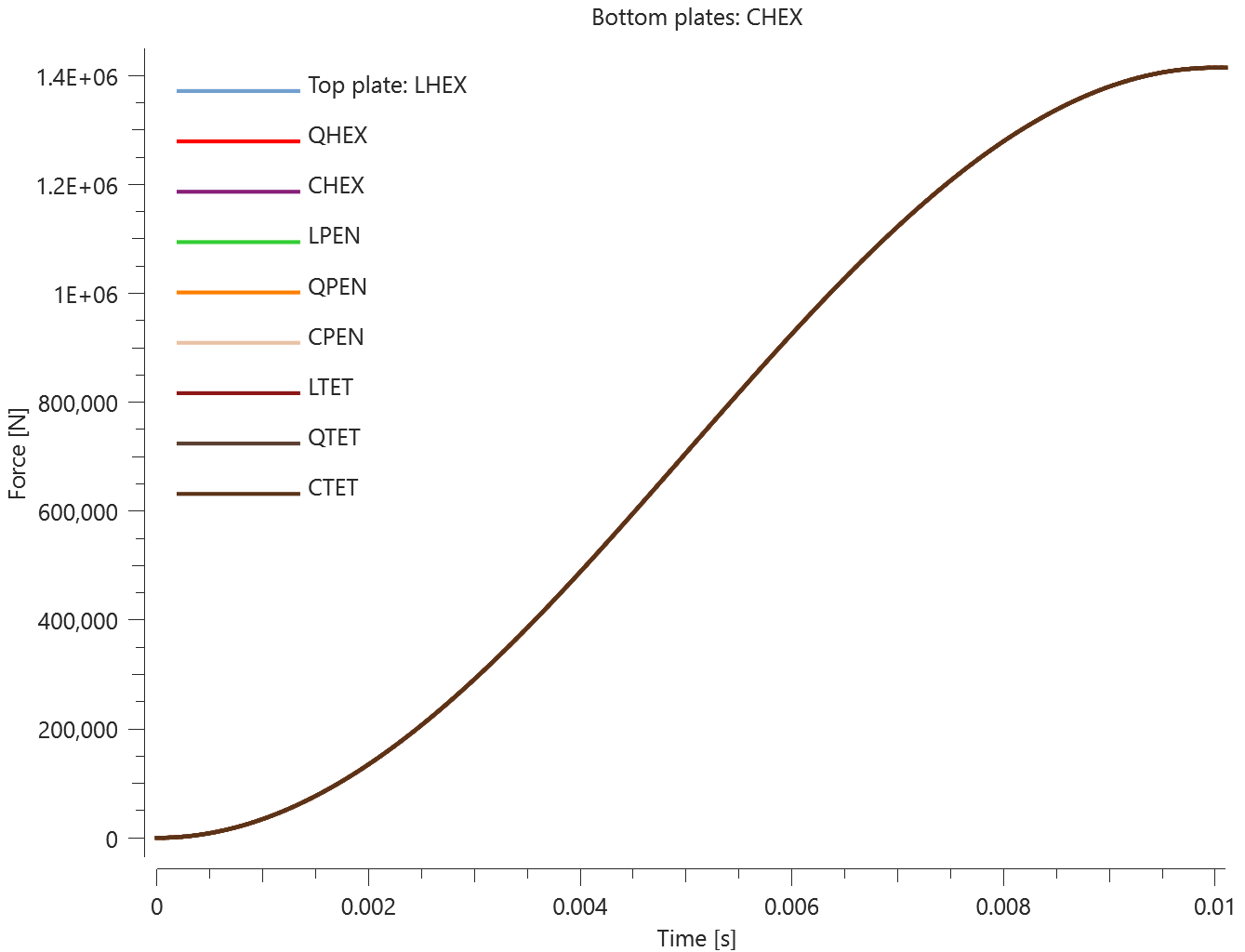

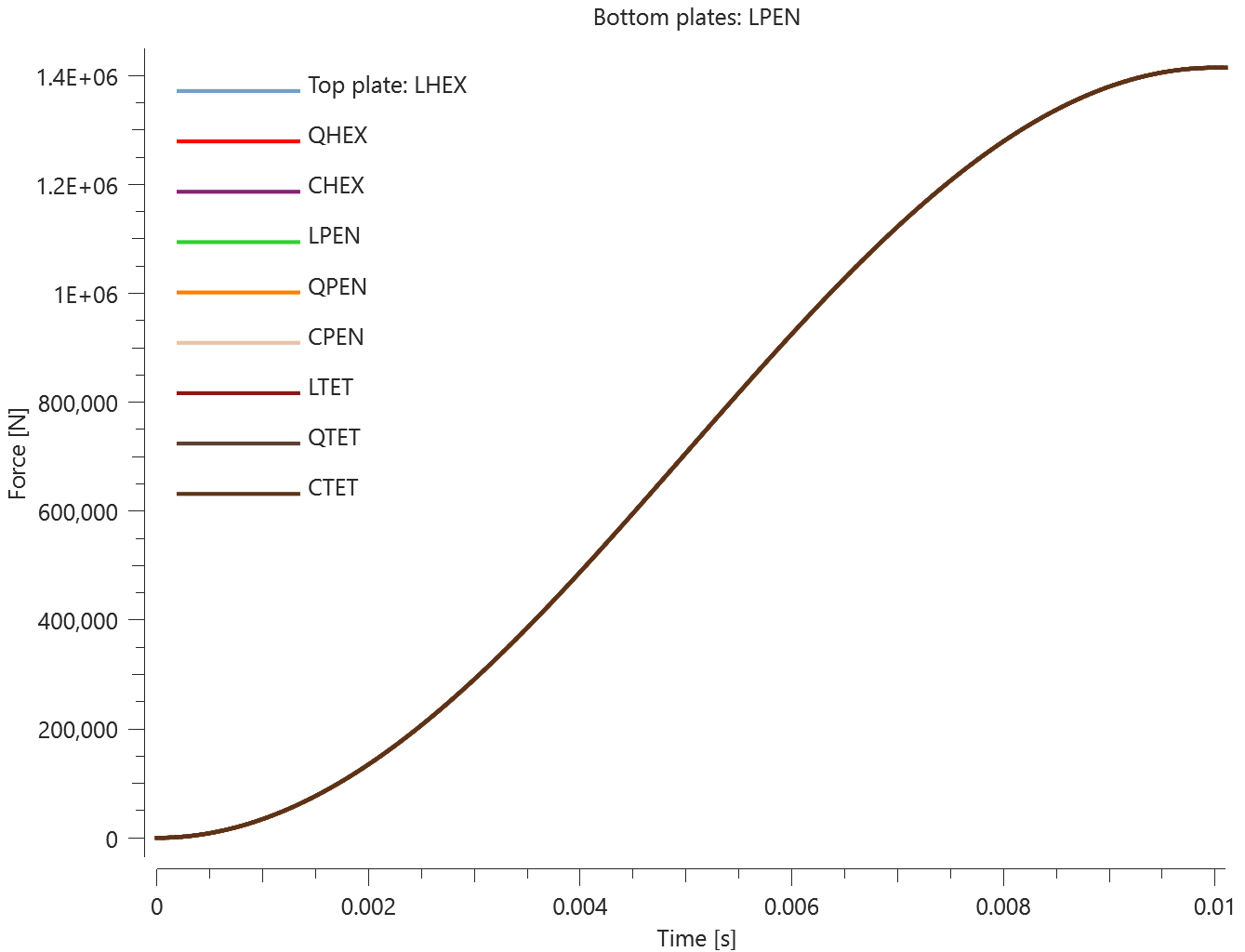

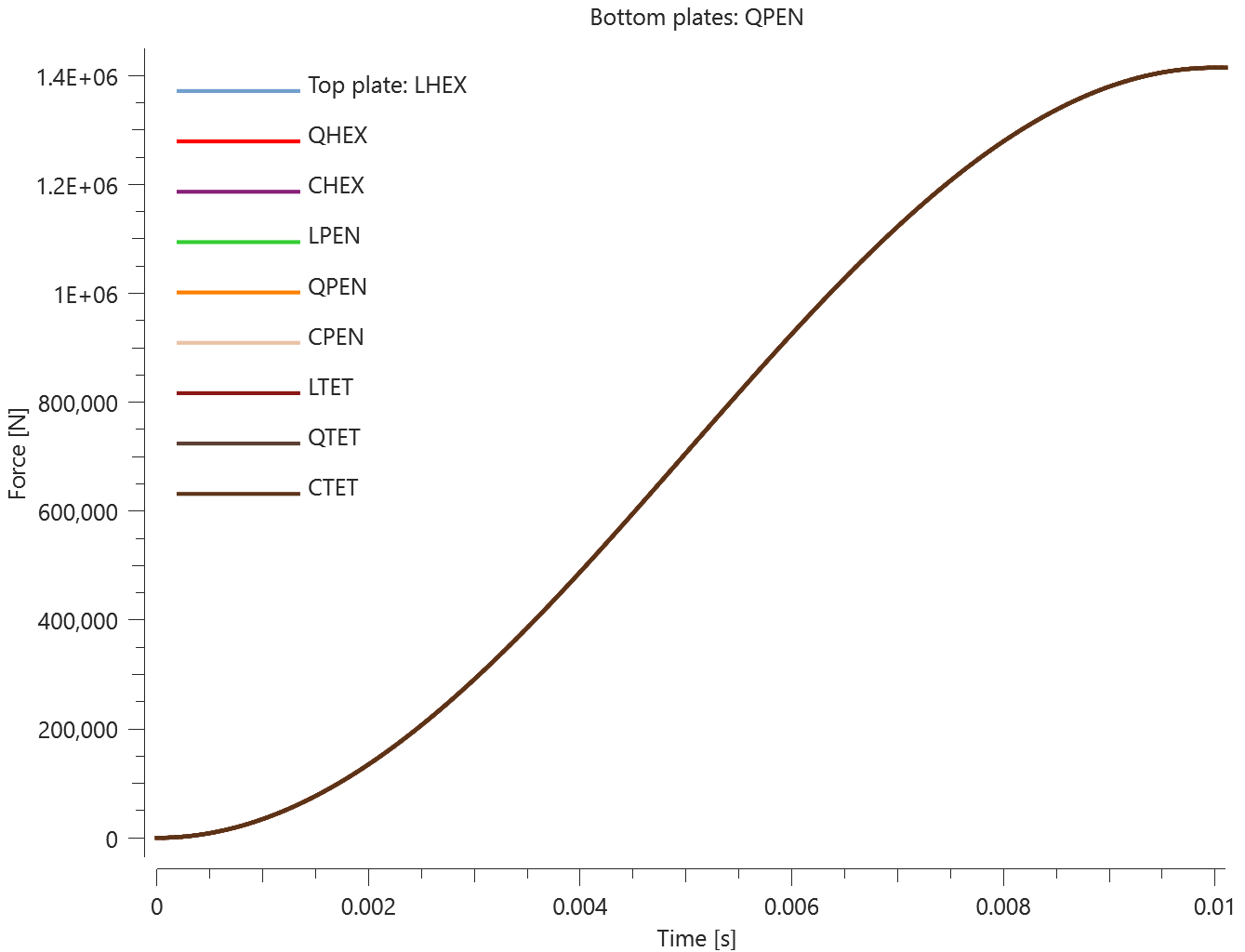

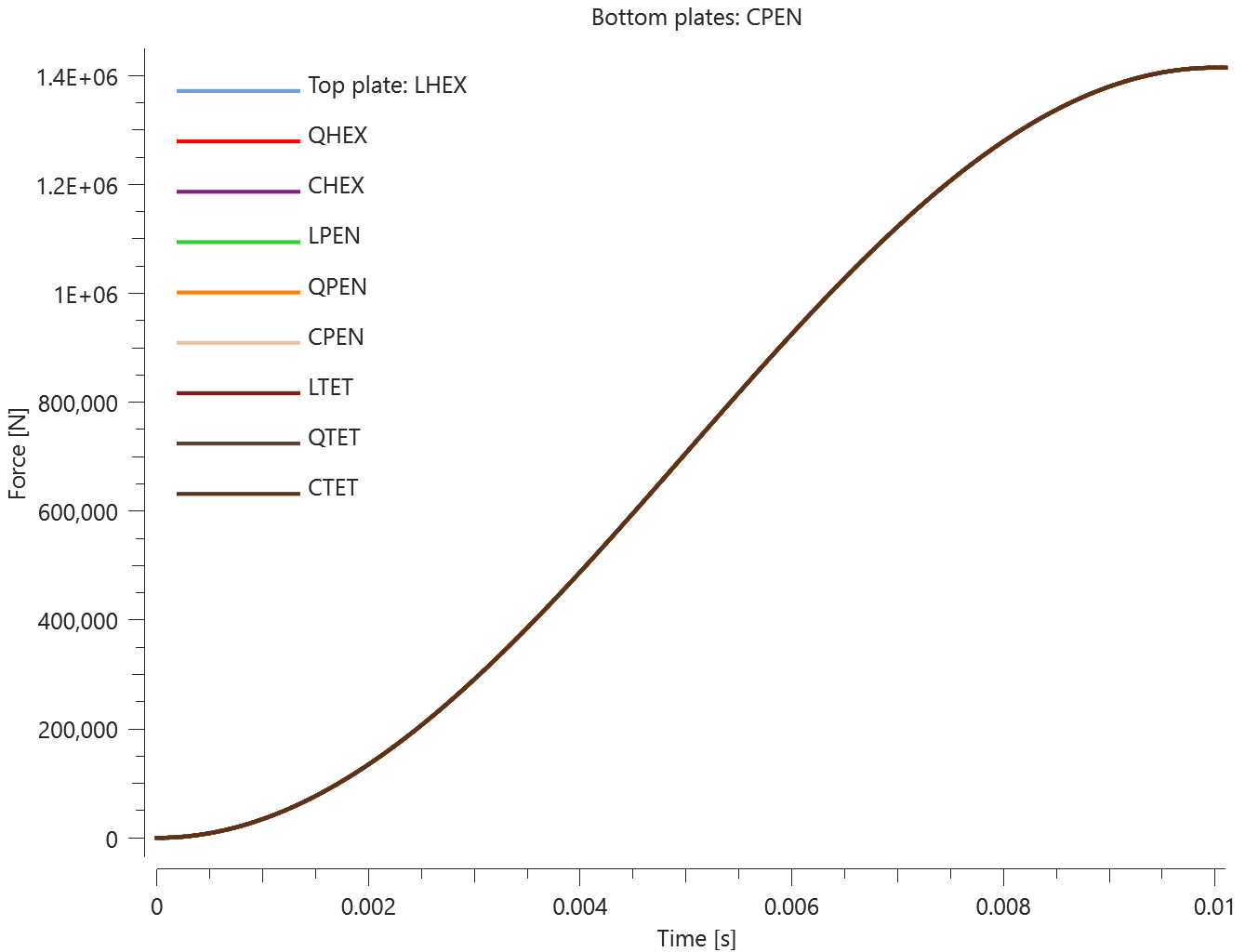

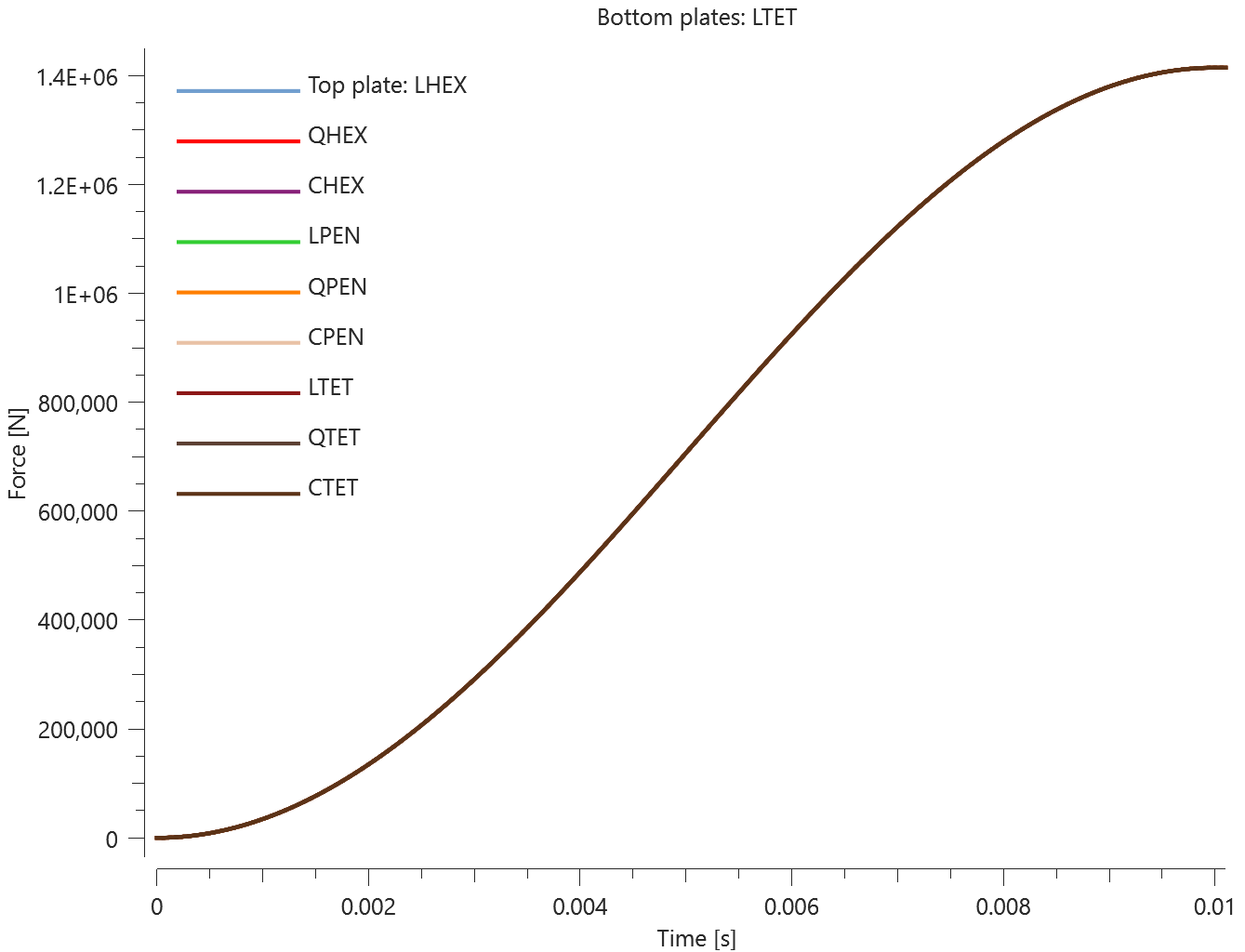

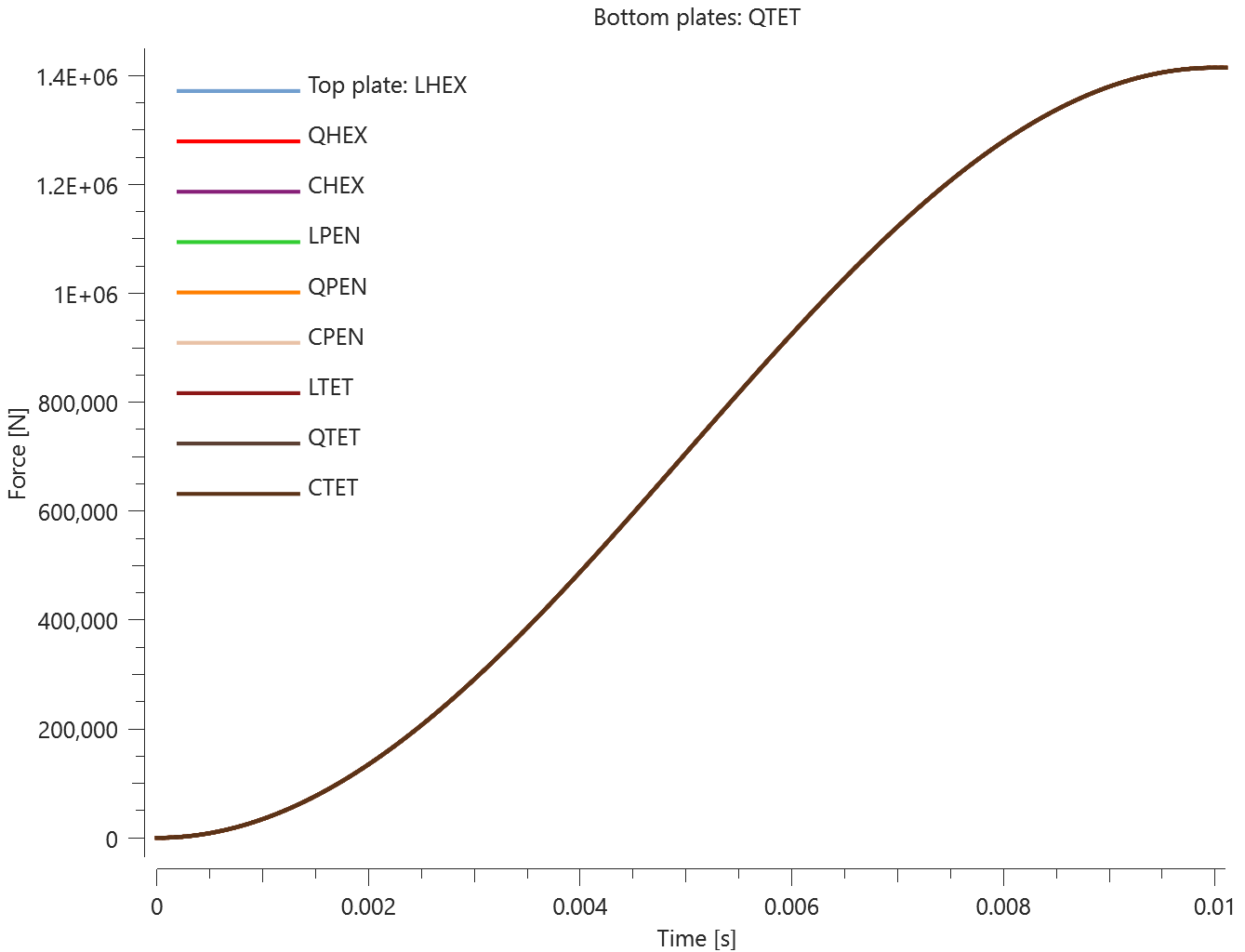

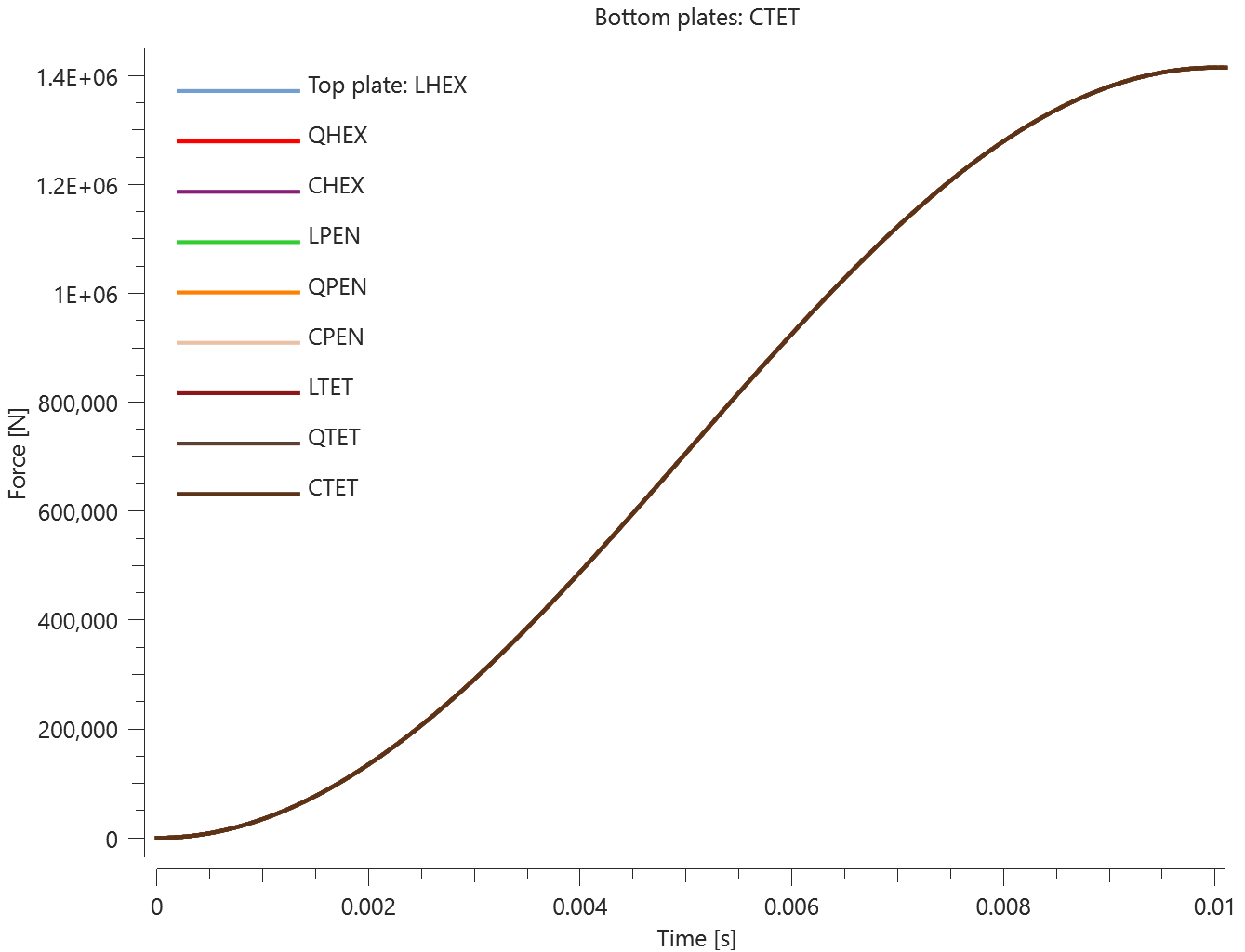

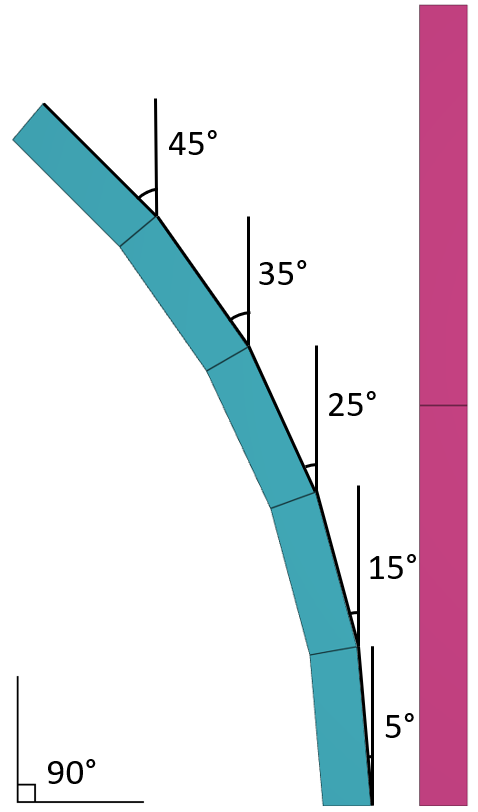

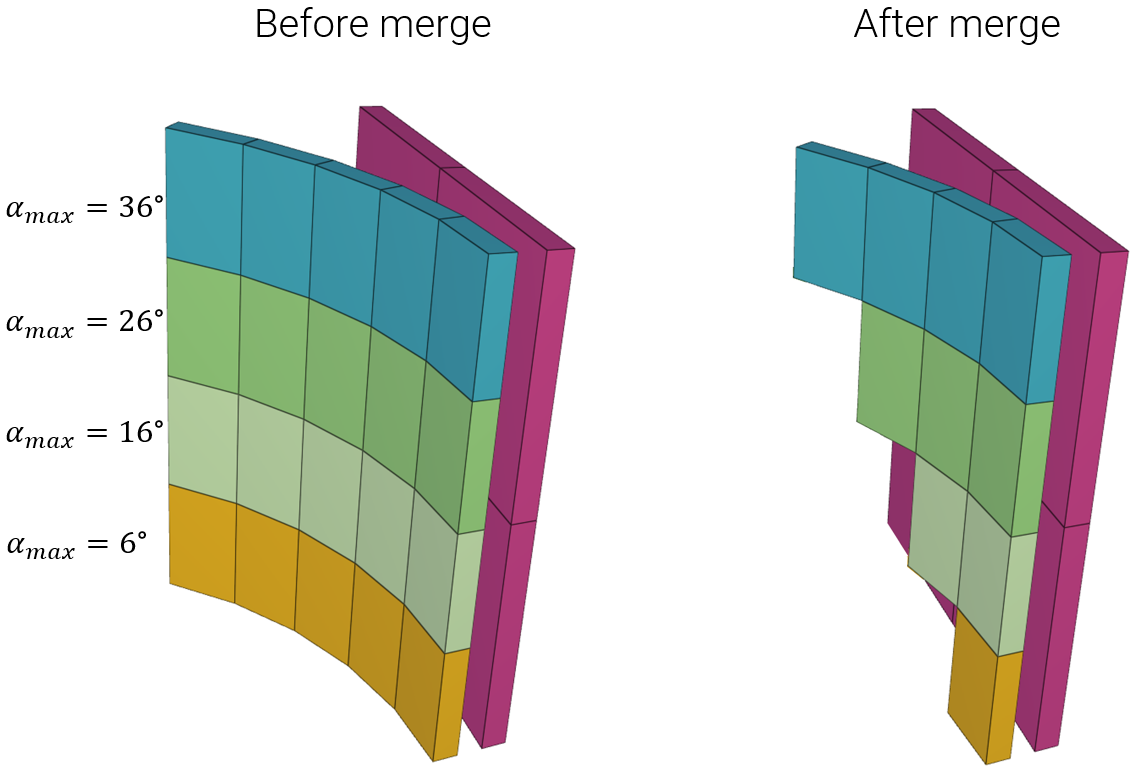

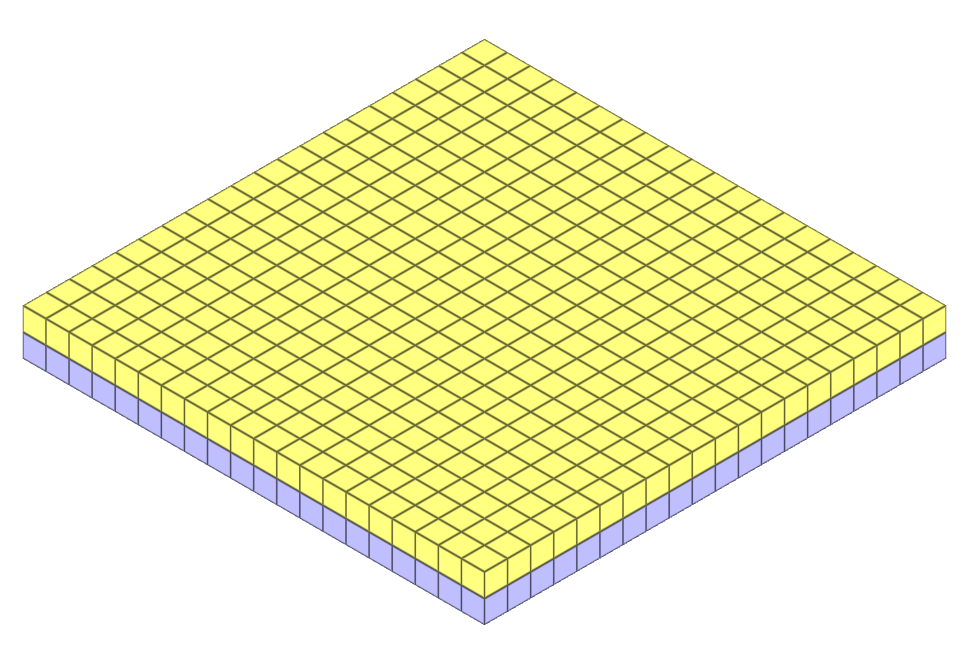

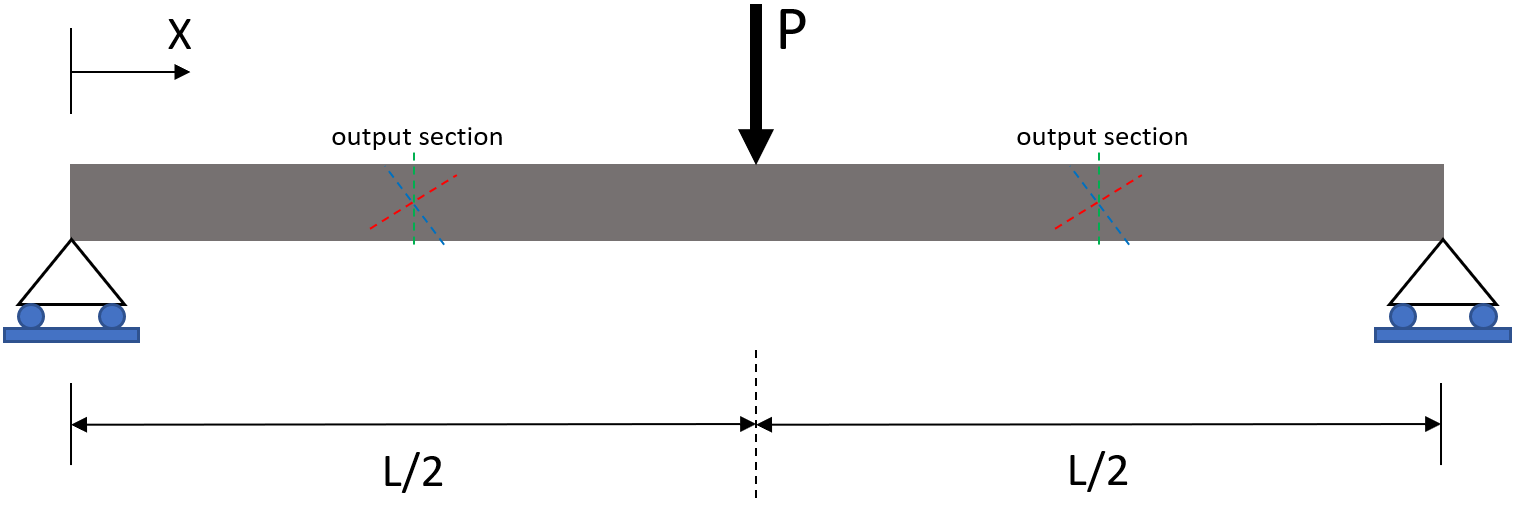

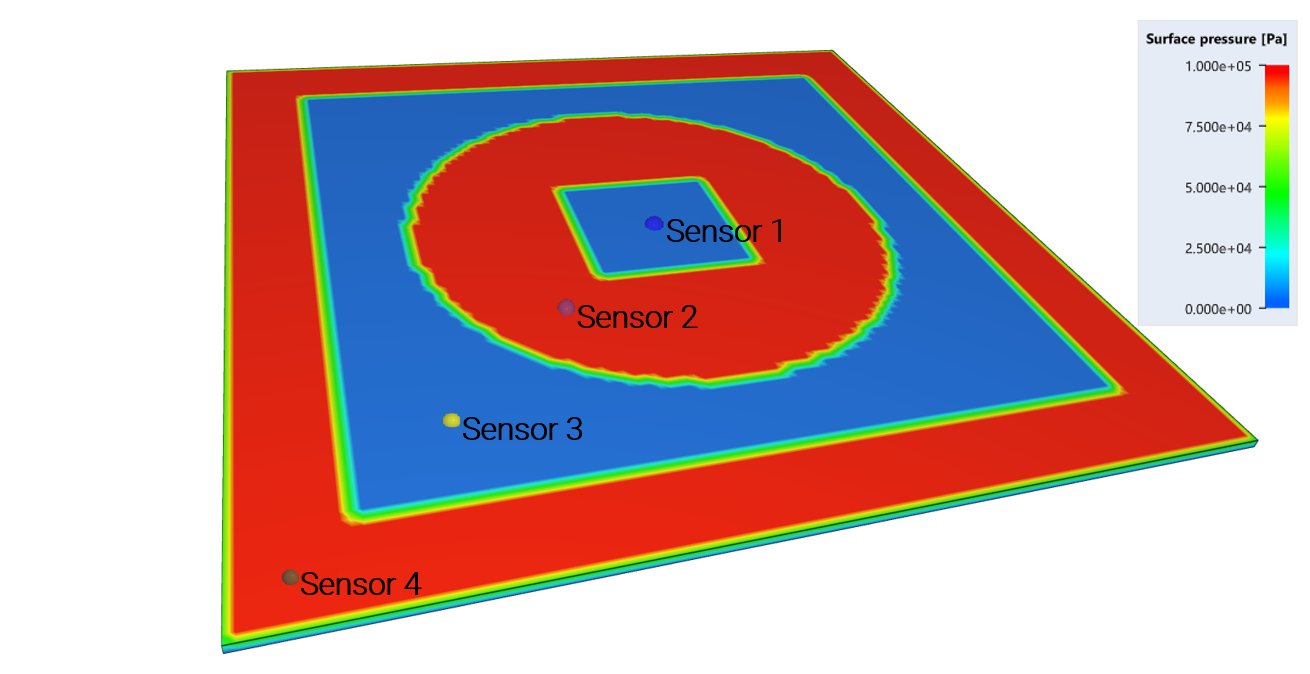

The test consists of 81 plate-pairs divided into nine models with nine plate-pairs in each model. One of the nine models is presented in Figure 1. The nine bottom plates in each model are of the same element type, but the type differs between the nine models. Each of the nine top plates consists of a unique type of elements and are the same in all models.

The type of elements used in the bottom plates in each model is presented in Table 1. Each row of top plates consists of a certain element type and each column of elements of a certain polynomial order. Top to bottom: tetrahedrons, pentahedron, hexahedron. Left to right: linear, quadratic, cubic.

The plates are first pressed together by a prescribed pressure (*LOAD_PRESSURE) and then a prescribed motion (*BC_MOTION) is causing the top plates to slide against the fixed bottom plates.

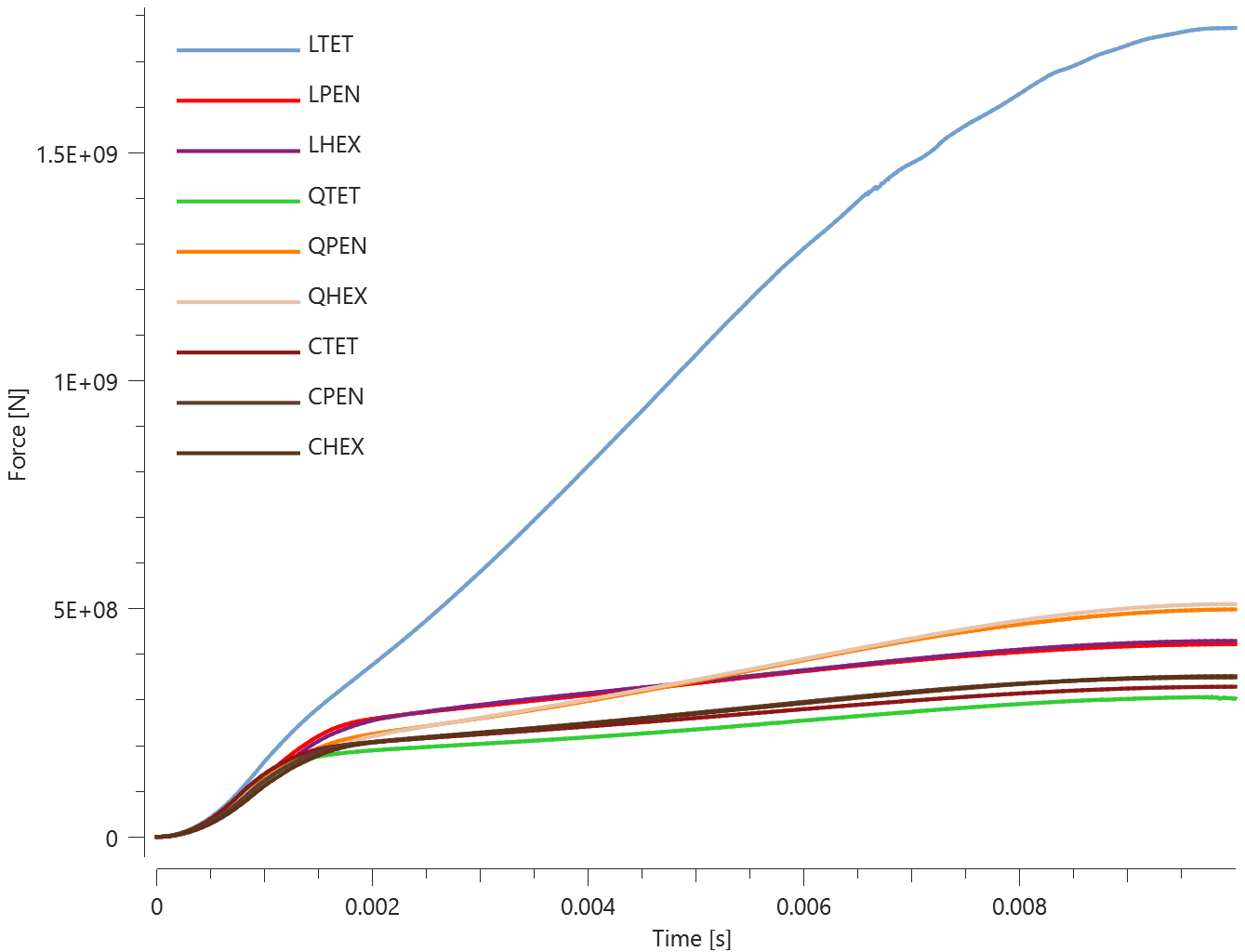

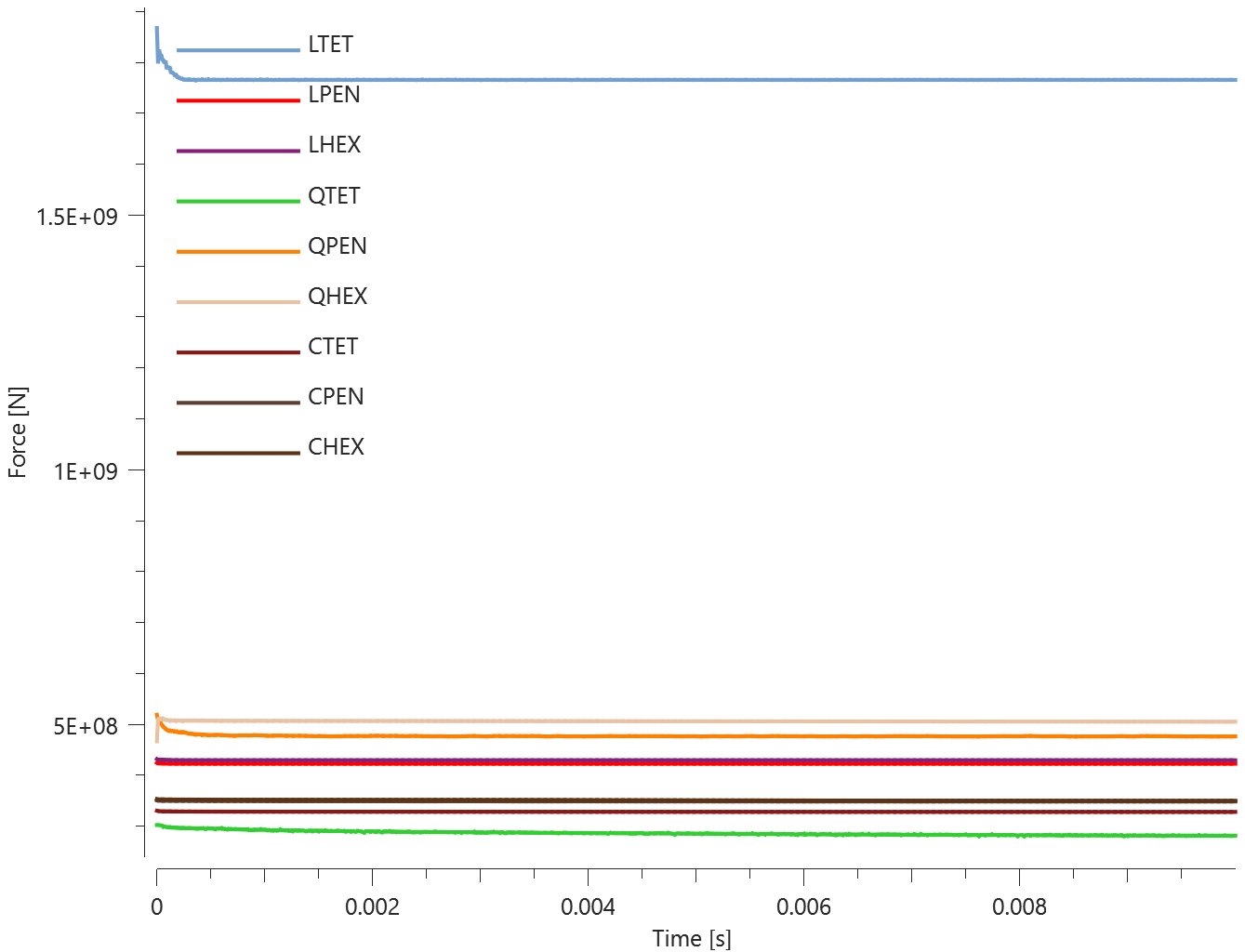

The contact force in the direction of the applied pressure vs. time for all plate-pairs and all models are presented in Figure 2 - 10 while the contact force in the sliding direction vs. time for all plate-pairs and all models are presented in Figure 11 - 19. Contour plots of the contact pressure for all models are presented in Figure 20 - 28.

The contact forces are checked at termination.

Tests

This benchmark is associated with 9 tests.

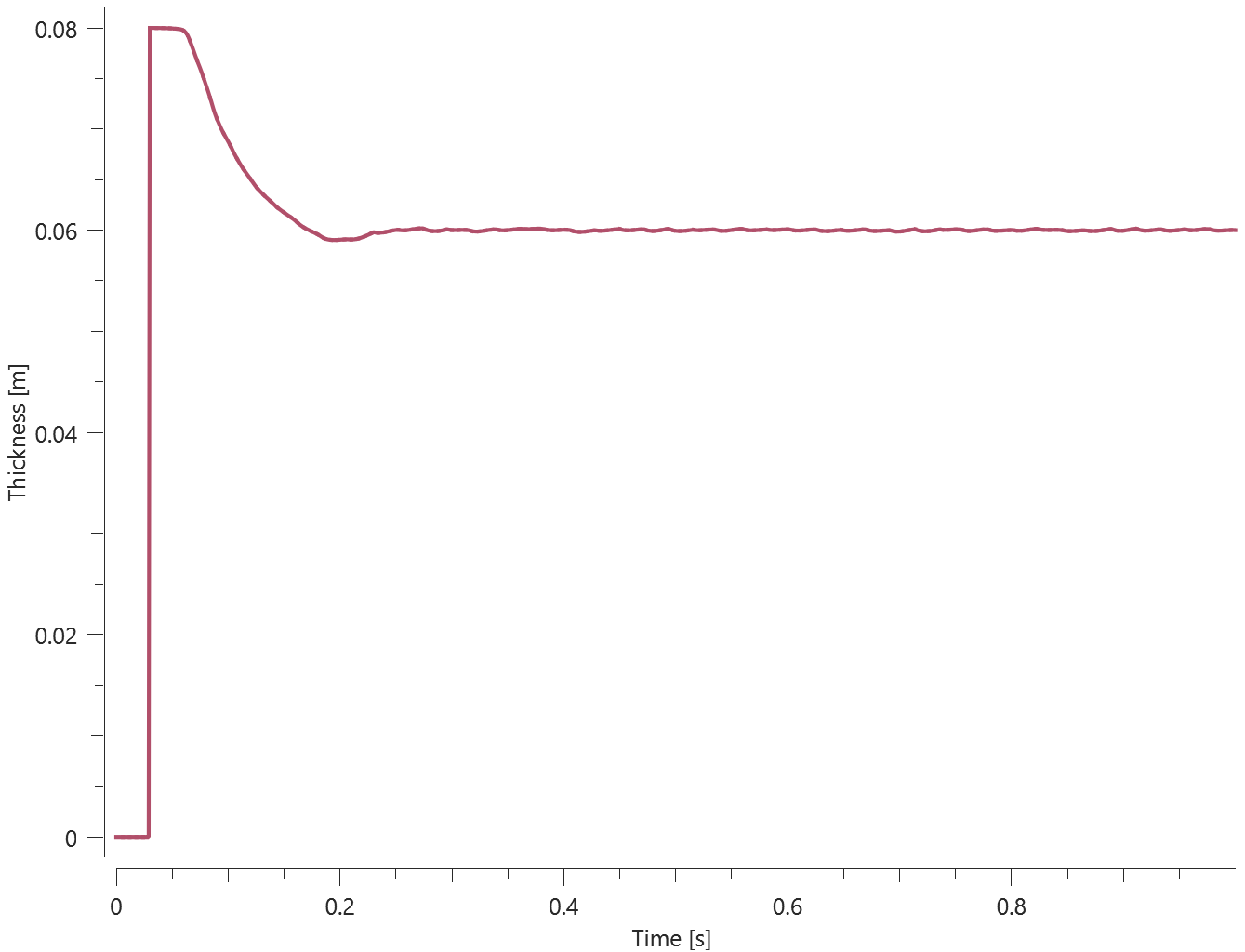

Continue from state-file

"Optional title"

$coid$, $accuracy_{}level$, $accuracy_{}edge$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $\mu$, $pfac$, $t_{beg}$, $t_{end}$

$merge$, $\xi$, $gid_0$, $gid_1$, $\delta_0^{offset}$, $\delta_0^{max}$, $\delta^{edge}$

$fid_{wear1}$, $fid_{wear2}$, $fid_{thermal}$, $\alpha_{edge}$, $one way$, $no_{}internal$

The contact force in a simulation based on a state-file is verified in this test.

Tested parameter:  (automatic calculation of penalty stiffness).

(automatic calculation of penalty stiffness).

The model consists of nine pairs of plates. Each pair consists of a certain type of solid elements: LTET, LPEN, LHEX, QTET, QPEN, QHEX, CTET, CPEN or CHEX.

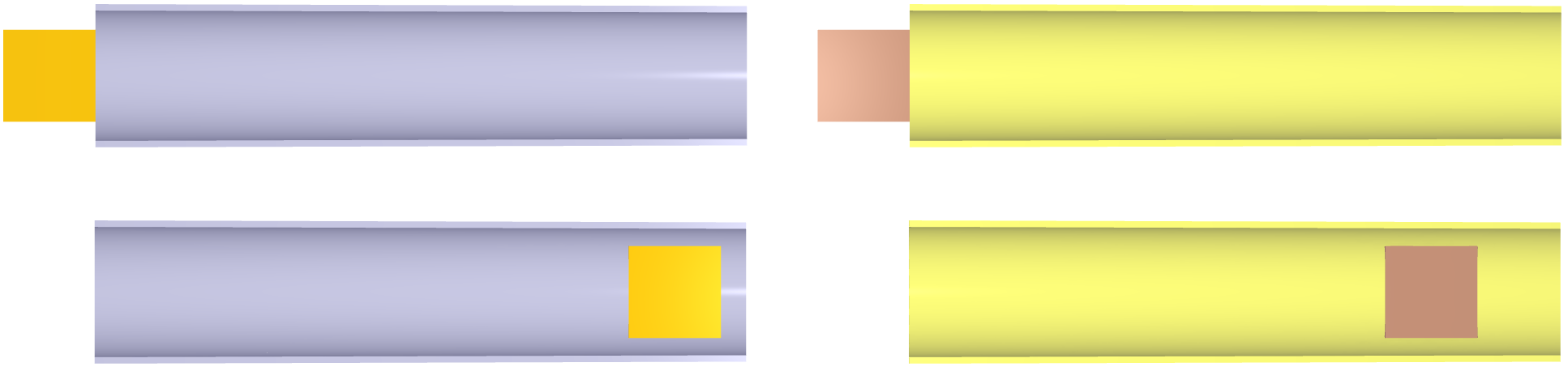

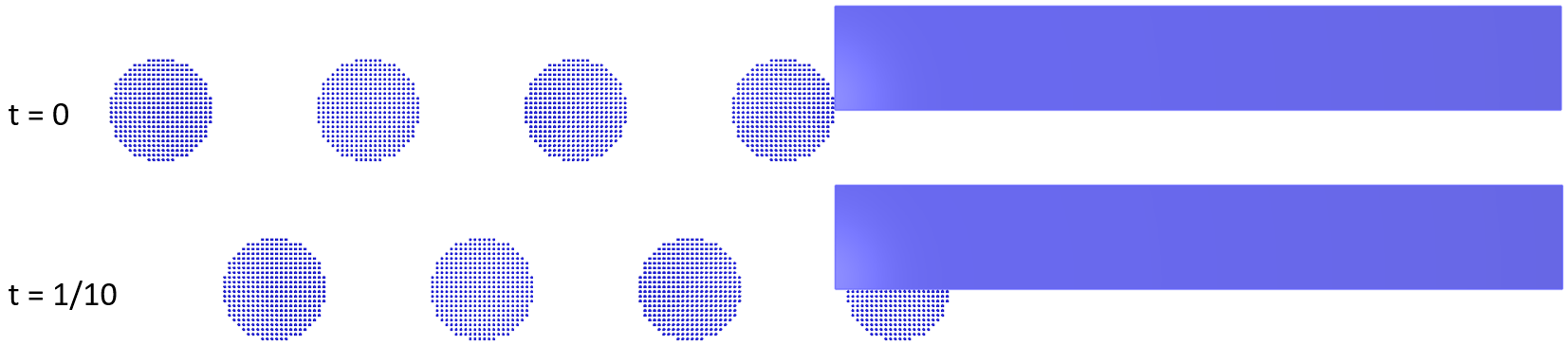

The process is divided into two steps. In step 1, the two plates in each pair are pressed together by a prescribed motion. At termination, the results are exported to a state-filek. The model at initiation and termination is displayed in Figure 1.

In step 2, the state-file is imported. The plates are fixed and a contact with the same configuration as in step 1 is defined. The contact force should therefore be of the same magnitude at termination of step 1, initiation of step 2 and at termination of step 2.

Contact forces in the direction of loading from step 1 and and step 2 are presented in Figure 2 and 3. The discrepancy in contact force between the different element types is mainly due to the coarse mesh that has been used. With a refined mesh, the discrepancy is reduced.

The contact forces are checked at initiation and termination in both steps.

Tests

This benchmark is associated with 2 tests.

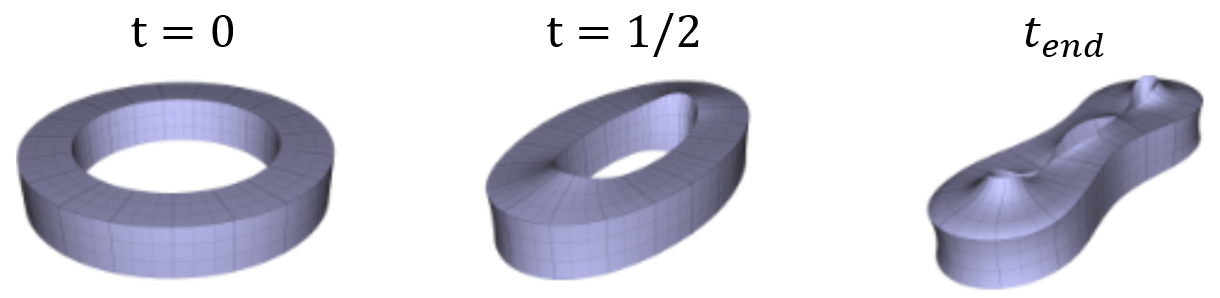

Expanding spheres

"Optional title"

$coid$, $accuracy_{}level$, $accuracy_{}edge$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $\mu$, $pfac$, $t_{beg}$, $t_{end}$

$merge$, $\xi$, $gid_0$, $gid_1$, $\delta_0^{offset}$, $\delta_0^{max}$, $\delta^{edge}$

$fid_{wear1}$, $fid_{wear2}$, $fid_{thermal}$, $\alpha_{edge}$, $one way$, $no_{}internal$

Contact between multiple parts by using the "all-to-all"-option in *CONTACT is verified in this test.

Tested parameters:  ,

,  and

and  (automatic calculation of penalty stiffness).

(automatic calculation of penalty stiffness).

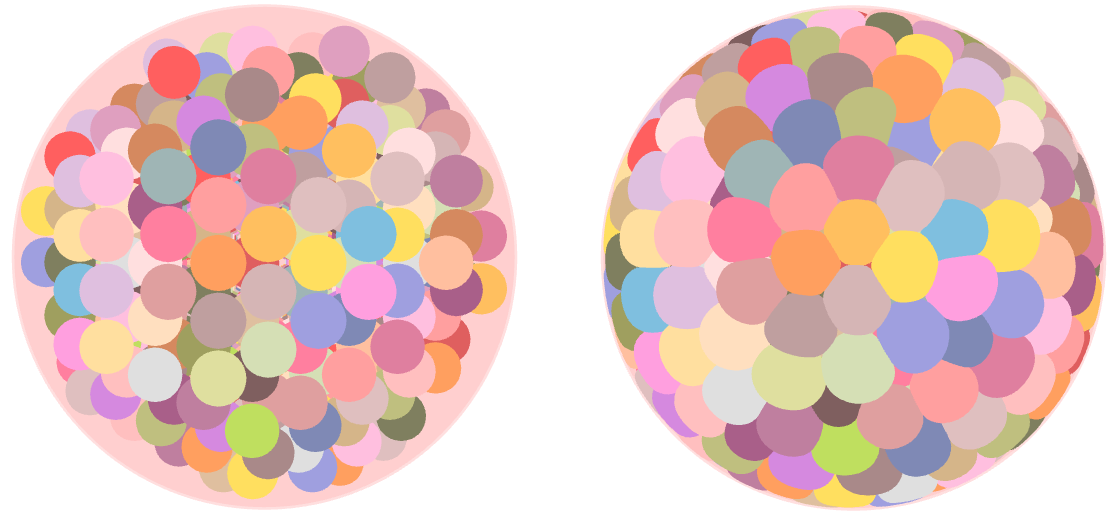

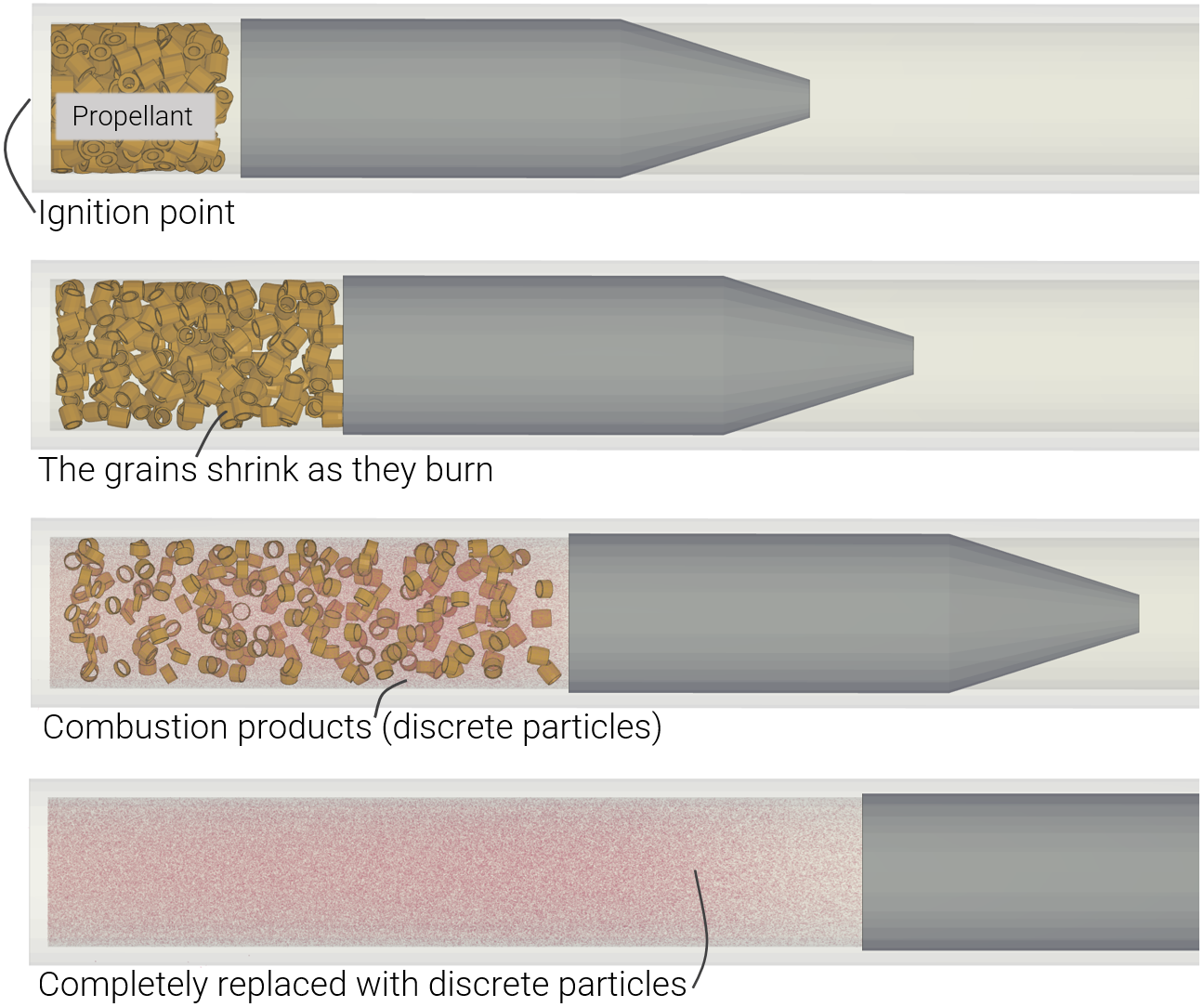

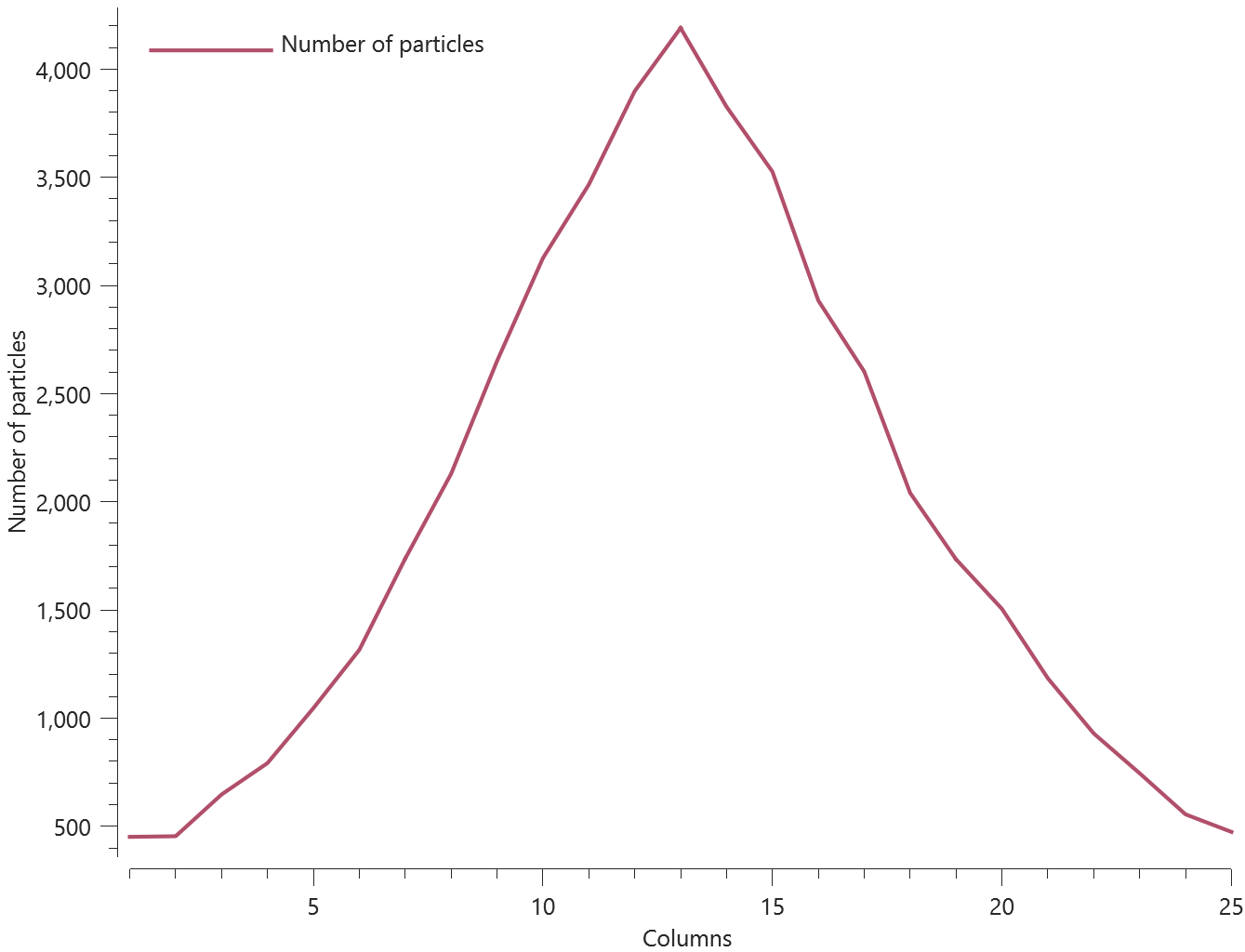

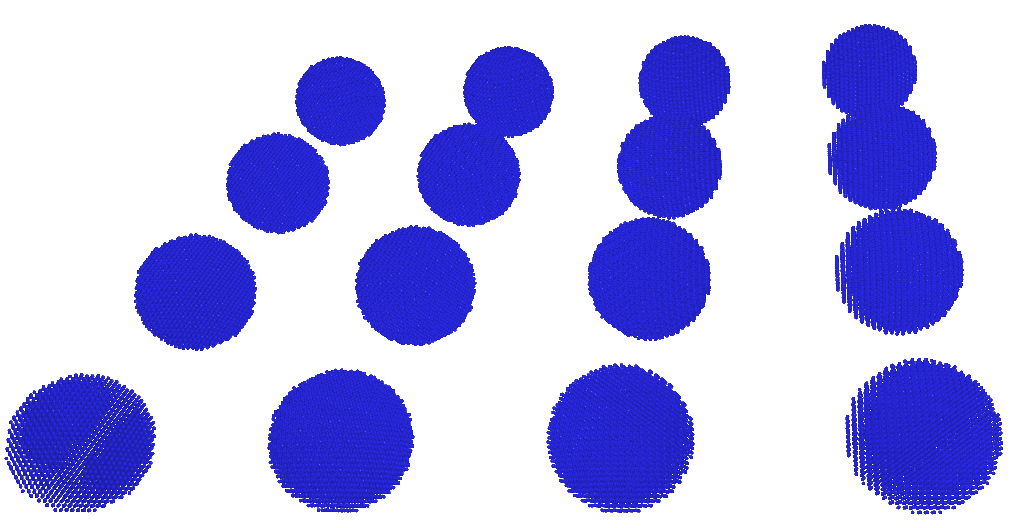

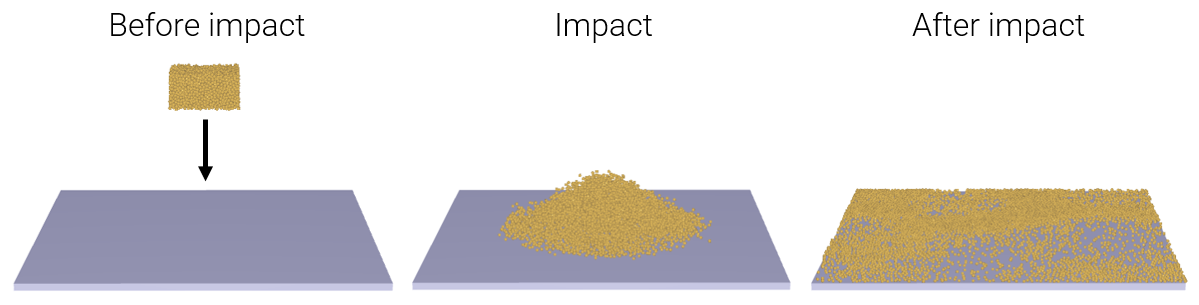

The model consists of 500 deformable spheres inside a rigid casing. There is no initial contact between the spheres, but the spheres are expanding during the course of the simulation, and contact emerges between the spheres.

Maximum contact penetration, contact area at termination and energy balance are checked for version control.

Tests

This benchmark is associated with 1 tests.

Friction work to heat

"Optional title"

$coid$, $accuracy_{}level$, $accuracy_{}edge$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $\mu$, $pfac$, $t_{beg}$, $t_{end}$

$merge$, $\xi$, $gid_0$, $gid_1$, $\delta_0^{offset}$, $\delta_0^{max}$, $\delta^{edge}$

$fid_{wear1}$, $fid_{wear2}$, $fid_{thermal}$, $\alpha_{edge}$, $one _way$, $no_{}internal$, $\sigma_{stick}$, $fric_heat$

Tested parameters: fric_heat.

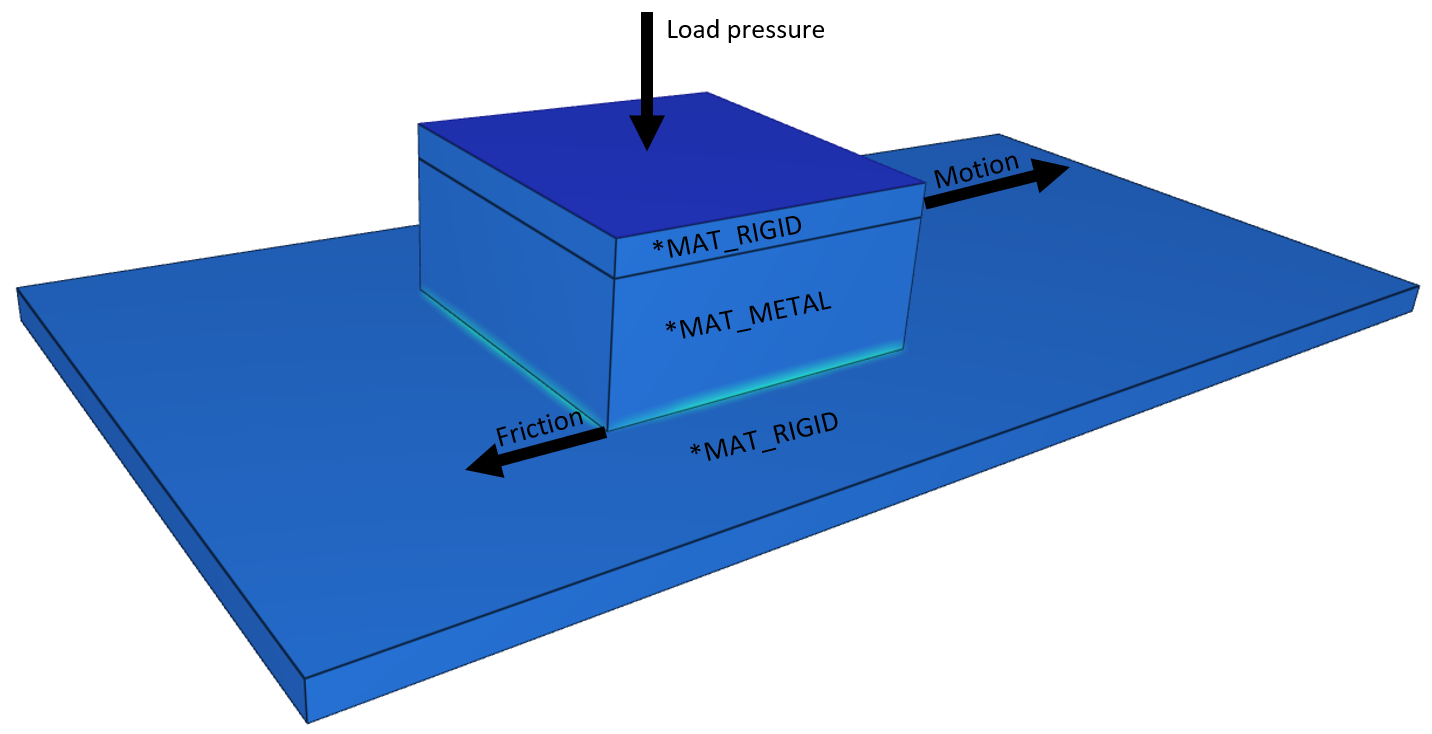

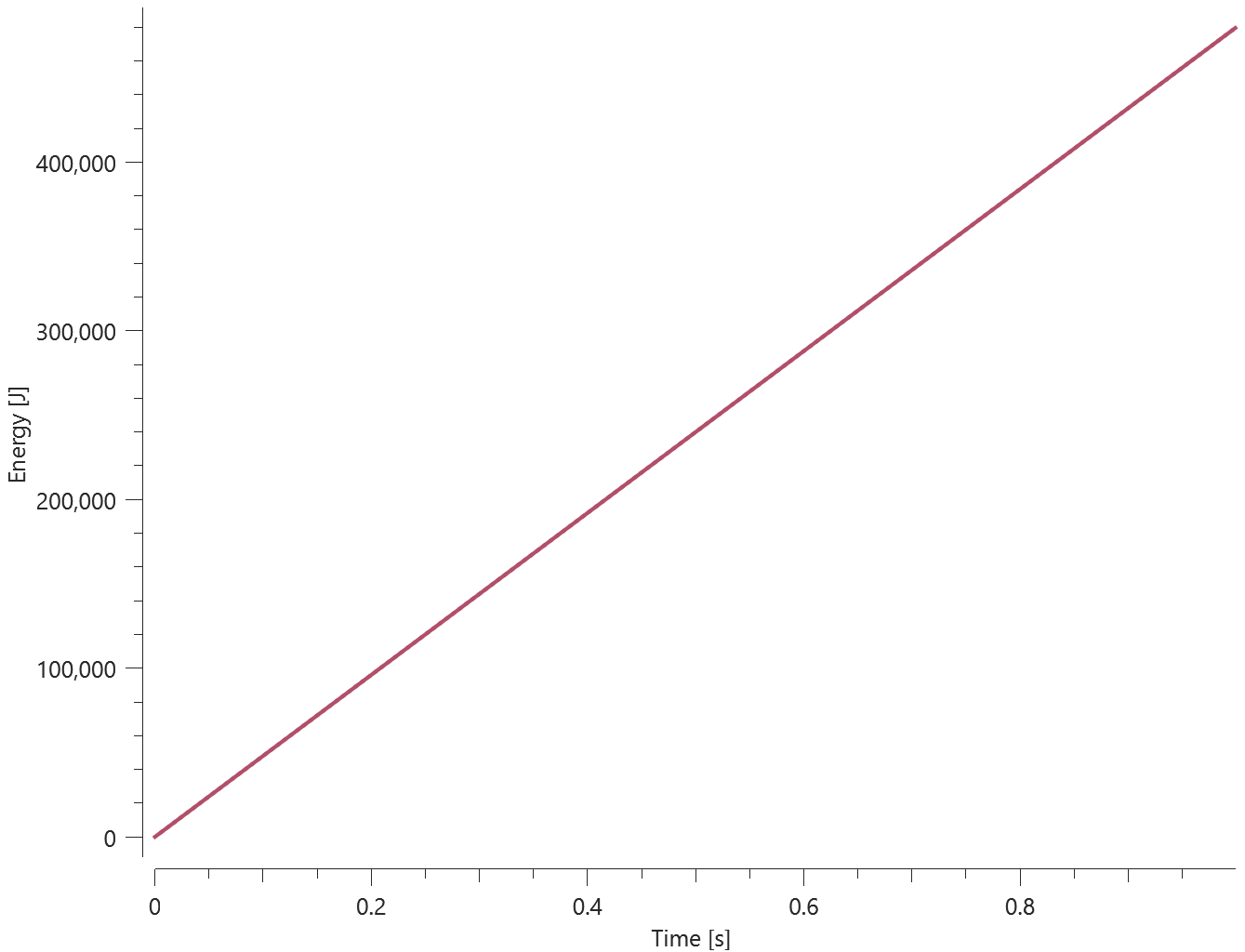

This is a general test for *CONTACT. The model tests friction to heat conversion which is generated when a block is sliding against a plate.

The test setup is displayed in Figure 1.

Targets:

The friction energy generated should be equal to the thermal energy that is added to the block and the plate.

First, average and last values for thermal energy and friction energy is checked for version control.

Tests

This benchmark is associated with 1 tests.

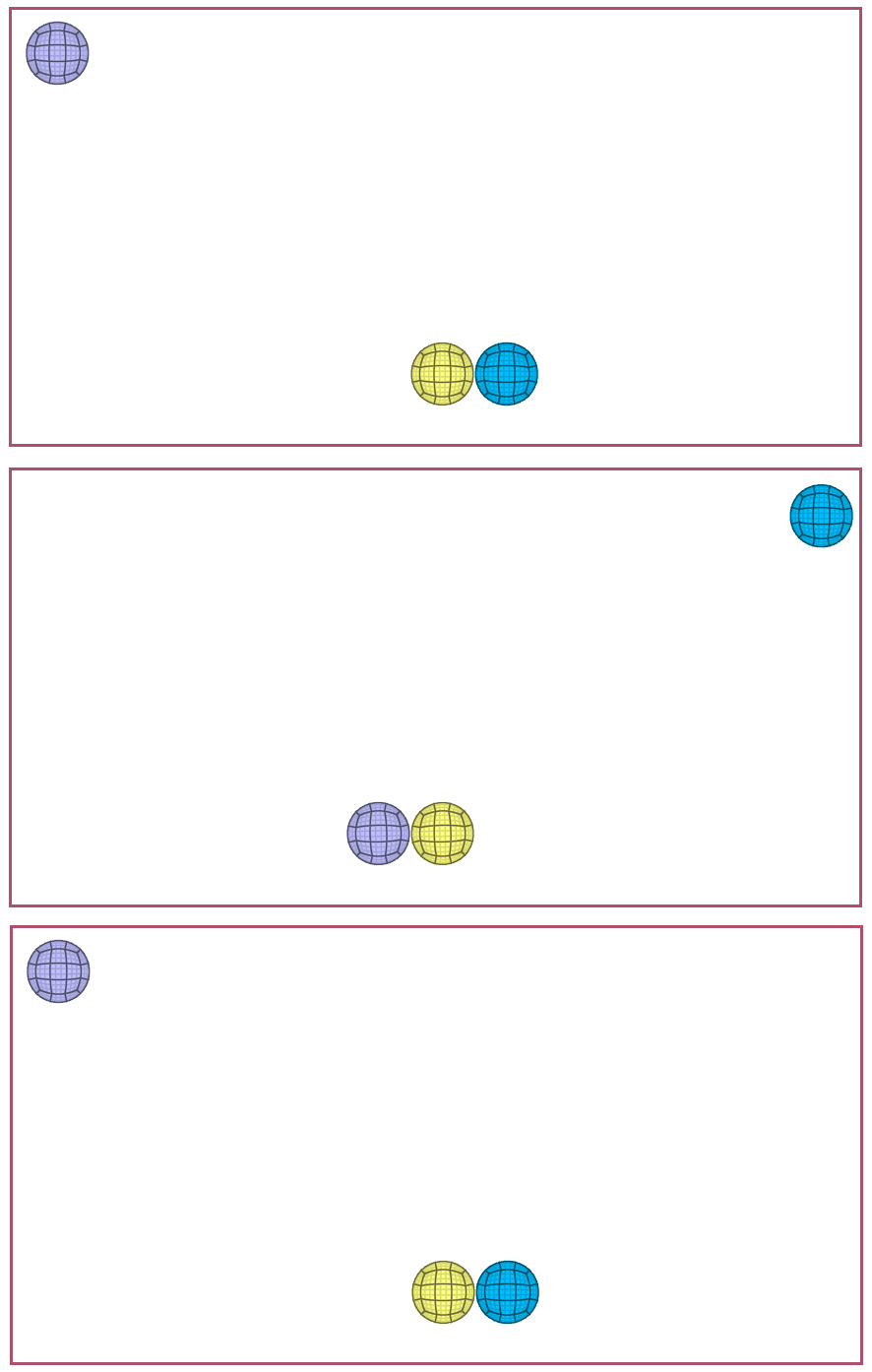

Newtons cradle

"Optional title"

$coid$, $accuracy_{}level$, $accuracy_{}edge$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $\mu$, $pfac$, $t_{beg}$, $t_{end}$

$merge$, $\xi$, $gid_0$, $gid_1$, $\delta_0^{offset}$, $\delta_0^{max}$, $\delta^{edge}$

$fid_{wear1}$, $fid_{wear2}$, $fid_{thermal}$, $\alpha_{edge}$, $one way$, $no_{}internal$

This is a general test for *CONTACT.

Tested parameter:  (automatic calculation of penalty stiffness).

(automatic calculation of penalty stiffness).

A Newton's cradle containing three balls is simulated in this test. The model is displayed in Figure 1. The collisons are elastic and no energy loss occurs in the system.

The energy balance, and maximum and minimum kinetic energy of the balls are checked.

Tests

This benchmark is associated with 1 tests.

Vickers hardness test

"Optional title"

$coid$, $accuracy_{}level$, $accuracy_{}edge$

$entype_1$, $enid_1$, $entype_2$, $enid_2$, $\mu$, $pfac$, $t_{beg}$, $t_{end}$

$merge$, $\xi$, $gid_0$, $gid_1$, $\delta_0^{offset}$, $\delta_0^{max}$, $\delta^{edge}$

$fid_{wear1}$, $fid_{wear2}$, $fid_{thermal}$, $\alpha_{edge}$, $one way$, $no_{}internal$

This is a general test for *CONTACT.

Tested parameters:  (automatic calculation of penalty stiffness).

(automatic calculation of penalty stiffness).

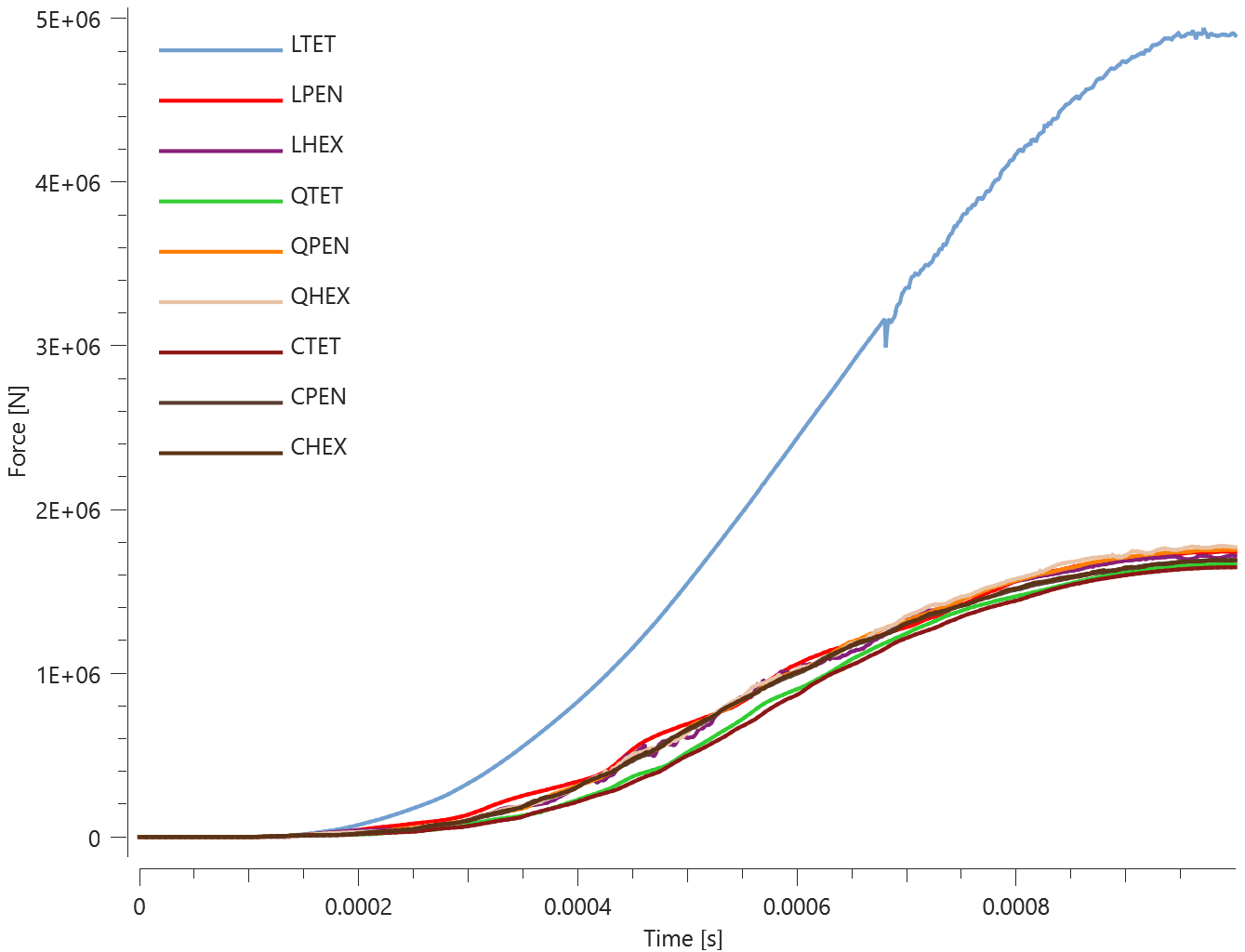

This is a model of a Vickers hardness test. The test is done with nine specimens, each modeled with a unique type of solid elements. The indenter is modeled with LHEX-elements in all cases, since negligible deformations are expected in the indenter. The specimen configuration is presented in Figure 1 and the maximum contact pressure is presented in Figure 2.

Contact forces vs. time are presented in Figure 3. Similar response is obtained from all specimens except for the linear tetrahedron specimen, which shows a significantly stiffer response.

Maximum contact force, maximum contact penetration and energy balance are checked.

Tests

This benchmark is associated with 1 tests.

*CONTACT_ACCURACY

Accuracy edge

"Optional title"

coid, entype, enid, accuracy_level, accuracy_edge

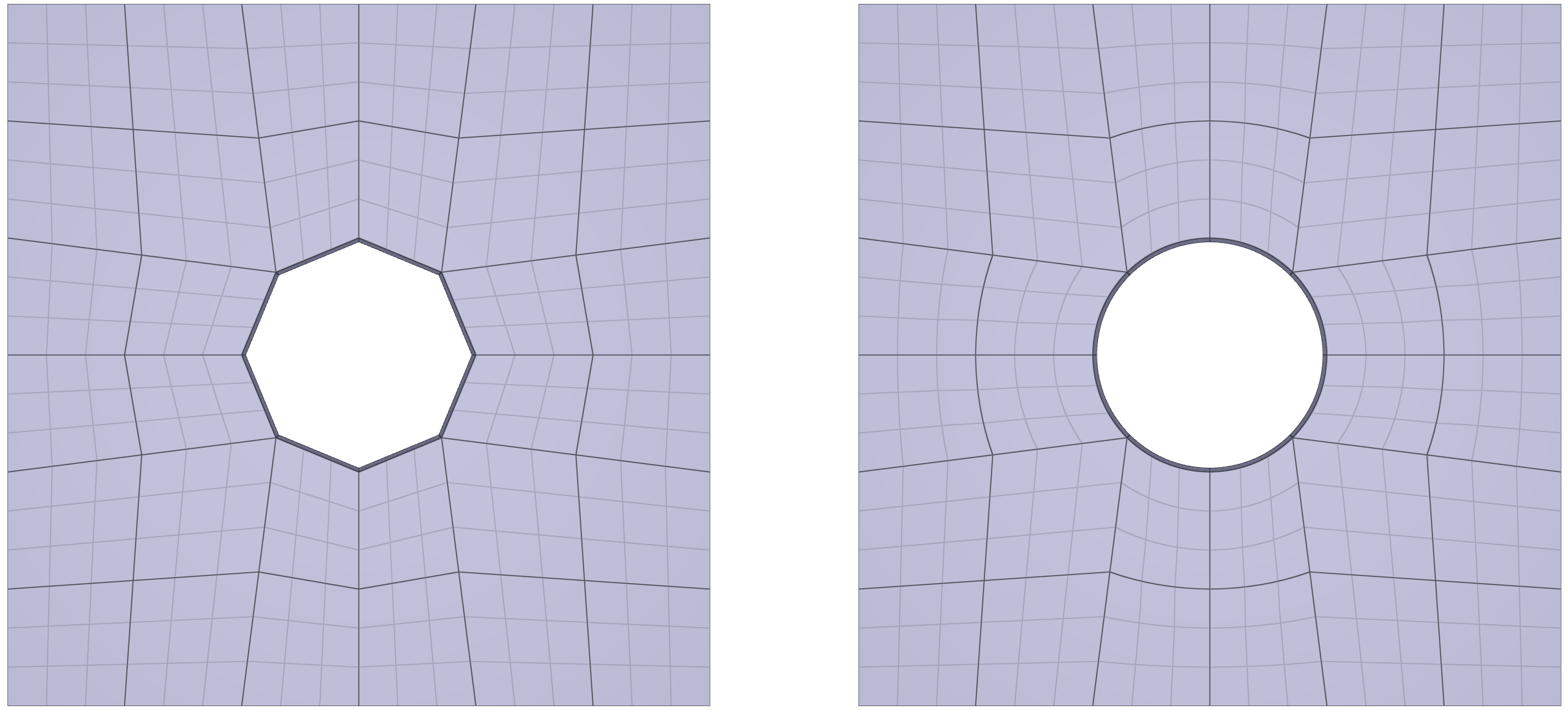

Accuracy edge in *CONTACT_ACCURACY is verified in this test.

Tested parameters: accuracy_edge

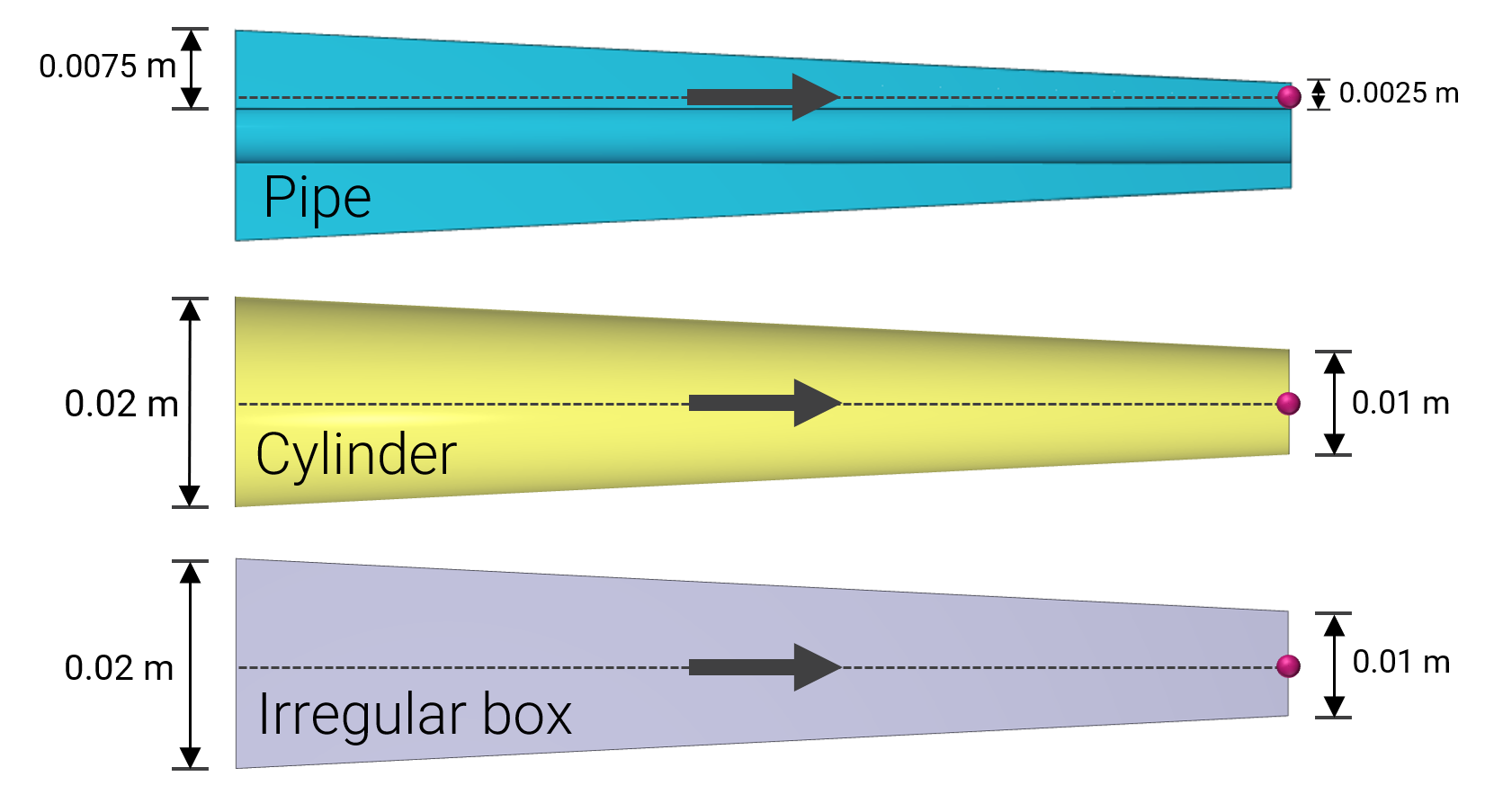

Two identical sets consisting of a cube and a cylinder are used in this test. The cylinders are linearly tapered, and the inner radius at one end equals the cubes face diagonal,  , while the radius on the other end equals

, while the radius on the other end equals  .

.

The cubes are positioned inside the cylinders, so that only edges are in contact, and given an initial velocity so that they move towards the other sides of the cylinders. The test setup is displayed in Figure 1.

Contact forces between the cubes and the cylinders increases gradually as the cubes are moving down the cylinders. The smoothness of the contact forces are controlled with contact accuracy. The accuracy level used is 10 for both sets but the flag to activate increased accuracy at sharp edges (Accuracy_edge) is activated for the second set (right) but not for the first set(left). The initial and final state of the model is displayed in Figure 2.

Contact force vs time for both sets is presented in Figure 3.

As seen in Figure 3, Accuracy_edge when activated leads to increased contact force.

Maximum and average contact force is checked for both sets.

Tests

This benchmark is associated with 1 tests.

Accuracy level

"Optional title"

coid, entype, enid, accuracy_level, accuracy_edge

Contact accuracy level in *CONTACT_ACCURACY is verified in this test.

Tested parameters: accuracy_level

Four identical sets consisting of a sphere and a cylinder are used in this test.The cylinders are linearly tapered, and the inner radius at one end equals the sphere radius,  , while the radius on the other end equals

, while the radius on the other end equals  .

.

The spheres are positioned inside the cylinders, at the end with a radius  , and given an initial velocity so that they move towards the other end of the cylinder. The initial and final state of the model is displayed in Figure 1.

, and given an initial velocity so that they move towards the other end of the cylinder. The initial and final state of the model is displayed in Figure 1.

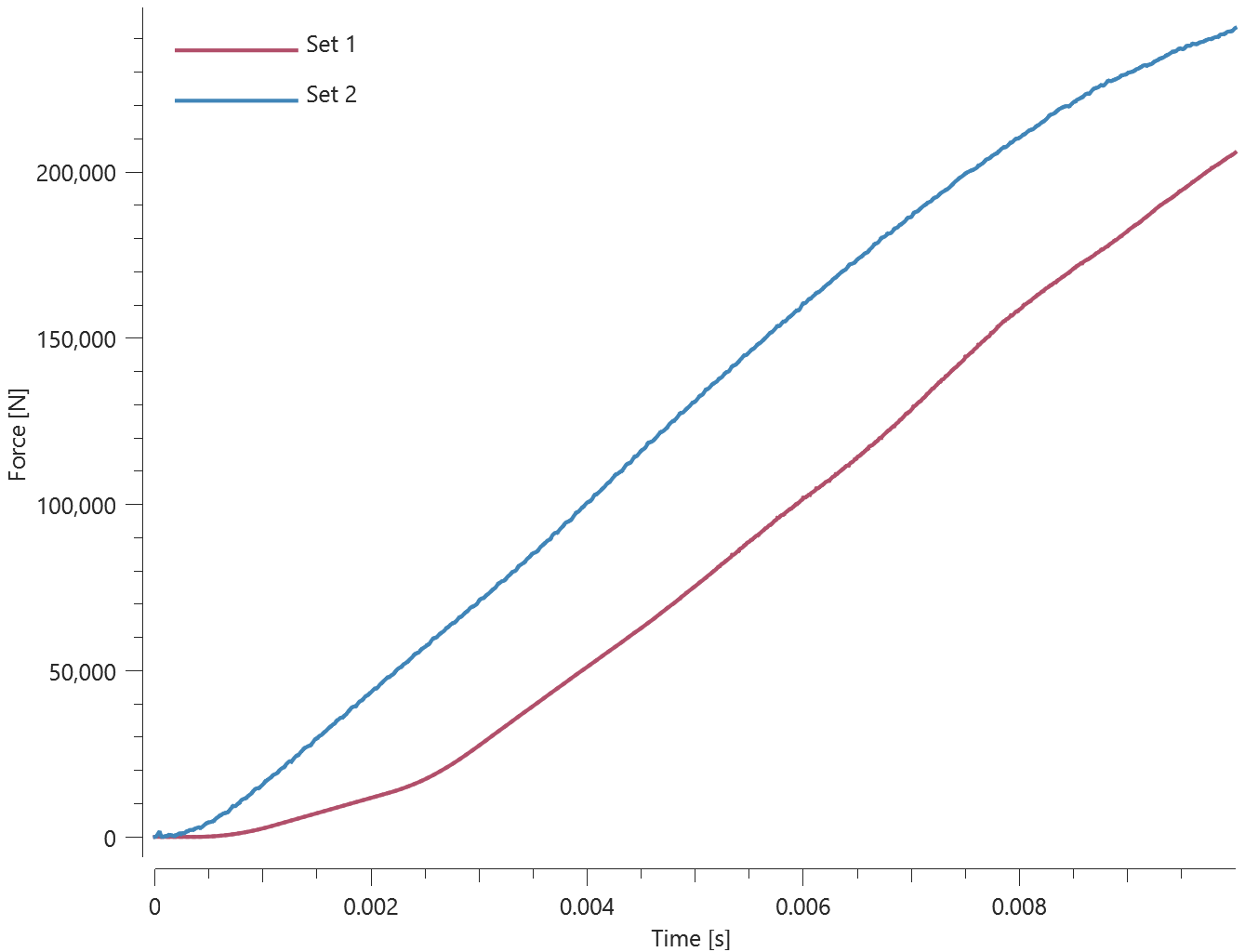

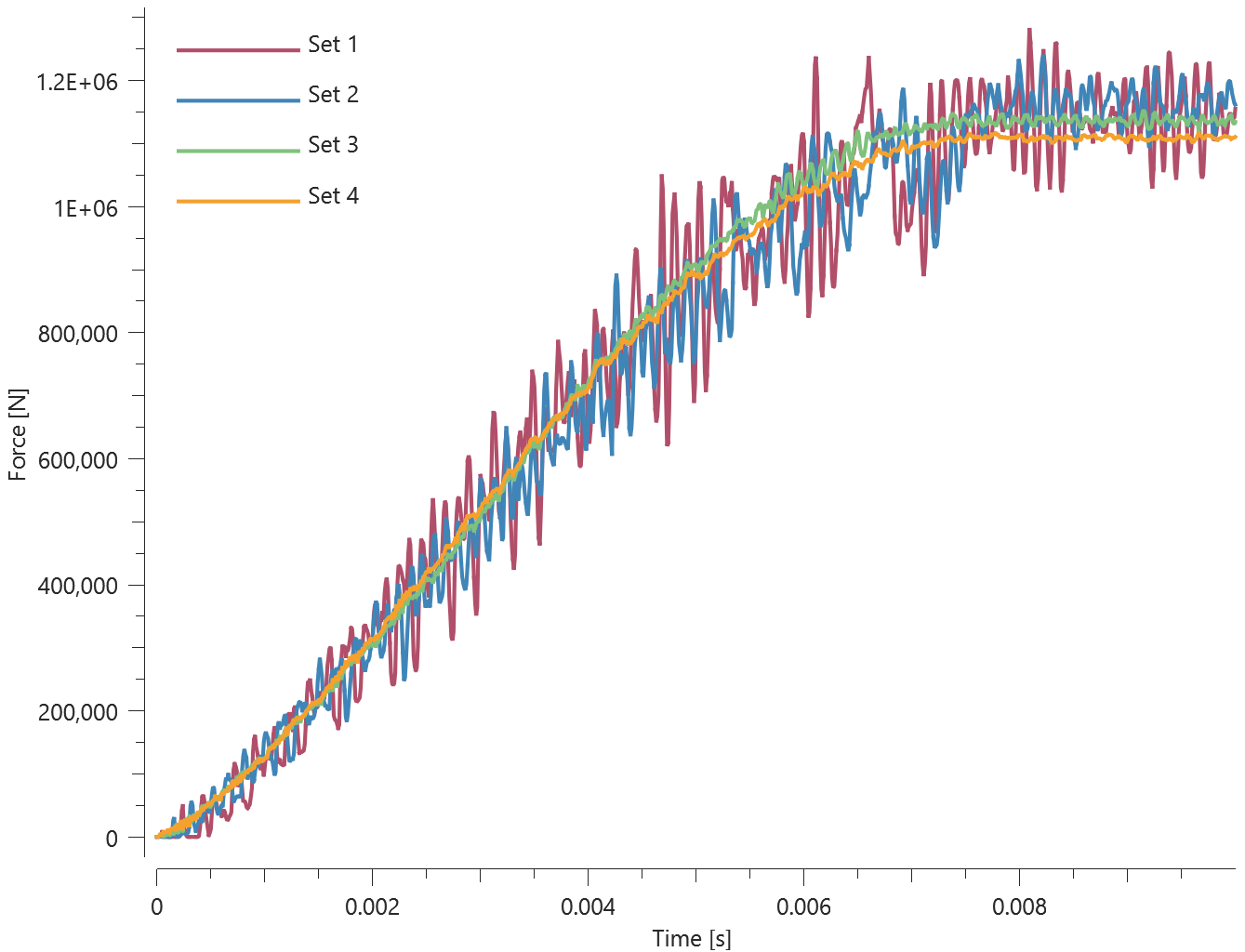

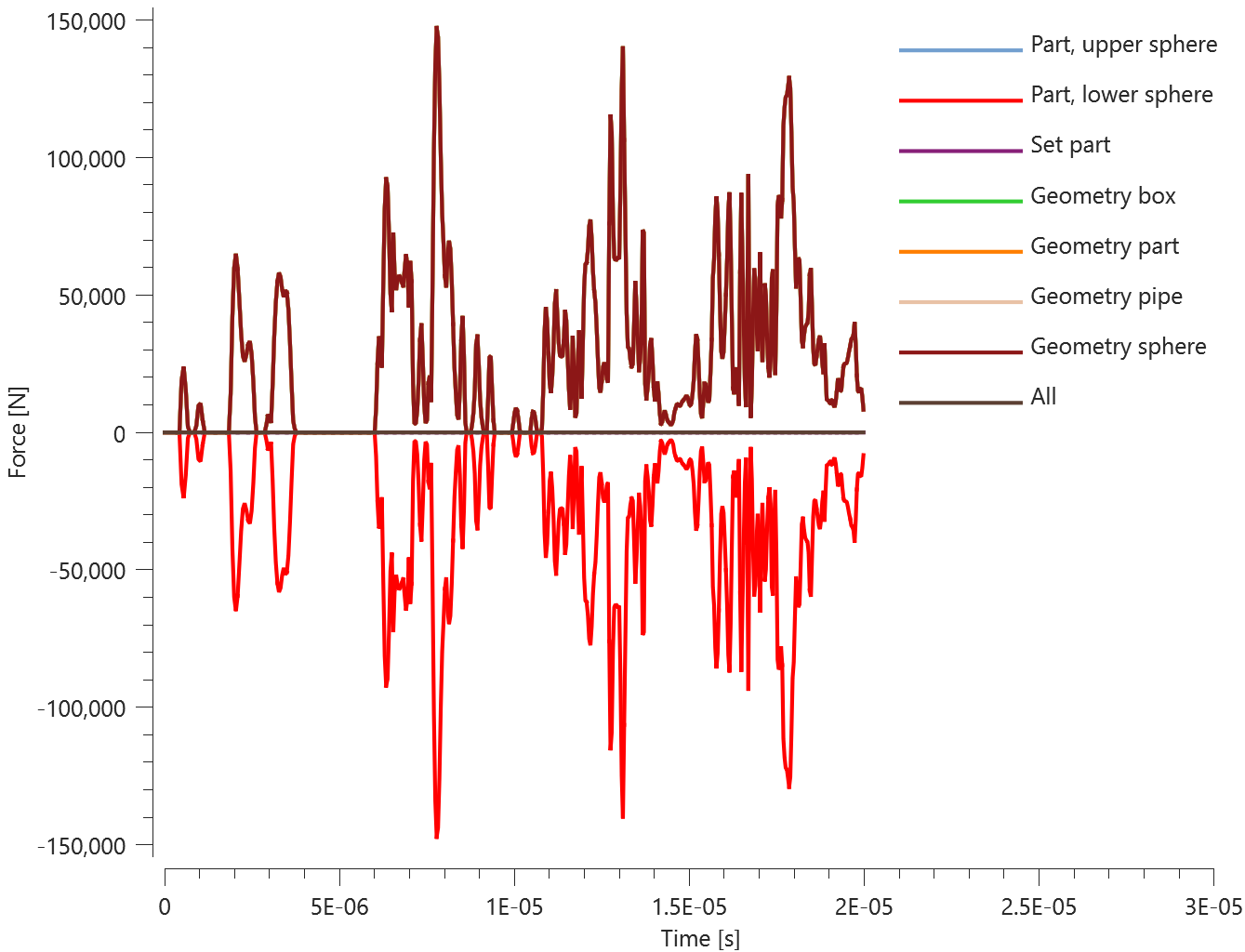

Contact forces between the spheres and the cylinders increase gradually as the spheres moves down the cylinder, and the smoothness of the contact forces are controlled by the contact accuracy. Investigated accuracy levels are 1, 2, 3 and 10 for set 1, 2, 3 and 4, respectively.

Contact force vs time for each set is presented in Figure 2.

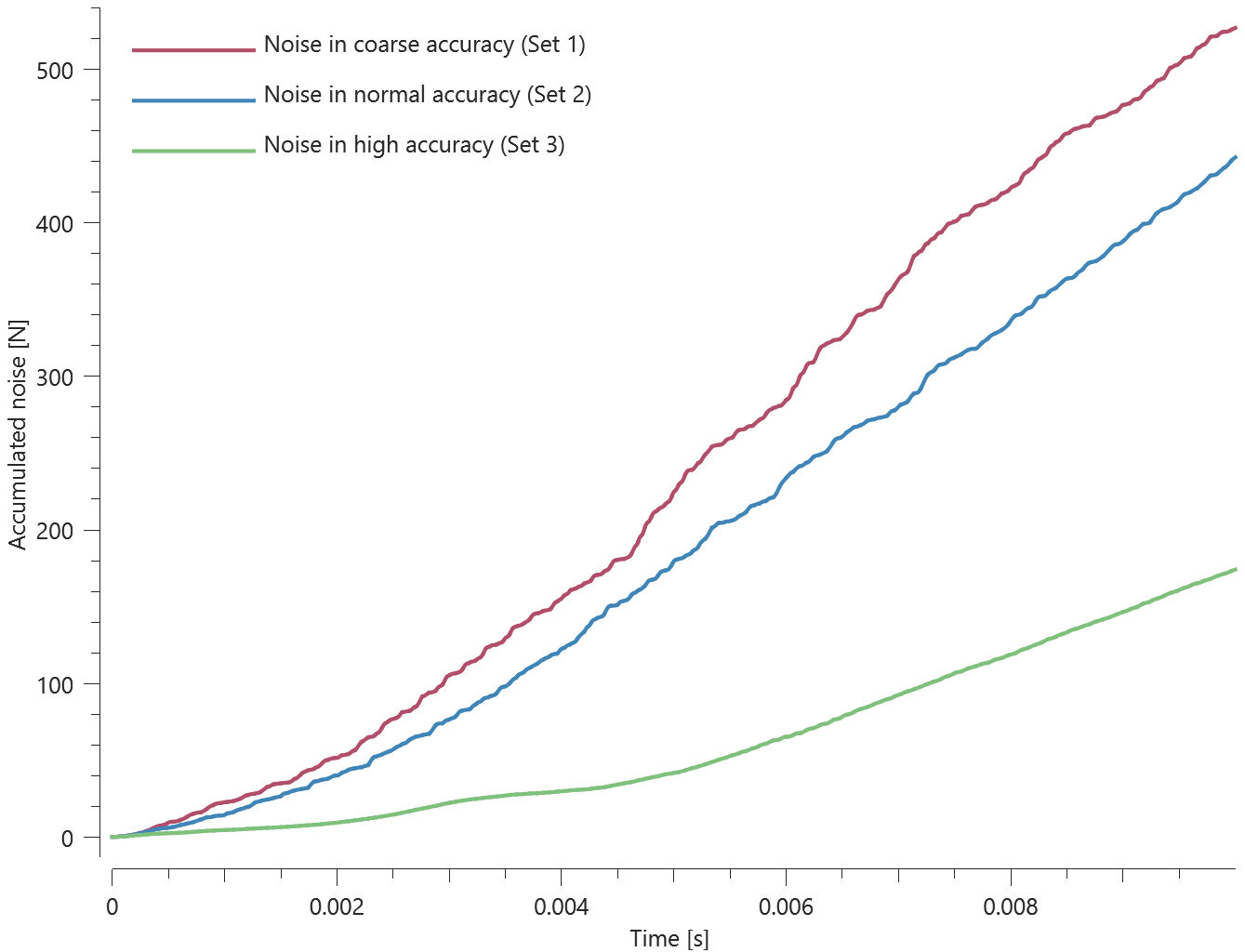

Quantifying the "noise" of the contact force in set 1, 2 and 3 is done by integrating the absolute value of the difference between contact force in set 1, 2, 3 and the contact force of set 4, meaning that contact force in set 4 acts as reference curve. The accumulated noise of set 1, 2, 3 is presented in Figure 3.

As seen in Figure 3, a higher contact accuracy leads to reduced level of noise.

Maximum and average contact force in set four is checked together with maximum and average accumulated noise in set 1, 2 and 3.

Tests

This benchmark is associated with 1 tests.

*CONTACT_REBAR

"Optional title"

$switch$

The command *CONTACT_REBAR is tested. The command is used to define contact between rebars and the "regular" FE-elements. Five boxes (*COMPONENT_BOX) and five rebars (*COMPONENT_REBAR) are used in the test, see Figure below.

The rebars are at rest at initiation whereas a prescribed velocity of 10 m/s is imposed on the boxes (towards the rebars). The boxes impacts the rebars and the kinetic energy of each rebar at termination is checked for version control. The largest contact penetration is also checked.

Tests

This benchmark is associated with 1 tests.

*COORDINATE_SYSTEM

Position

"Optional title"

csysid, $x_0$, $y_0$, $z_0$, pid

$\hat{x}_x$, $\hat{x}_y$, $\hat{x}_z$, $\bar{y}_x$, $\bar{y}_y$, $\bar{y}_z$

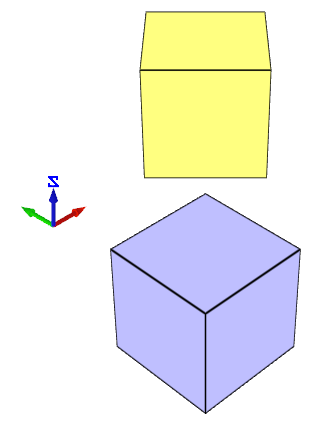

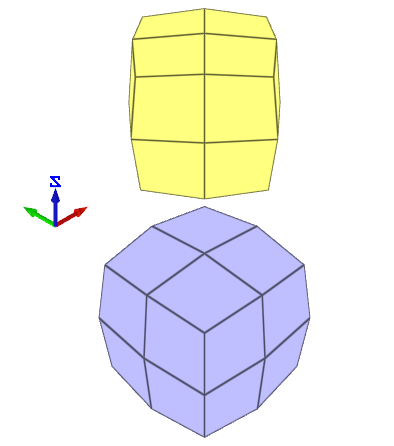

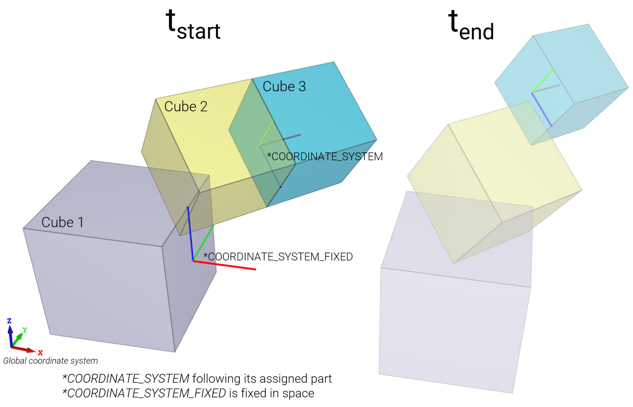

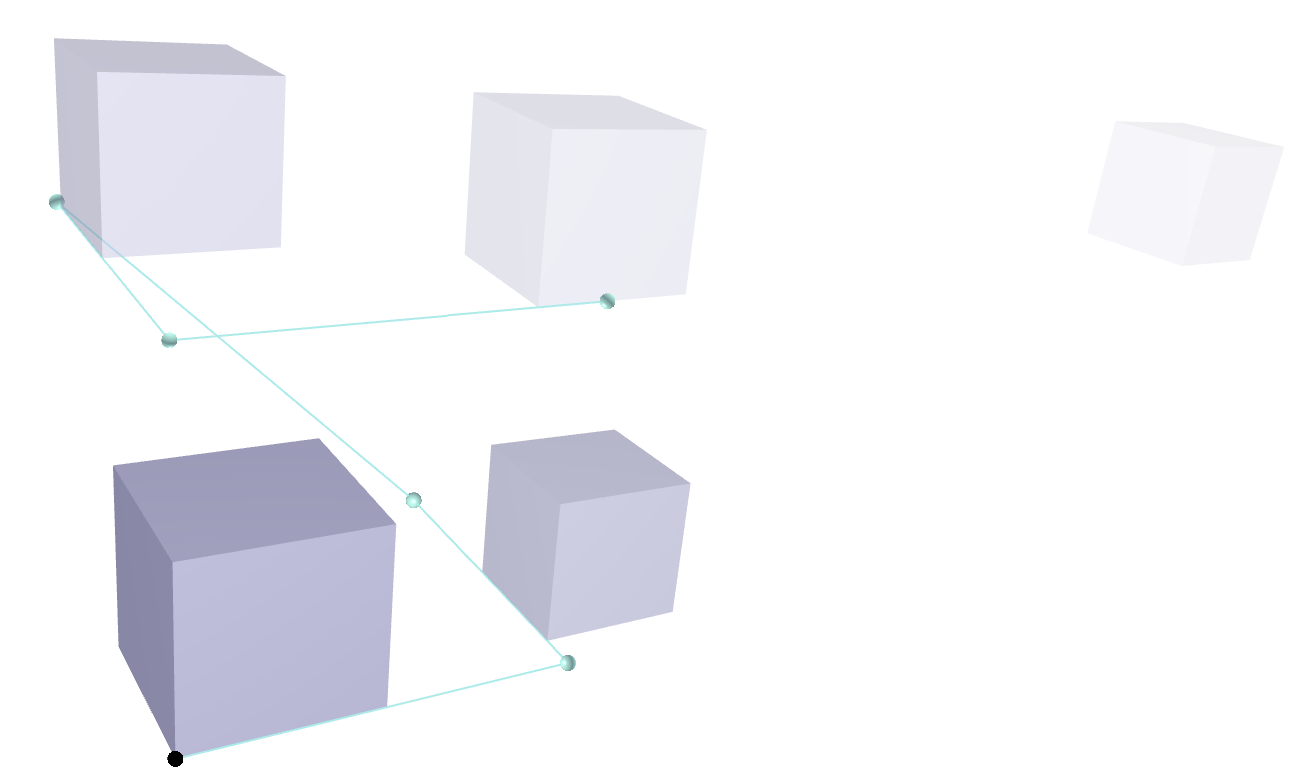

This model tests the *COORDINATE_SYSTEM command. Three identical cubes are created with side length 1.

Cube 1 is created with a fixed coordinate system while the other cubes are created with a tilted coordinate system with its origin located on the boundary between them.

The coordinate system is given an optional part ID of 3 which ties it to cube 3.

The cubes are set in motion and as cube 3 separates from cube 2, the coordinate system is forced to follow cube 3 while the fixed coordinate system remains at its initial location.

See Figure 1.

The final positions of the coordinate systems are checked in the version control.

Tests

This benchmark is associated with 1 tests.

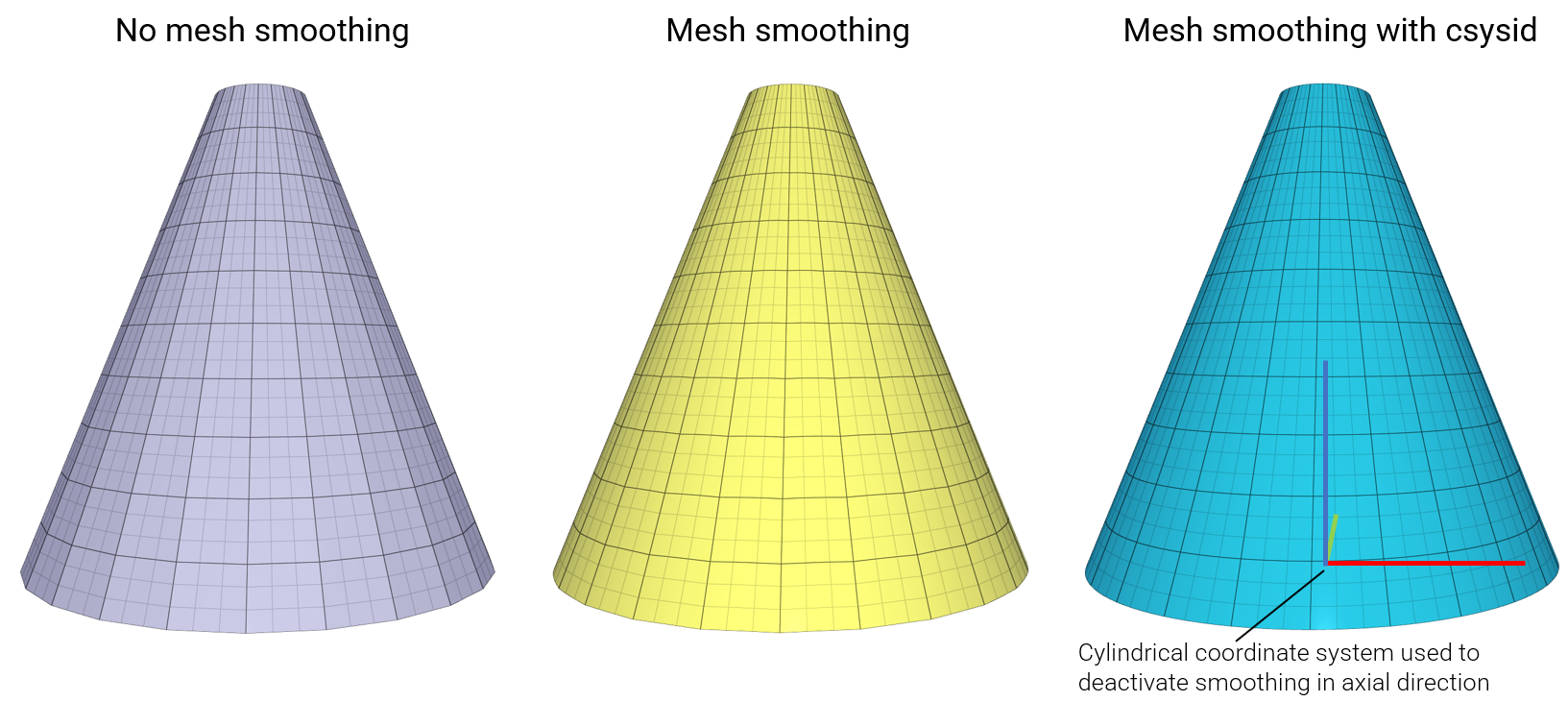

*COORDINATE_SYSTEM_CYLINDRICAL

$csysid$, $x_0$, $y_0$, $z_0$

$\hat{z}_x$, $\hat{z}_y$, $\hat{z}_z$, $\hat{R}_{0x}$, $\hat{R}_{0y}$, $\hat{R}_{0z}$

This tests the *COORDINATE_SYSTEM_CYLINDRICAL command. This command is used with *TRANSFORM_MESH_CYLINDRICAL to transform a mesh with defined cylindrical coordinates. The model is a pipe. In the transformation, inner and outer radius are decreased and the model is translated in the axial direction. Final coordinates of two nodes at opposite ends are checked for version control. One is at the inner radius, the other at the outer radius.

Tests

This benchmark is associated with 1 tests.

*COORDINATE_SYSTEM_FIXED

$csysid$, $x_0$, $y_0$, $z_0$

$\hat{x}_x$, $\hat{x}_y$, $\hat{x}_z$, $\bar{y}_x$, $\bar{y}_y$, $\bar{y}_z$

This model tests the *COORDINATE_SYSTEM_FIXED command. Two elements are created, one at the center of the global coordinate system and one at the center of a fixed, local coordinate system. The latter system is shifted one unit along all axis and the direction of the X-axis in the global coordinate system has the unit vector ( ). It is therefore at a 45° angle in the XY-plane relative to the global system.

). It is therefore at a 45° angle in the XY-plane relative to the global system.

The center of the cubes are at origin of their respective coordinate systems, with side lengths of 1 unit. Node 1 of the first cube should thus have coordinates ( ). The corresponding node of the second cube, node 9, should have coordinates (

). The corresponding node of the second cube, node 9, should have coordinates ( ). This is checked in the version control.

). This is checked in the version control.

Tests

This benchmark is associated with 1 tests.

*COORDINATE_SYSTEM_FUNCTION

Coordinate system defined with functions

"Optional title"

csysid, $x_0$, $y_0$, $z_0$

$\hat{x}_x$, $\hat{x}_y$, $\hat{x}_z$, $\bar{y}_x$, $\bar{y}_y$, $\bar{y}_z$

Tested parameters : csysid,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  ,

,  .

.

This model tests the command *COORDINATE_SYSTEM_FUNCTION.

A local coordinate system with its origin following sensor ID=1 and with prescribed, time dependent, direction cosines.

It is rotating 360° around its Z-axis for the time duration.

A cube with side length  is given a prescribed displacement of

is given a prescribed displacement of  in the global X-direction.

The local coordinate system is used as a translational constraint for the cube, restricting its motion in the current local Y- and Z-axis.

Hence, the cube will only translate in the local coordinate system's current X-direction. See Figure 1.

in the global X-direction.

The local coordinate system is used as a translational constraint for the cube, restricting its motion in the current local Y- and Z-axis.

Hence, the cube will only translate in the local coordinate system's current X-direction. See Figure 1.

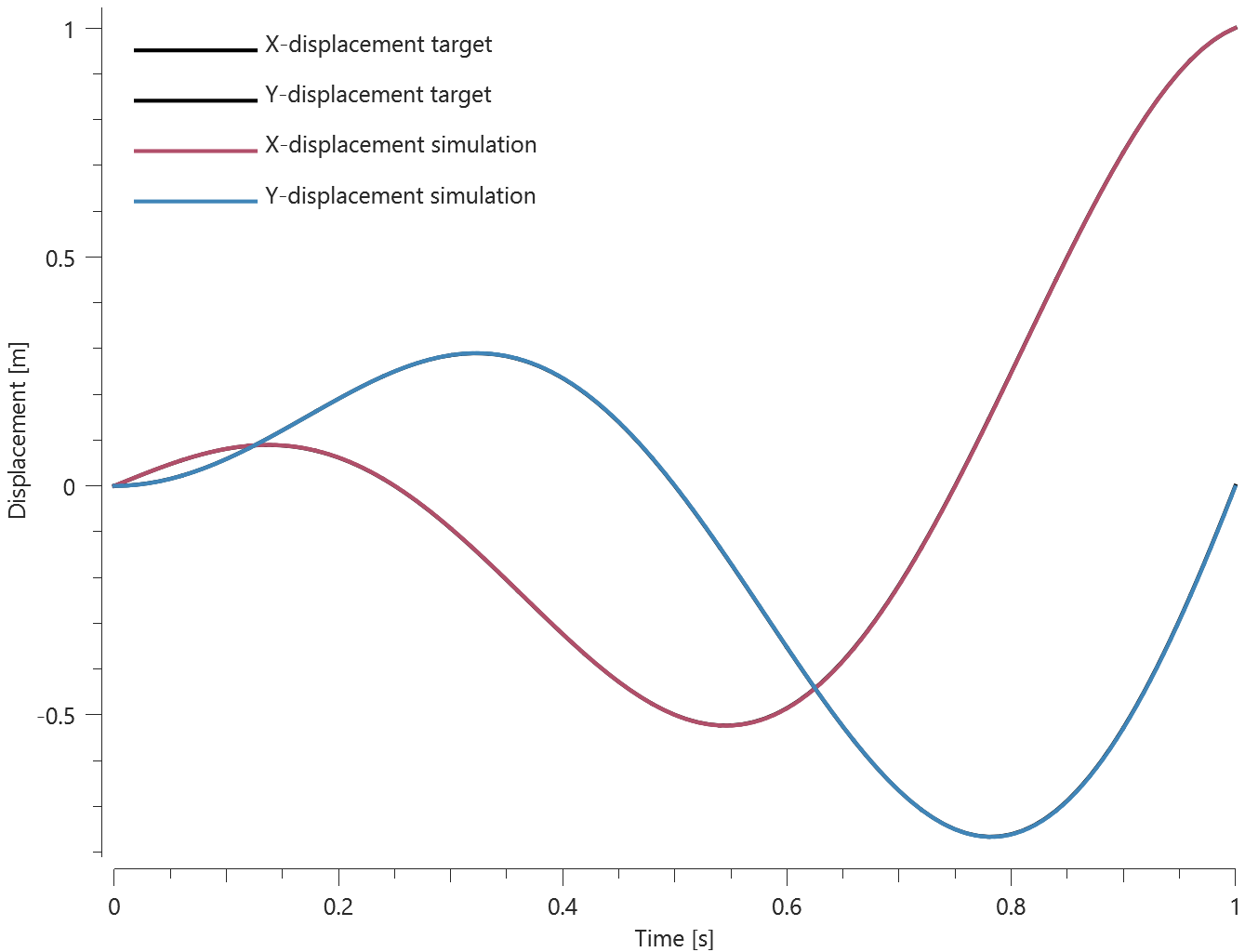

The displacement of the cube is displayed in Figure 2 together with target curves from a verification script.

Final translation should be  in the global X-direction. The position of the cube is checked for version control.

in the global X-direction. The position of the cube is checked for version control.

Tests

This benchmark is associated with 1 tests.

*COORDINATE_SYSTEM_NODE

$csysid$, $N_1$, $N_2$, $N_3$

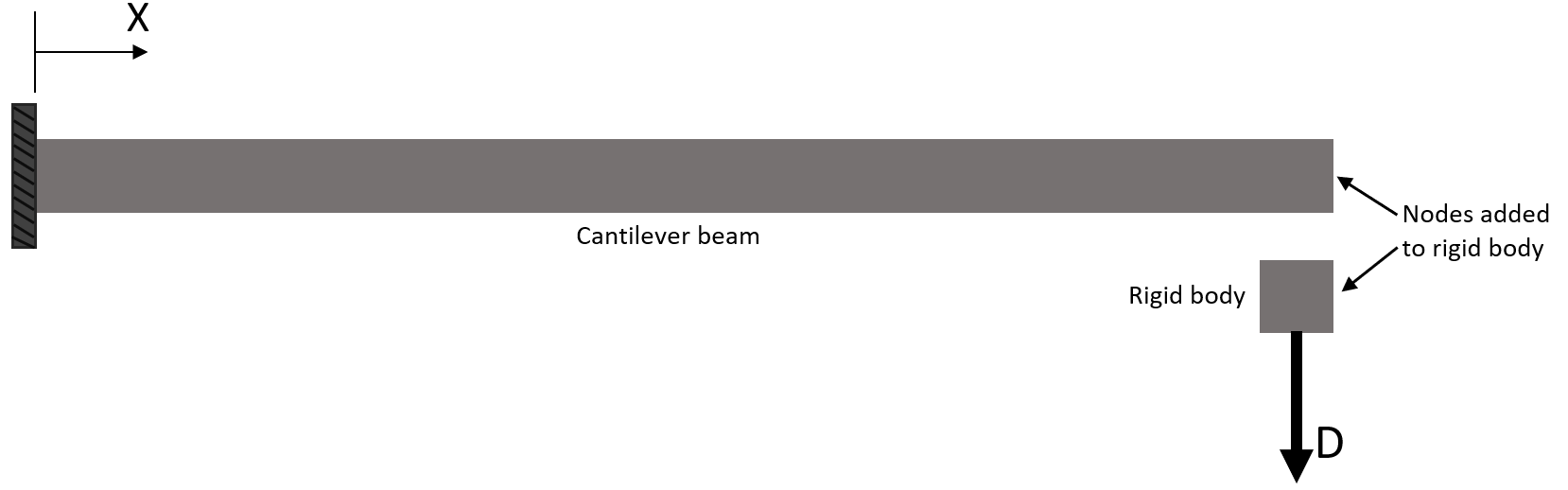

This tests the *COORDINATE_SYSTEM_NODE command. A metal box has a rigid box merged to it at one end. A constant force is applied to the rigid body with *LOAD_FORCE. This force is defined in a node coordinate system so as to always act perpendicular to the length of the model. It thus acts as a torque on the box.

At the opposite end, in the plane of the applied force, the corner nodes are constrained in all directions such that the box can only rotate about the z-axis. The torque is parallel to the Z-axis, in the opposite direction ( ).

).

The spin of the rigid body about the Z-axis should therefore decrease linearly. This is checked for version control.

Tests

This benchmark is associated with 1 tests.

*CURVE

"Optional title"

$cid$, $sf_{\mathrm{x}}$, $sf_{\mathrm{y}}$, $type_{\mathrm{x}}$, $type_{\mathrm{y}}$

$x_1$, $y_1$

.

$x_{\mathrm{n}}$, $y_{\mathrm{n}}$

This tests the *CURVE command. Three rigid elements are moved by the *BC_MOTION command. All motion is defined by displacement set by *CURVE inputs. One element follows a simple linear trajectory before returning to initial position, while the two other elements follows trajectories that have scaled abissa or ordinate values. Displacement of elements are checked for version control.

Tests

This benchmark is associated with 1 tests.

*DEFINE_ELEMENT_SET

Change element type in impact zone

"Optional title"

coid

entype, enid, fid, padding

Tested parameters: coid, entype, enid, fid, padding.

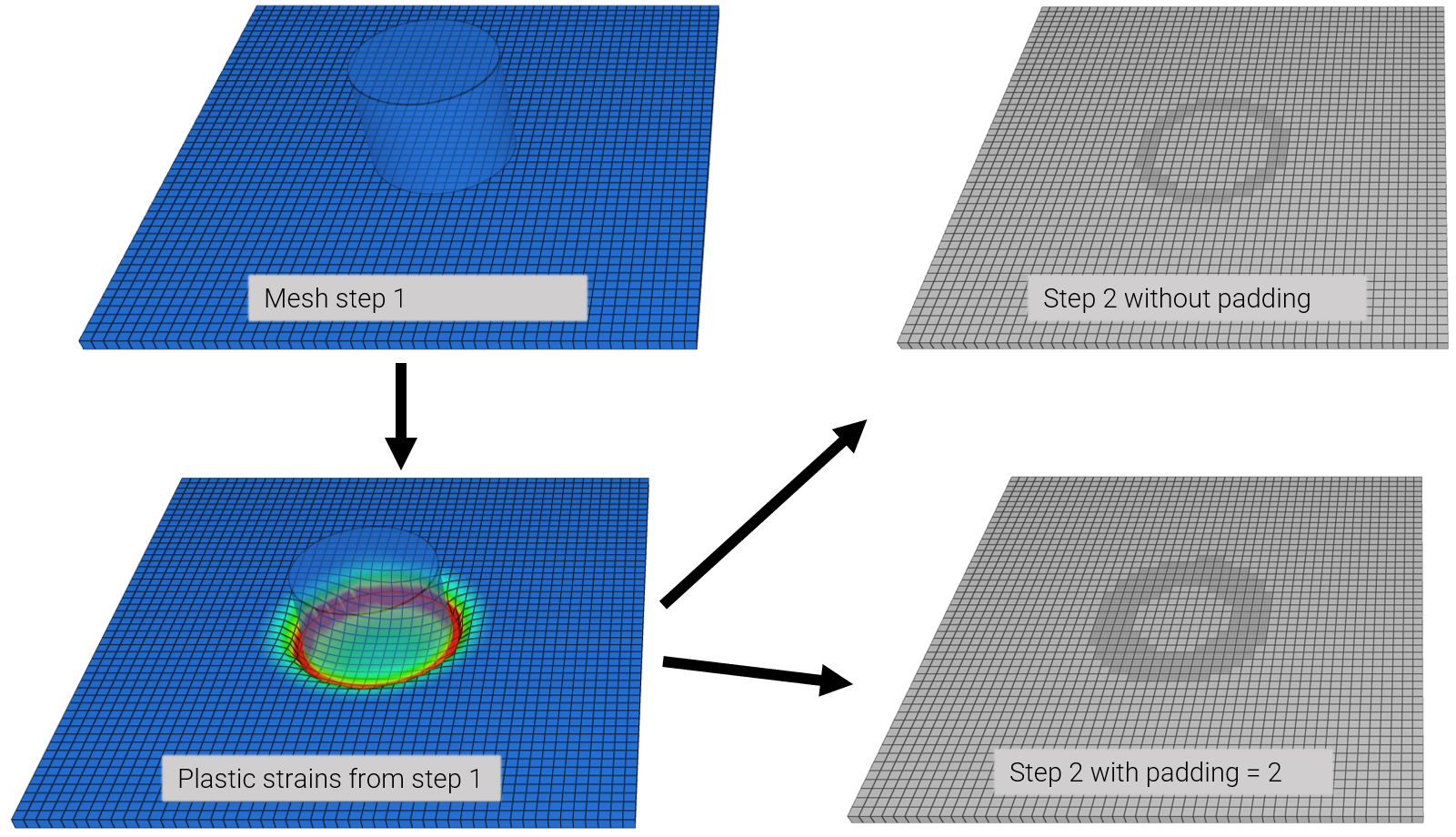

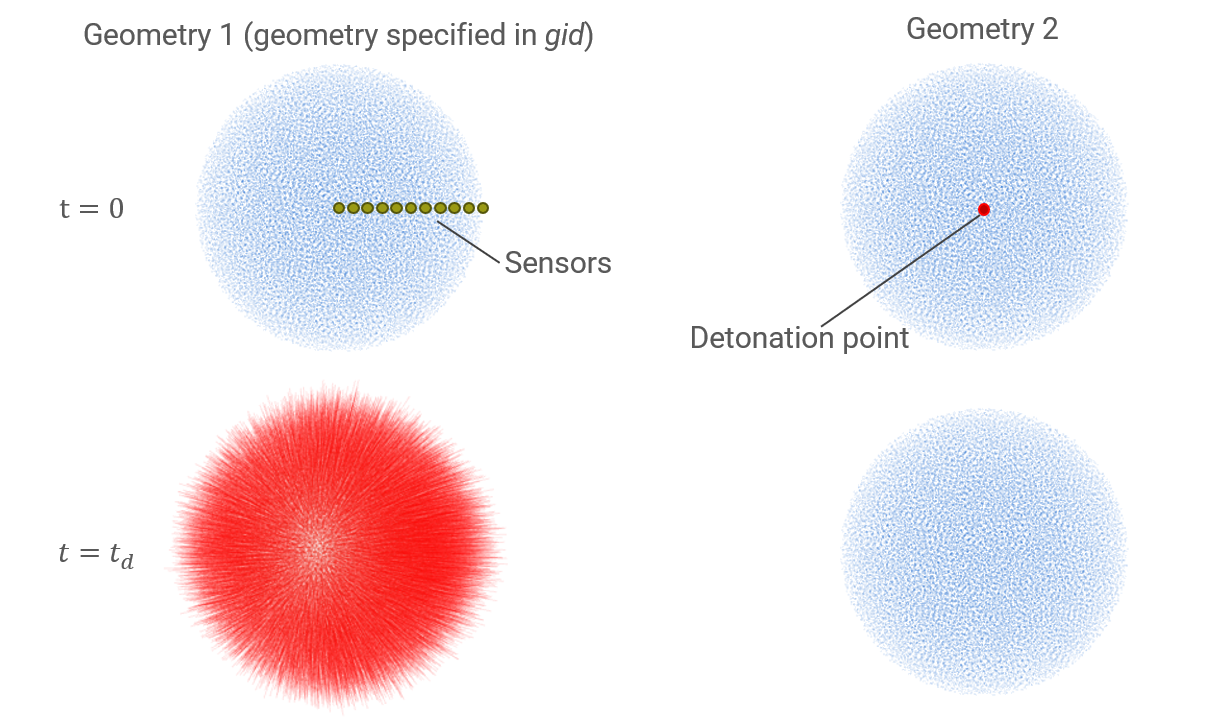

This model tests the command *DEFINE_ELEMENT_SET. It consists of two steps.

A cylindrical impactor punches a hole in a plate. The model is first run with only linear elements (Step 1).

The purpose of this step is to identify the region undergoing large deformations.

This is done by formulating an inclusion criteria by setting a FUNCTION (here defined as elements with effective plastic strains larger than 0.5).

The FUNCTION is evaluated for each element in the part.

An element will be included in the part set if the function returns a positive value.

At termination, the element set is written to the file element_set_X.k, (where X=coid) which will be used in step 2.

In subsequent simulations (Step 2) elements in the set are converted to 3rd order hexahedra (for increased accuracy).

To test the paramater padding, two element sets are generated, one with and one without padding.

See Figure 1.

The element sets generated are checked for version control.

Tests

This benchmark is associated with 3 tests.

*ELEMENT_SHELL

Contact

$eid$, $pid$, $nid_1$, $nid_2$, $nid_3$, $nid_4$

This tests the contact interference of *ELEMENT_SHELL and other deformable bodies. *ELEMENT_SHELL can only be used to generate rigid bodies. The element thickness is specified in *PART, but this thickness is not active in contact situations.

The set-up is a rigid cone with an initial velocity impacting at the center of the open face of a pipe. The pipe has a lesser radius than the cone, bringing the cone to halt. The initial kinetic energy of the cone is  (

( ,

,  ), and this value is checked against the final energy balance found in "energy.out".

), and this value is checked against the final energy balance found in "energy.out".

Note that by using linear elements in the first test, the stiffness is artificially high. This offset is improved in the second and third run, in which quadratic and cubic elements are used.

Tests

This benchmark is associated with 3 tests.

Volume_and_mass_verification

$eid$, $pid$, $nid_1$, $nid_2$, $nid_3$, $nid_4$

This tests that *ELEMENT_SHELL and *PART generates elements correctly. Mass and volume of a 1  square rigid shell with a thickness of 1

square rigid shell with a thickness of 1  is checked in part.out. The density of the material is 1000

is checked in part.out. The density of the material is 1000  .

.

Tests

This benchmark is associated with 1 tests.

*ELEMENT_SOLID

Higher_order_elements

$eid$, $pid$

$nid_{01}$, ... , $nid_{10}$

$nid_{11}$, ... , $nid_{20}$

$...$

This tests the higher order *ELEMENT commands. This includes quadratic and cubic hexahedron, pentahedron, and tetrahedron elements - six element types in total (Figure 1 to 6). The pentrahedron elements can be oriented in two different ways, both are tested for both the quadratic and cubic element.

The element mesh has been created using *ELEMENT_SOLID and *CHANGE_P-ORDER and then exported to an input file that has the higher order *ELEMENT commands. In these tests, these input files are checked using *BC_MOTION. The geometry is a block with side length of  . It is stretched in Z-direction with a logarithmic strain of 1. Hardening of material is Ramberg Osgood (

. It is stretched in Z-direction with a logarithmic strain of 1. Hardening of material is Ramberg Osgood ( ). The yield strengh is

). The yield strengh is  , Young's modulus is

, Young's modulus is  , and Poisson's ratio is

, and Poisson's ratio is  .

.

For version control, we check stress and strain at the end of the simulation.

Tests

This benchmark is associated with 8 tests.

Linear_elements

$eid$, $pid$

$nid_{1}$, $nid_{2}$, $nid_{3}$, $...$

This tests the *ELEMENT_SOLID command. This includes linear hexahedron, pentahedron and tetrahedron elements. In these tests, the elements are checked using *BC_MOTION. The geometry is a block with side length of  . It is stretched in Z-direction with a logarithmic strain of 1. Hardening of material is Ramberg-Osgood (

. It is stretched in Z-direction with a logarithmic strain of 1. Hardening of material is Ramberg-Osgood ( ). The yield strength is

). The yield strength is  , Young's modulus is

, Young's modulus is  , and Poisson's ratio is

, and Poisson's ratio is  .

.

For version control, we check stress and strain at the end of simulation.

Tests

This benchmark is associated with 4 tests.

*END

This tests the *END command. The test is identical to the *LOAD_GRAVITY benchmark, with the addition of an *INITIAL_VELOCITY command after the *END command. If the *END card doesn't end the input correctly, the elements will output different velocities and the checks will fail.

Tests

This benchmark is associated with 1 tests.

*EOS_GRUNEISEN

Shock wave test

eosid, $S$, $\Gamma$, $L$, $p_{cut}$

Tested parameters: eosid,  ,

,  .

.

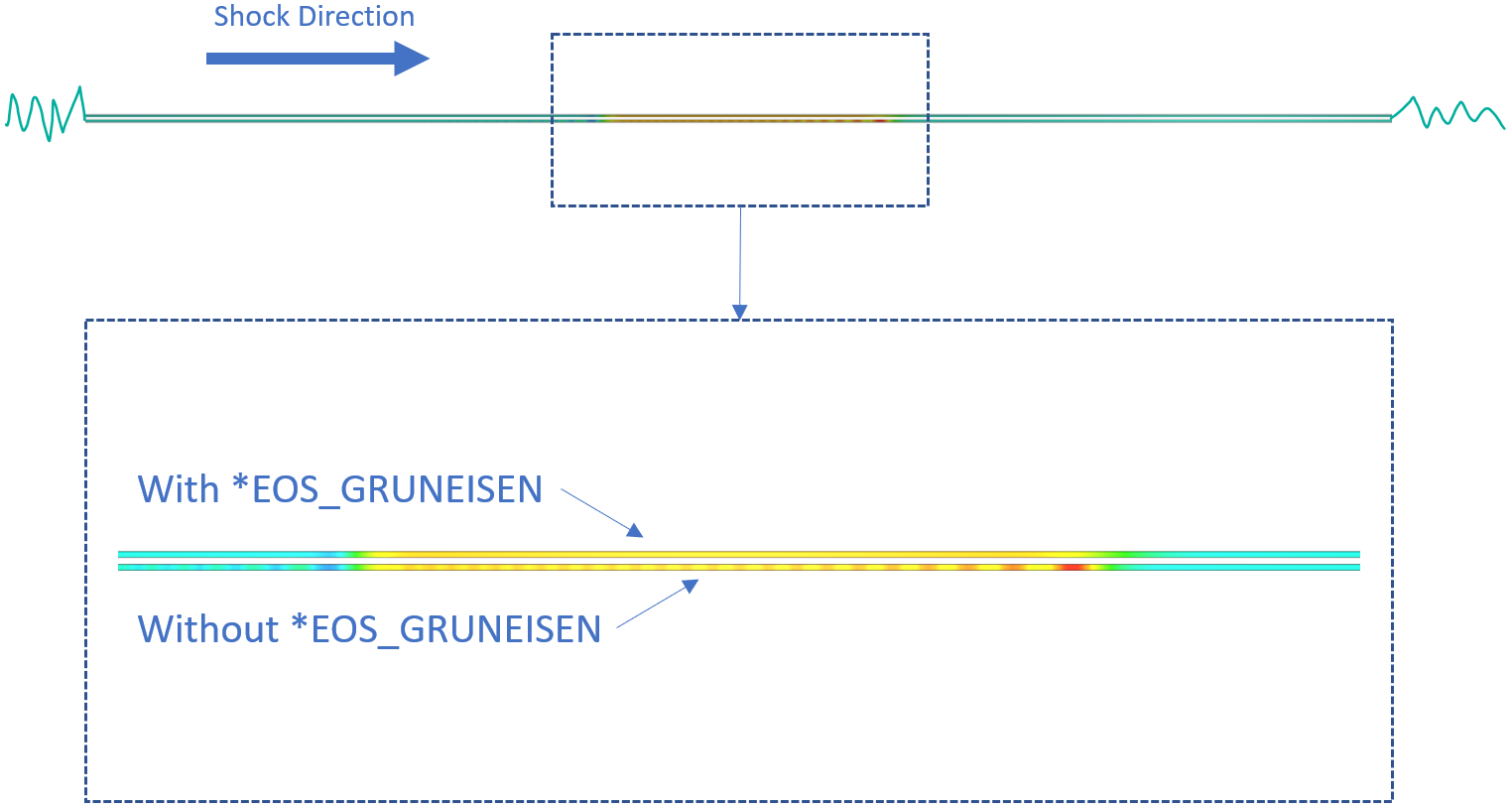

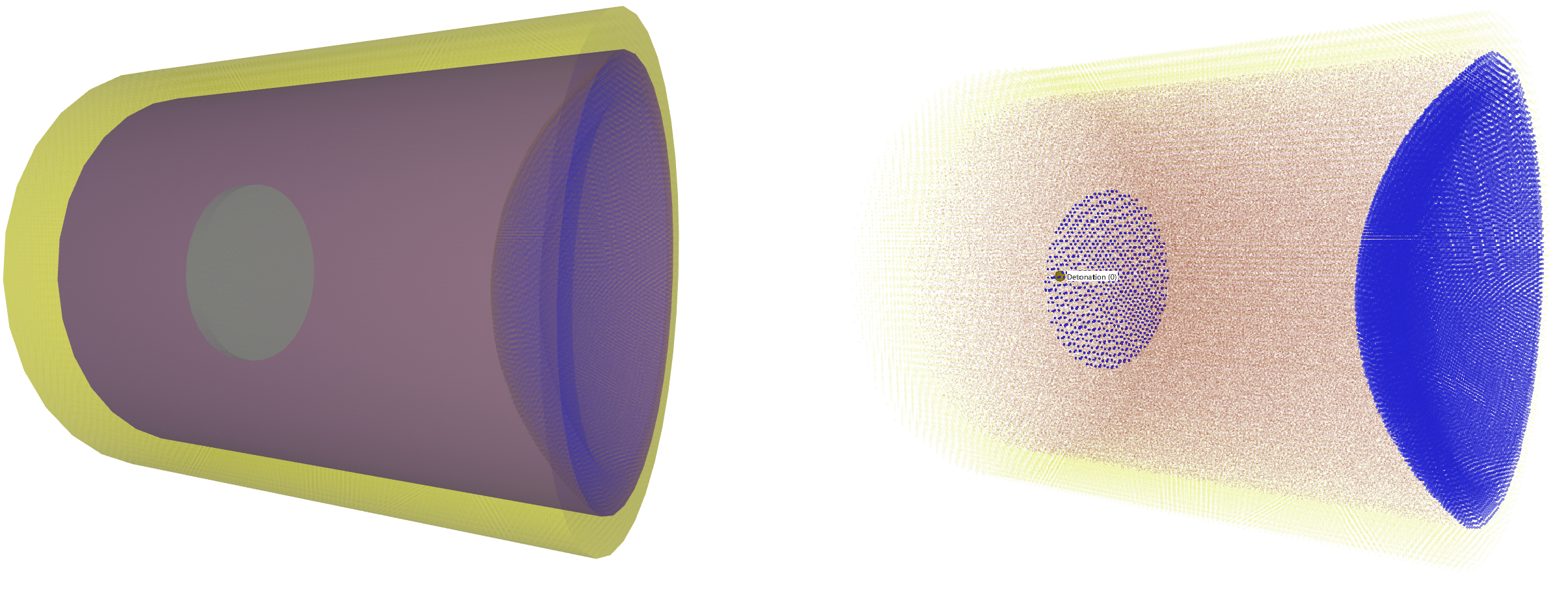

This model tests the *EOS_GRUNEISEN command.

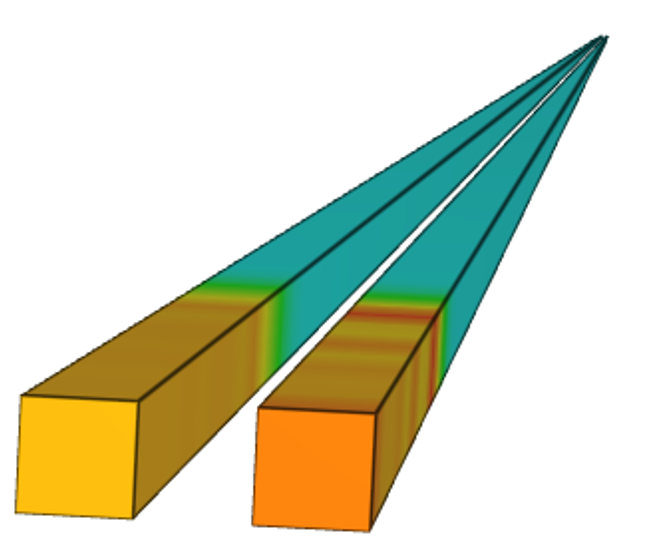

An abrupt pressure is introduced on one side of a highly elongated rectangular cuboid with dimensions:

Length = 1 m

Width = 0.001 m

Height = 0.001 m

As the shock wave travels along its length, 10 equally-distanced sensors are measuring pressure. The Mie-Gruneisen equation of state is implemented with the command *EOS_GRUNEISEN. For comparison one cuboid with *EOS_GRUNEISEN and one without it is tested for.

The test setup is displayed in Figure 1 and Figure 2.

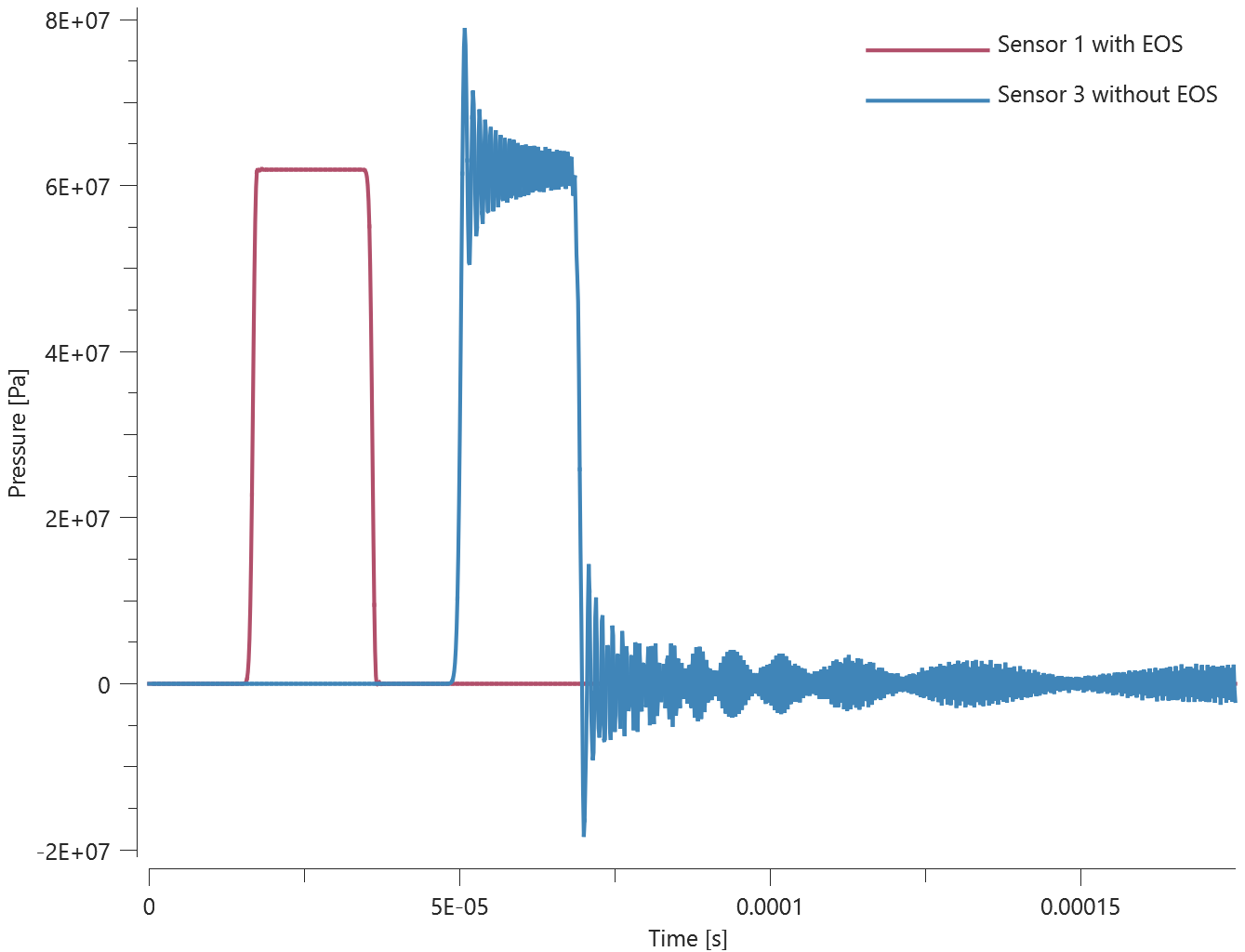

The wave induced by the shock pulse takes the shape of a square wave. This can be seen in Figure 3, where the difference between the two test cases is visble. Only two sensors are displayed for clarity.

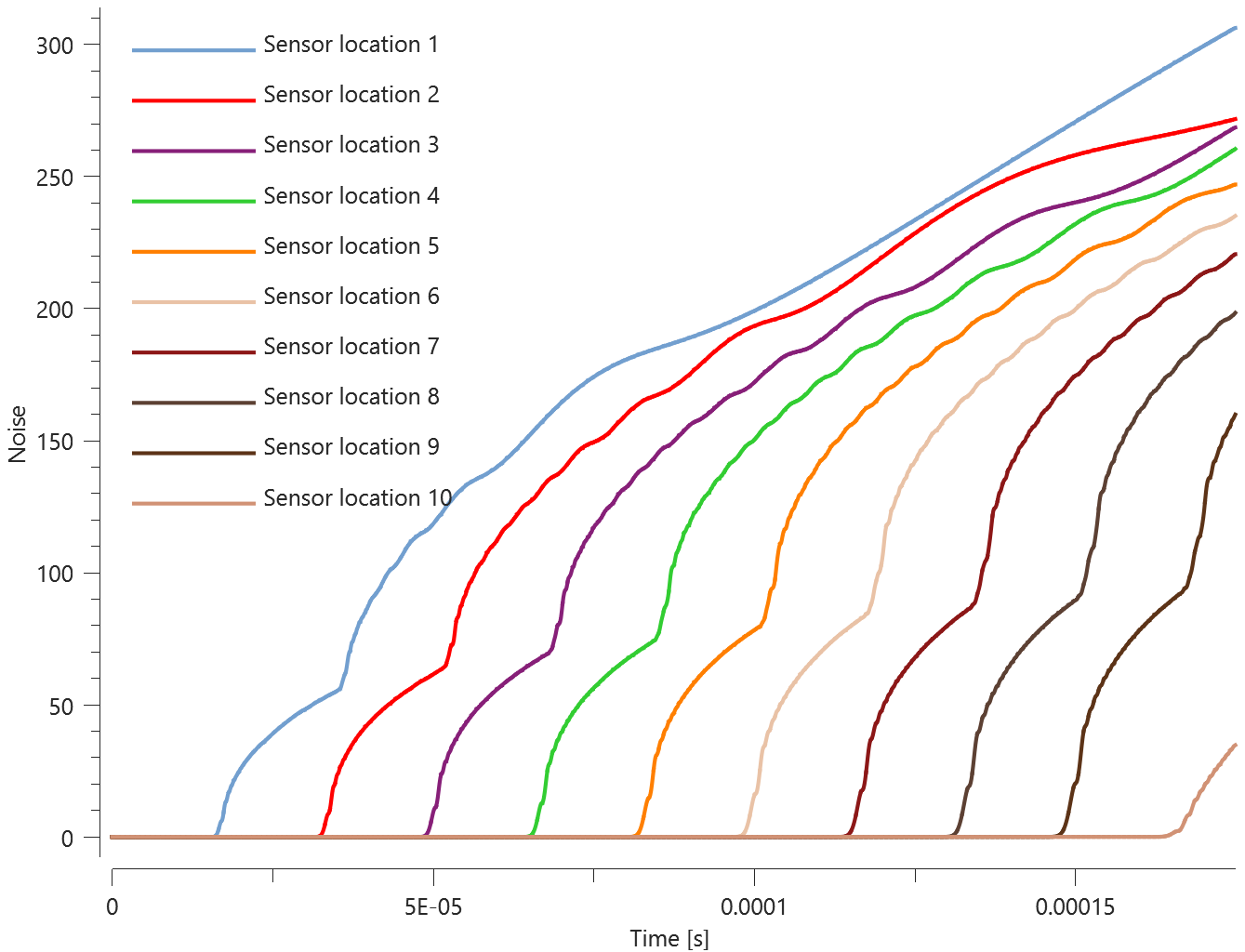

The noise is measured by integrating the absolute value of the pressure difference between the test cases at each sensor. See Figure 4.

The maximum value of the pressure difference at each sensor is checked for version control.

Tests

This benchmark is associated with 1 tests.

*EROSION_CRITERION

Element erosion

coid

entype, enid, $\Delta t_{erode}$, $\epsilon^{erode}_{geo}$, $\epsilon^{erode}_{v}$

This test is similar to the test "*PART - Element erosion". In this test, the erosion criteria are instead defined with *EROSION_CRITERION.

Tests

This benchmark is associated with 1 tests.

Priority test

coid

entype, enid, $\Delta t_{erode}$, $\epsilon^{erode}_{geo}$, $\epsilon^{erode}_{v}$

This test is similar to the test "*EROSION_CRITERION - Element erosion". In this test, the erosion criteria are defined with *EROSION_CRITERION but also in *PART.

It is tested that the erosion parameters defined in *PART have higher priority.

Tests

This benchmark is associated with 1 tests.

*FREQUENCY_CUTOFF

Testing LOAD_DAMPING - Mass damping

"Optional title"

coid

entype, enid, $\Delta t_{target}$, $sf_{cap}$, $t_{start}$, $t_{end}$

Tested parameters: coid, entype, enid,  .

.

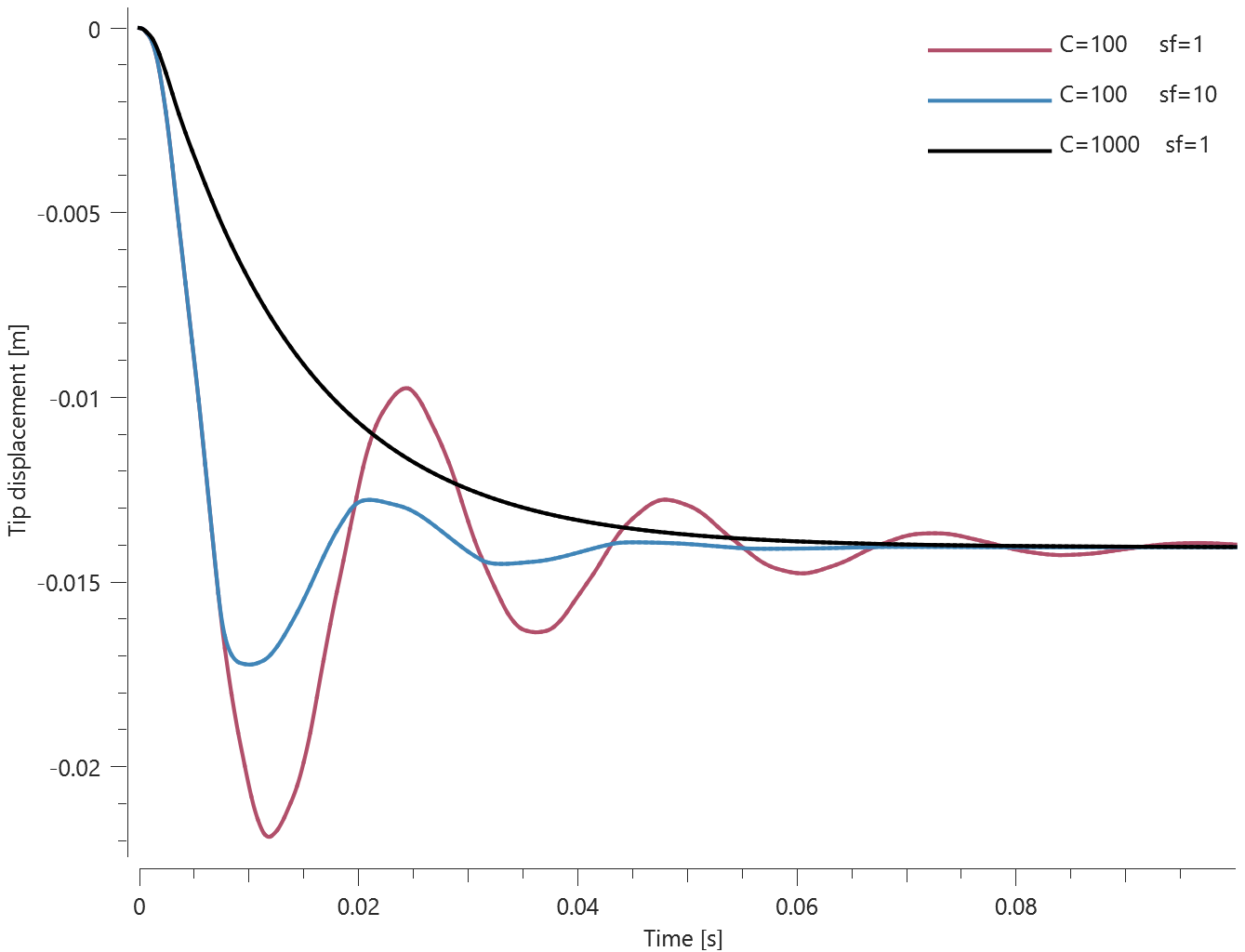

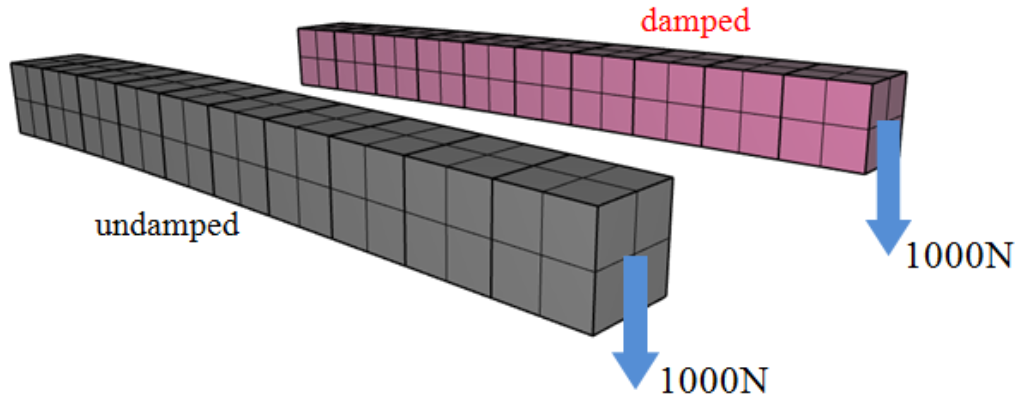

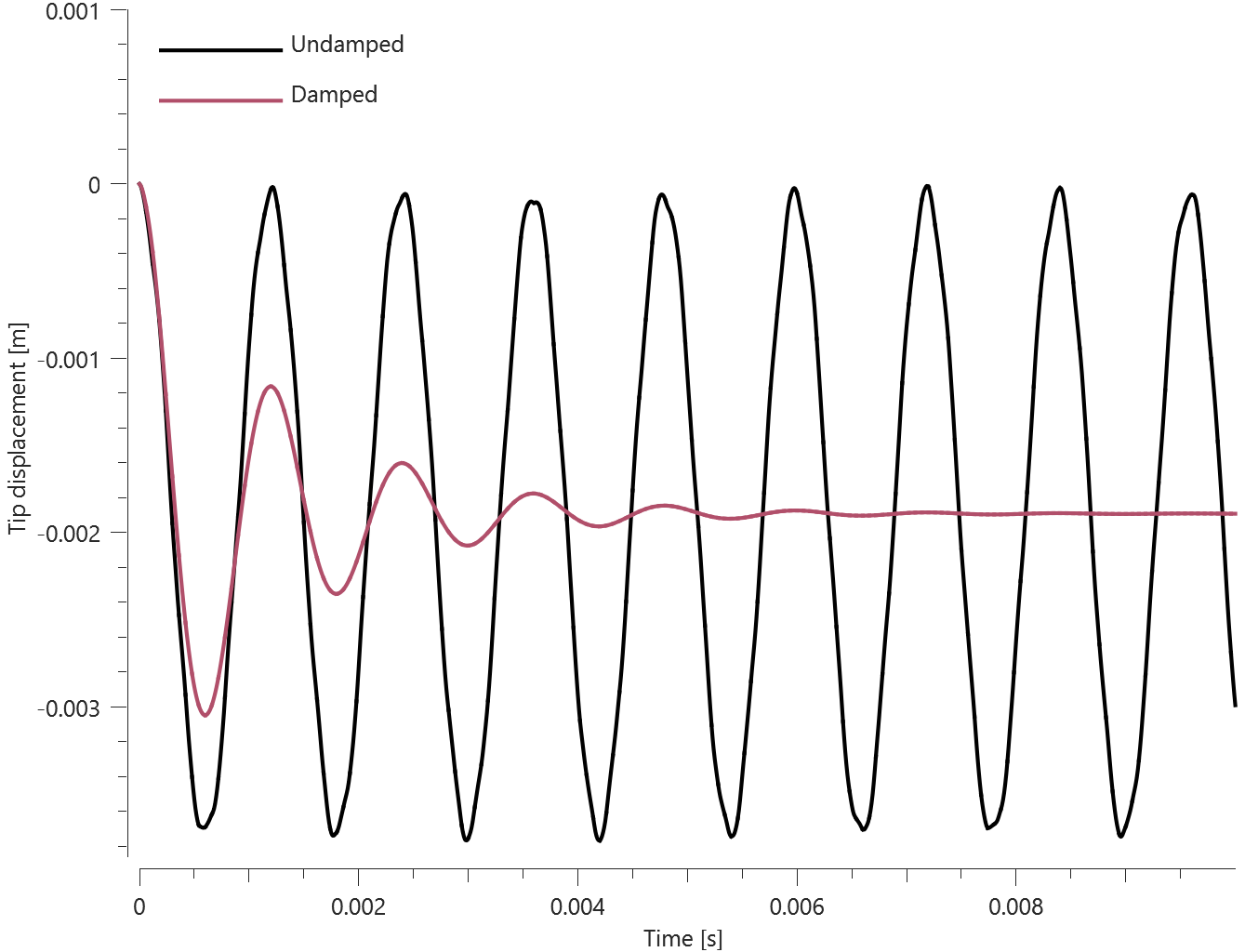

This model tests the *FREQUENCY_CUTOFF command for the already existing test, See LOAD_DAMPING - Mass damping.

The objective of this test is to speed up the simulation time without compromising accuracy. This is done by suppressing angular frequencies  which allows for larger time steps.

The target time step size is set to

which allows for larger time steps.

The target time step size is set to  .

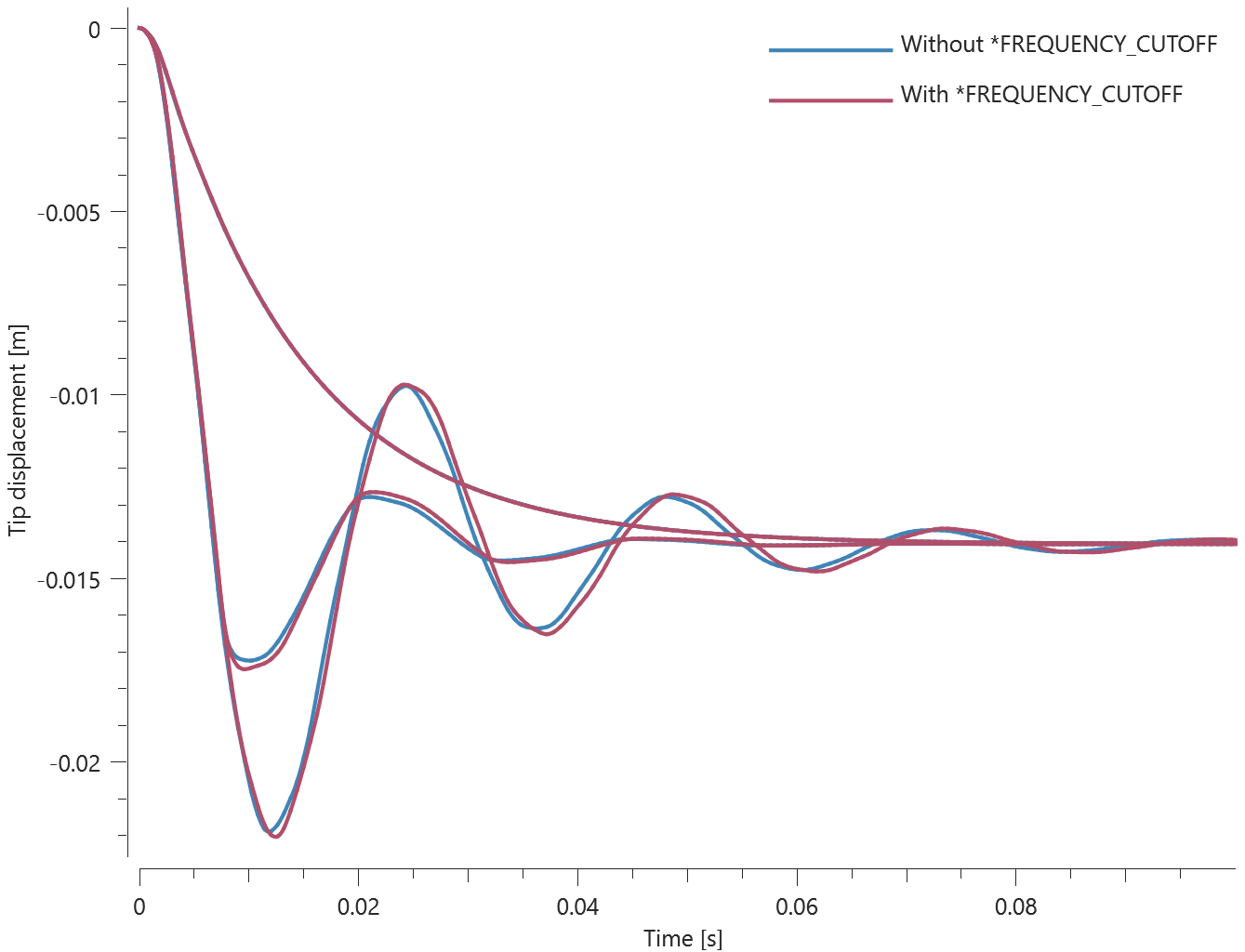

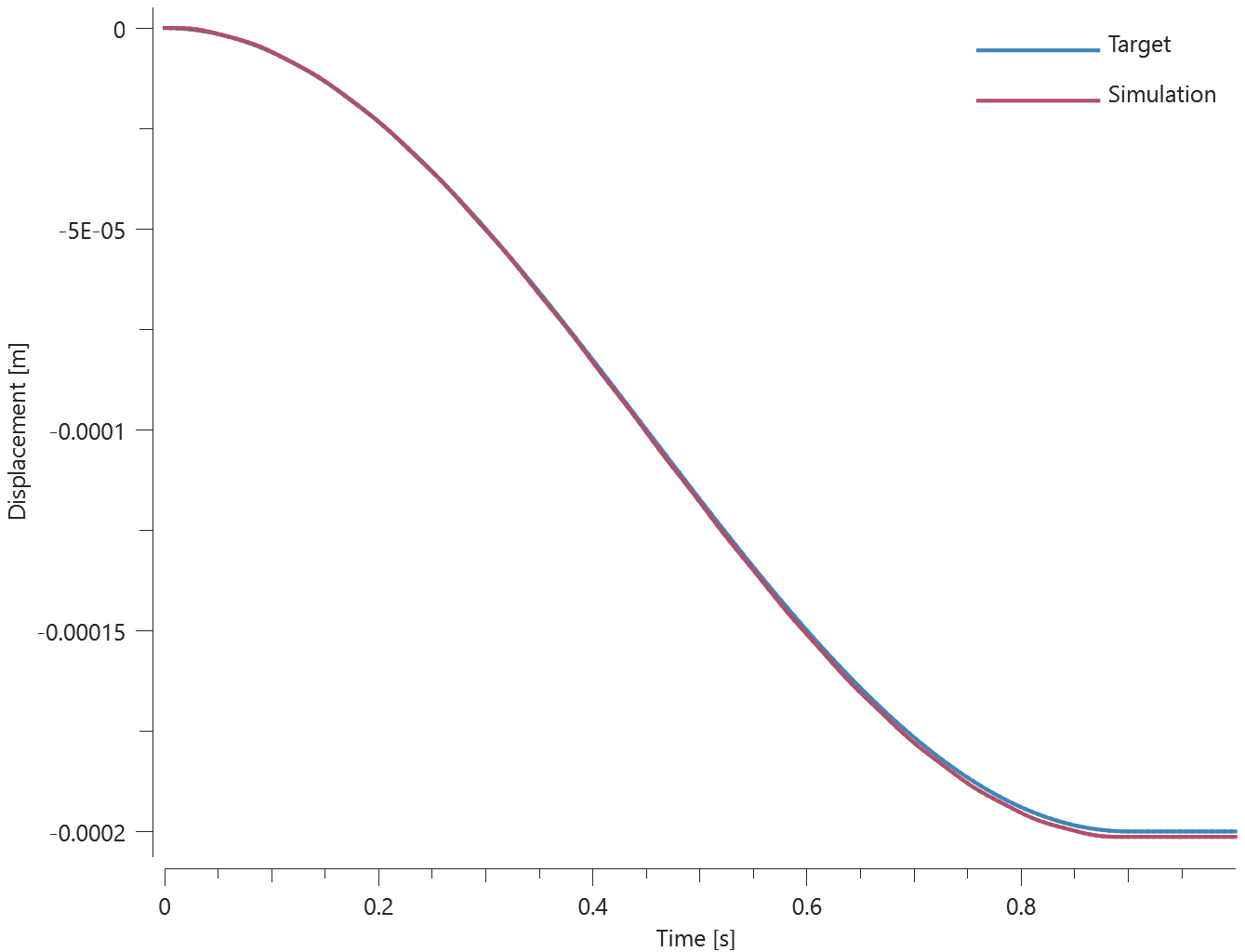

Tip displacement of the beams from the original test (without *FREQUENCY_CUTOFF) compared with this test (with *FREQUENCY_CUTOFF) can be seen in Figure 1.

.

Tip displacement of the beams from the original test (without *FREQUENCY_CUTOFF) compared with this test (with *FREQUENCY_CUTOFF) can be seen in Figure 1.

First, average, min and last values of tip displacements are checked for version control.

Tests

This benchmark is associated with 1 tests.

Testing MAT_METAL - Quasi-static yield stress

"Optional title"

coid

entype, enid, $\Delta t_{target}$, $sf_{cap}$, $t_{start}$, $t_{end}$

Tested parameters: coid, entype, enid,  .

.

This model tests the *FREQUENCY_CUTOFF command for the already existing test, See MAT_METAL - Quasi-static yield stress. The objective is to speed up the simulation time without compromising accuracy.

The primary purpose of the command is to allow for larger time steps in quasi-static processes. This is achieved by suppressing angular frequencies  .

The scale factor,

.

The scale factor,  which limits the maximum increase of time step size is set to 4.

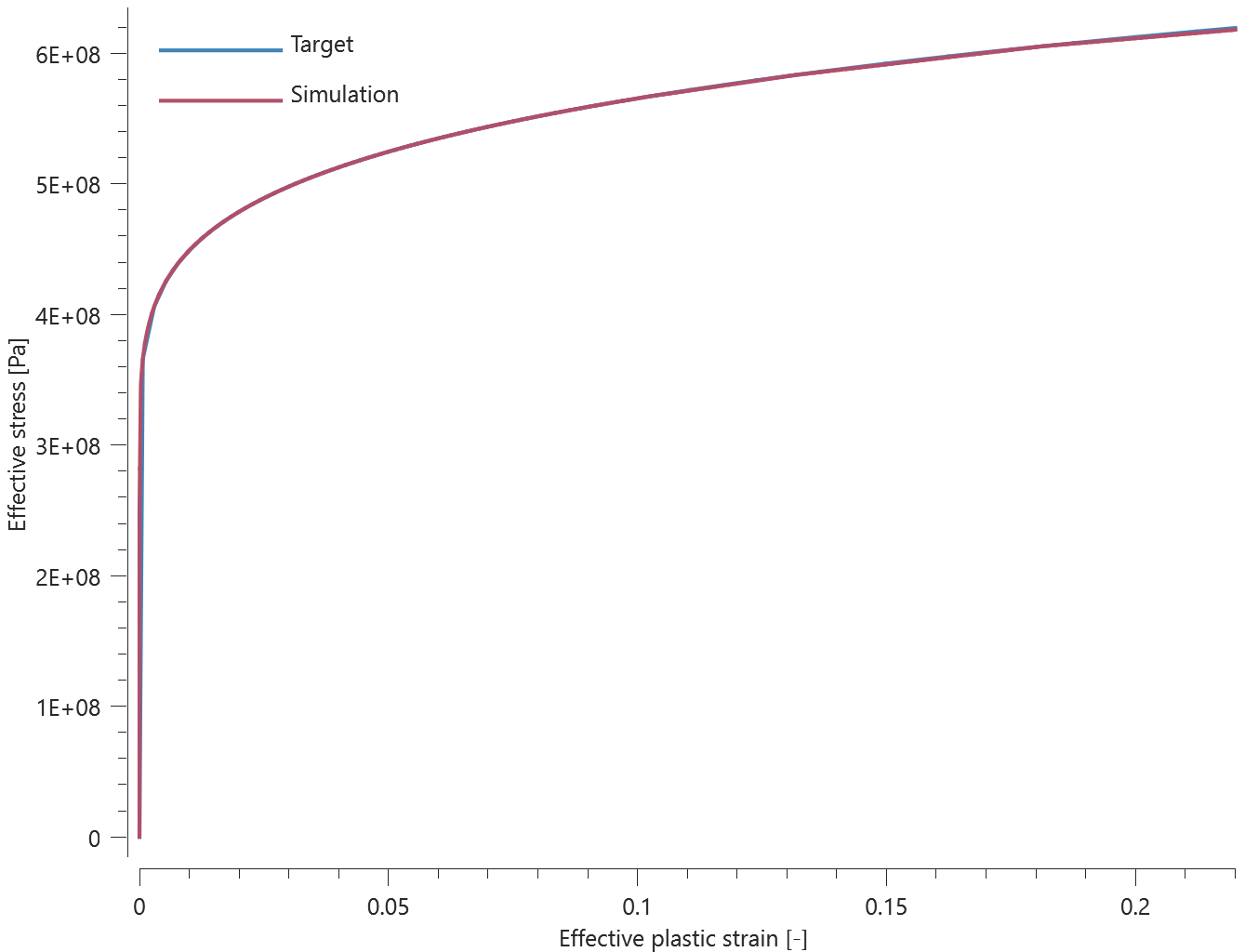

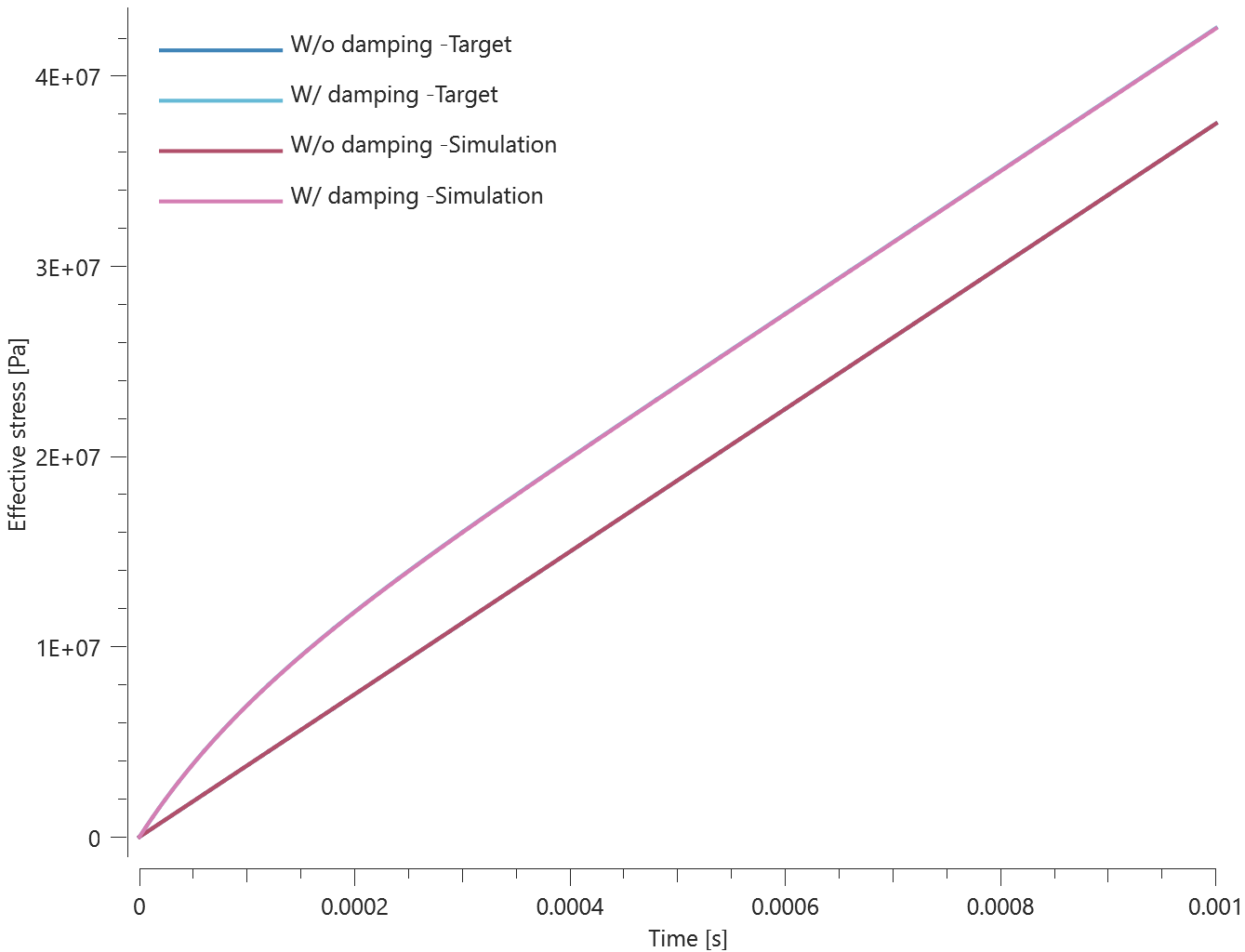

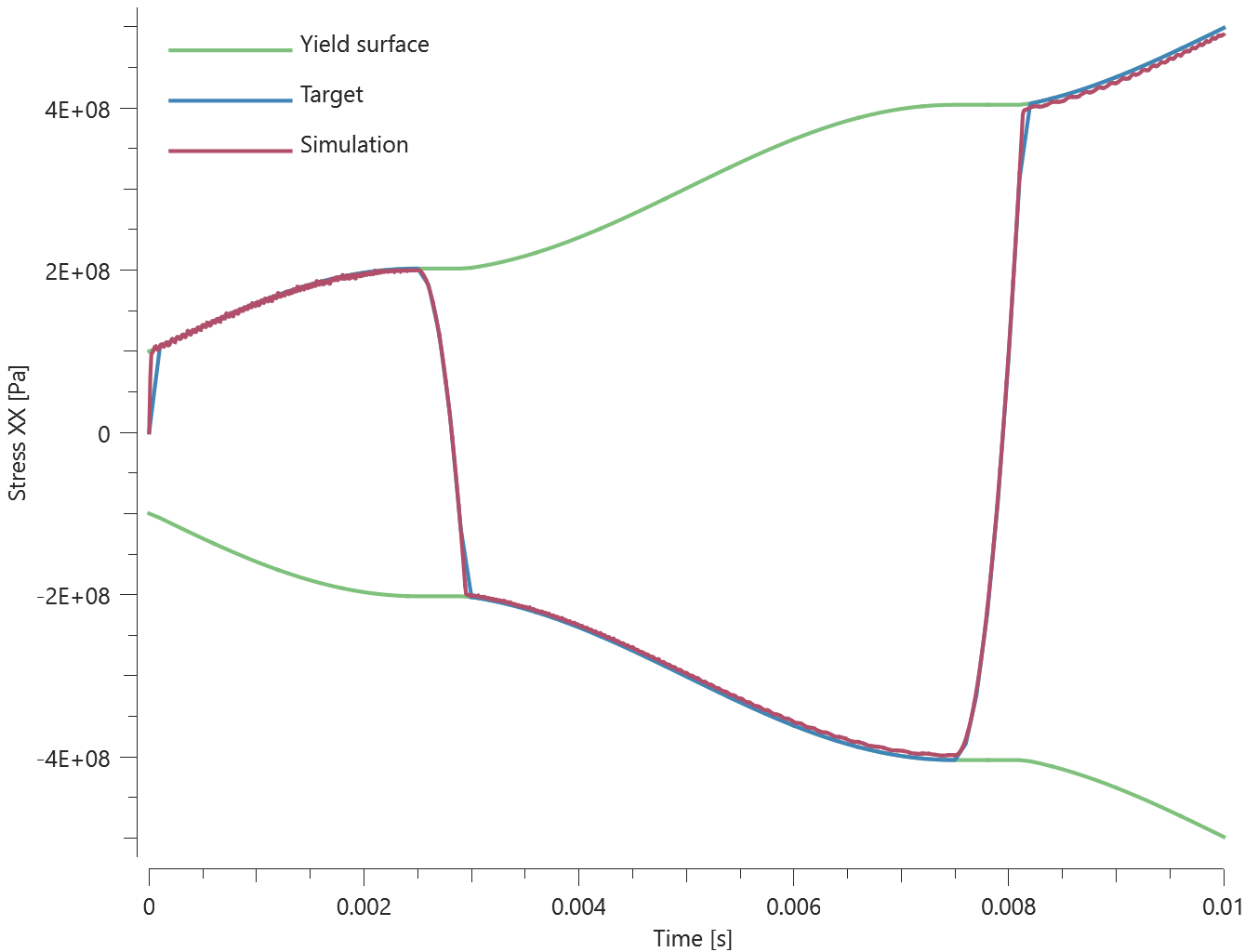

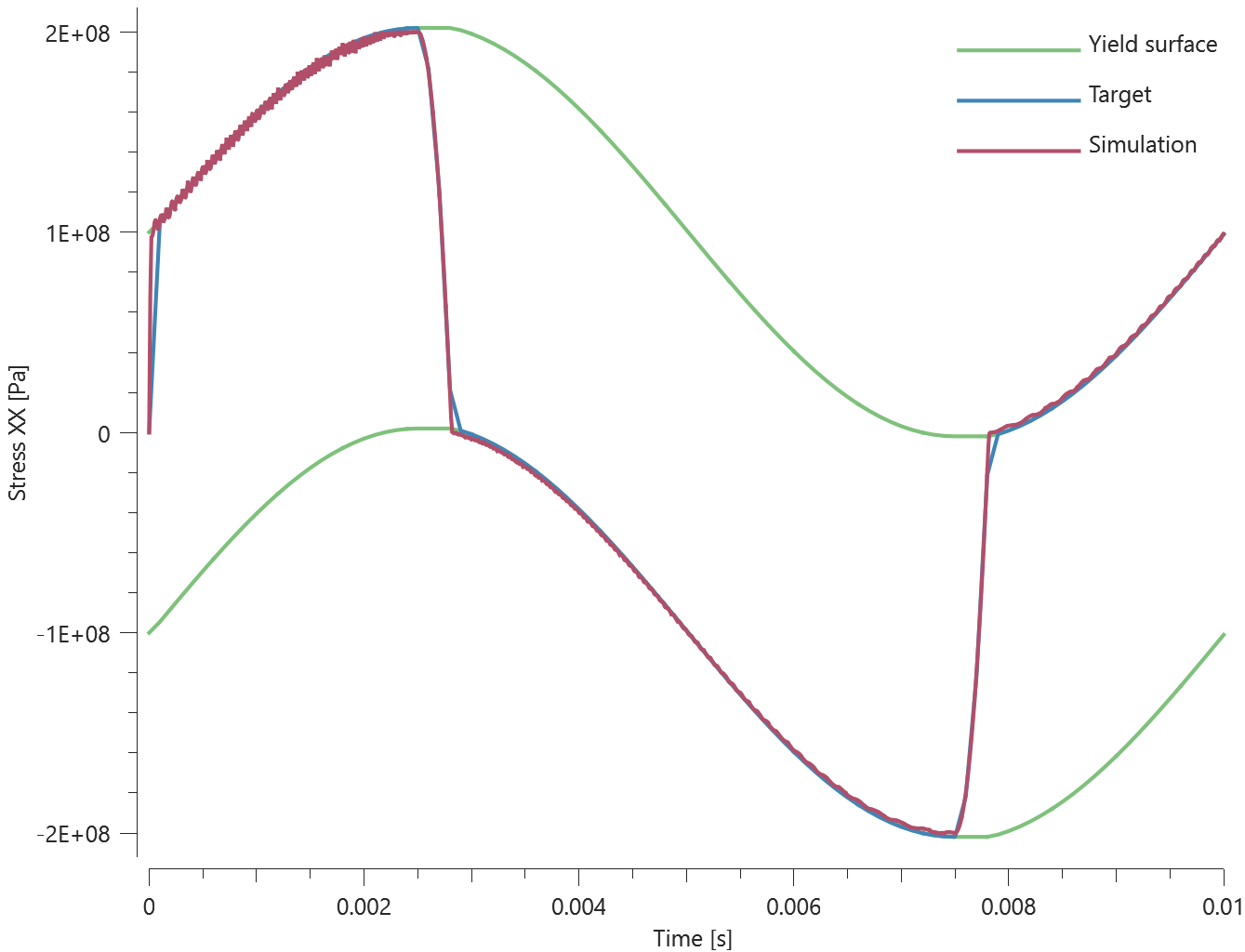

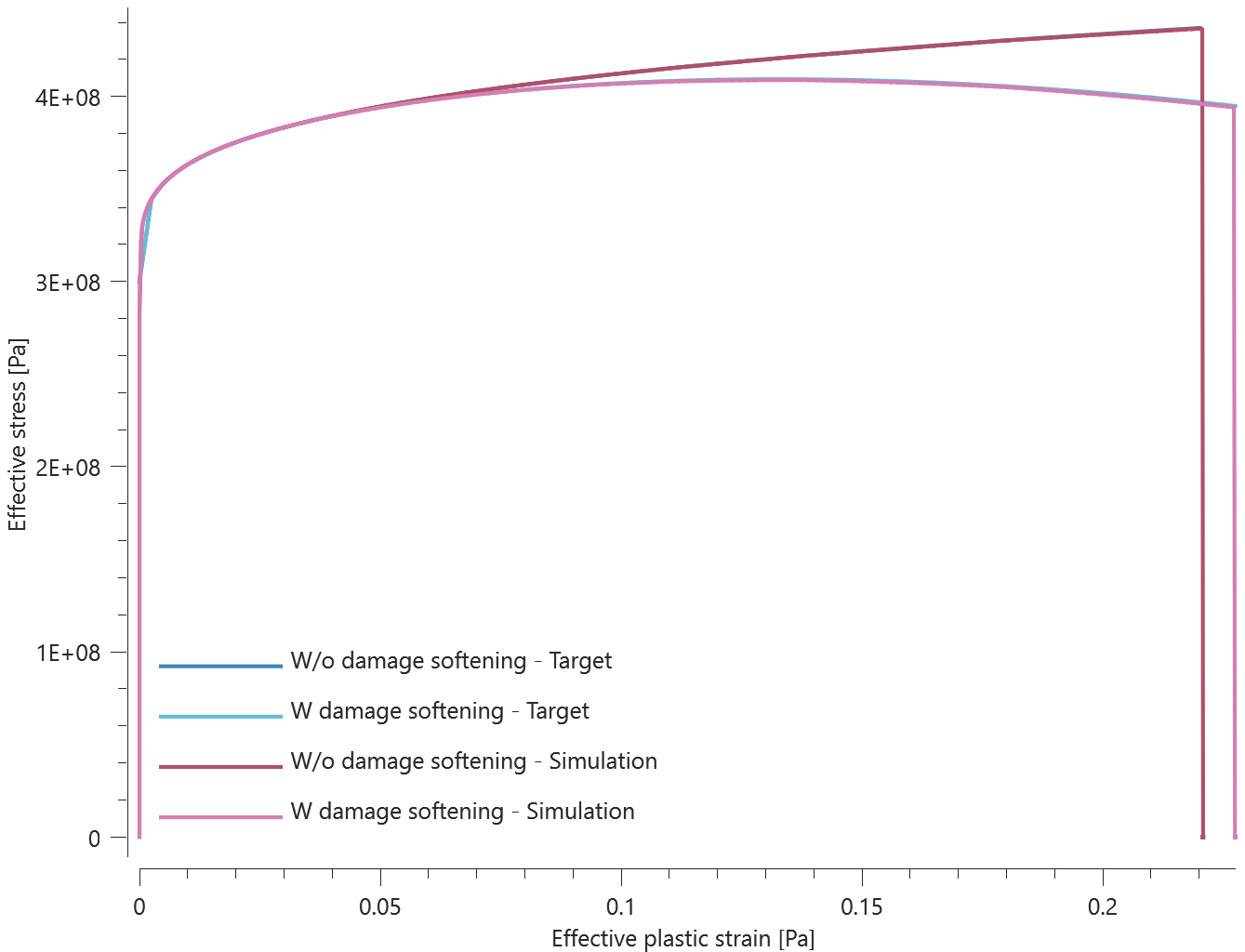

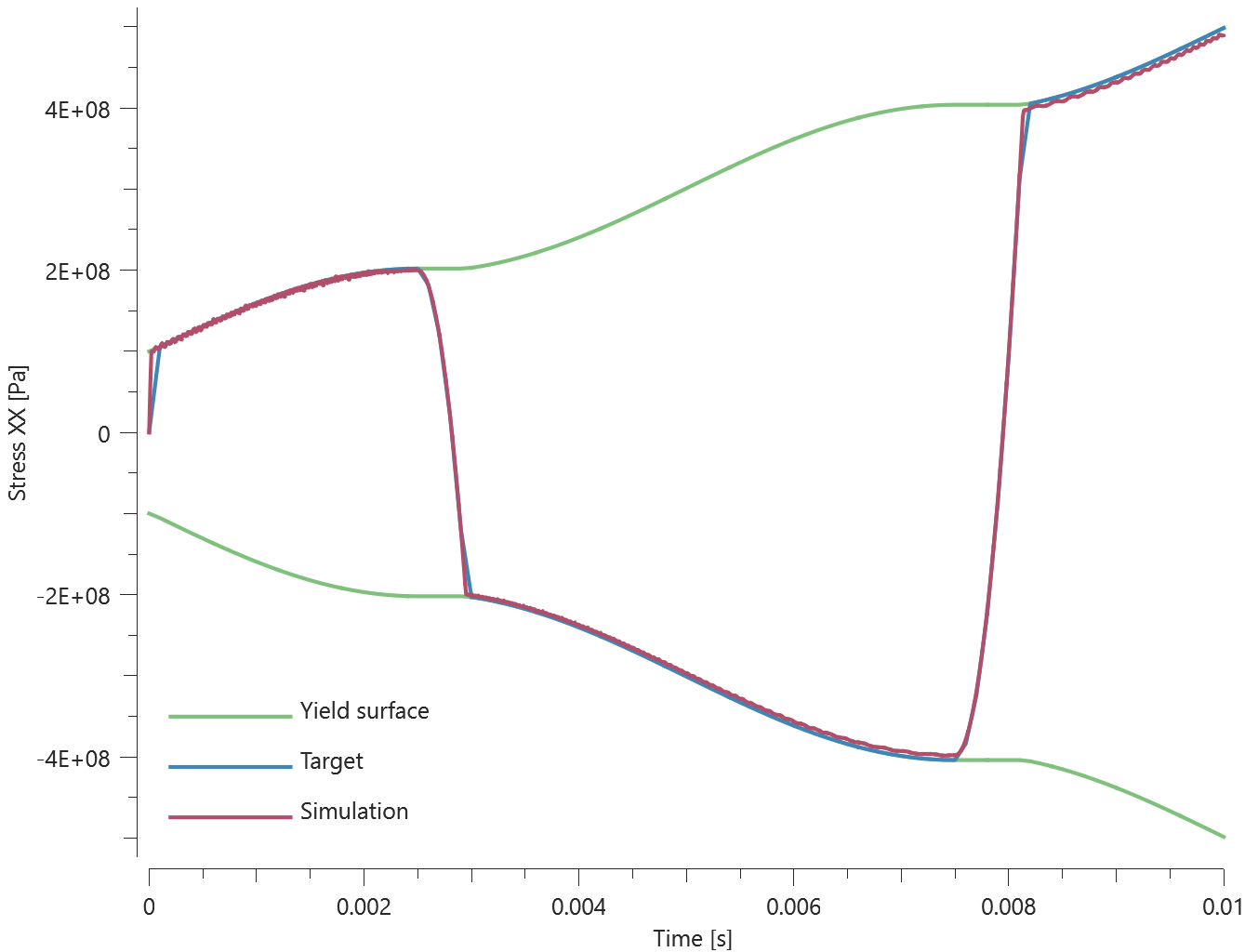

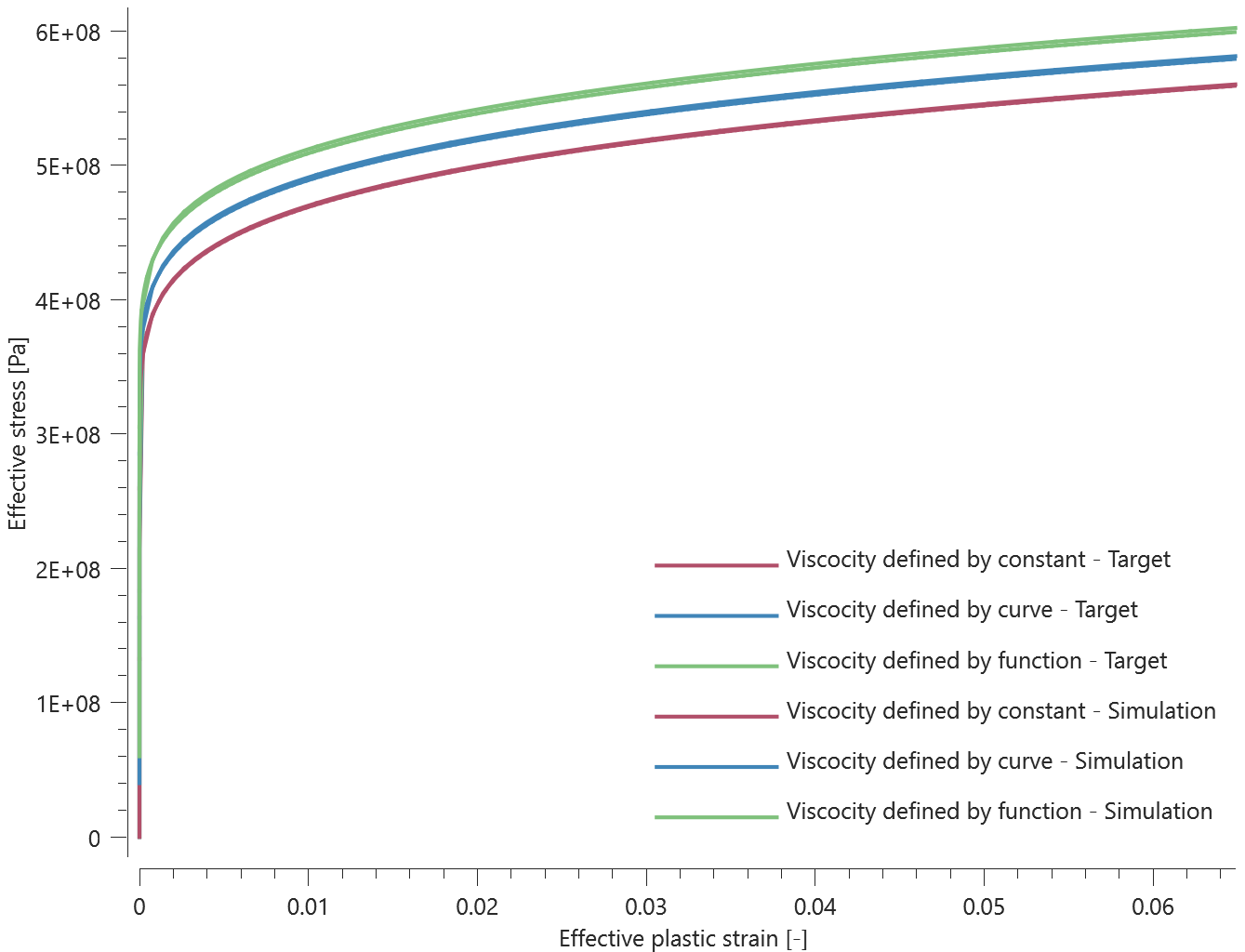

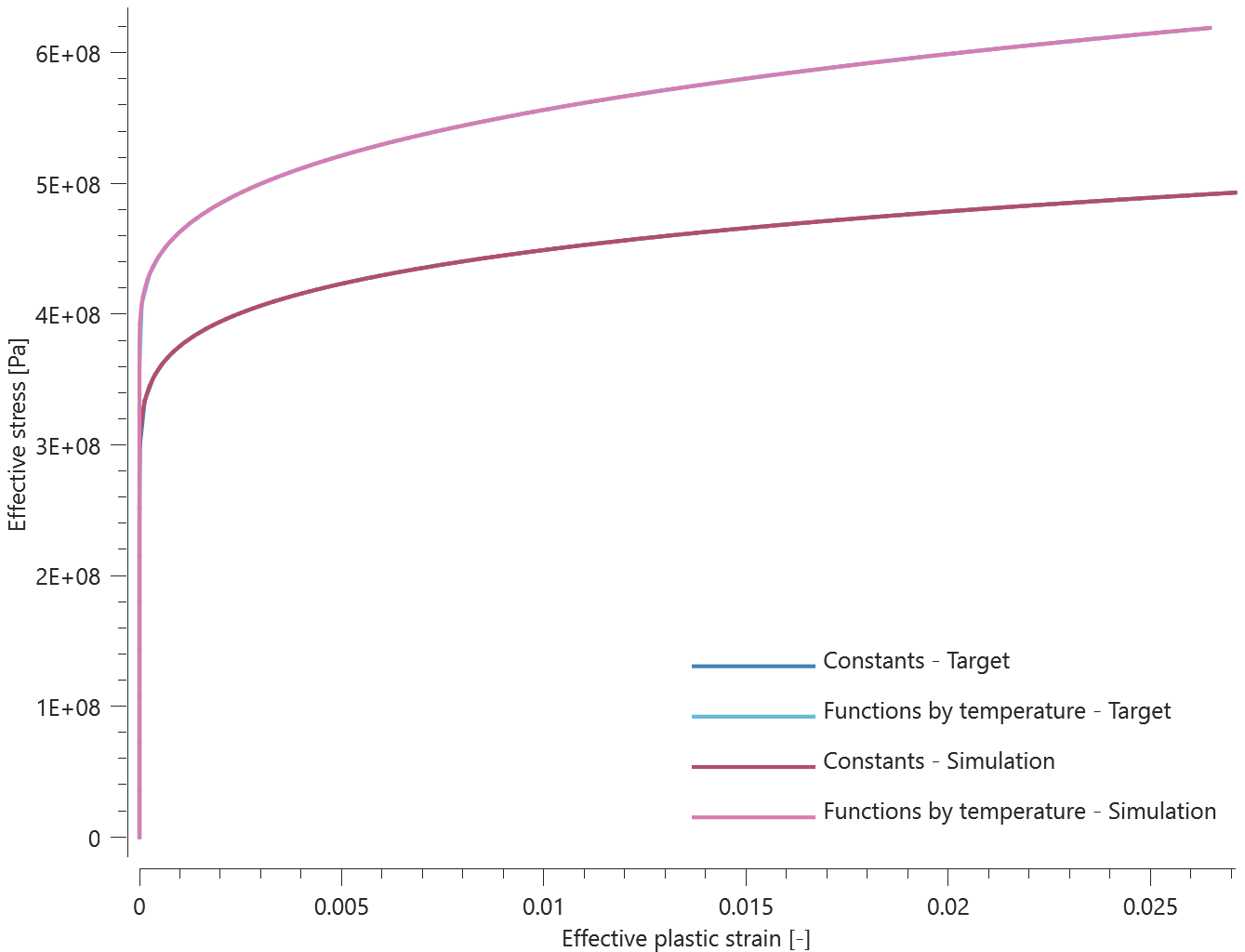

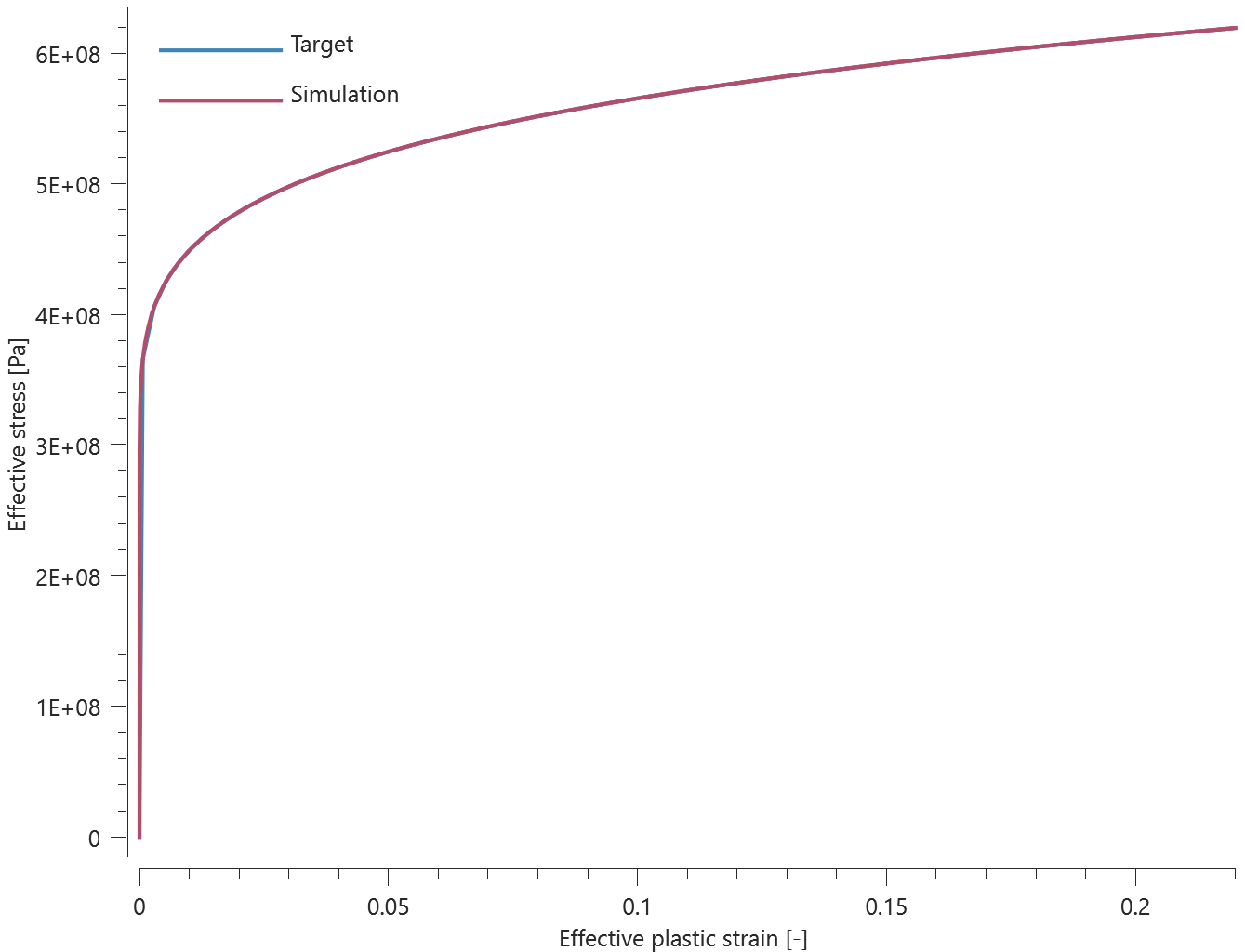

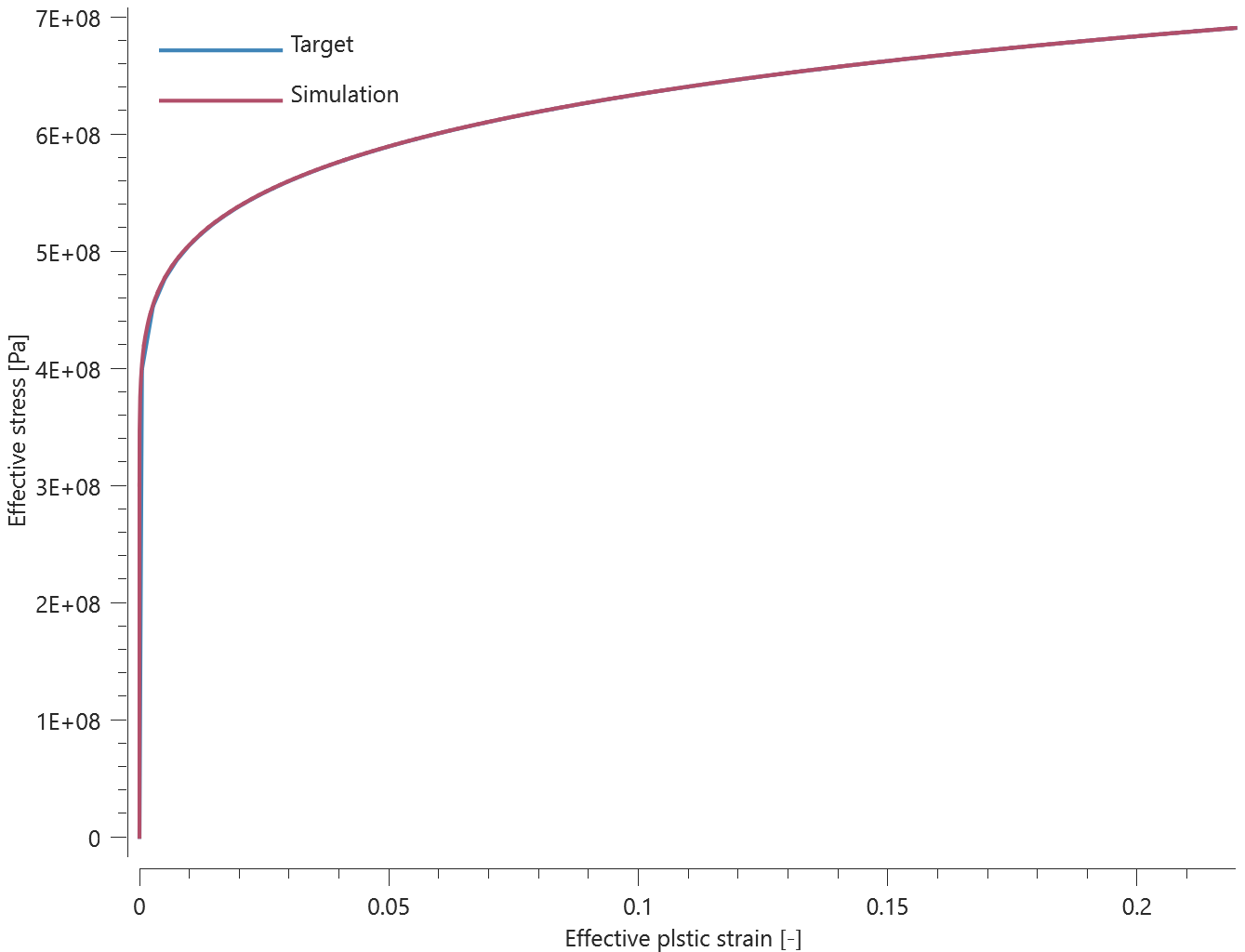

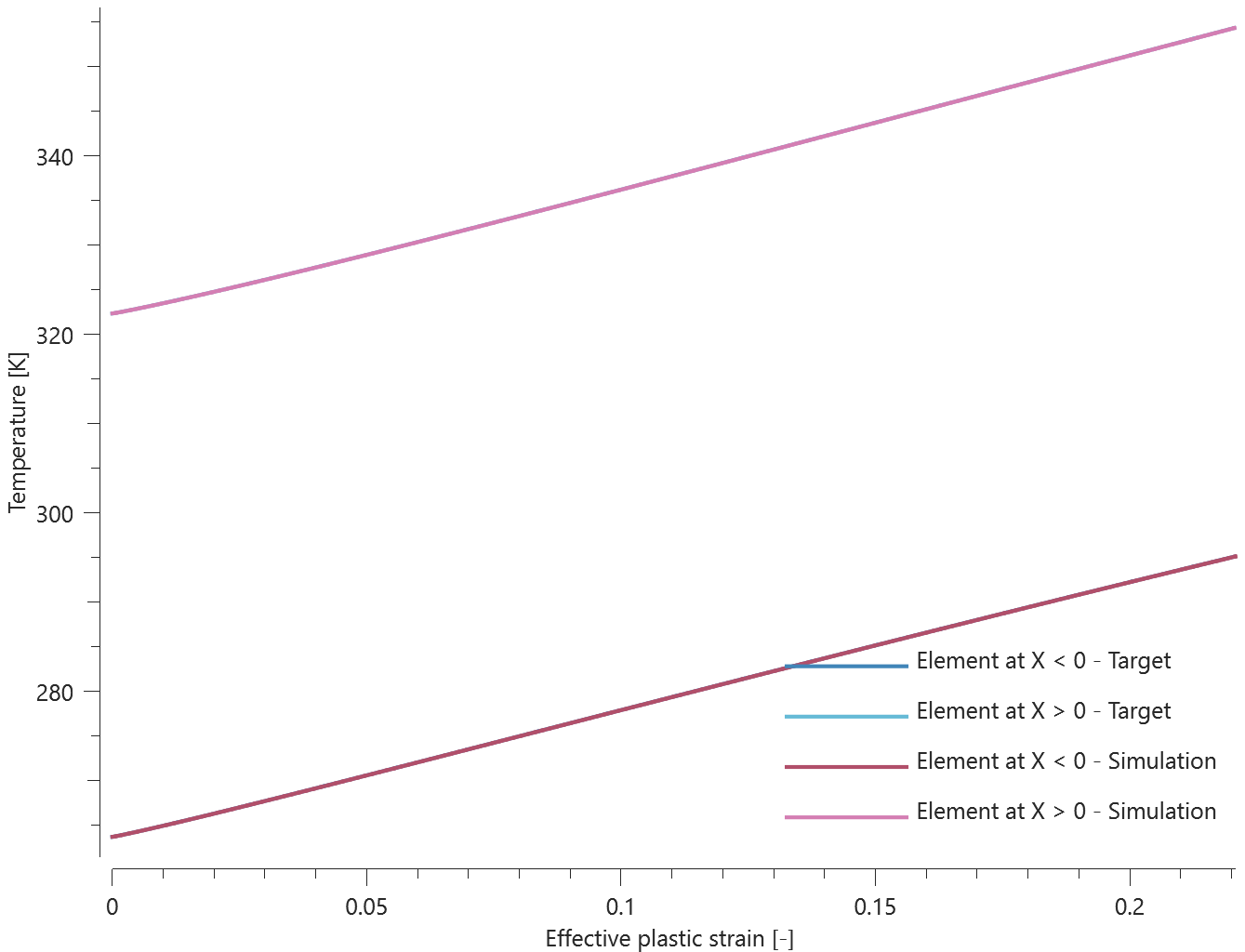

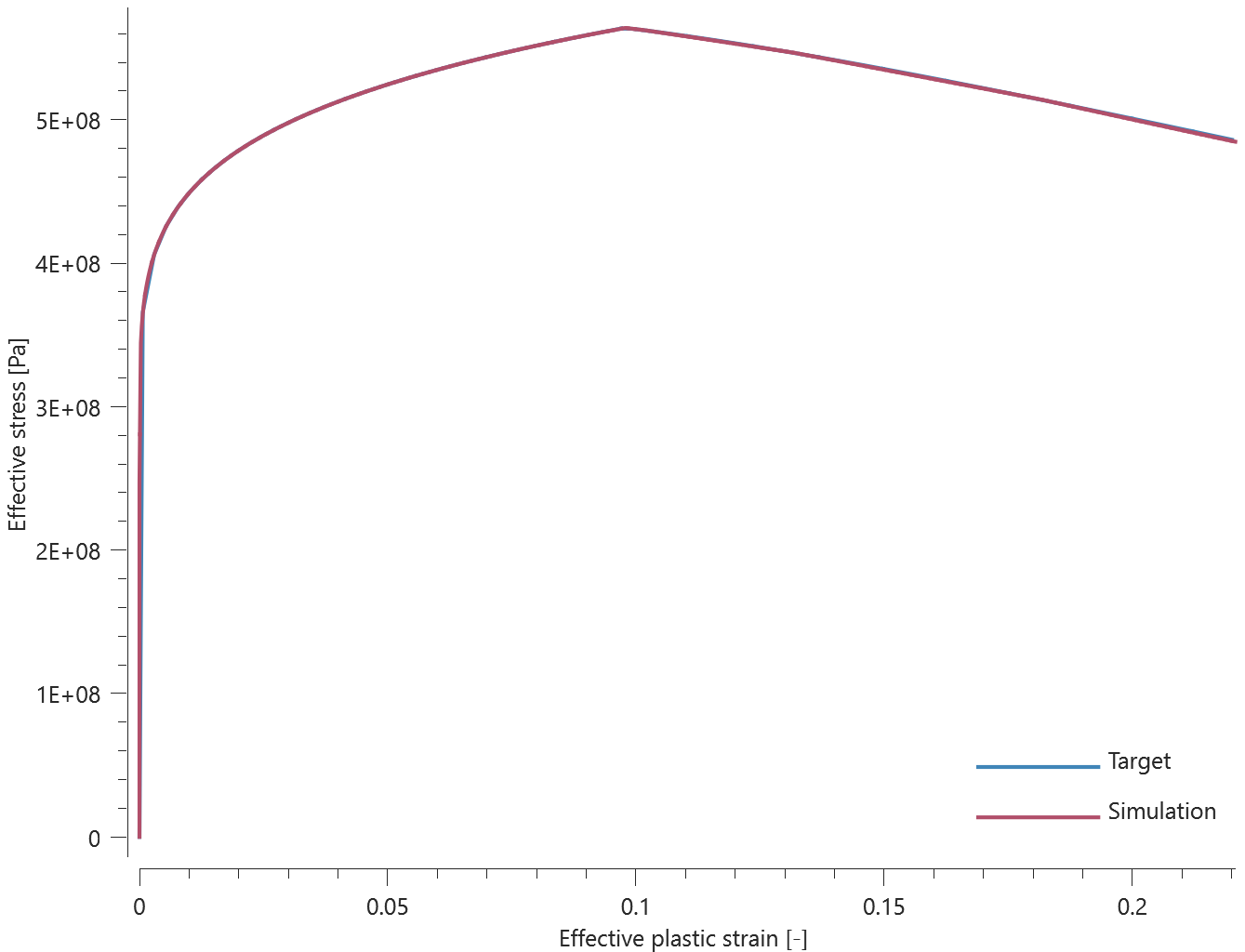

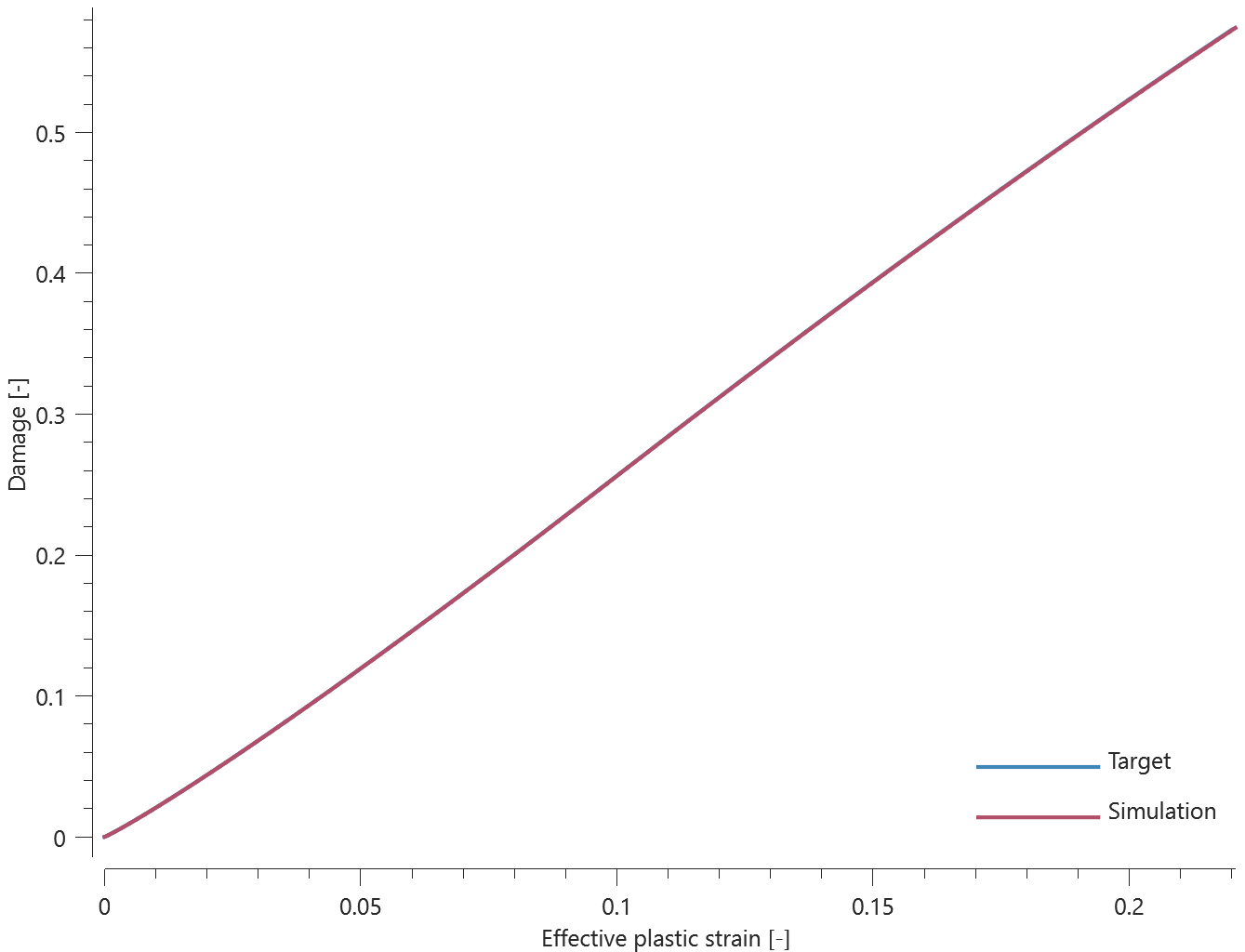

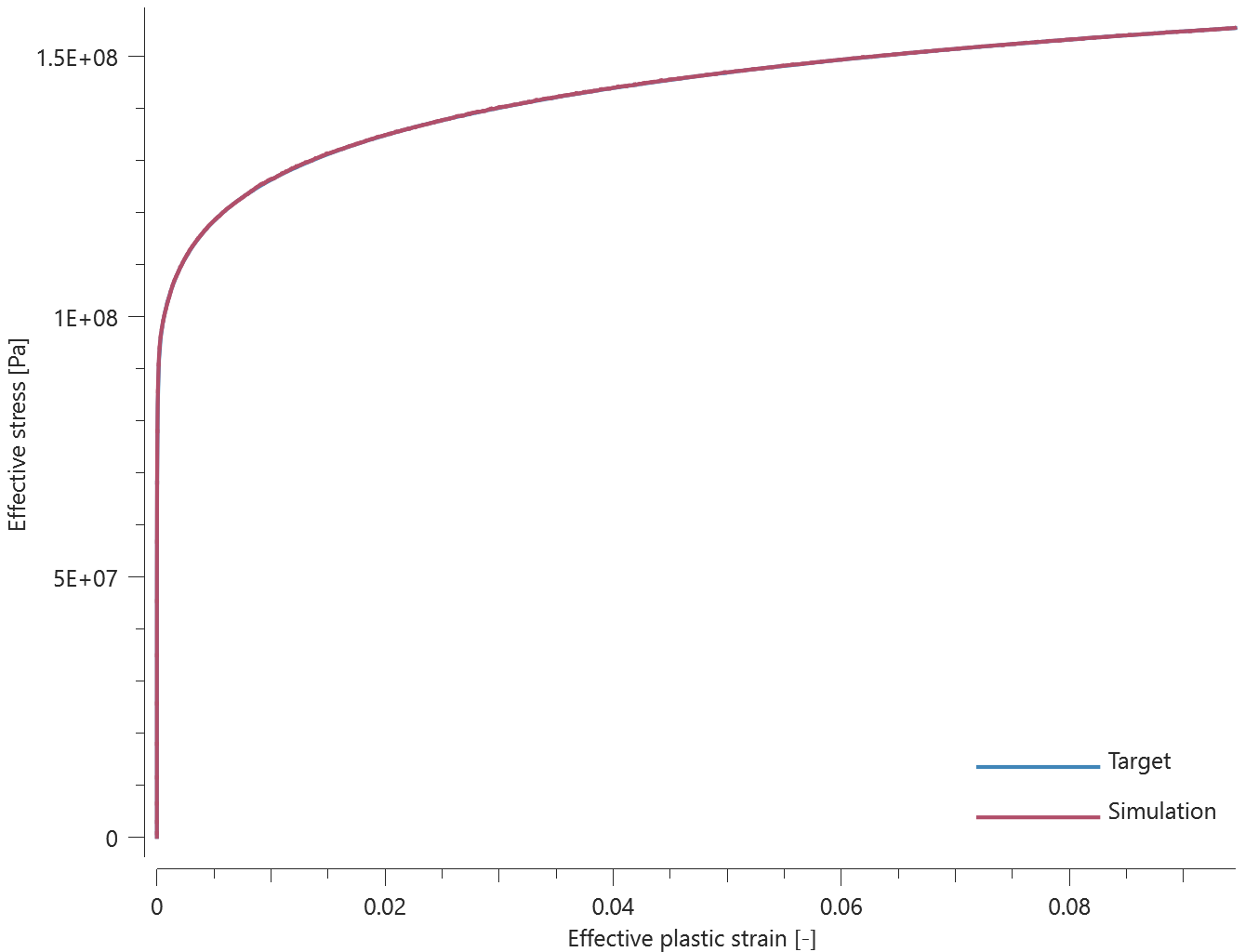

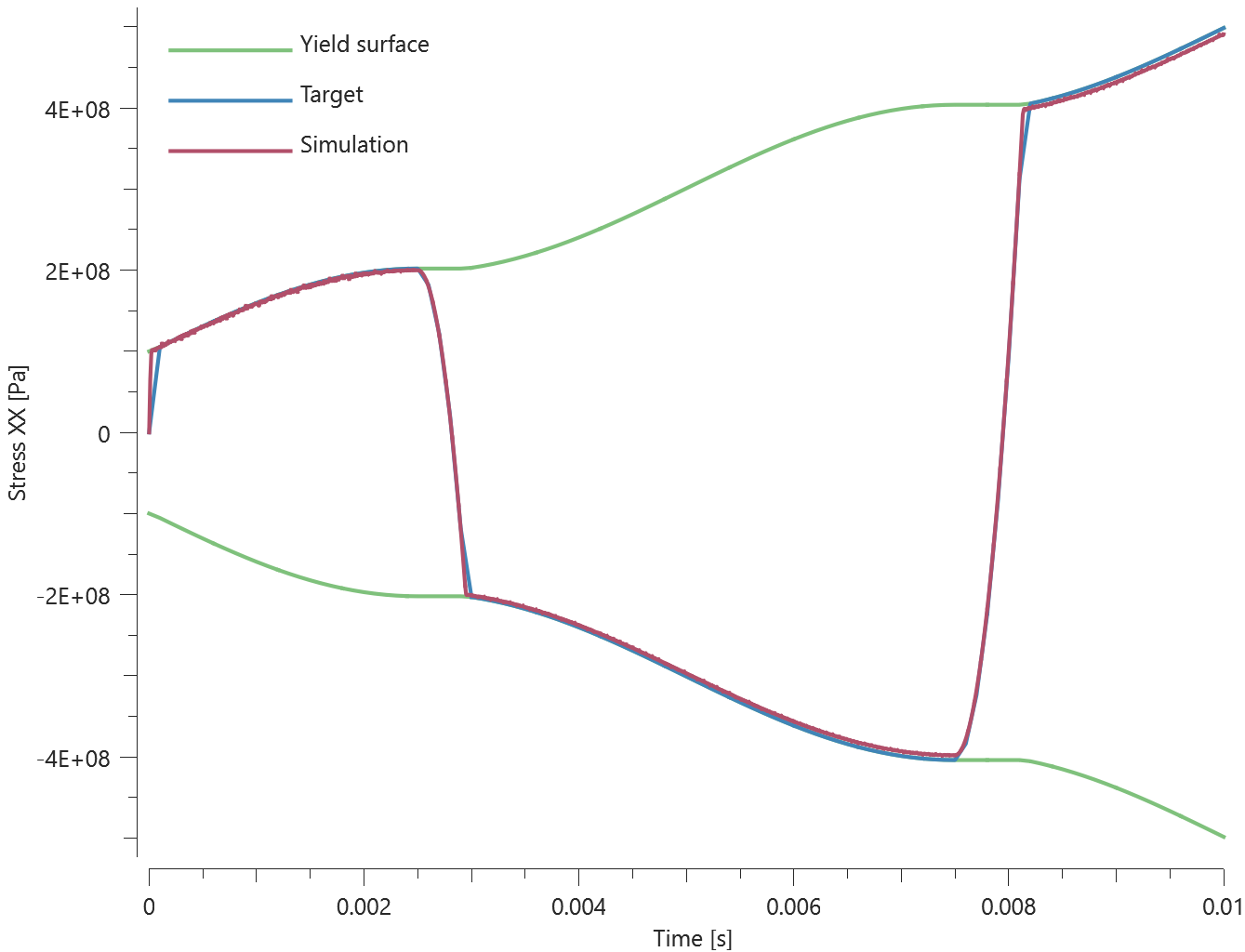

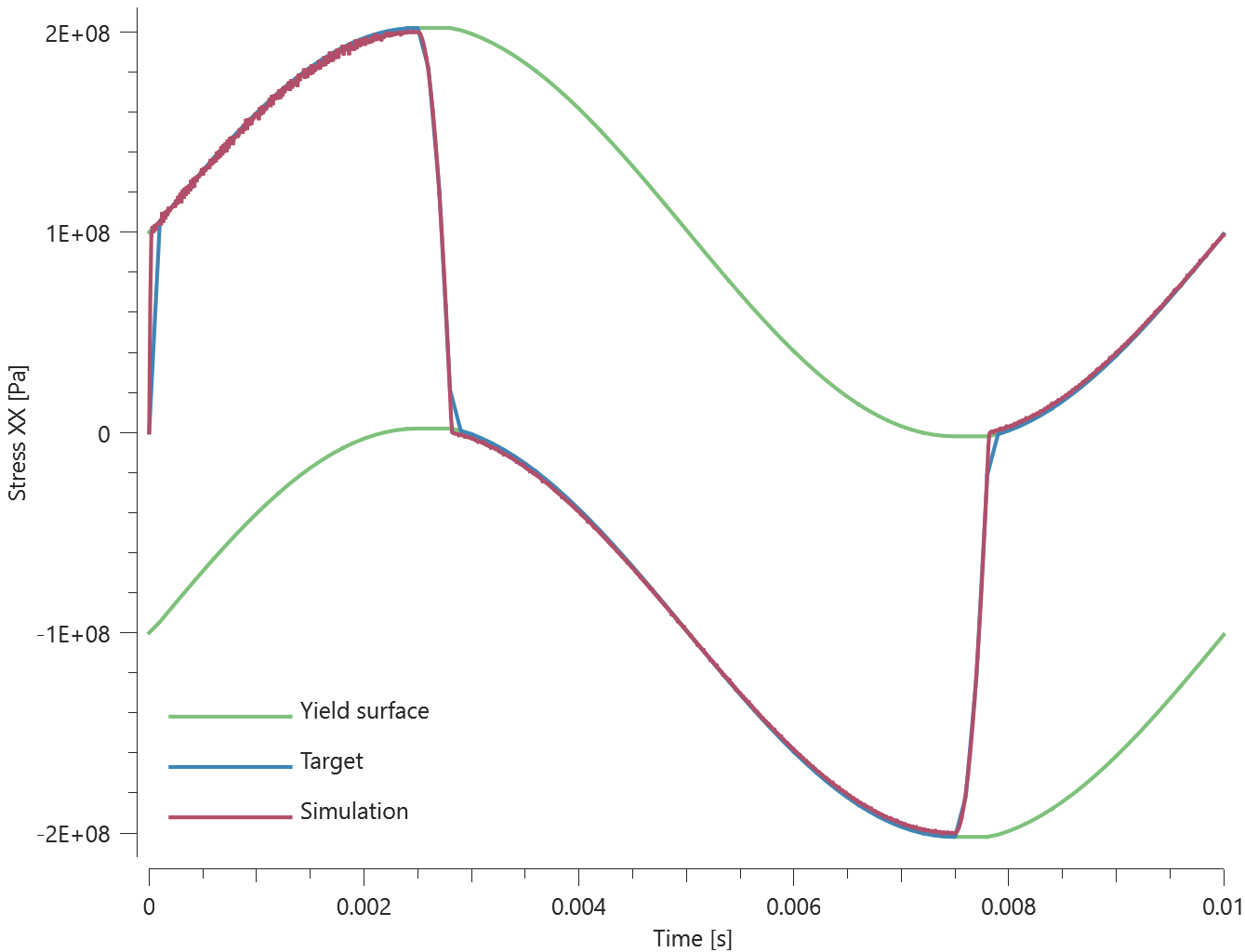

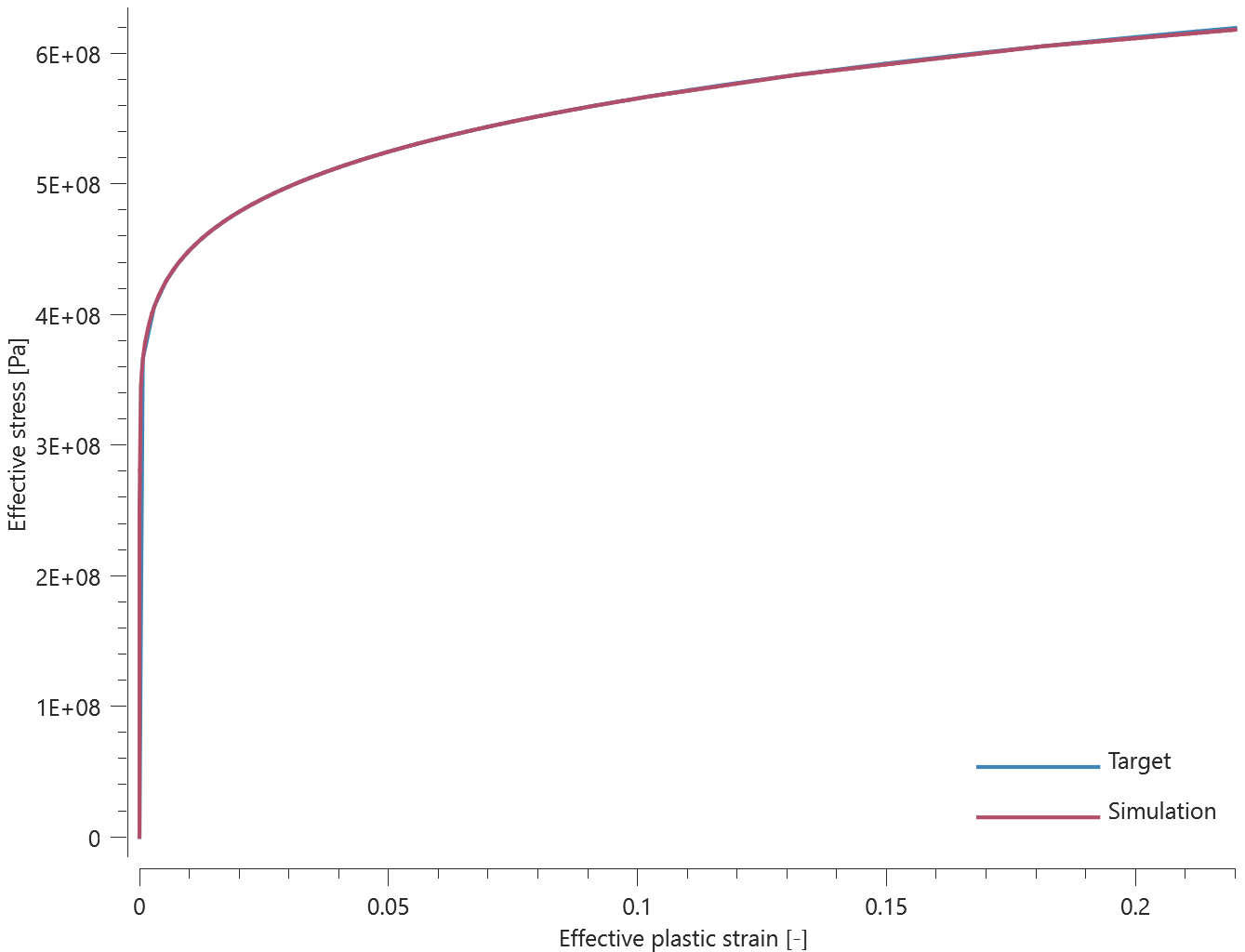

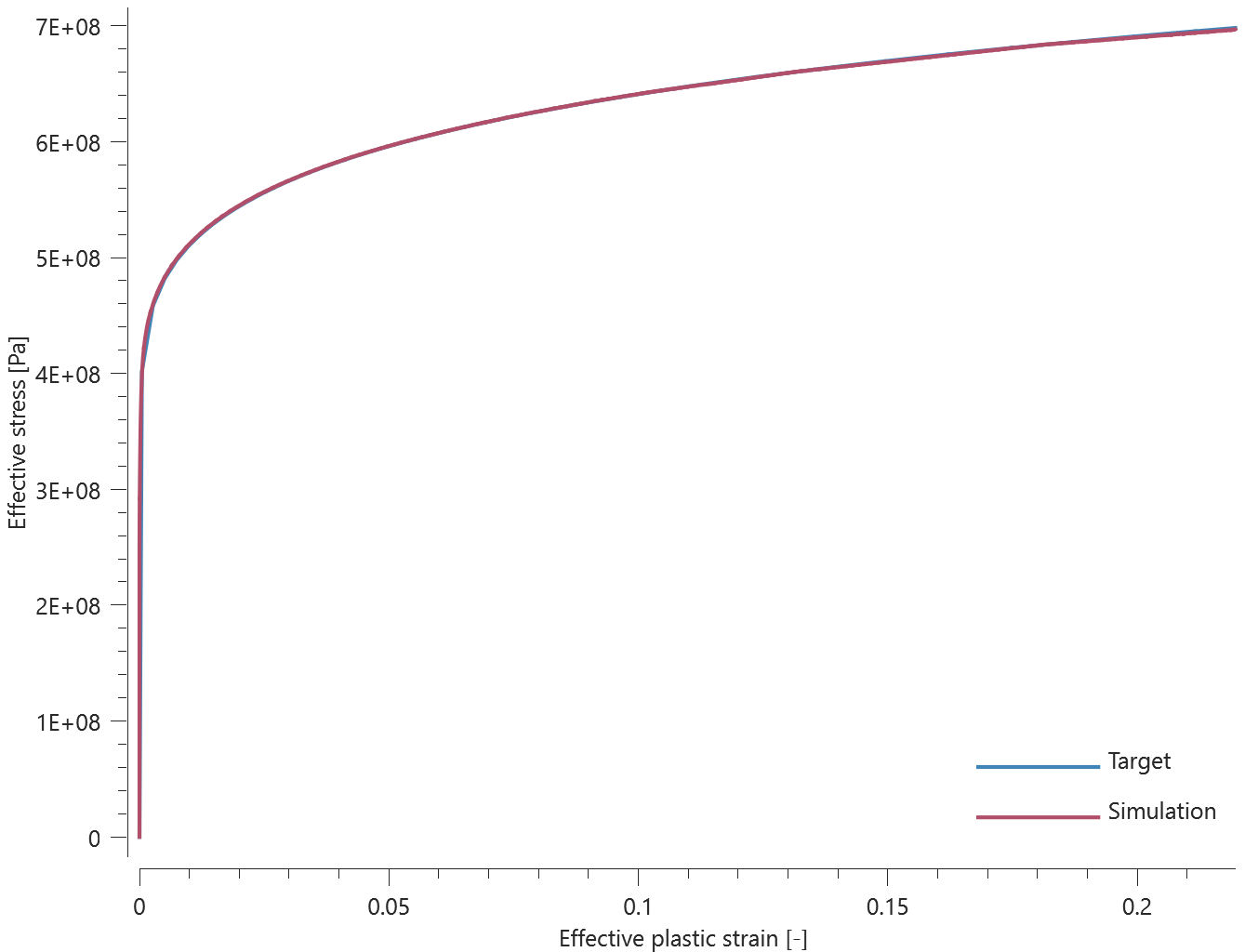

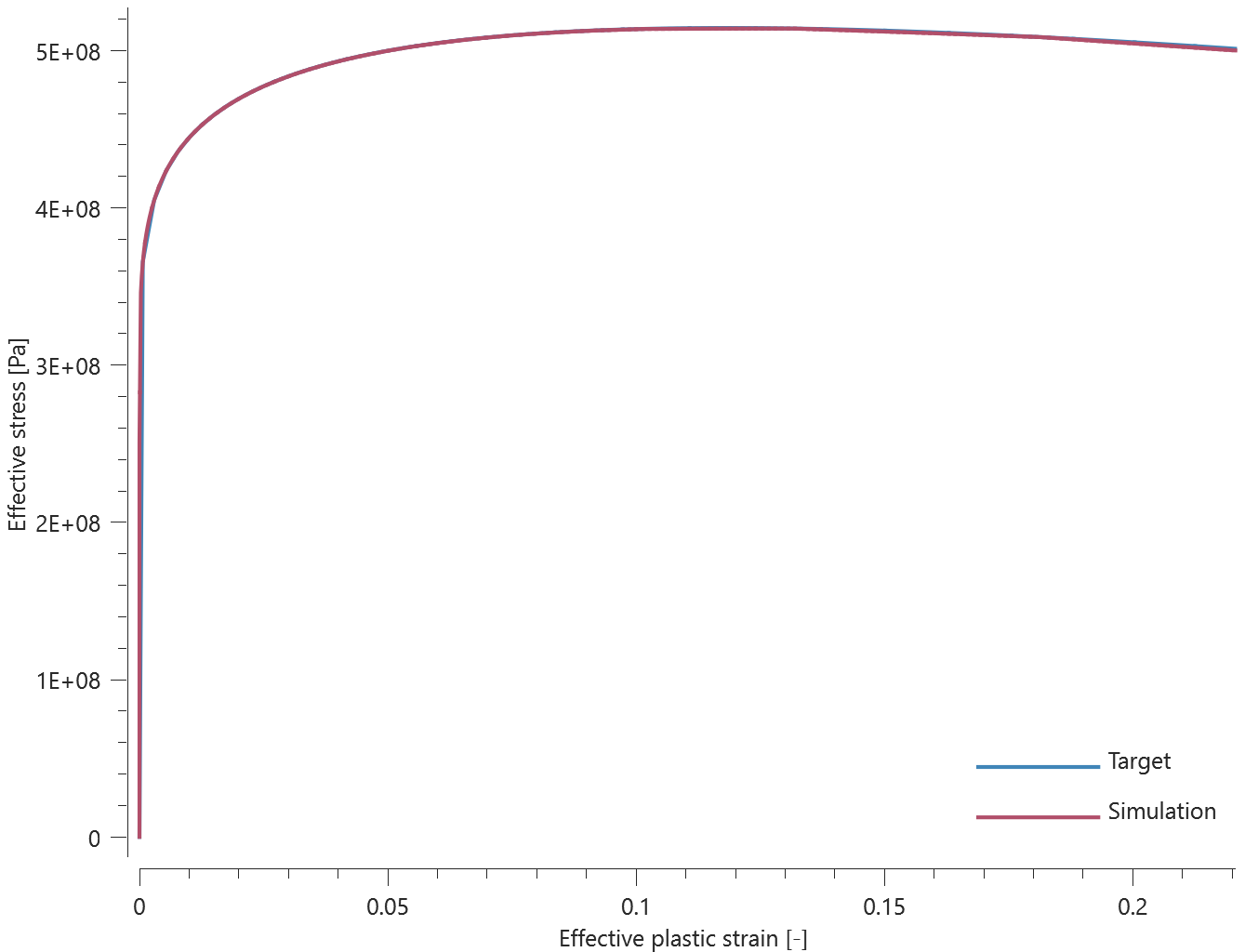

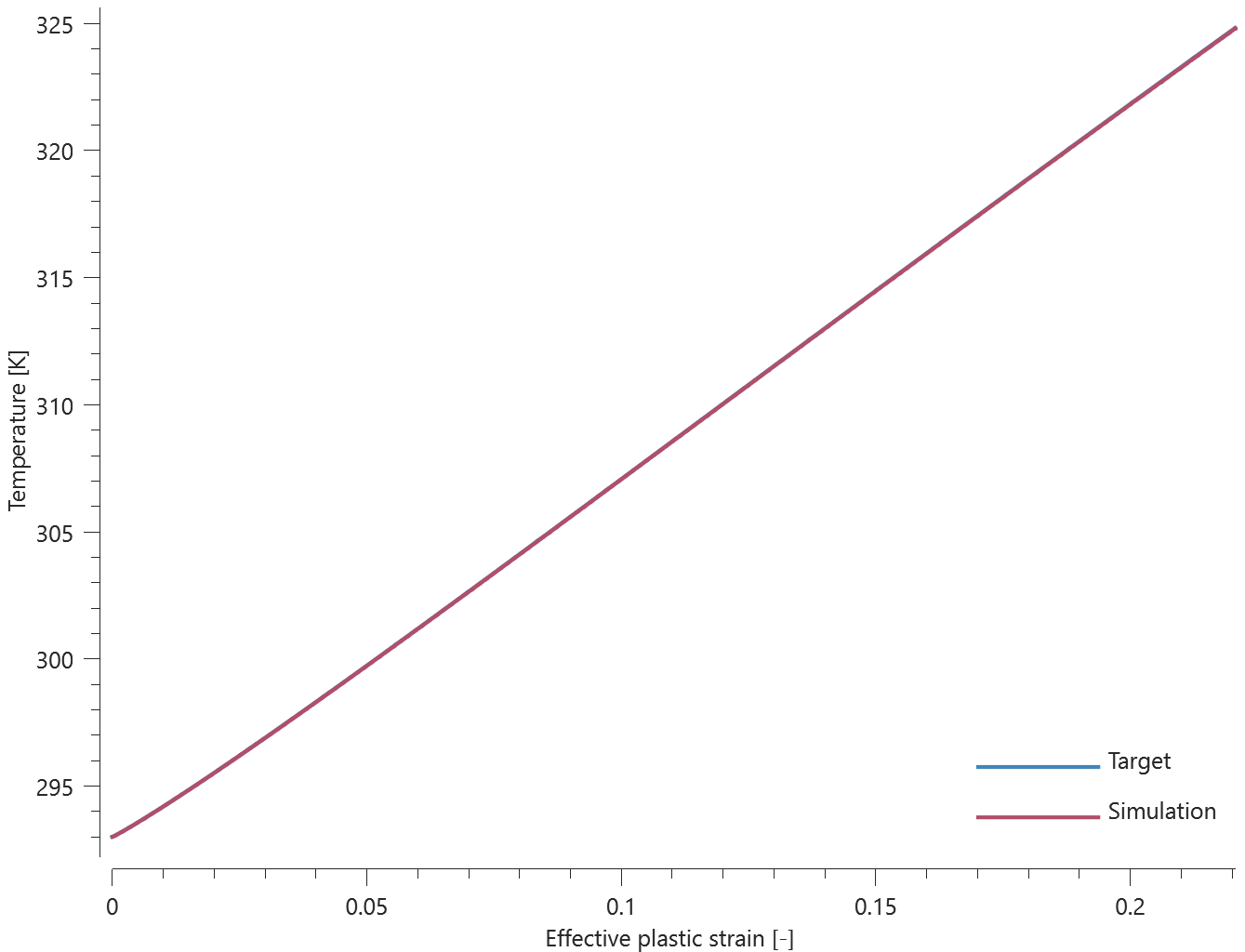

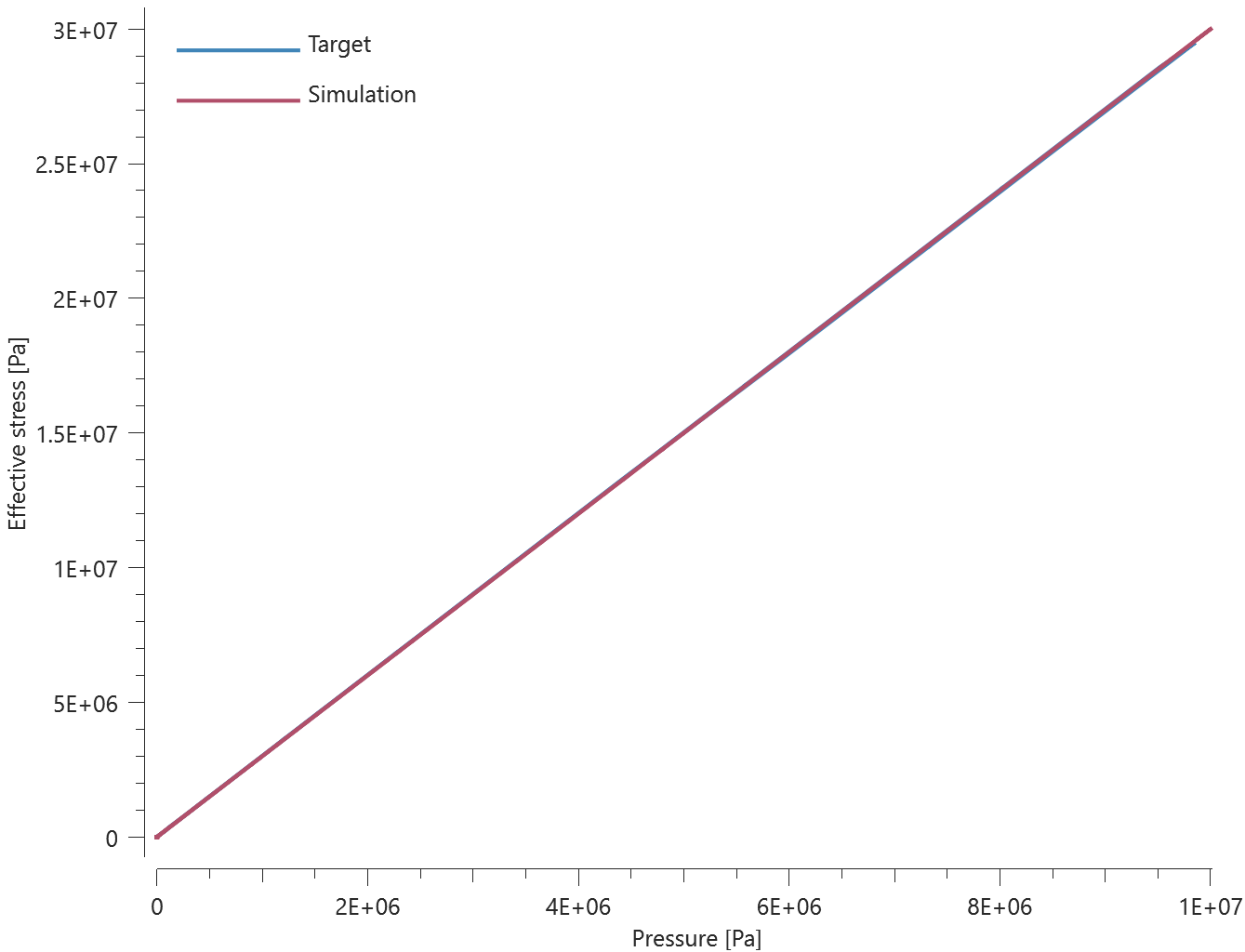

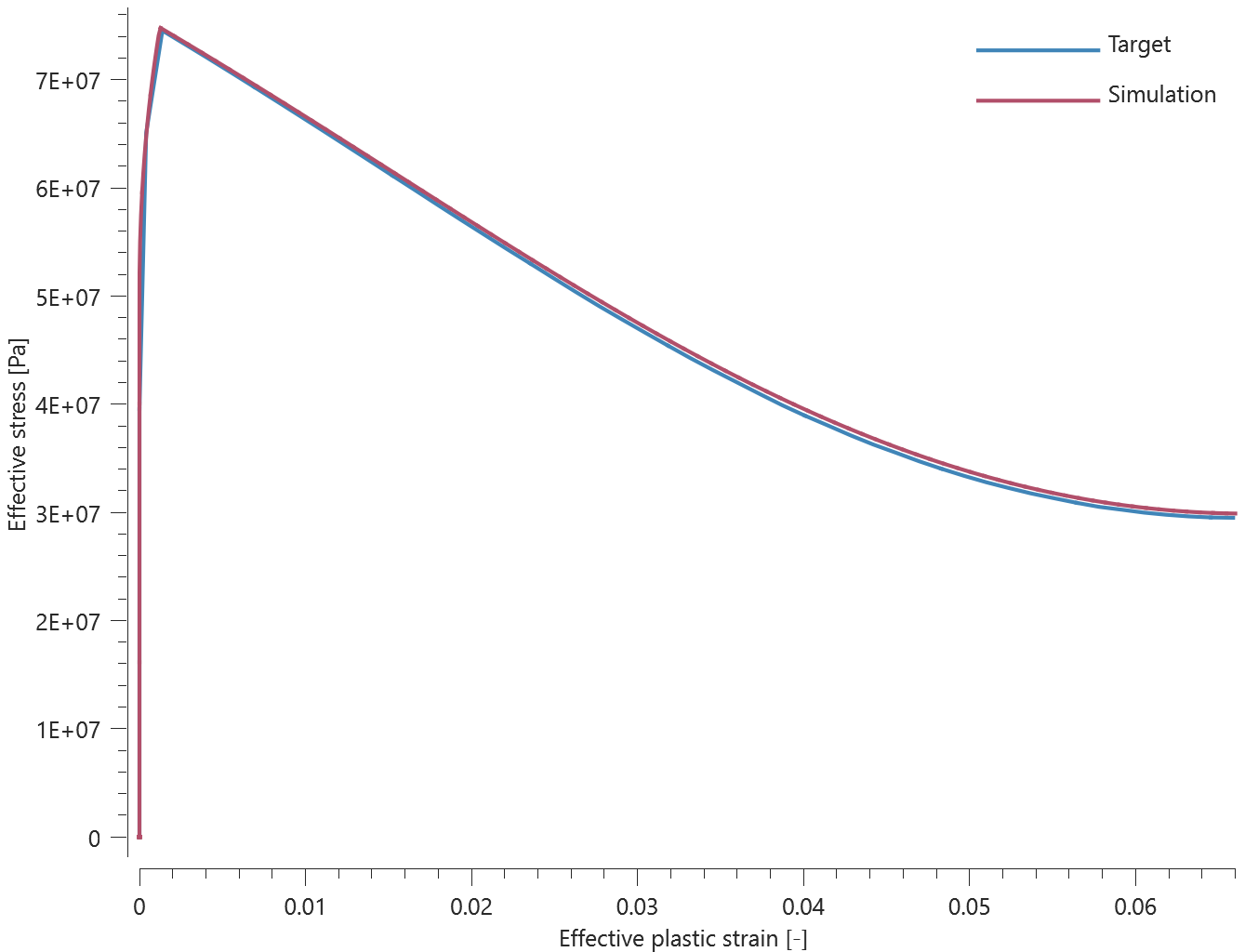

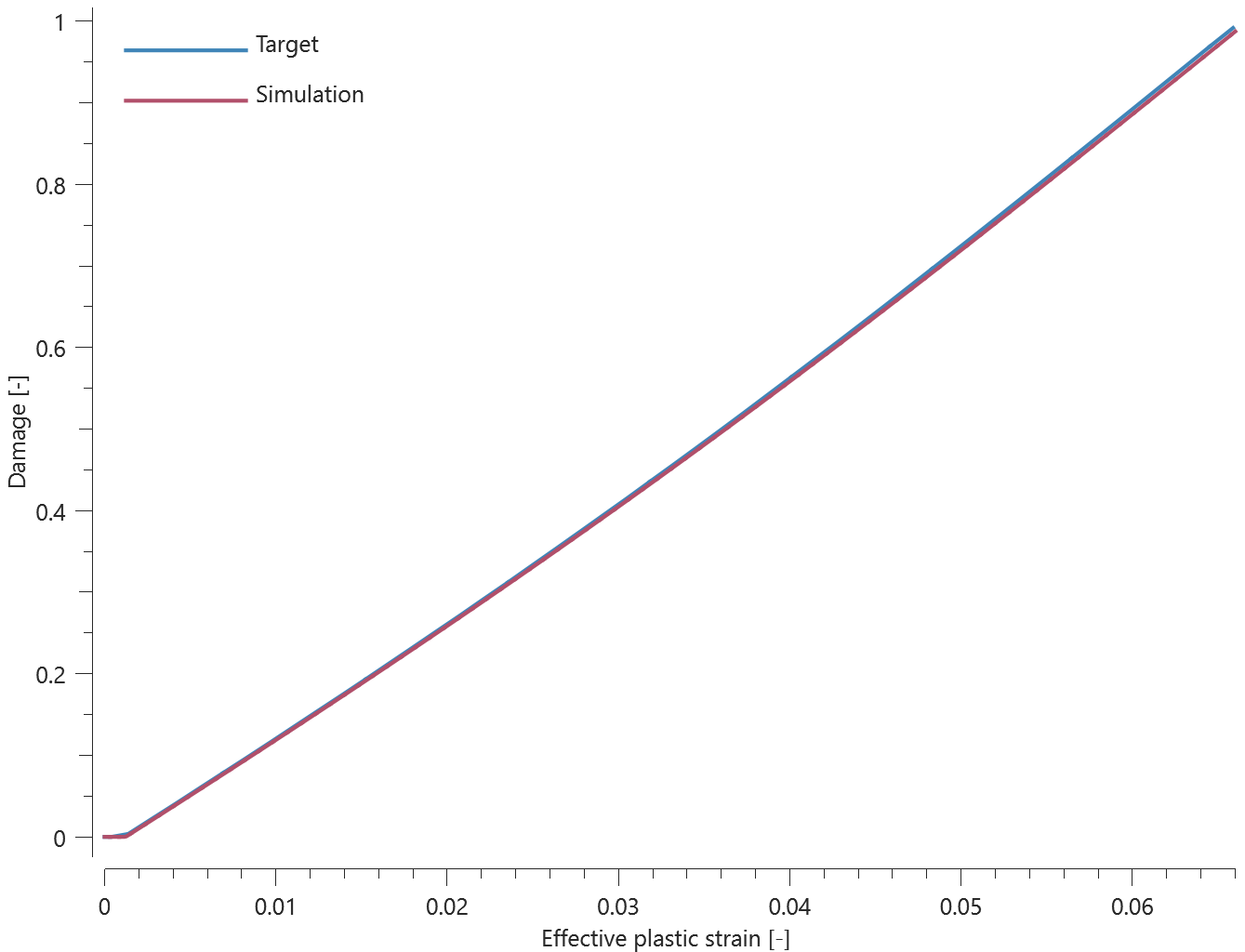

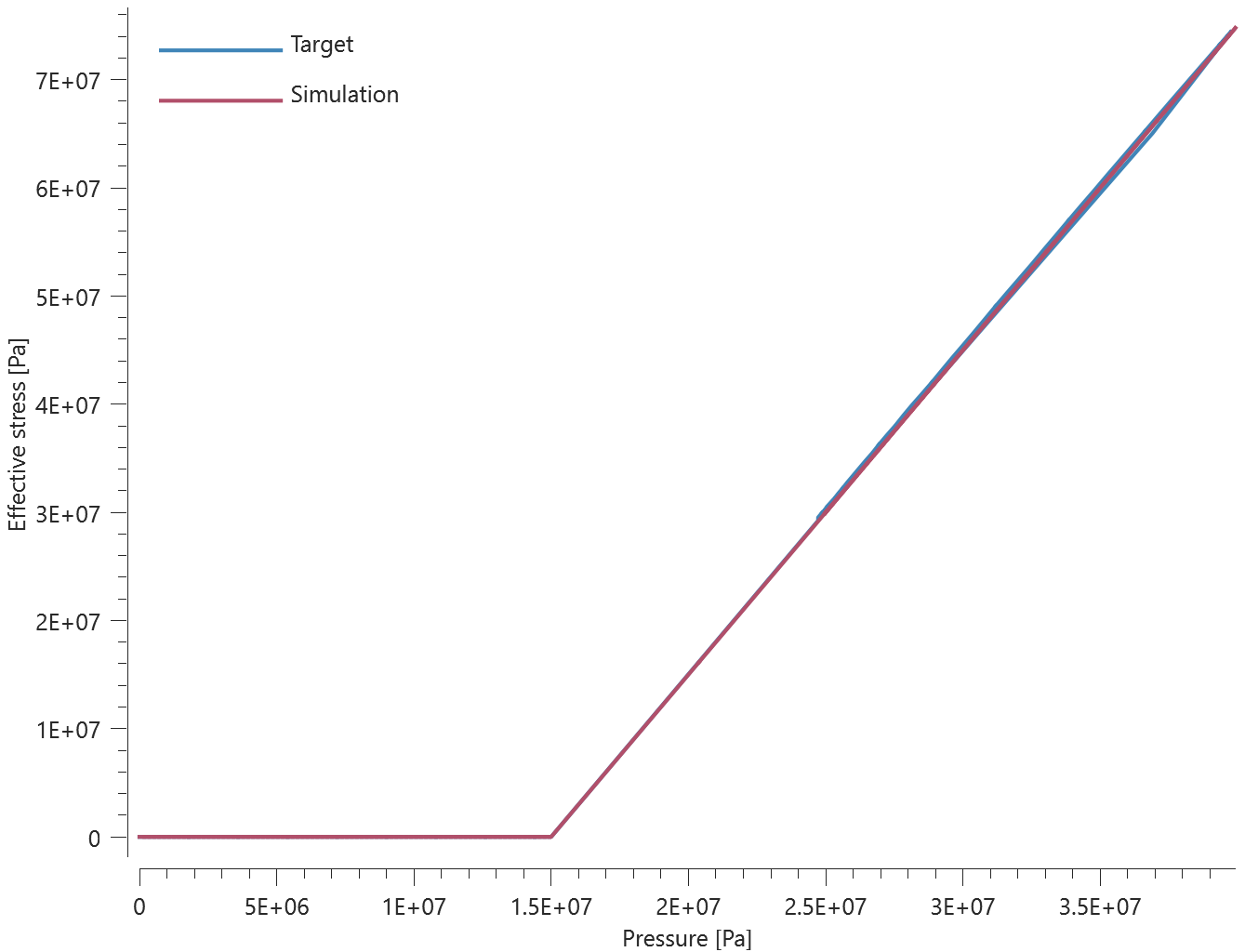

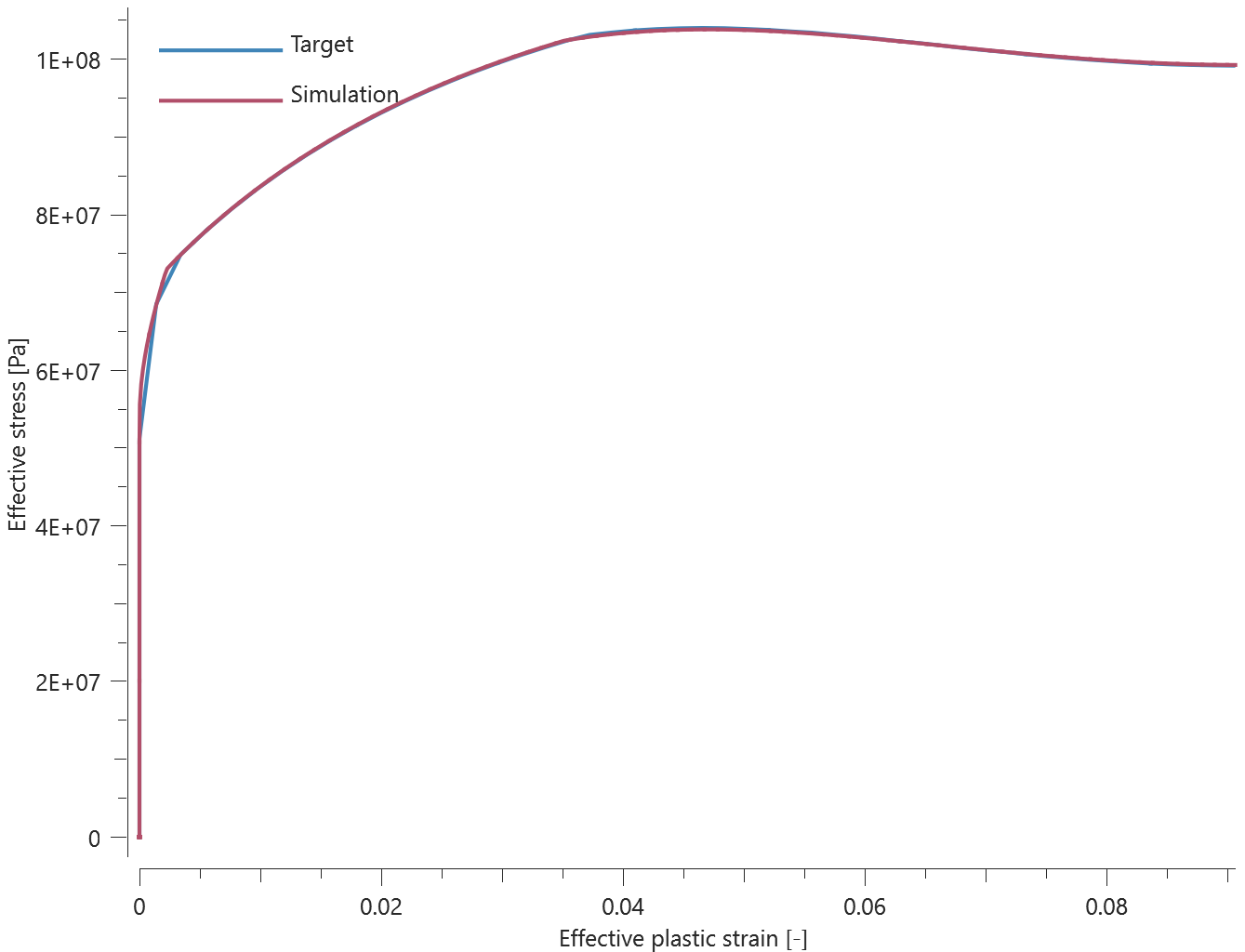

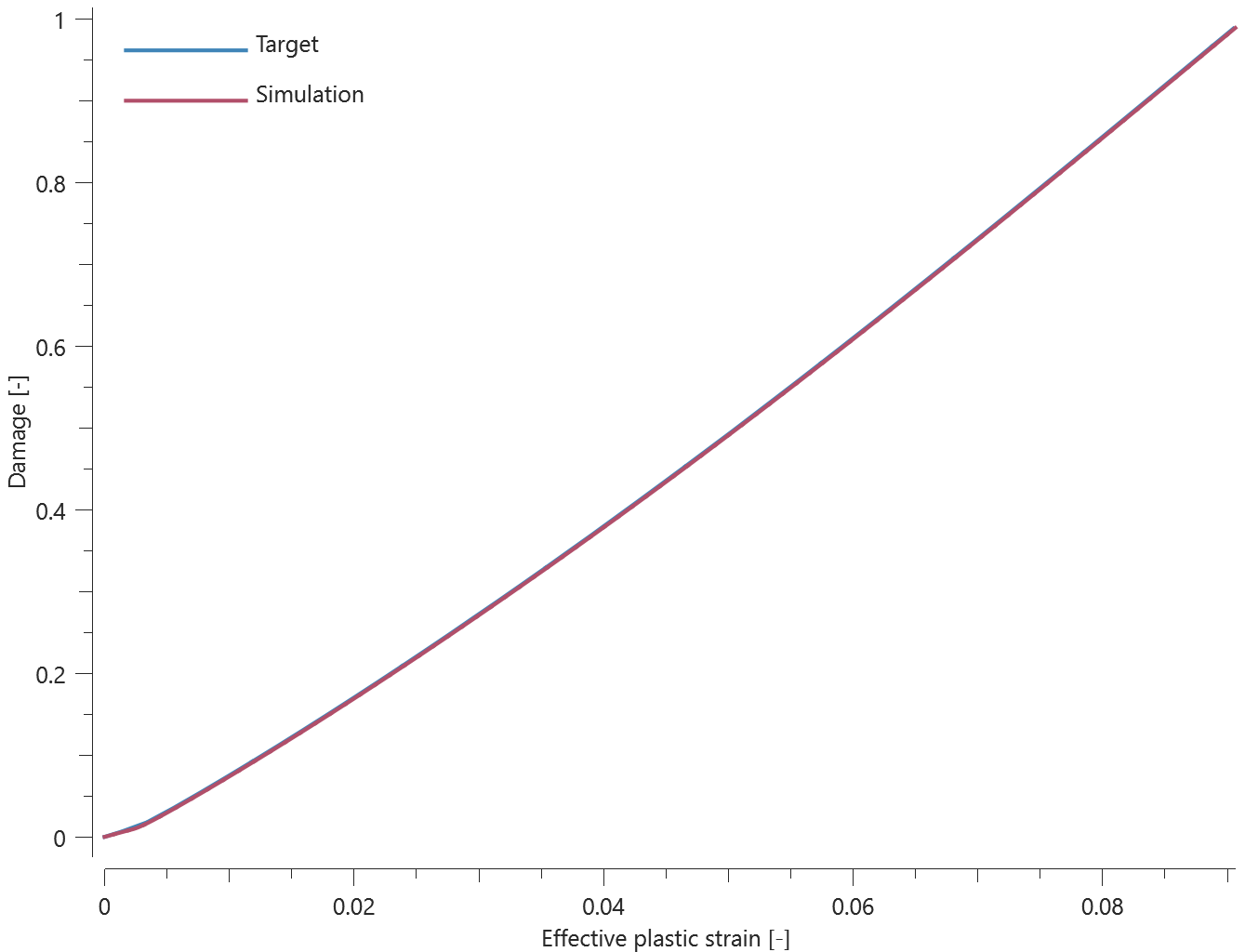

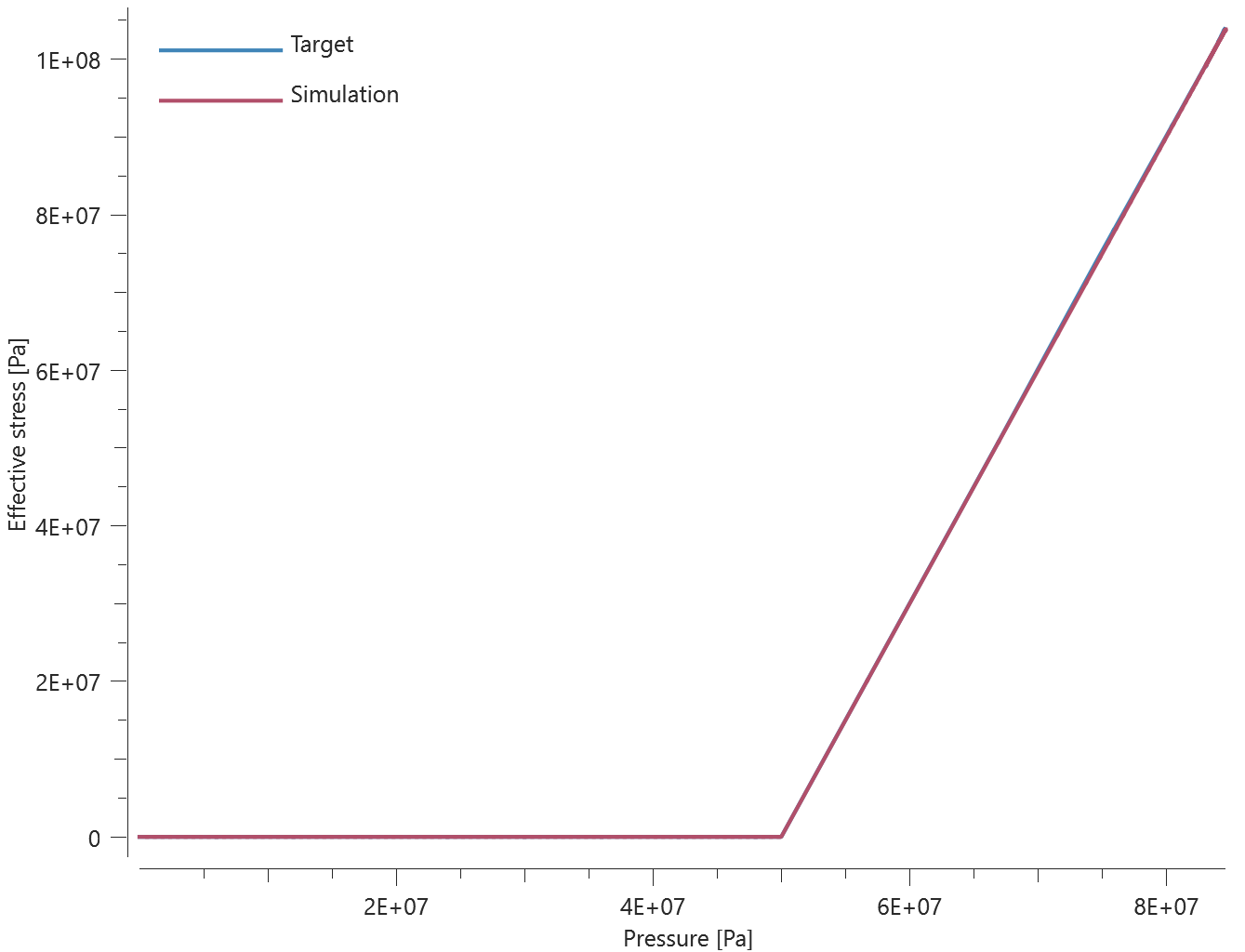

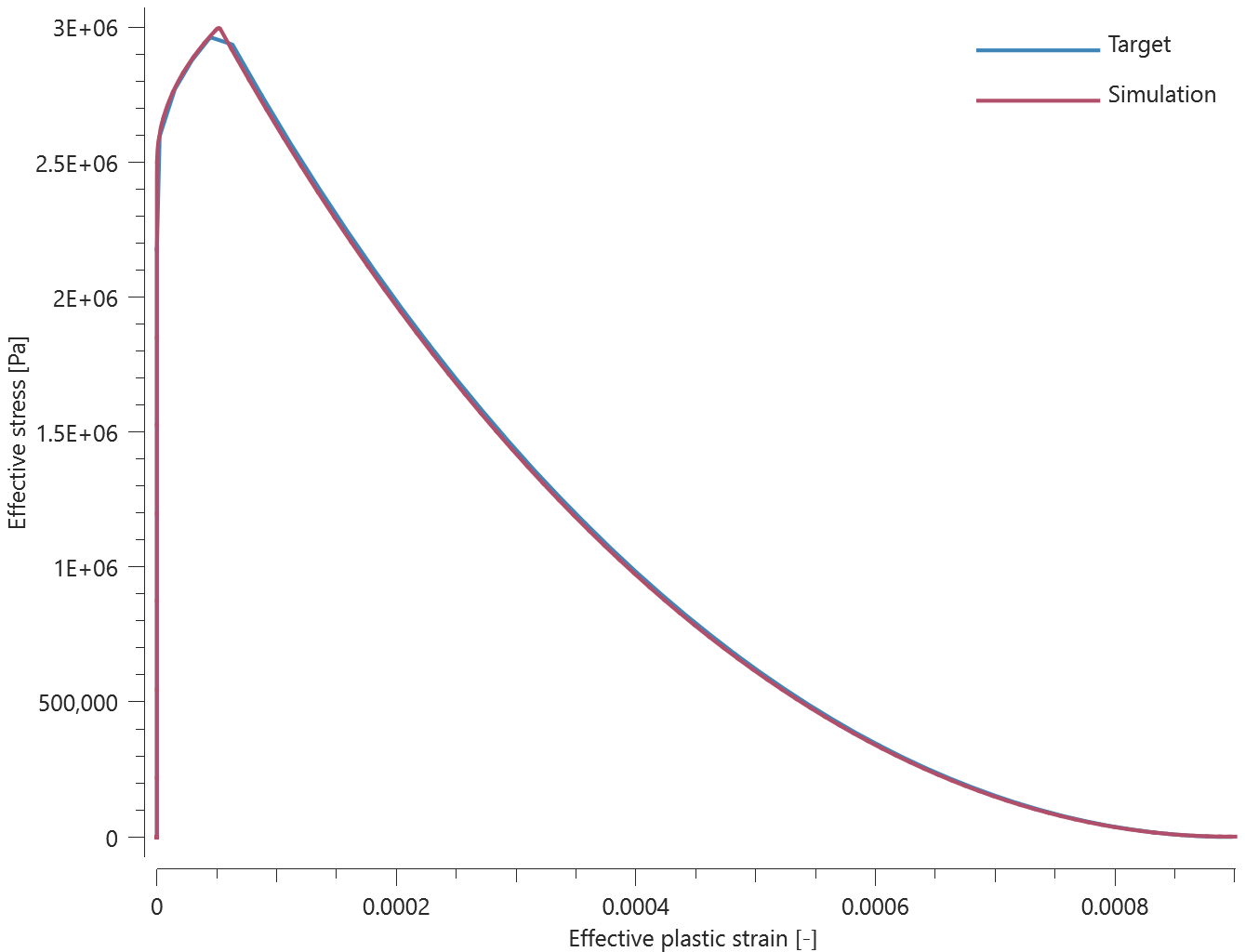

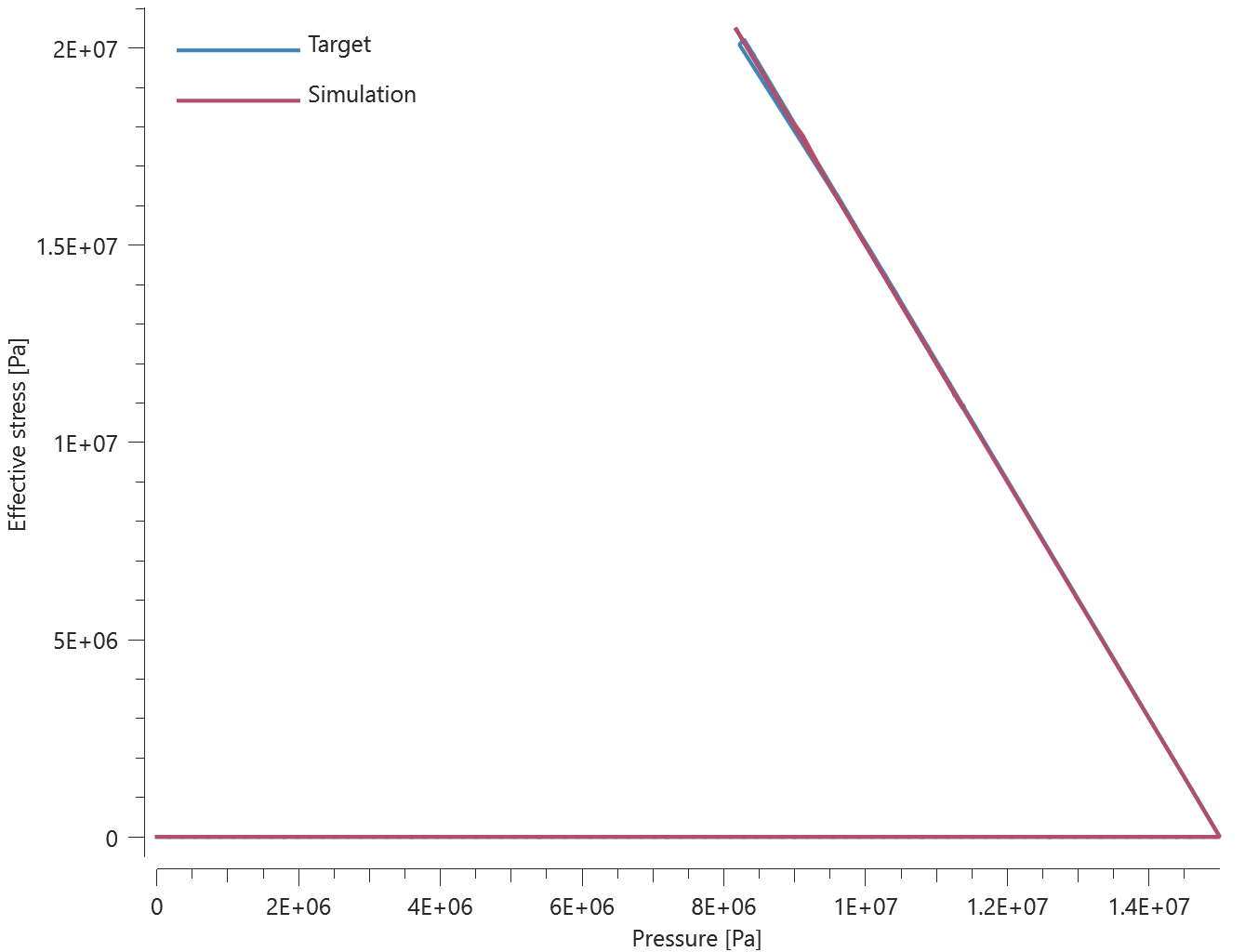

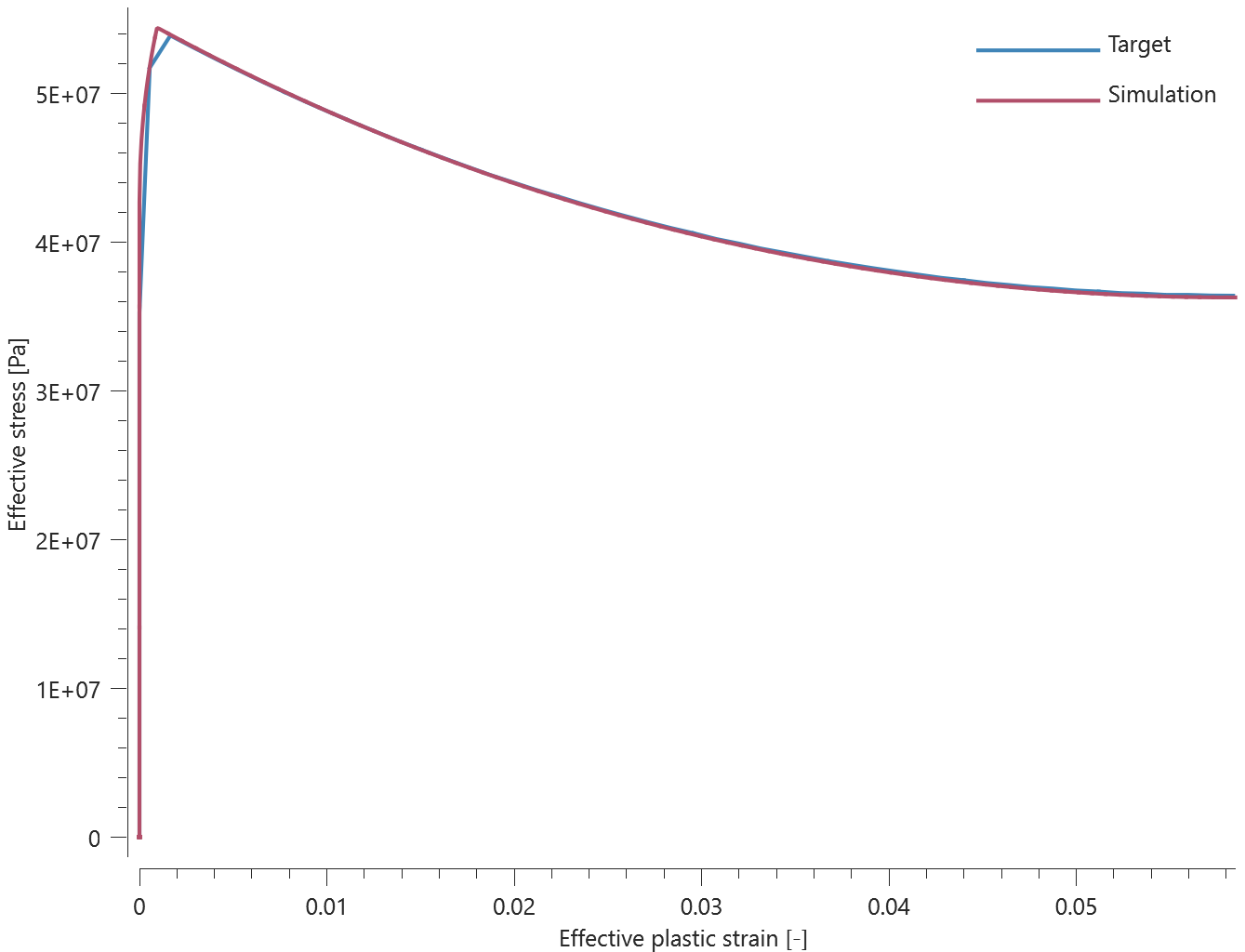

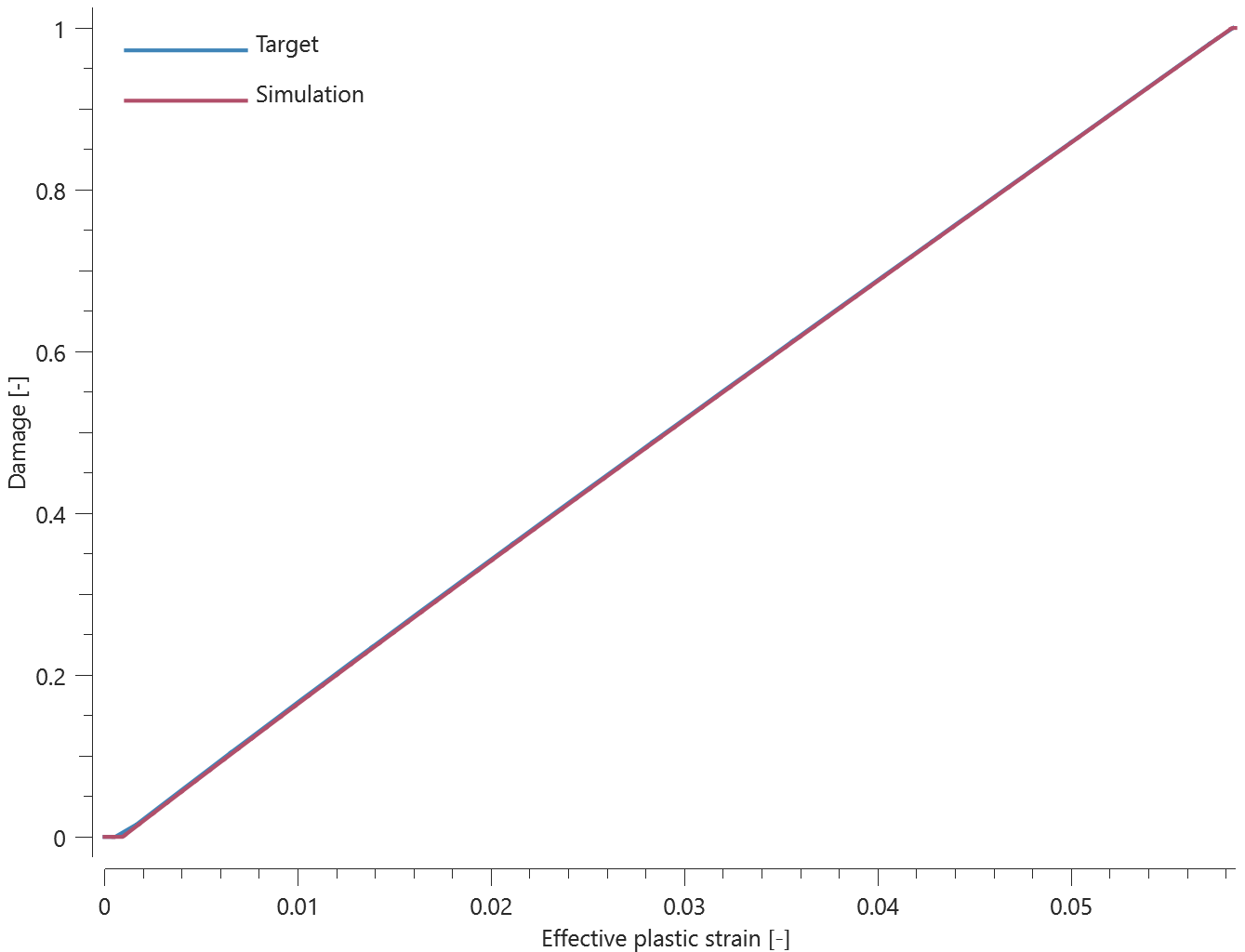

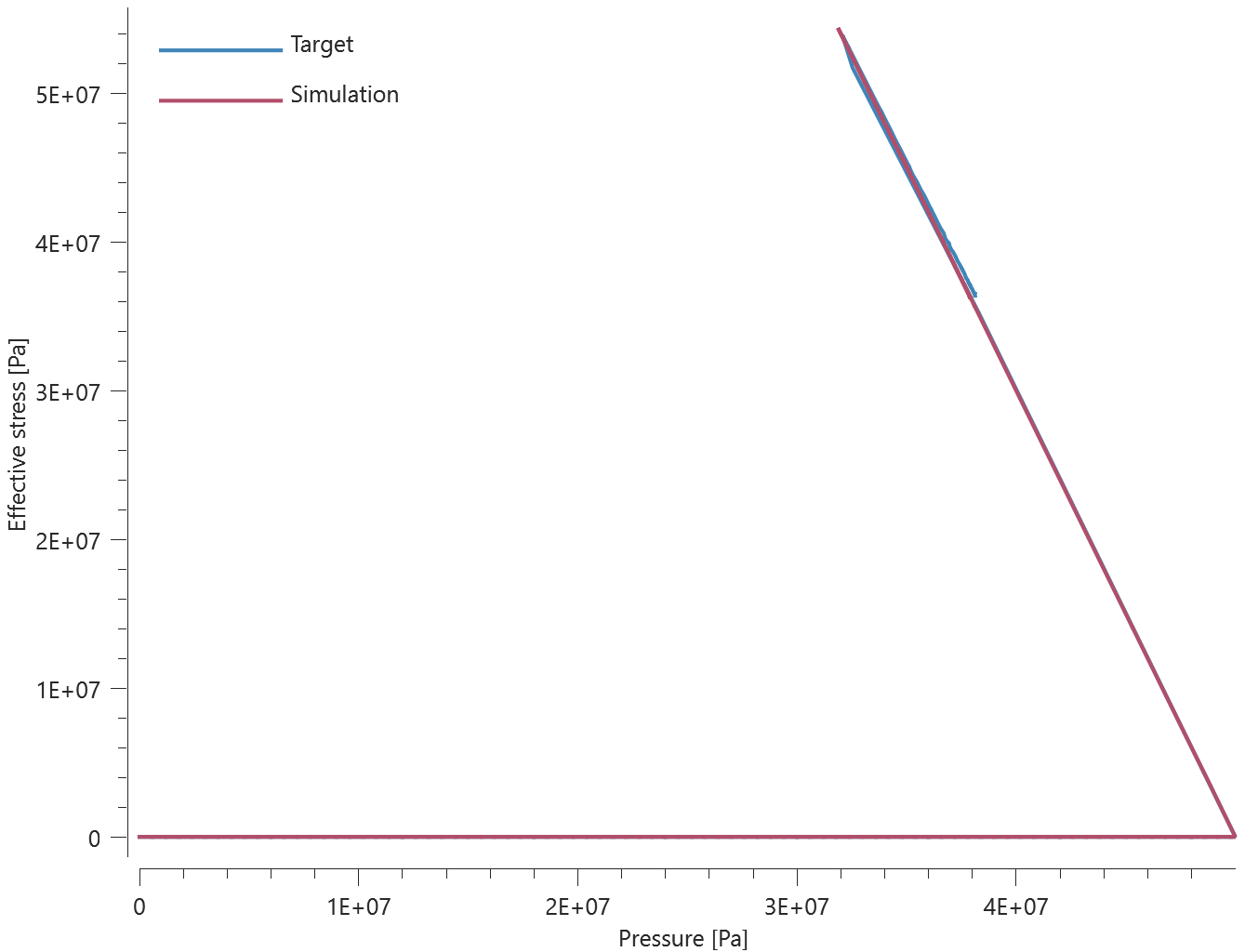

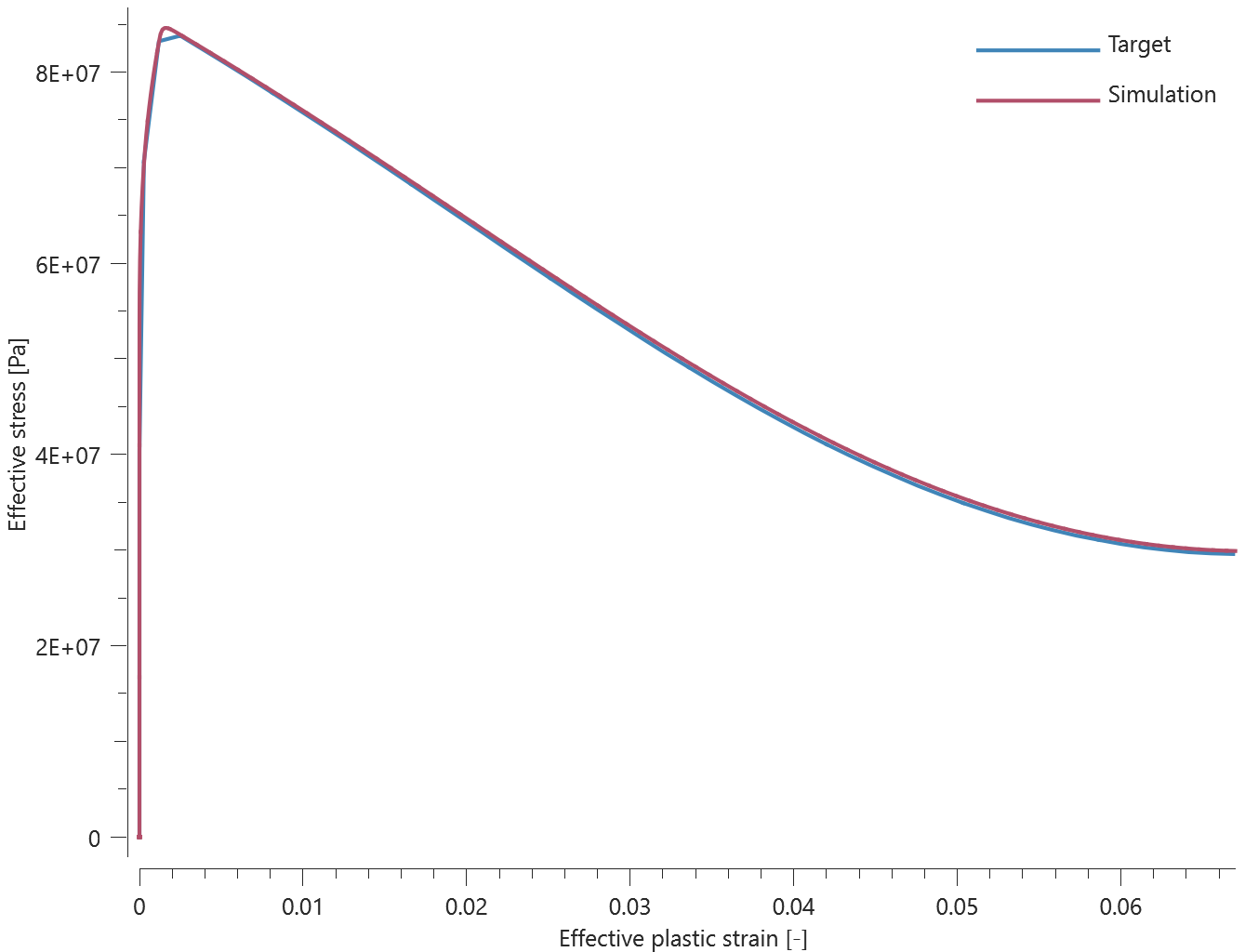

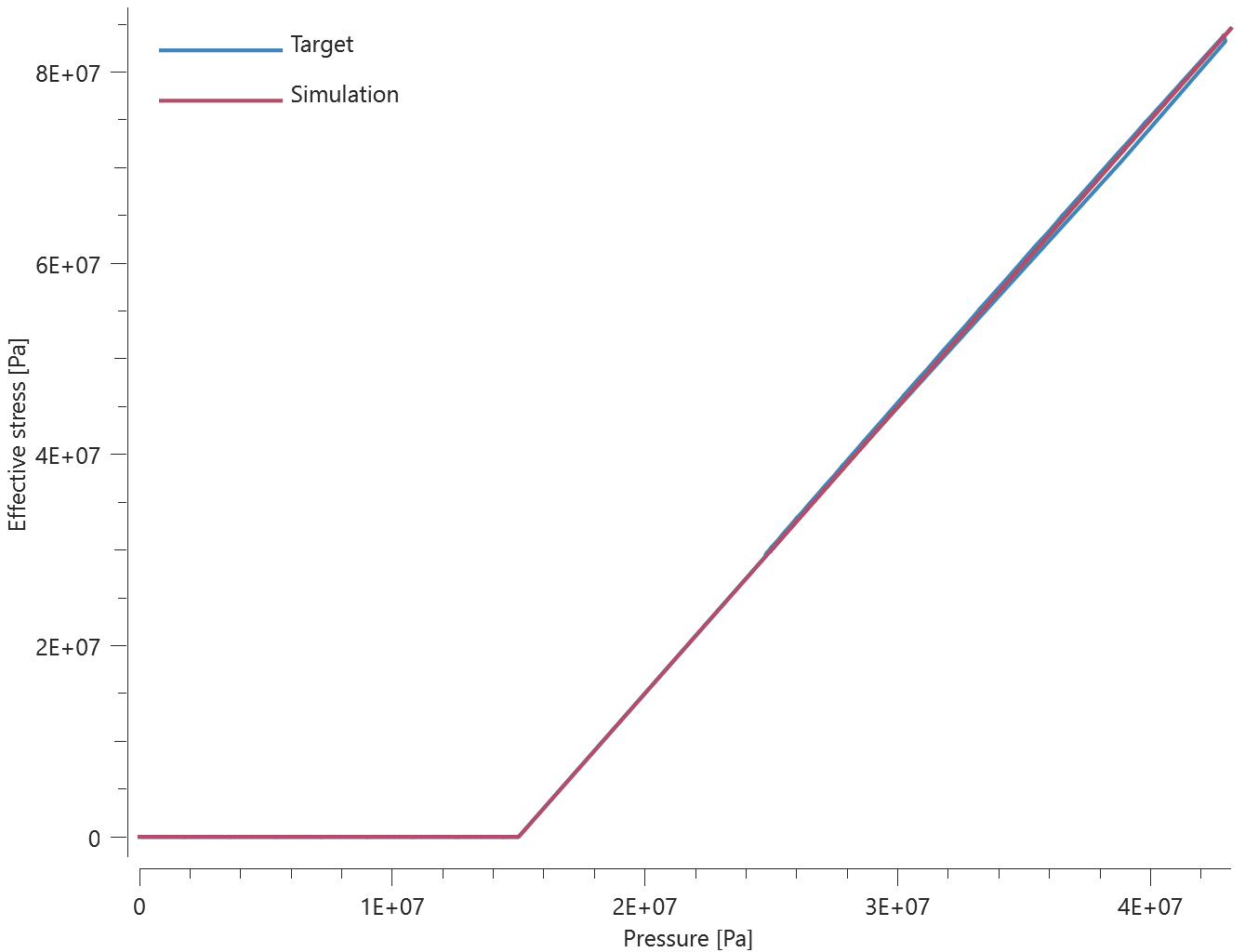

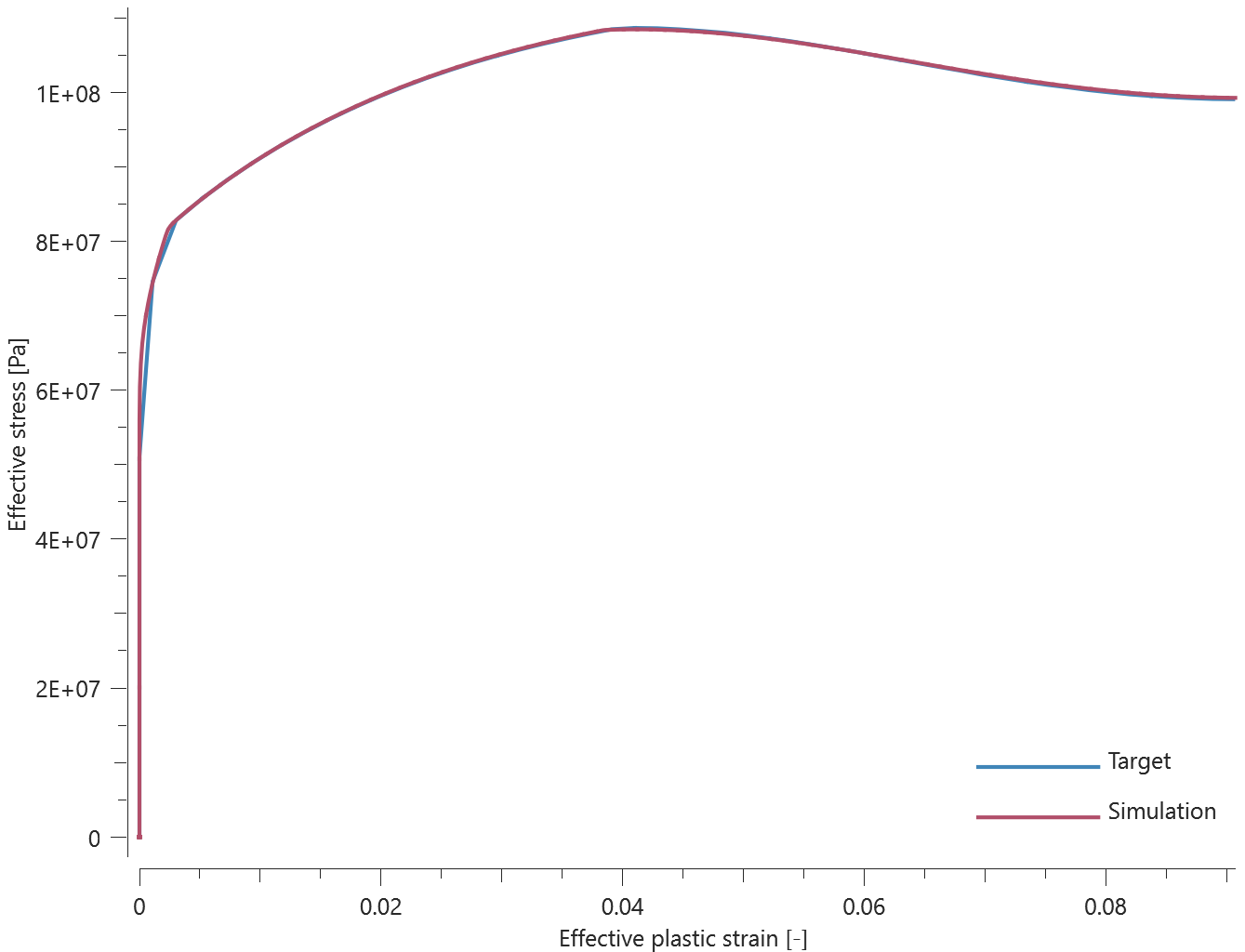

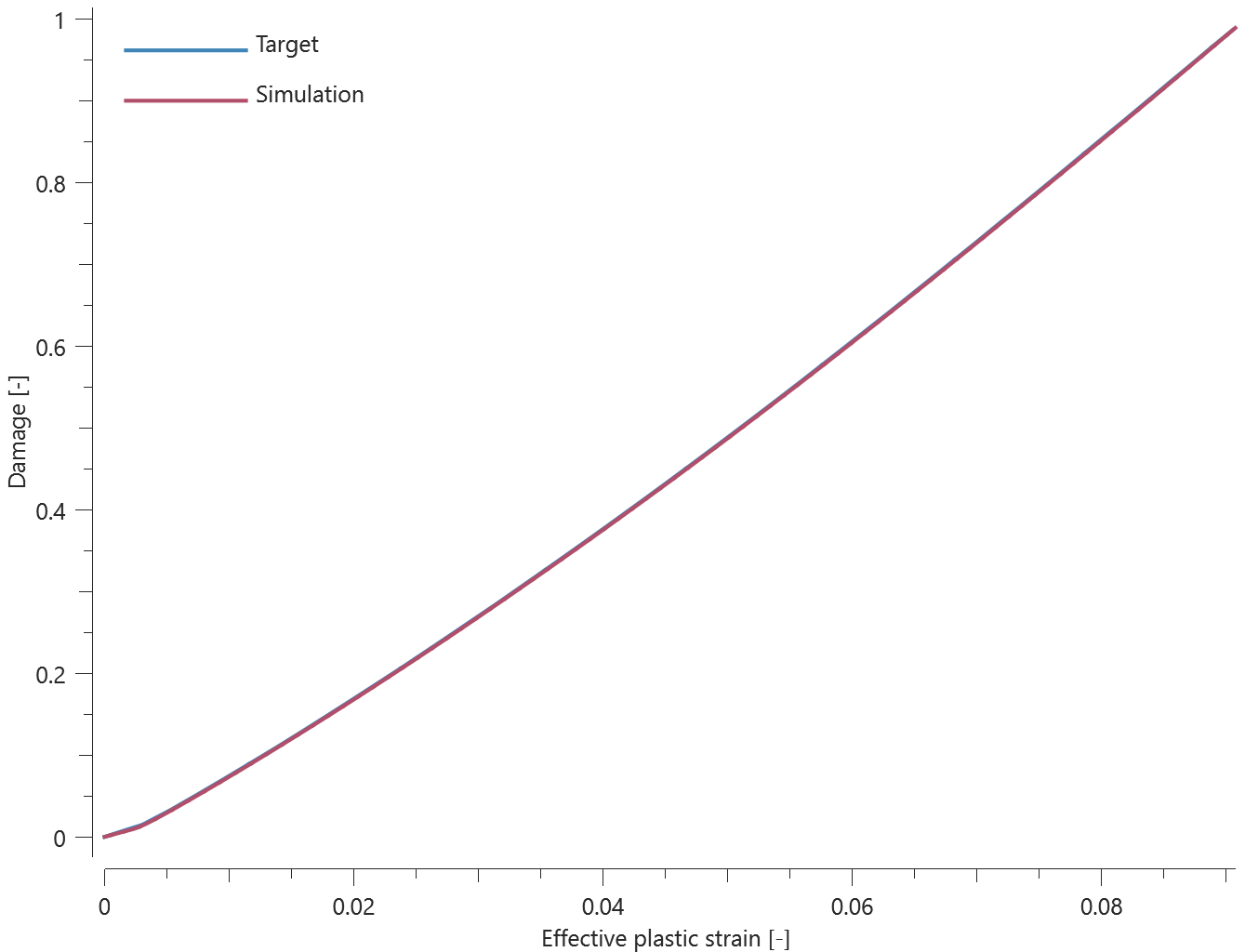

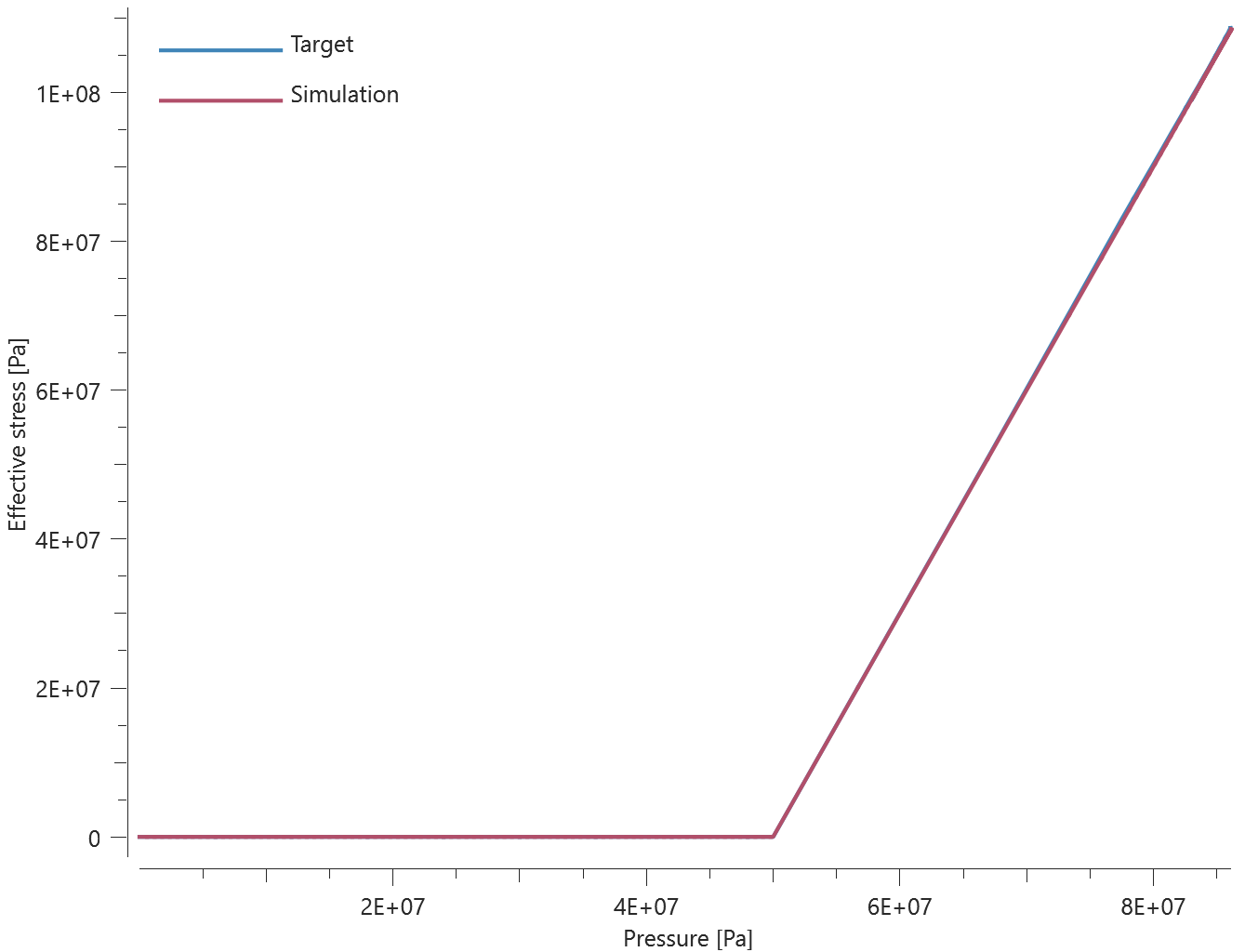

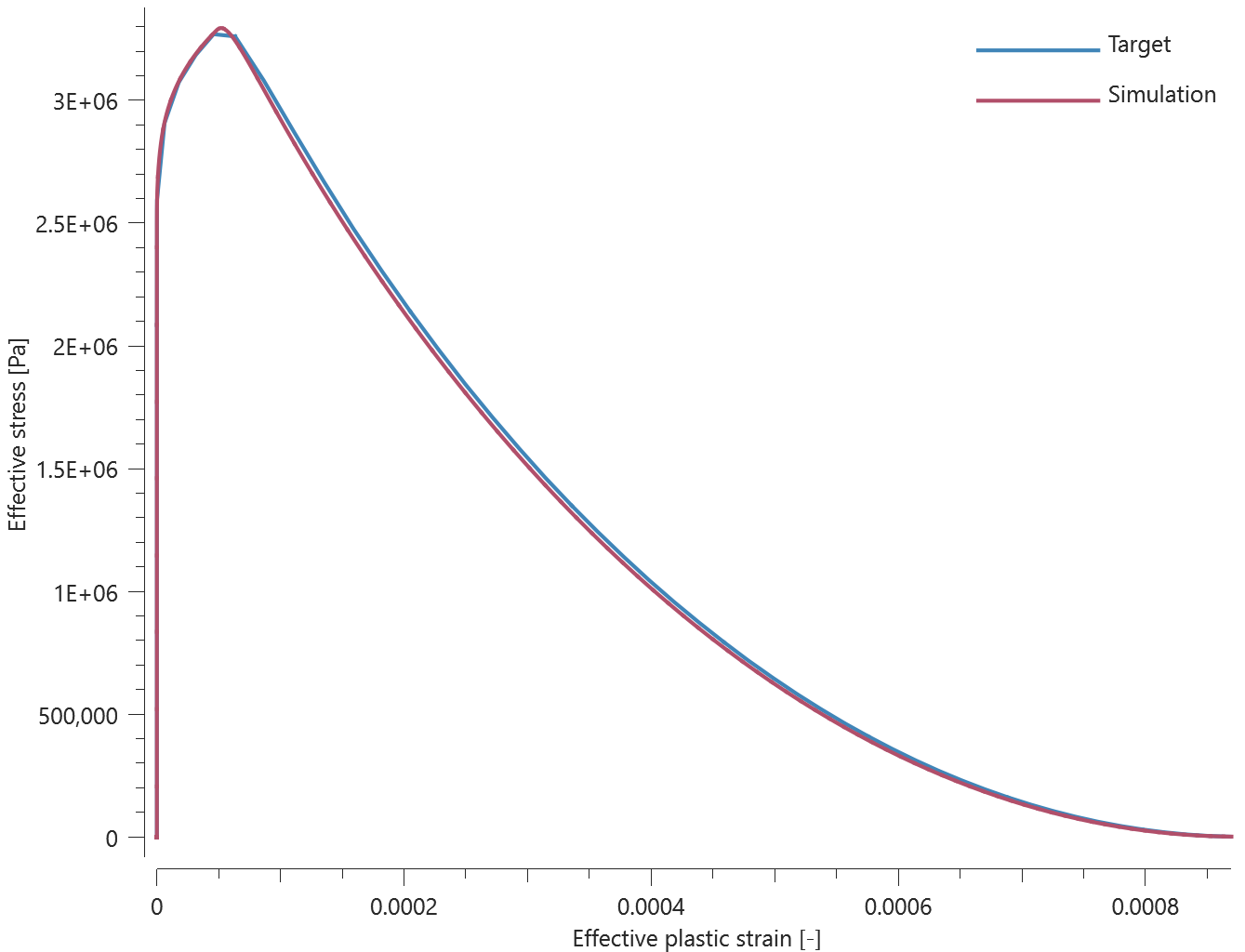

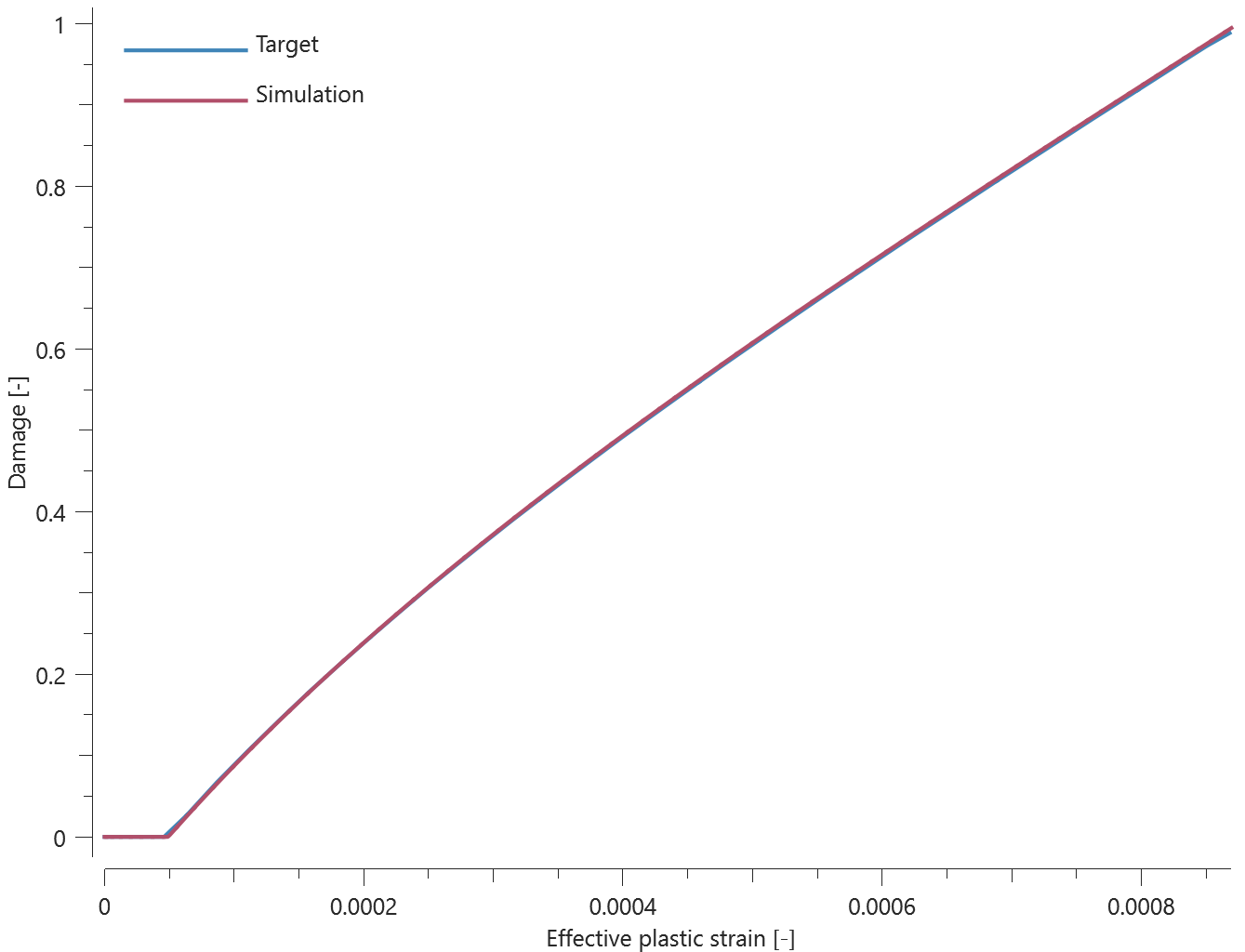

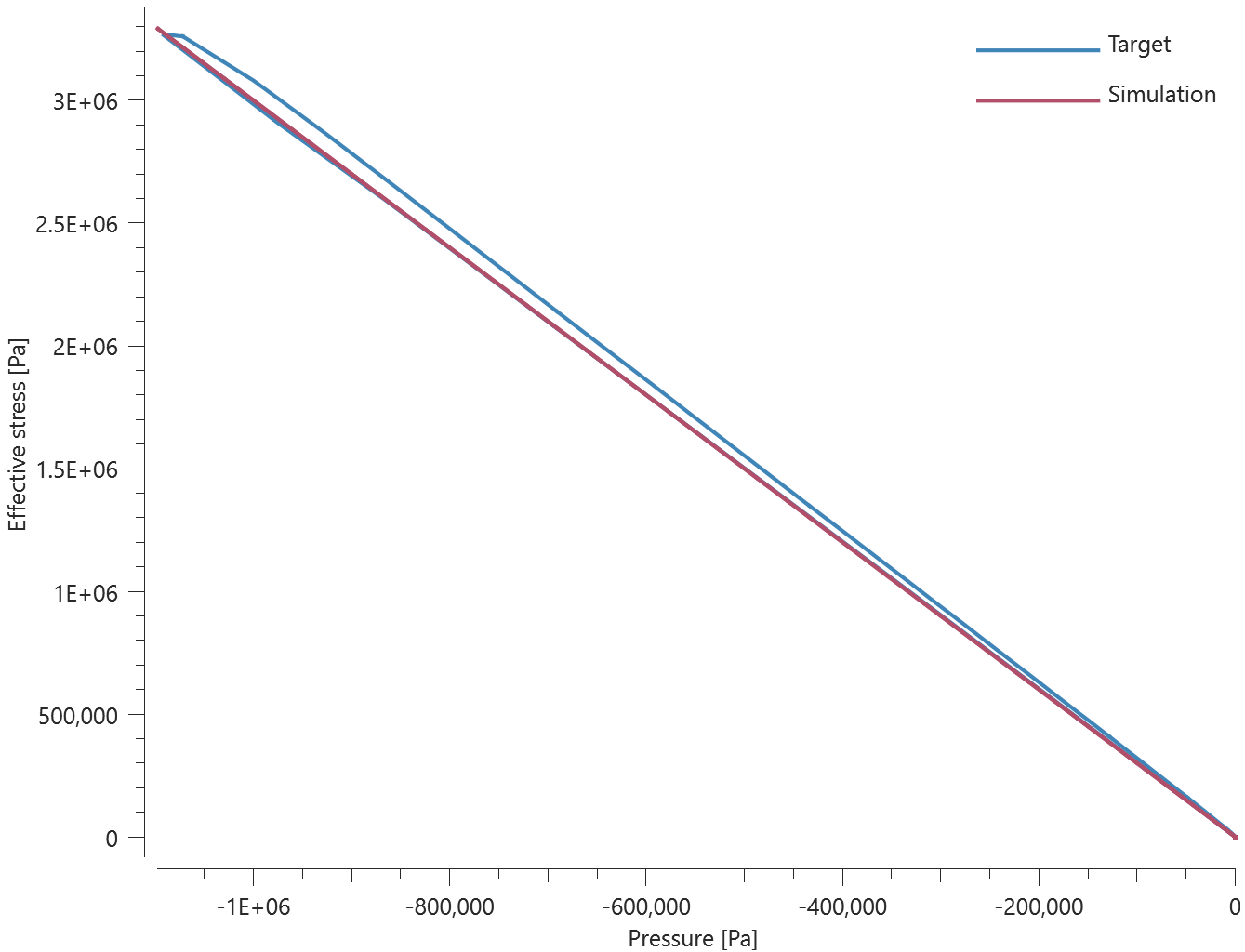

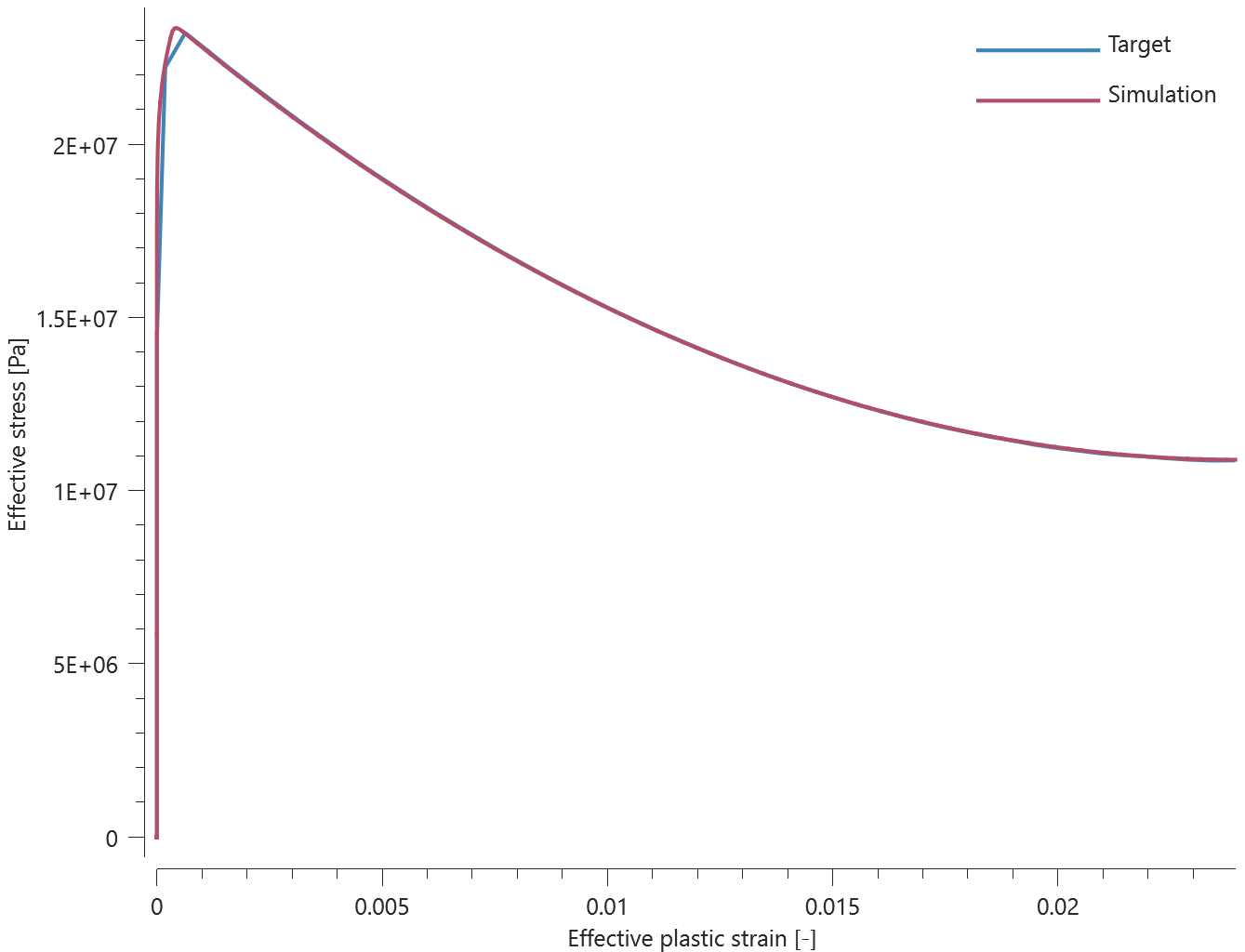

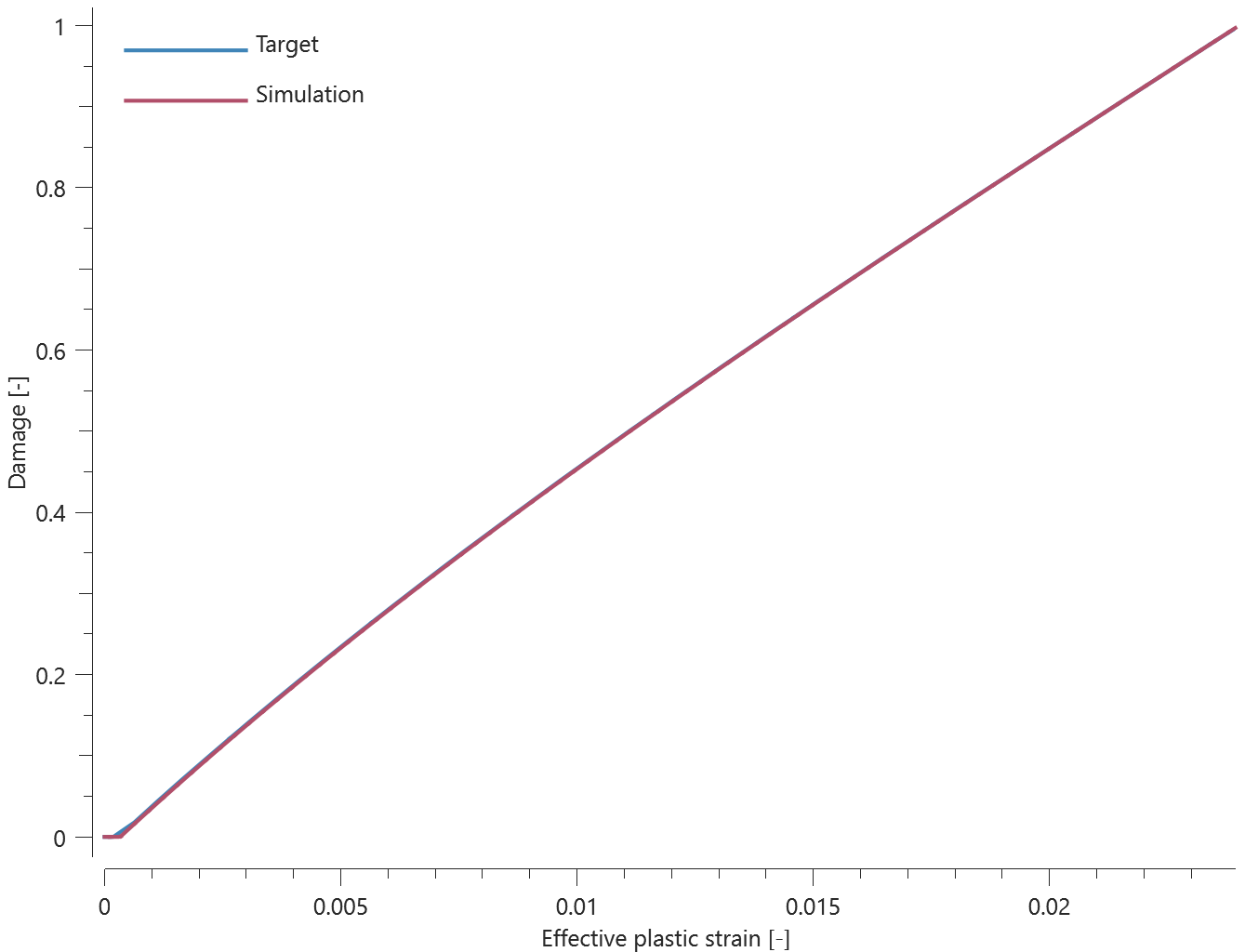

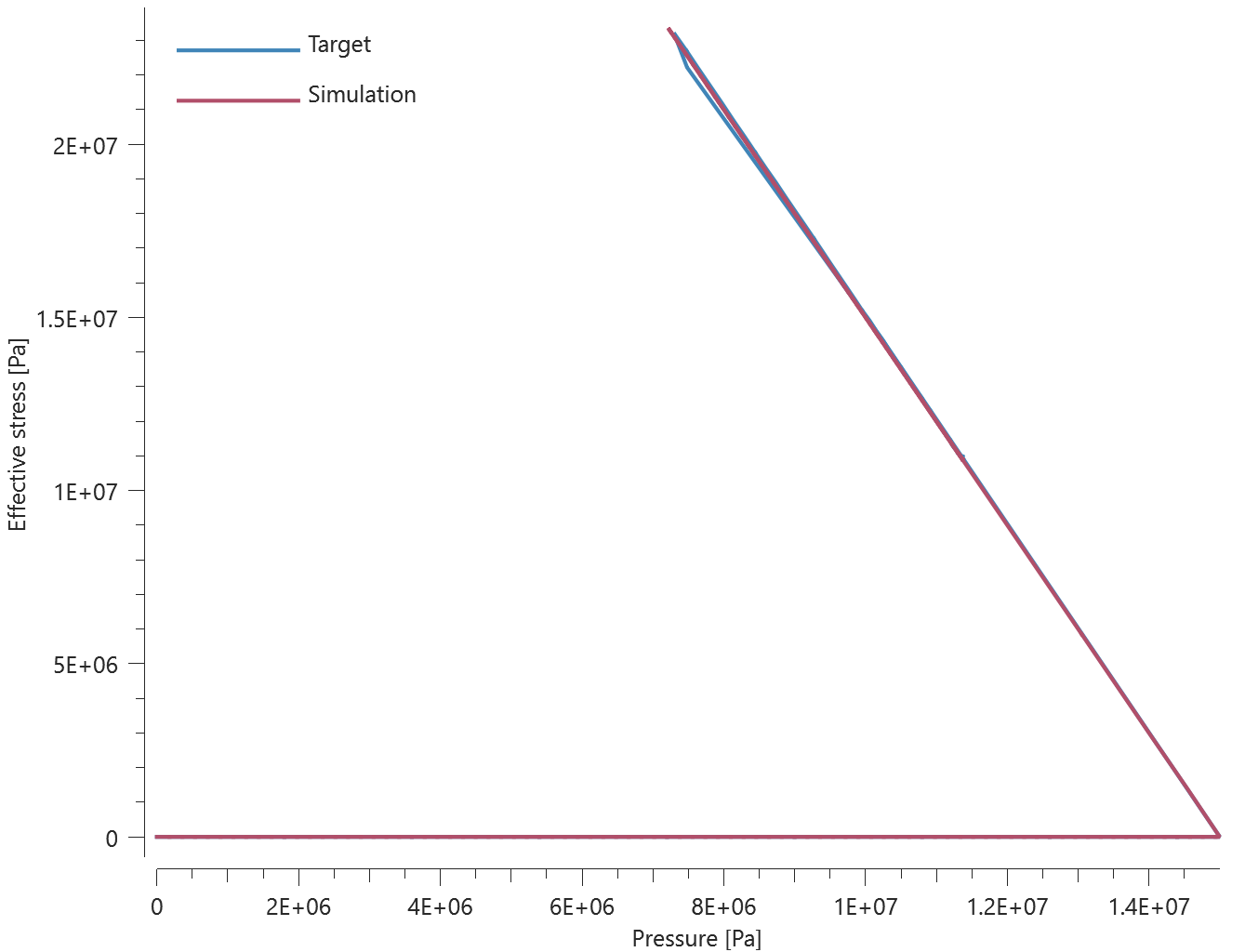

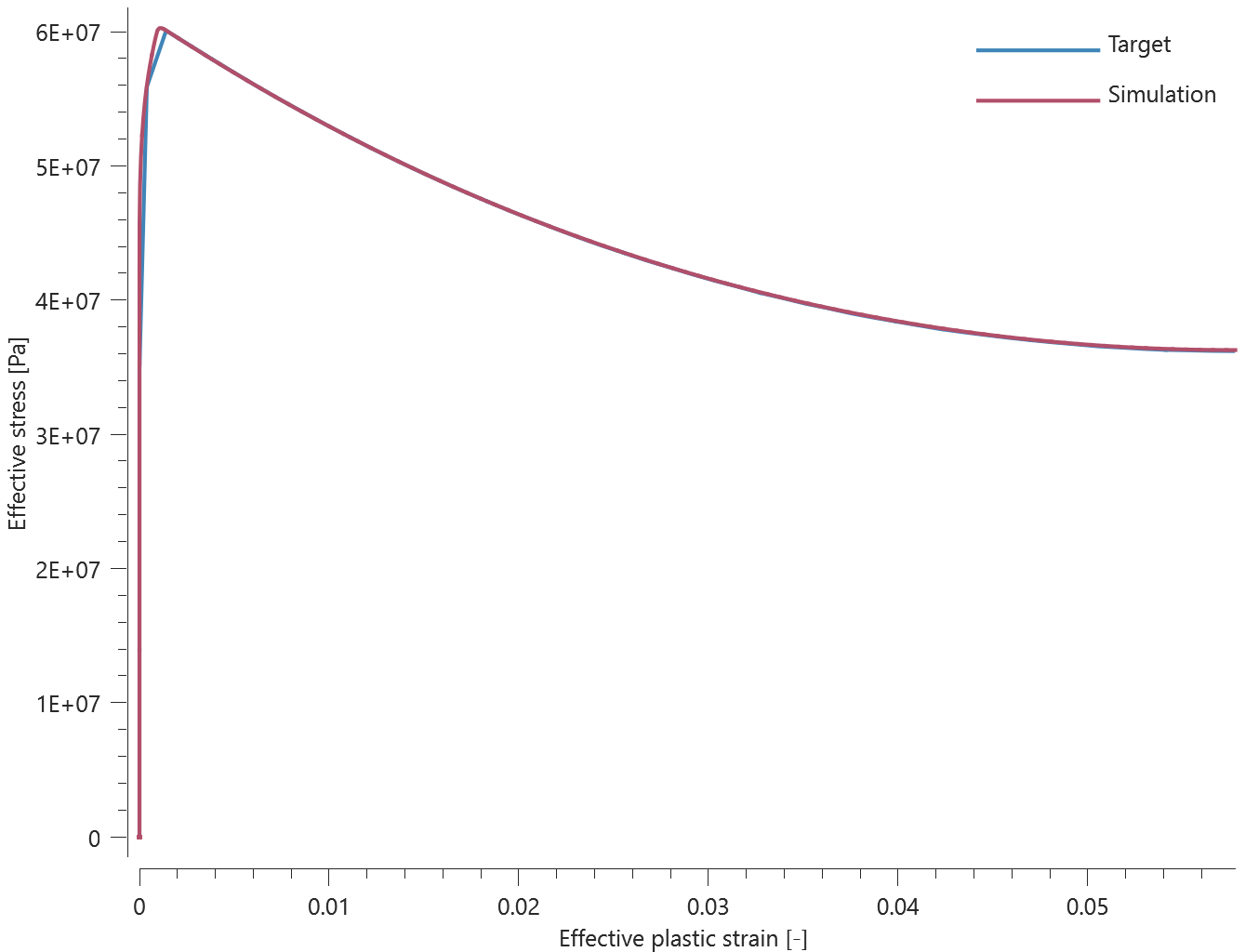

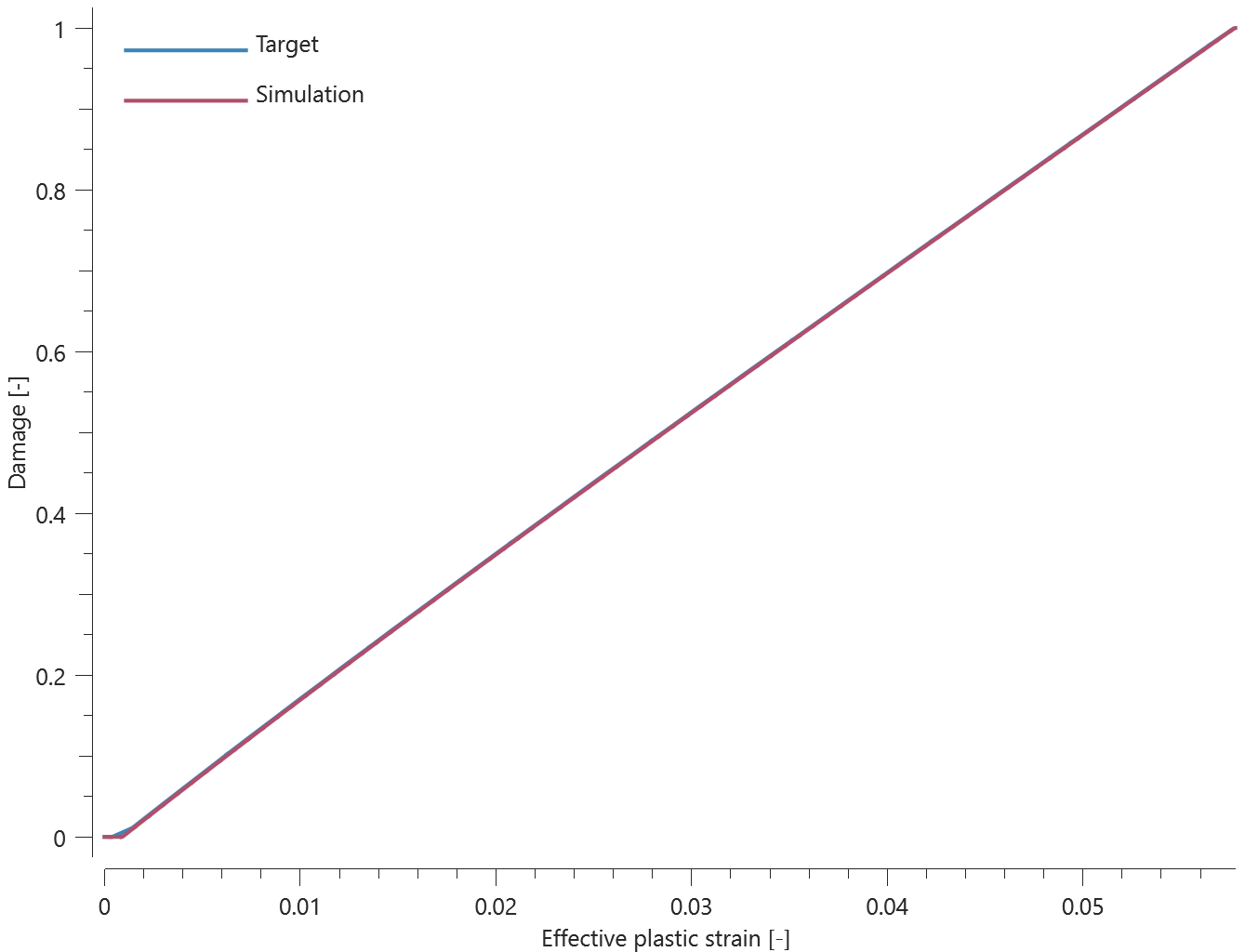

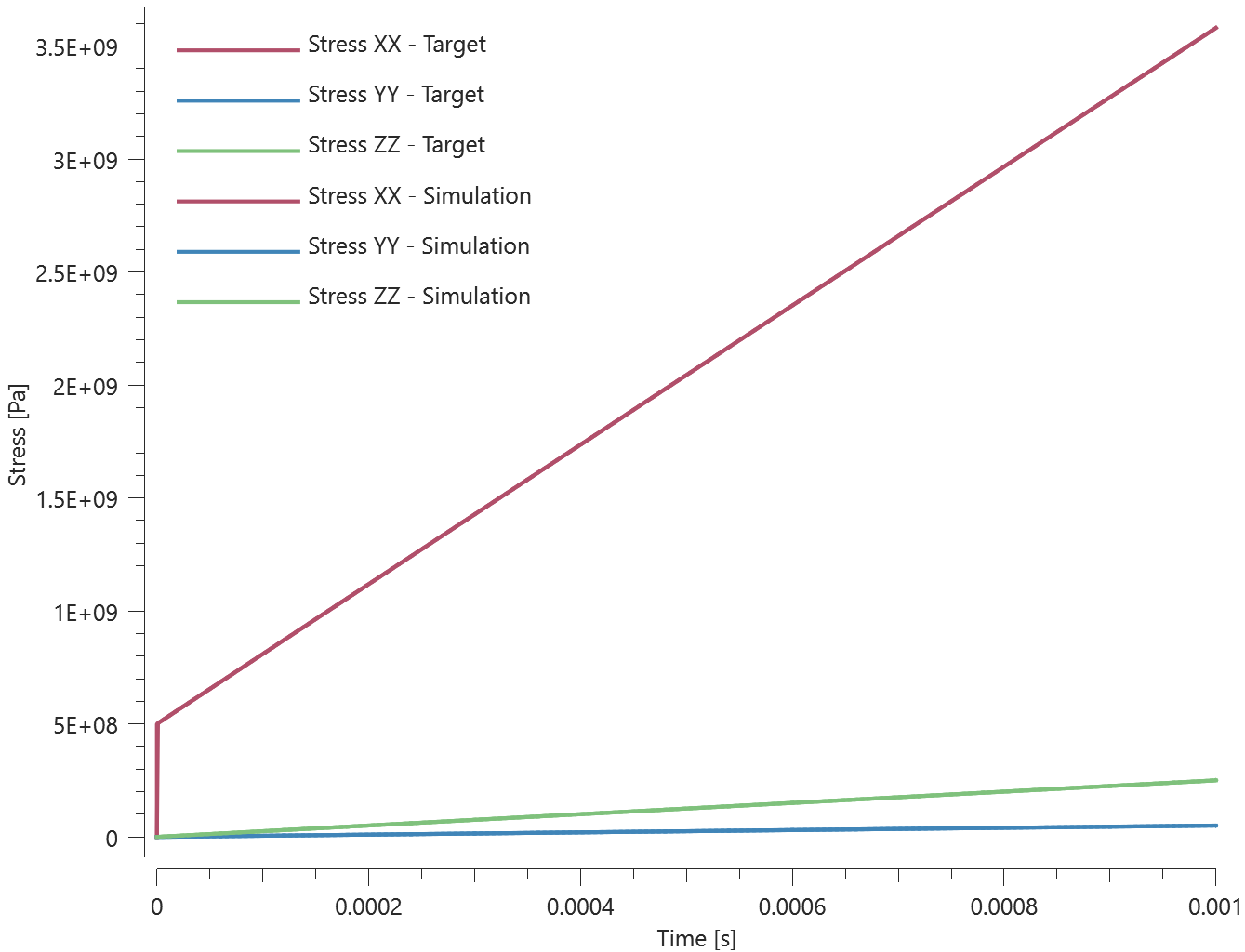

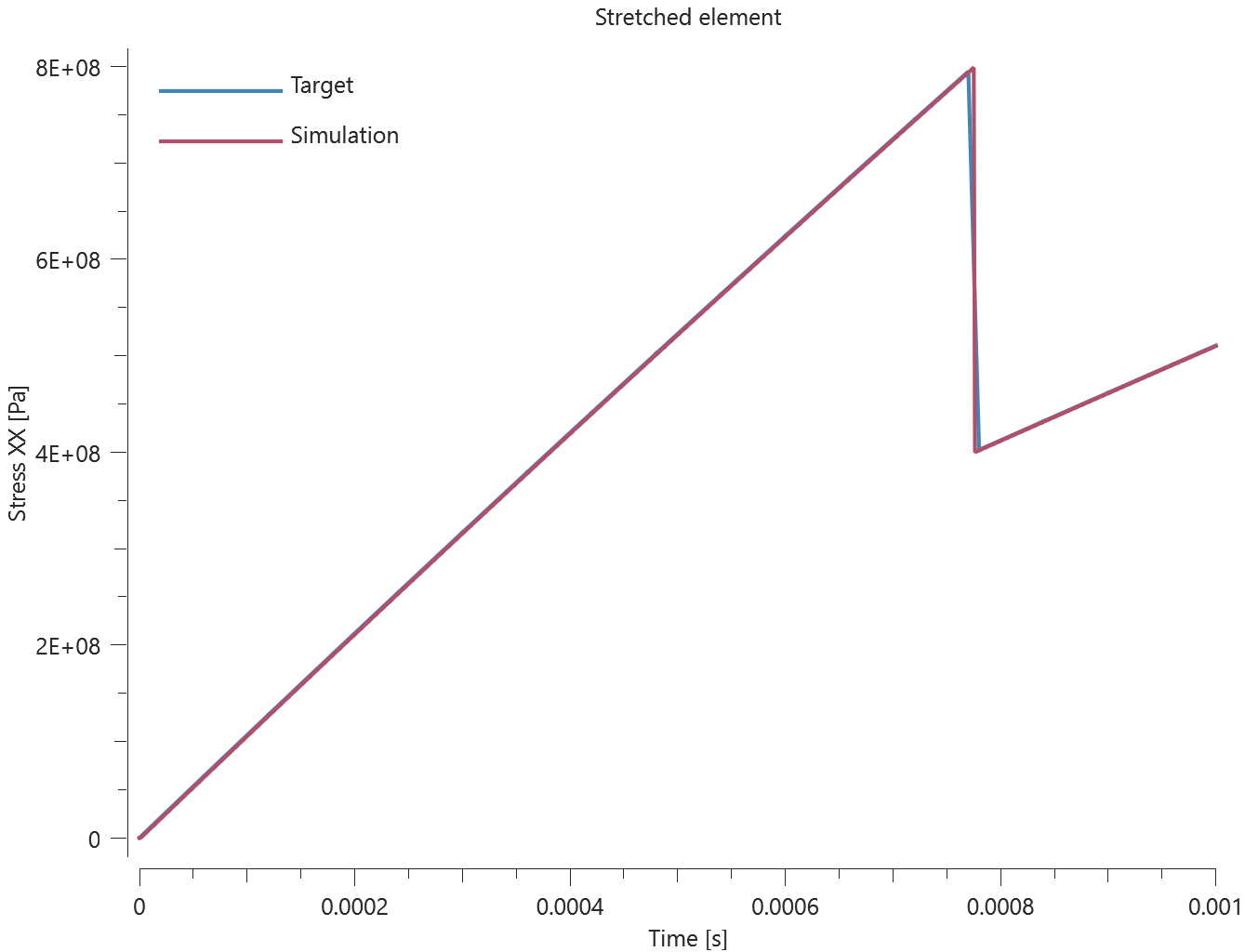

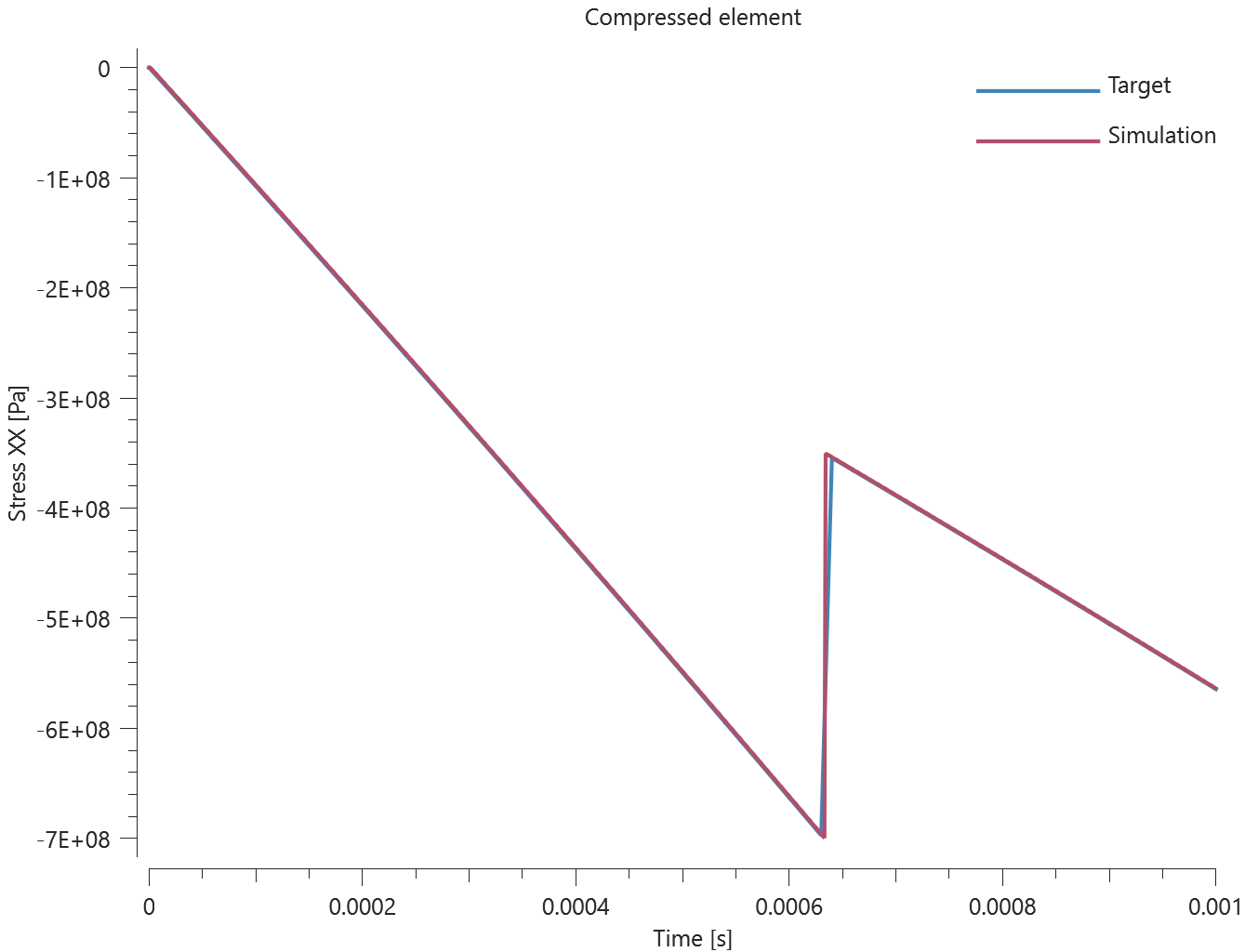

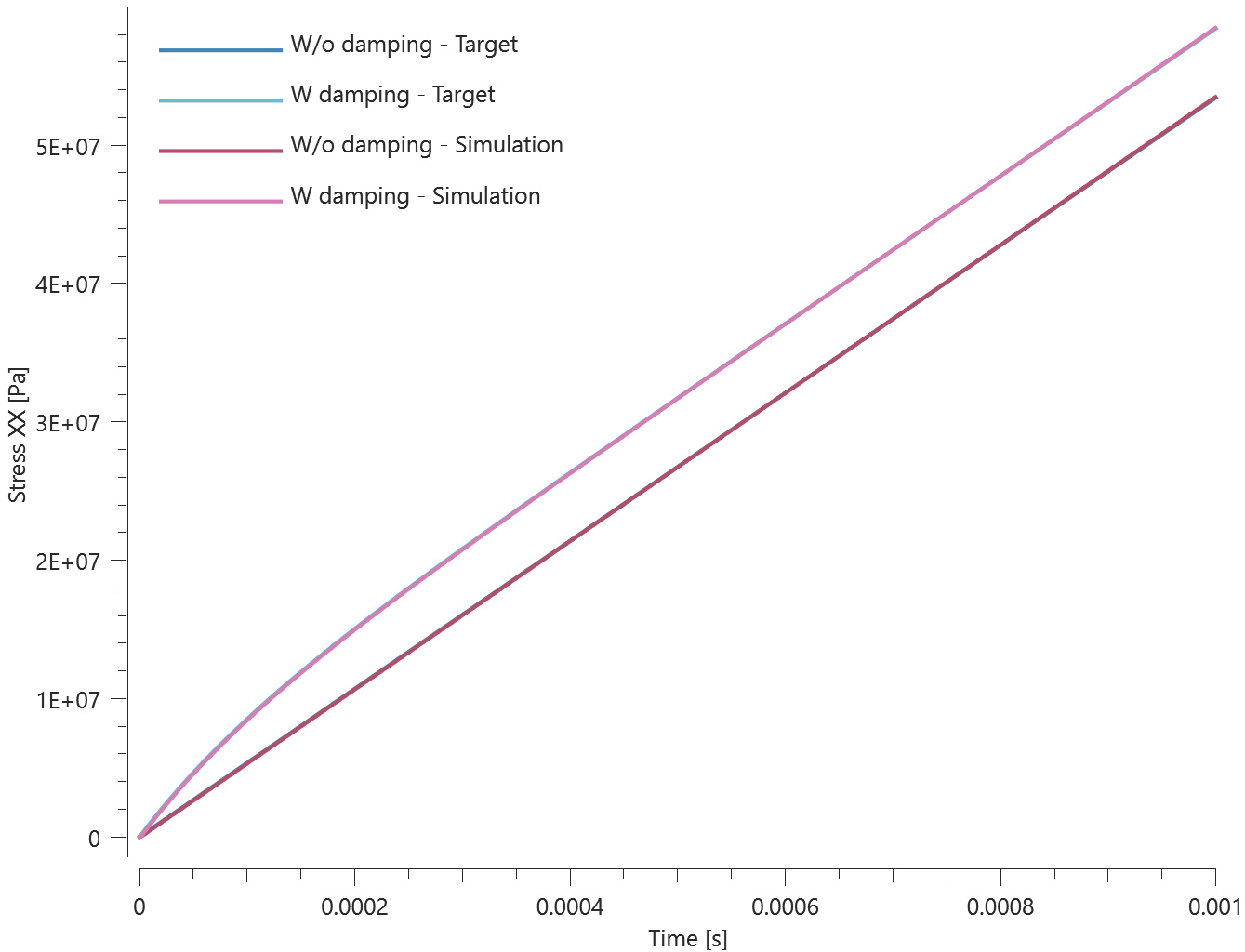

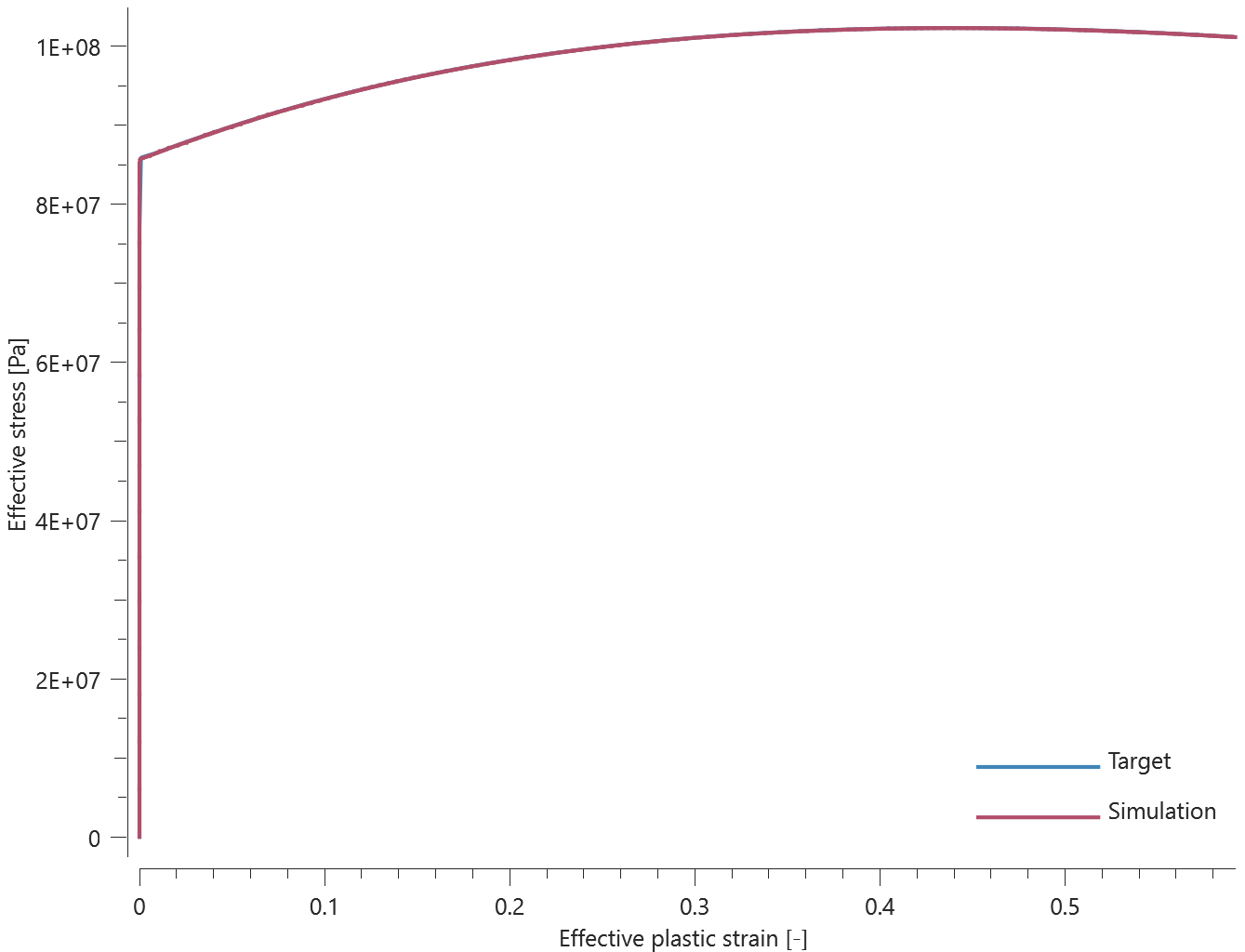

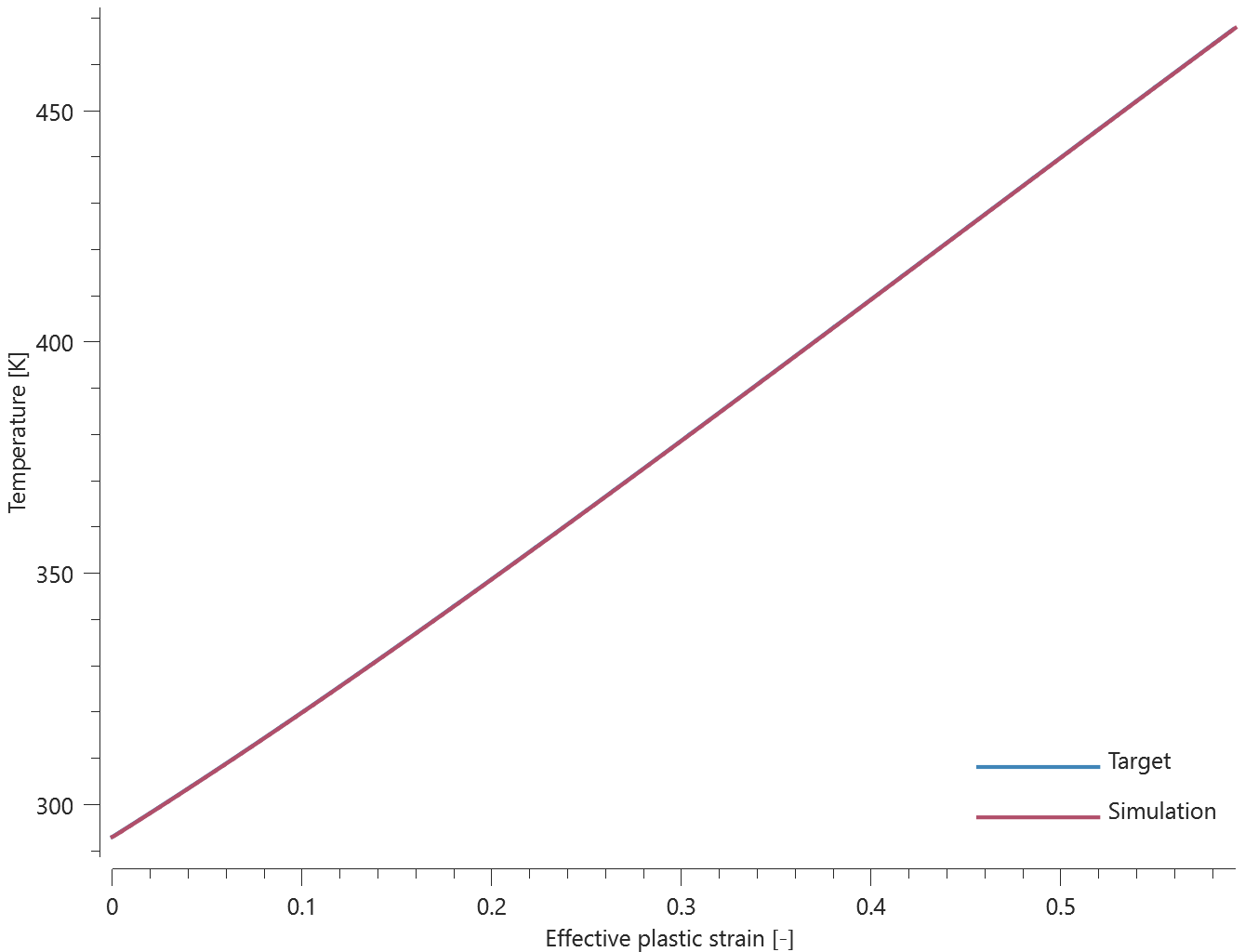

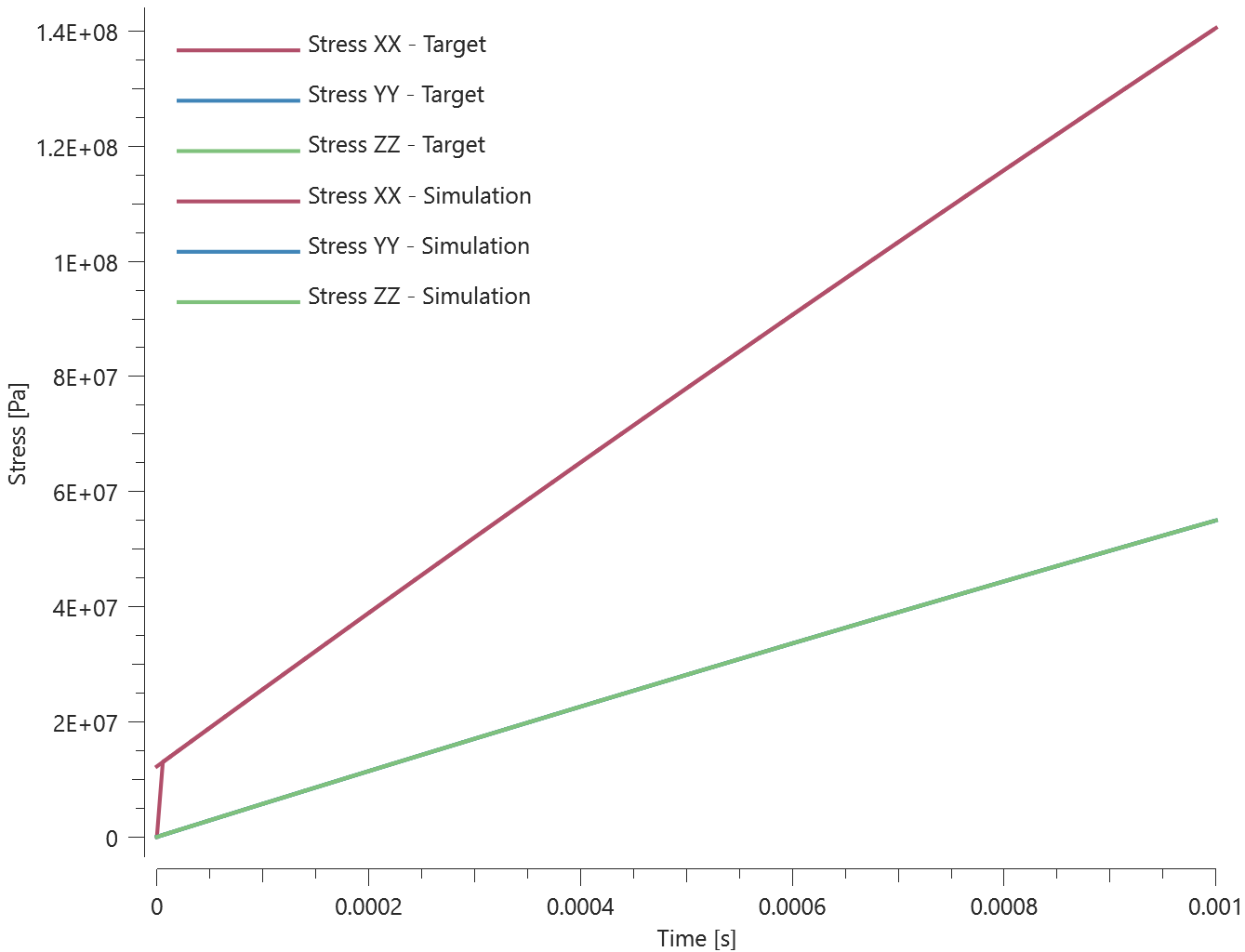

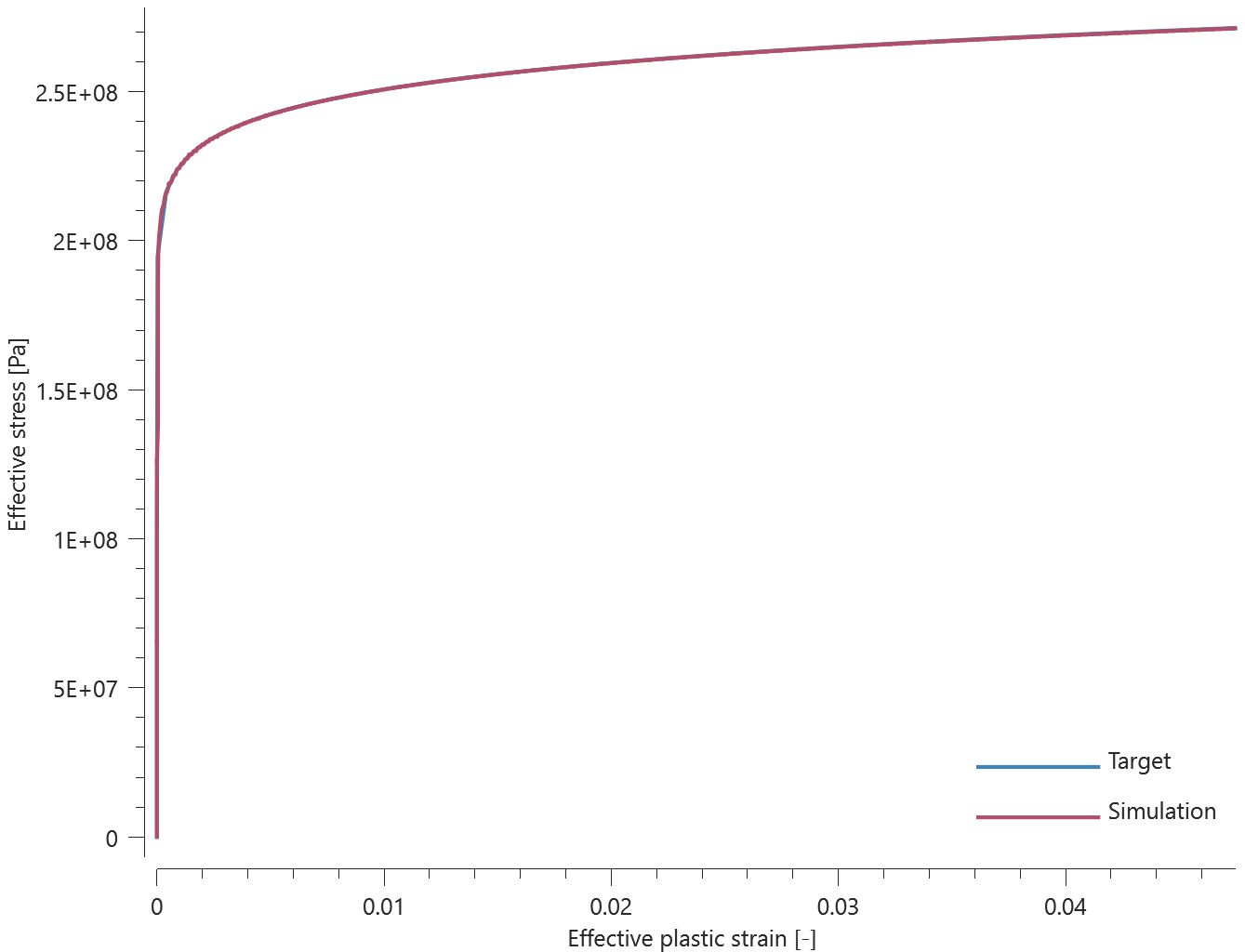

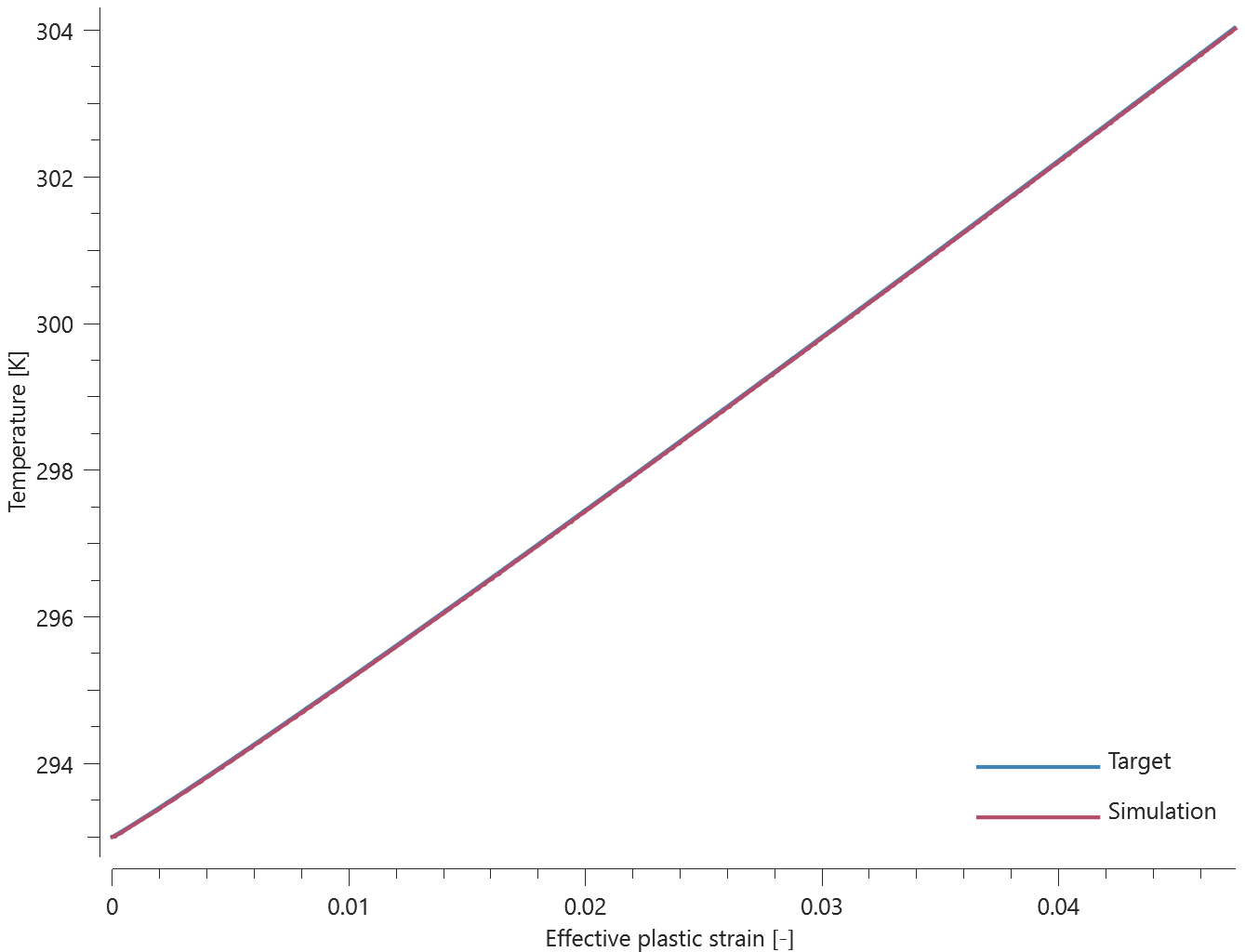

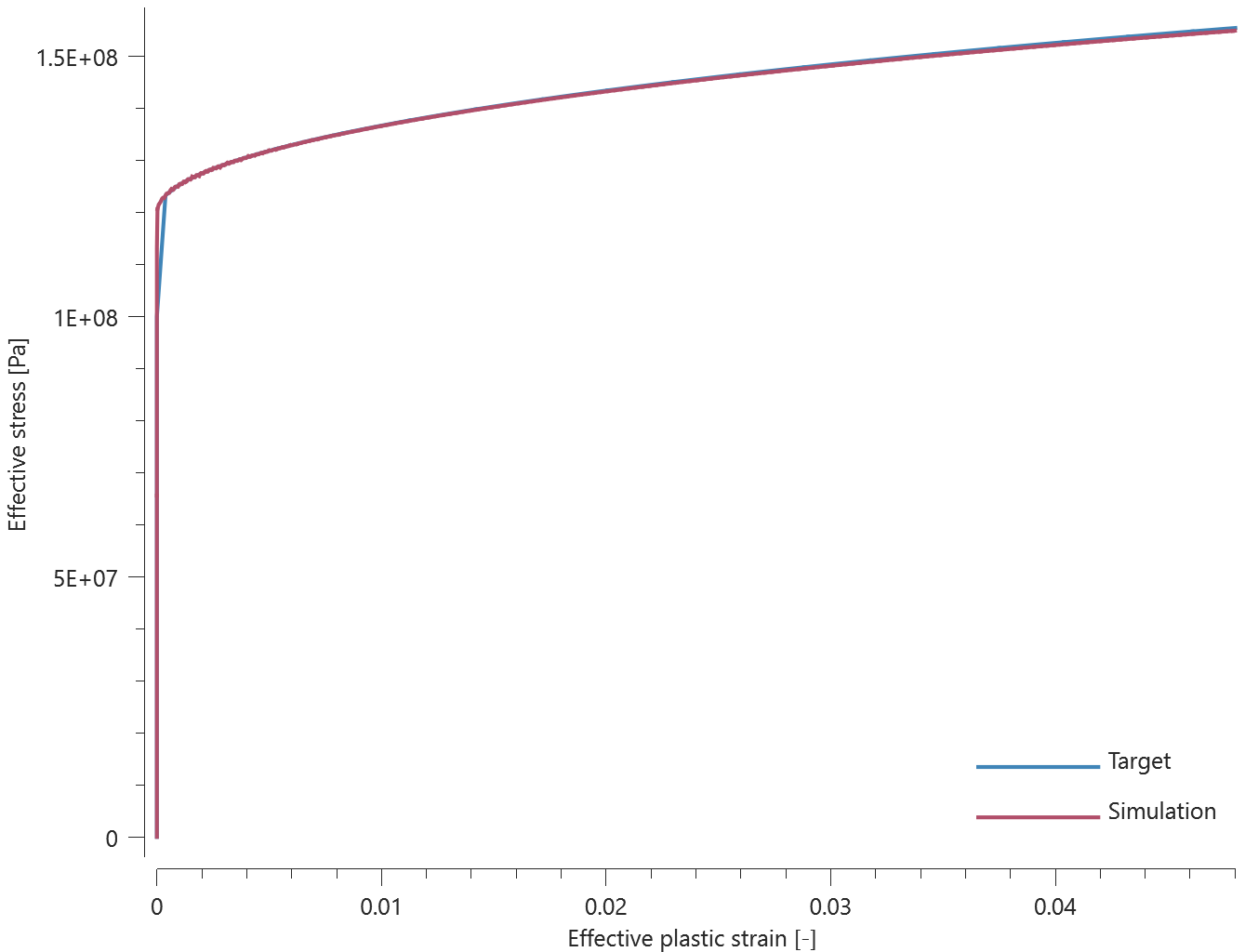

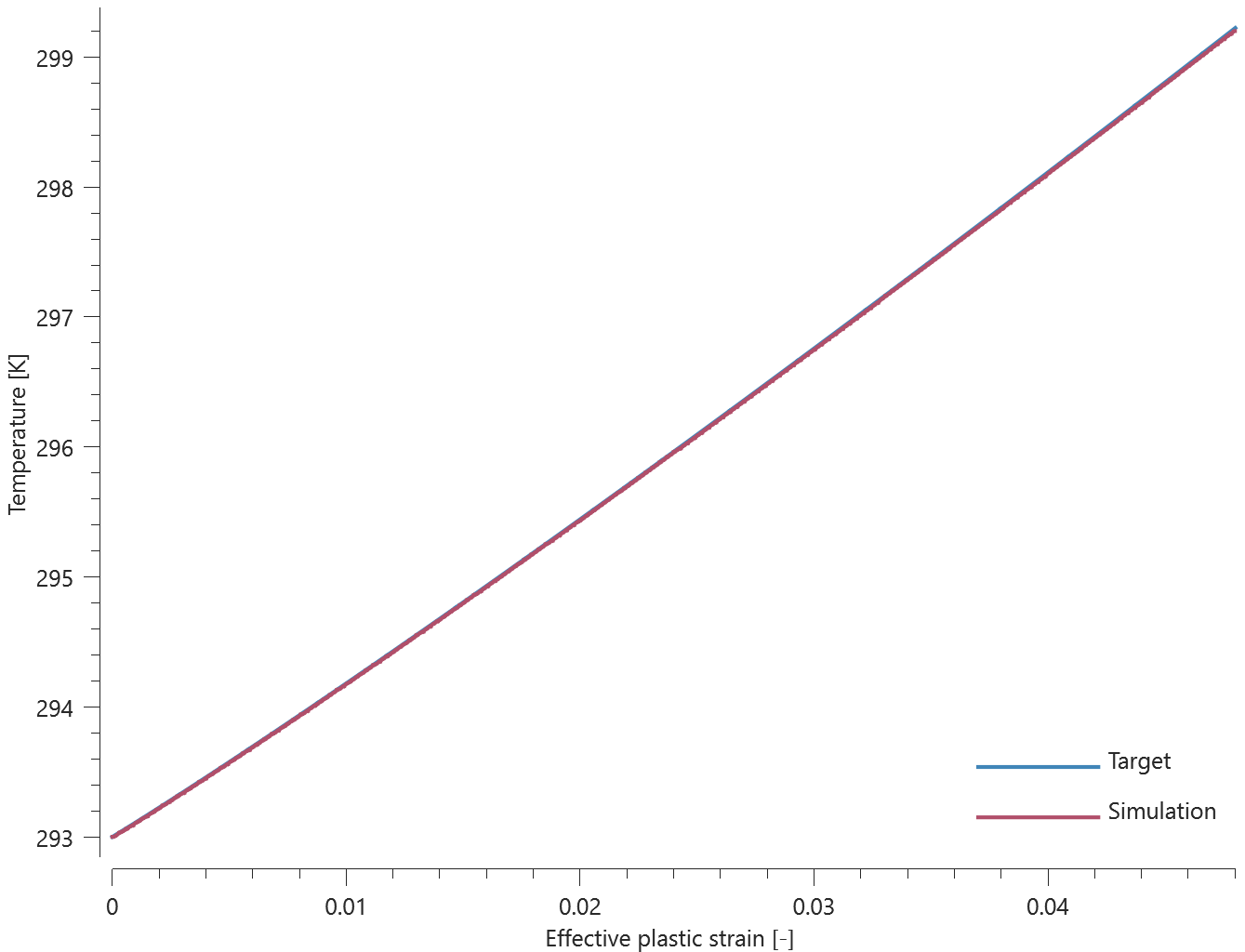

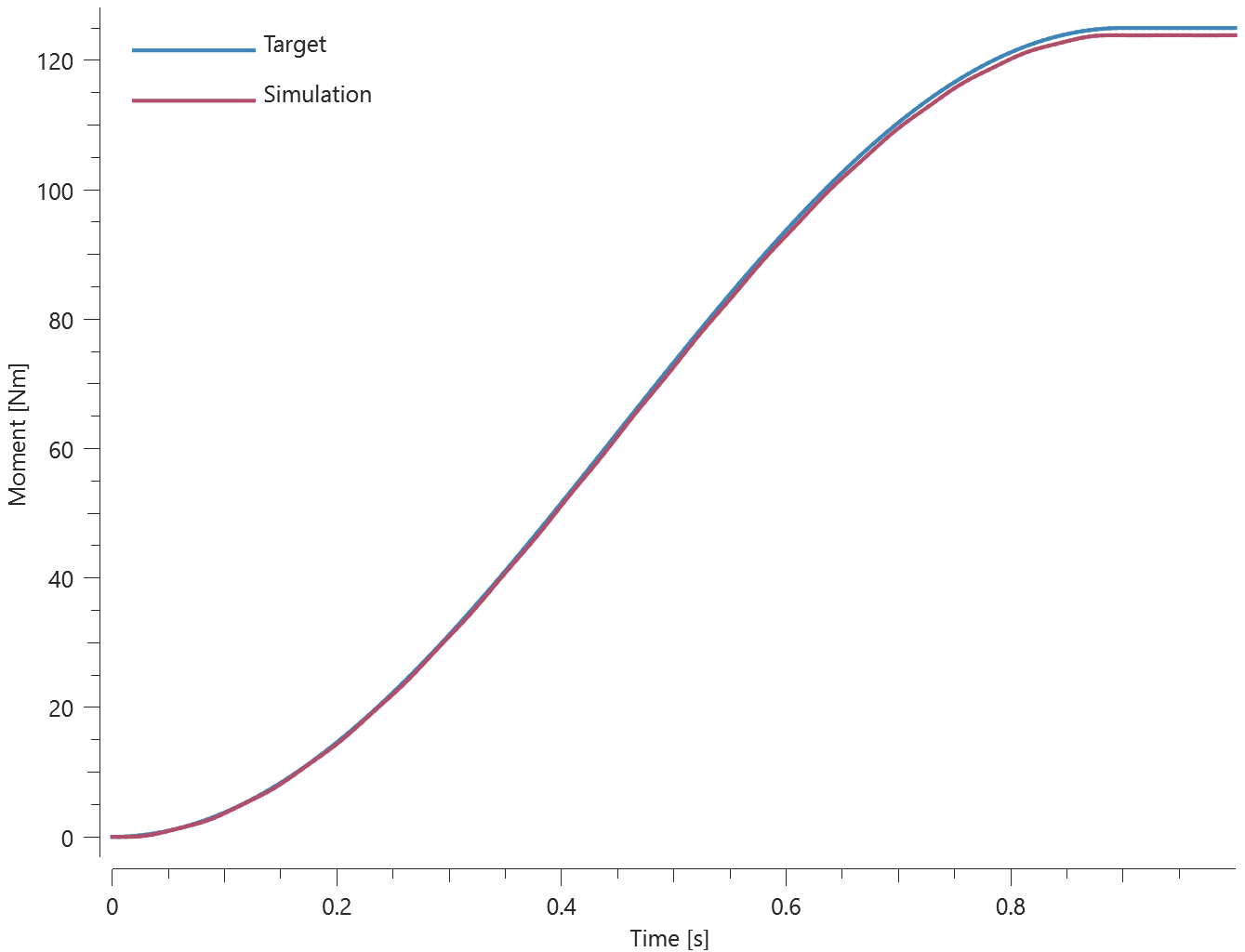

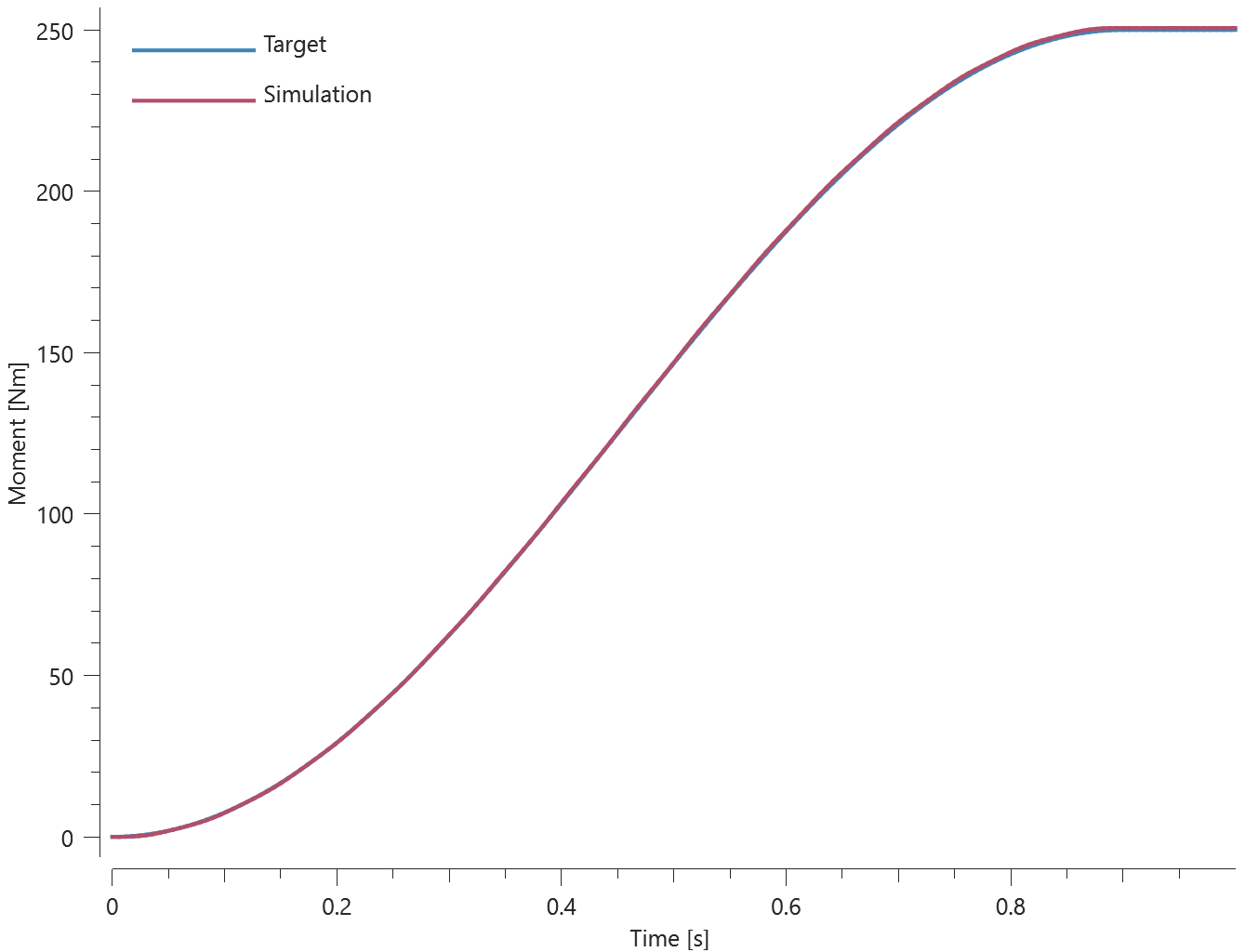

Effective stress vs. effective plastic strain is presented in Figure 1 together with a target curve from a verification script.

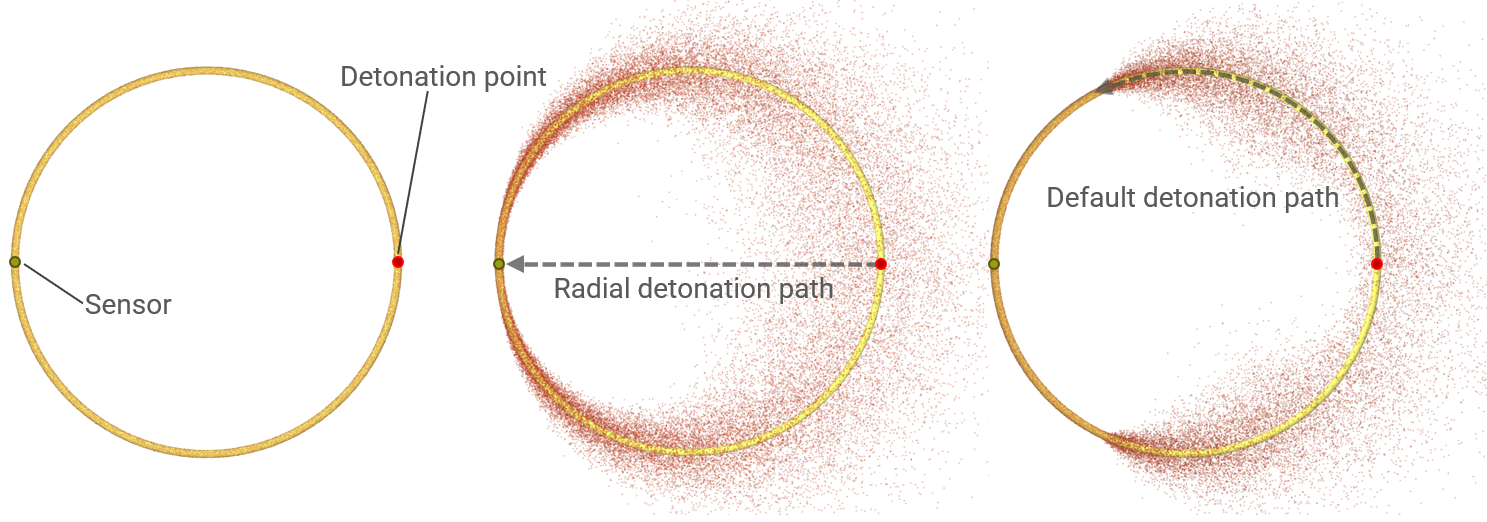

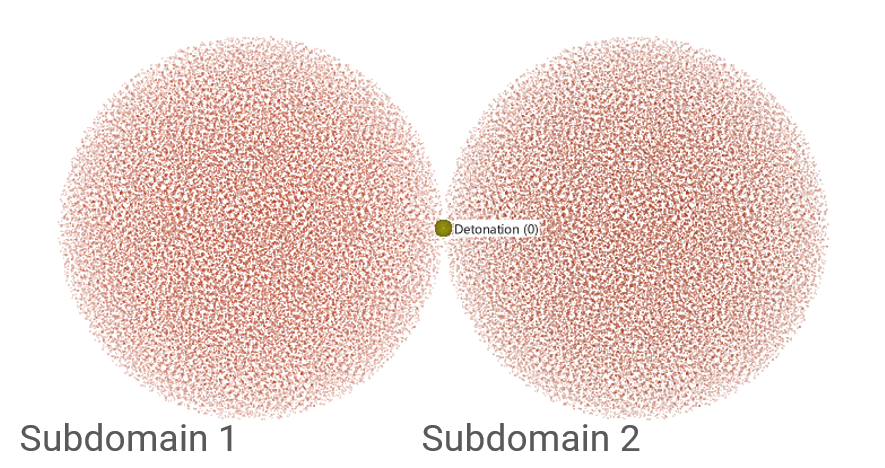

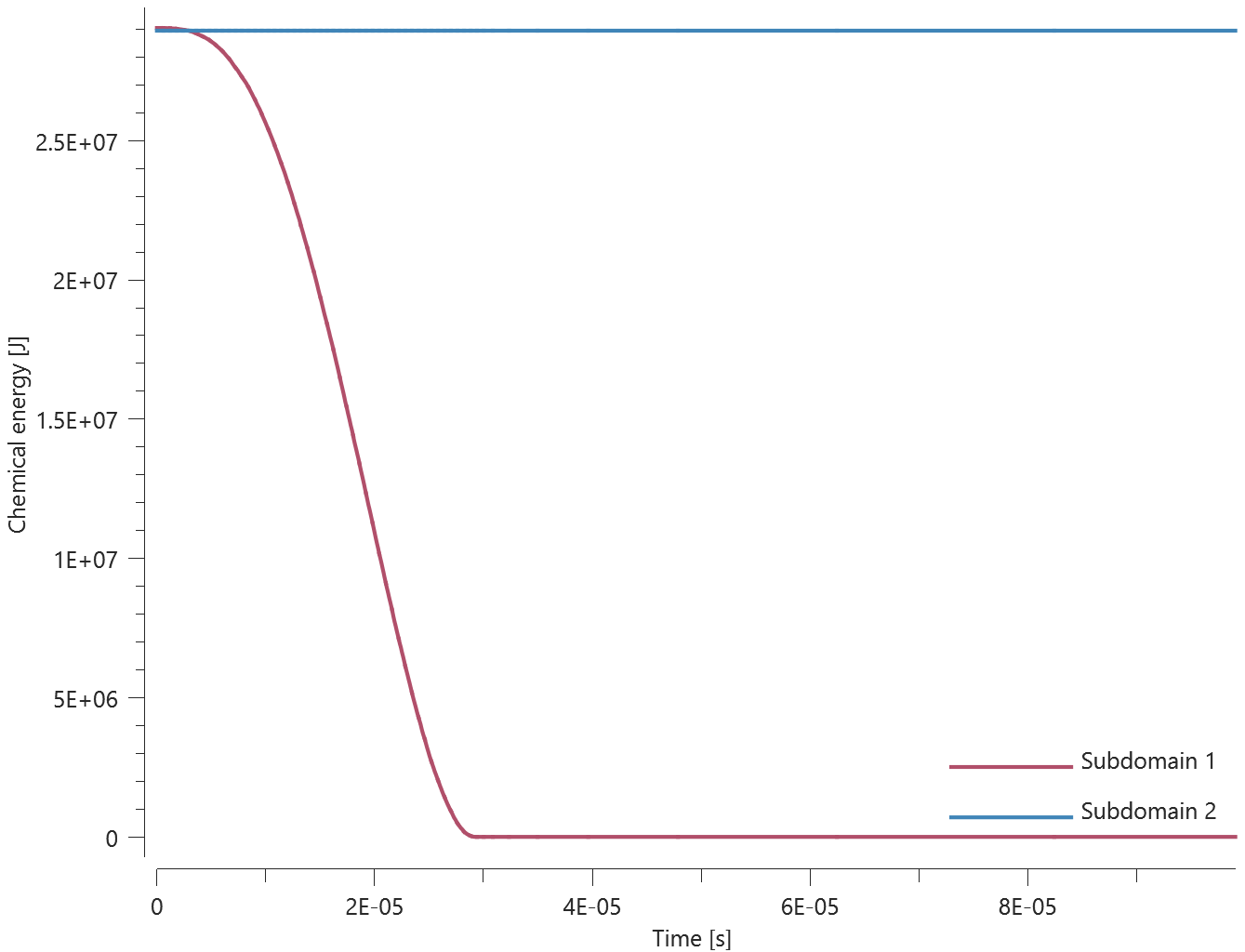

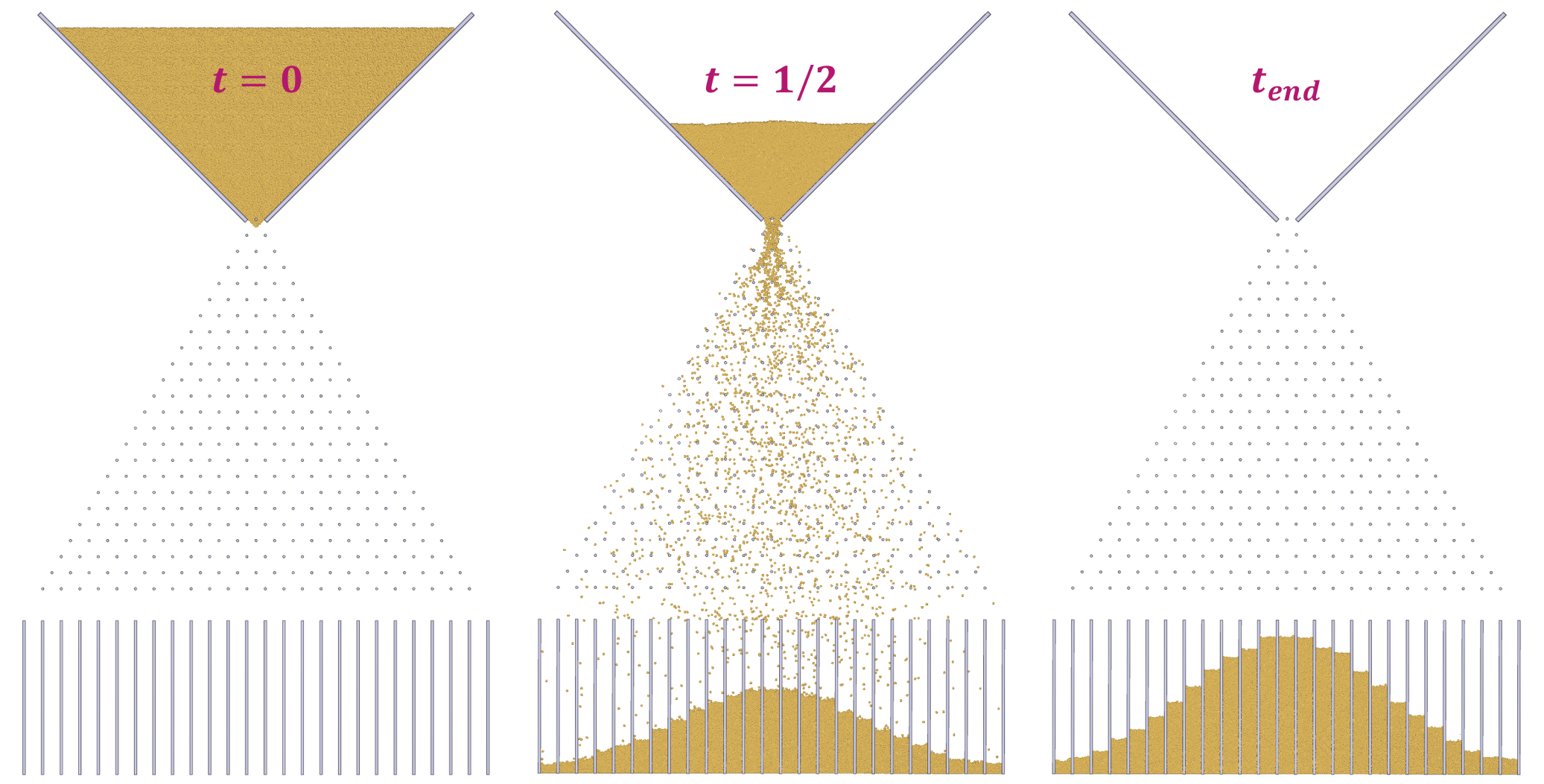

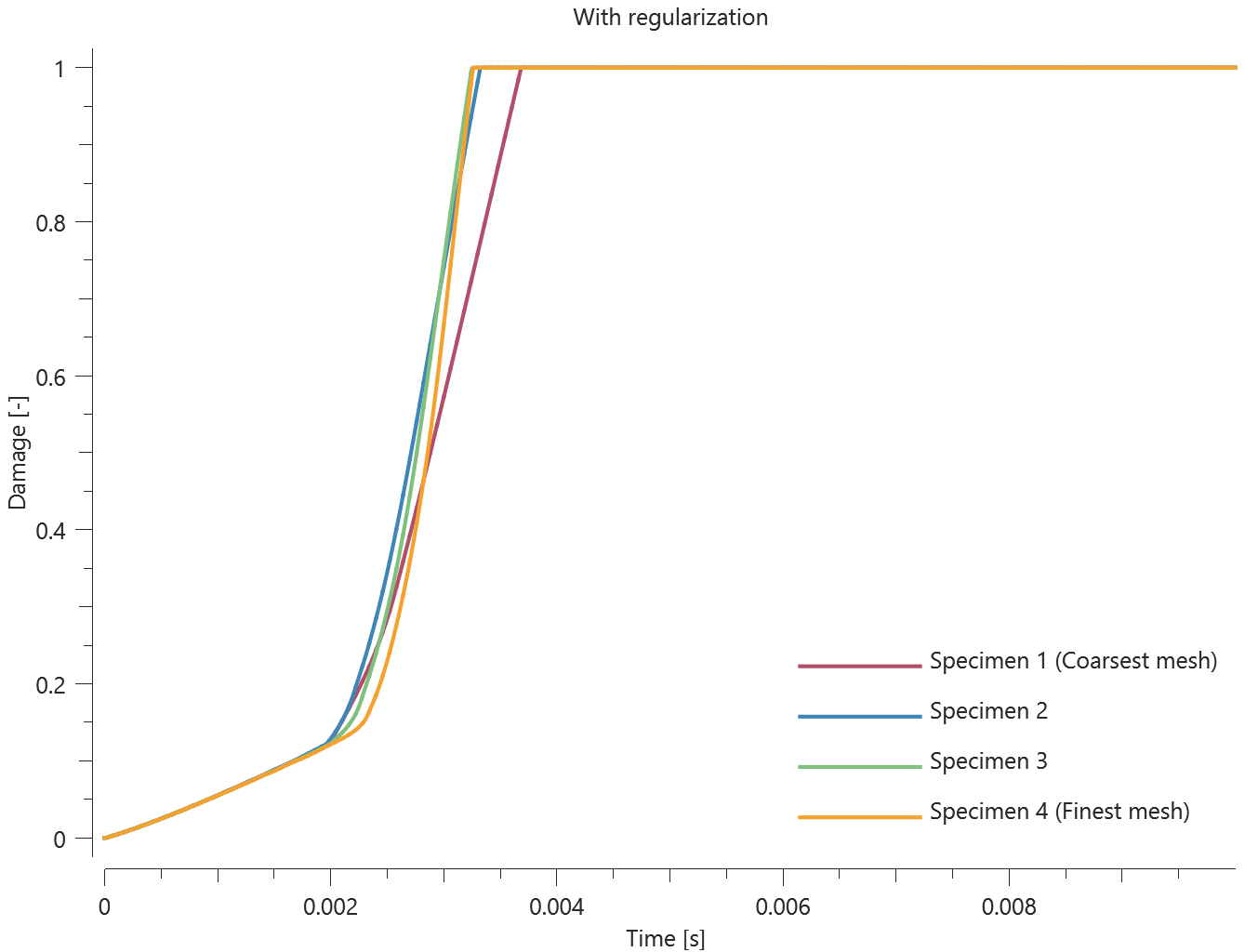

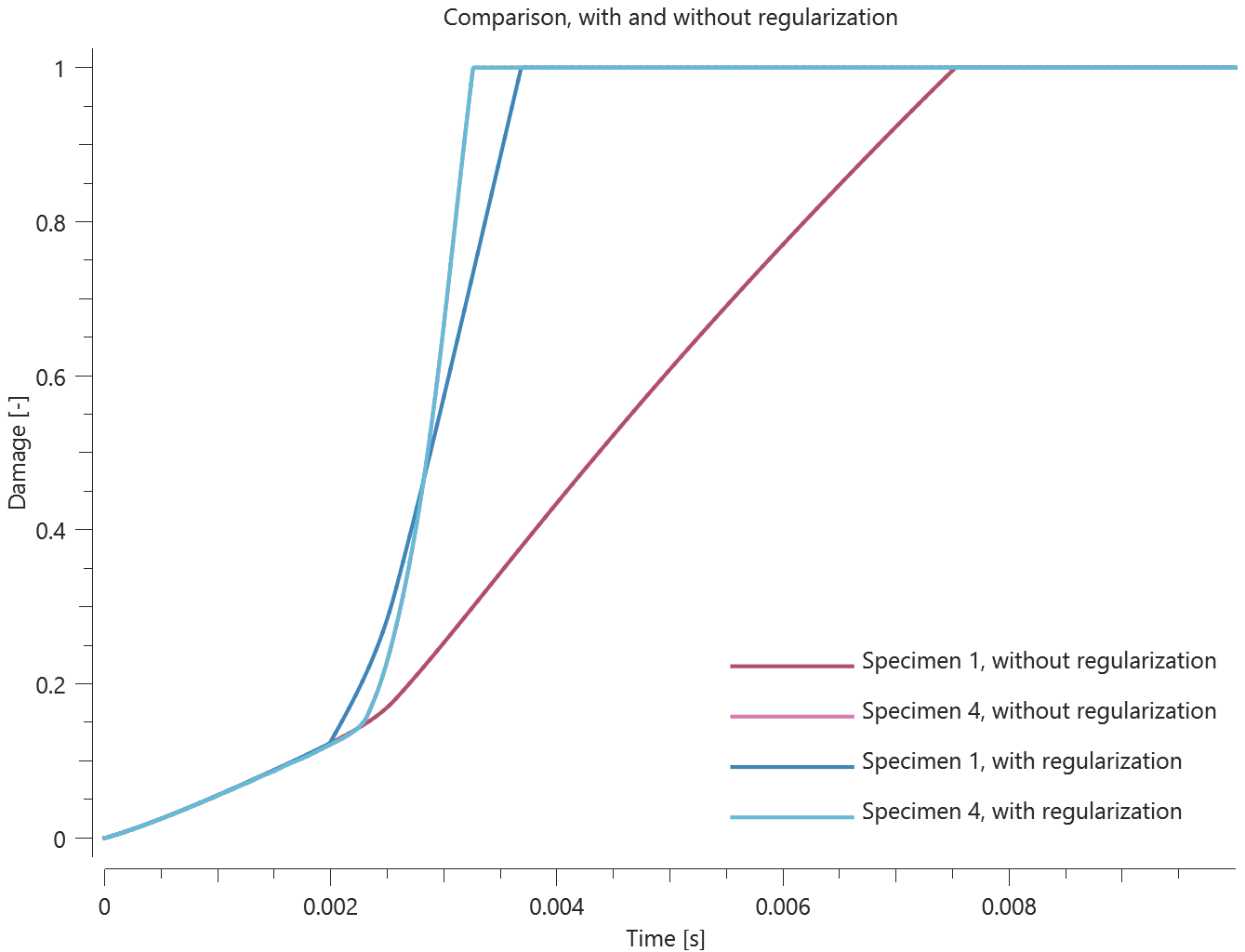

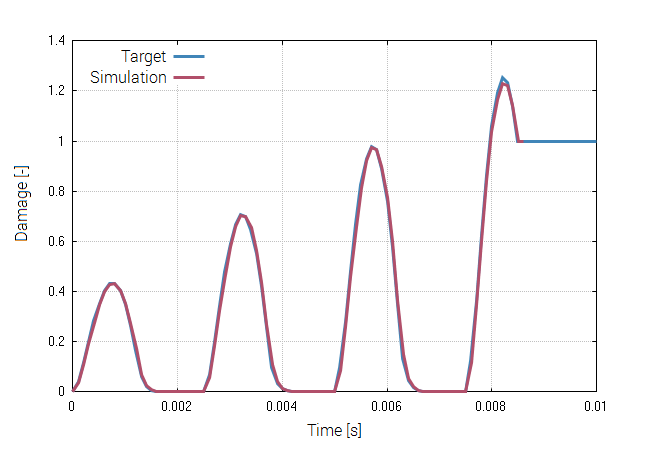

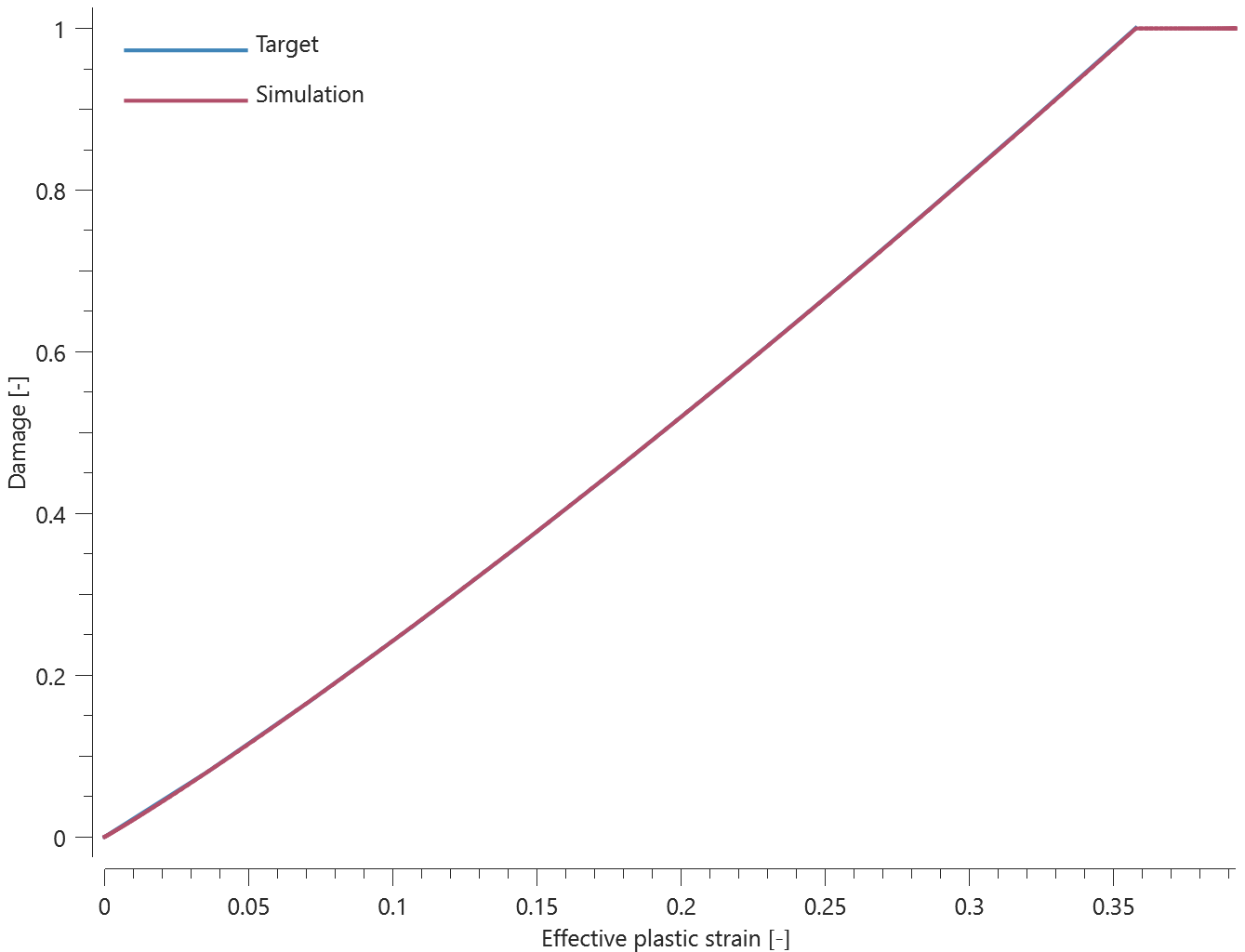

which limits the maximum increase of time step size is set to 4.